Professional Documents

Culture Documents

Hesap Raporu r1 22.10

Uploaded by

castle_risingCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hesap Raporu r1 22.10

Uploaded by

castle_risingCopyright:

Available Formats

EPRO MHENDSLK

1/40

EPRO MHENDSLK

NDEKLER

1. GR............................................................................................................................................................ 3

2. SSTEM KEST ......................................................................................................................................... 4

3. STANDARTLAR, YNETMELKLER VE KAYNAKLAR ................................................................. 5

4. TASARIM PARAMETRELER................................................................................................................ 6

4.1. MALZEME ................................................................................................................................................................ 6

4.1.1. Beton......................................................................................................................................................................... 6

4.1.2. Betonarme Donats .................................................................................................................................................. 6

4.1.3. Pas paylar................................................................................................................................................................ 6

4.2. ZEMN PARAMETRELER ................................................................................................................................... 6

5. YK ANALZ ............................................................................................................................................ 7

5.1. ZAT YKLER ......................................................................................................................................................... 7

5.2. HAREKETL YKLER ........................................................................................................................................... 8

5.3. ZEMN ETKLER ................................................................................................................................................... 9

5.4. DEPREM YK ..................................................................................................................................................... 10

6. YKLEME KOMBINASYONLARI ...................................................................................................... 11

7. STATK VE BETONARME HESAPLAR.............................................................................................. 12

7.1. BLGSAYAR MODEL VE YKLEMELER .................................................................................................... 12

7.2. BETONARME HESAPLAR ...................................................................................................................................21

7.3. ZEMN EMNYET GERLMES KONROL .....................................................................................................38

8. SAP2000 PROGRAMI YN KABULLER ........................................................................................... 40

2/40

EPRO MHENDSLK

1. GR

Bu rapor Tpra Rafineri Mdrl TCDD Boru Geii ii kapsamnda yaplacak olan 2.50 x 4.50

Menfez Projesine ait analizleri ve tasarm hesaplarn kapsamaktadr.

Bu raporda yaplarn tasarmnda kullanlacak olan artnameler, uygulanacak hesap yntemleri, ykler,

yaplarn yapmnda kullanlacak olan malzeme bilgileri ile birlikte, yapya ait betonarme hesaplar

bulunmaktadr.

Yapsal analizler, sonlu eleman yntemi kullanlarak, boyutlu analiz yapabilen ve Prof. E. L. Wilson ve

A.Habibullah tarafndan gelitirilen SAP 2000 V.14.1.0 program kullanlarak yaplmtr.

3/40

EPRO MHENDSLK

2. SSTEM KEST

4/40

EPRO MHENDSLK

3. STANDARTLAR, YNETMELKLER VE KAYNAKLAR

1.

2.

3.

4.

5.

6.

7.

TSE, TS 498 Yap Elemanlarnn Boyutlandrmasnda Alnacak Ykler

TSE, TS 500 Betonarme Yaplar Hesap ve Yapm Kurallar, 2000

Betonarme Yaplar, 2005, Zekai Celep, Nahit Kumbasar

Deprem Mhendisliine Giri, 2001, Zekai Celep, Nahit Kumbasar

Afet Blgelerinde Yaplacak Yaplar Hakknda Ynetmelik (A.B.Y.Y.H.Y), 2007

American Association of State Highway and Transportation Officials, Standard Specifications for

Highway Bridges (AASHTO), 17 th Edition 2002

Eurocodes EN 1991-2

5/40

EPRO MHENDSLK

4. TASARIM PARAMETRELER

4.1. MALZEME

4.1.1. Beton

Betonarme betonu

: C35 (fck = 35 Mpa)

fck, 15x30 silindir numunede %10 risk altnda tanmlanan karakteristik beton basn mukavemetidir.

4.1.2. Betonarme Donats

Aksi belirtilmedike btn yap ksmlarnda kullanlan betonarme donats S420 (St IIIa) olacaktr.

fyk = 420 Mpa (Karakteristik akma mukavemeti)

4.1.3. Pas paylar

st Tabliye ve Perdelerde

: 5.0 cm

Alt Tabliyede

: 5.0 cm

4.2. ZEMN PARAMETRELER

zin Verilebilir Emniyet Gerilmesi

em = 150 kN/m2

Zemin Yatak Katsays:

Ko = 10000 kN/m3

6/40

EPRO MHENDSLK

5. YK ANALZ

DL

Wv

LL

PS

PA

LLS

LLA

PD

: Yap zati arl

: Yap zerindeki dolgu yk

: Dey hareketli yk

: Zemin basnc (Sukunette)

: Zemin basnc (Aktif)

: Srarj yatay itkisi (Sukunette)

: Srarj yatay itkisi (Aktif)

: Deprem yk

5.1. ZAT YKLER

z arlklarn hesabnda aadaki birim hacim arlklar dikkate alnmtr.

Betonarme yap ksmlarnda

: b = 25 kN/m3

Dolgu arlklarnda

: d = 19 kN/m3

Tabliye zerindeki dolgu yk:

Wv = 0.80 x 19 = 15.2 kN/m2

7/40

EPRO MHENDSLK

5.2. HAREKETL YKLER

8/40

EPRO MHENDSLK

5.3. ZEMN ETKLER

9/40

EPRO MHENDSLK

5.4. DEPREM YK

10/40

EPRO MHENDSLK

6. YKLEME KOMBINASYONLARI

Ykleme kombinasyonlar AASHTO Blm I, Tablo 3.22.1.A ya gre oluturulmutur.

1. KOMBNASYON:

2. KOMBNASYON:

3. KOMBNASYON:

4. KOMBNASYON:

5. KOMBNASYON:

DL+Wv+LL+PS+LLS

DL+Wv+LL+PA+LLA

1.3.(DL+Wv+PS+1.7(LL+LLS))

1.3.(DL+Wv+PA+1.7(LL+LLA))

DL+Wv+PA+DP

11/40

EPRO MHENDSLK

7. STATK VE BETONARME HESAPLAR

7.1. BLGSAYAR MODEL VE YKLEMELER

Bilgisayar modeline ait grn ve yklemeler devam eden sayfalarda sunulmaktadr

12/40

EPRO MHENDSLK

SAP2000

6.28.10 13:03:20

MATEMATK MODEL

SAP2000 v14.1.0 - File:2.5x4.5 - 3-D View - Tonf, m, C Units

13/40

EPRO MHENDSLK

SAP2000

6.28.10 13:04:18

DOLGU YK

-1.52

-1.40

-1.29

-1.17

-1.05

-0.94

-0.82

-0.70

-0.58

-0.47

-0.35

-0.23

-0.12

0.00

SAP2000 v14.1.0 - File:2.5x4.5 - Area Uniform (Wv) (GLOBAL - Z) - Tonf, m, C Units

14/40

EPRO MHENDSLK

SAP2000

10.21.10 16:32:59

TREN YK

-13.3

-12.3

-11.3

-10.2

-9.2

-8.2

-7.2

-6.1

-5.1

-4.1

-3.1

-2.0

-1.0

0.0

SAP2000 v14.1.0 - File:2.5x4.5 - Area Uniform (LL) (GLOBAL - Z) - Tonf, m, C Units

15/40

EPRO MHENDSLK

SAP2000

6.28.10 13:04:54

YANAL TOPRAK BASINCI (SUKUNETTE)

0.00

0.25

0.50

0.74

0.99

1.24

1.49

1.73

1.98

2.23

2.48

2.72

2.97

3.22

SAP2000 v14.1.0 - File:2.5x4.5 - Area Surface Pressure - Face Top (PS) - Tonf, m, C Units

16/40

EPRO MHENDSLK

SAP2000

6.28.10 13:05:07

YANAL TOPRAK BASINCI (AKTF)

0.00

0.14

0.28

0.43

0.57

0.71

0.85

1.00

1.14

1.28

1.42

1.57

1.71

1.85

SAP2000 v14.1.0 - File:2.5x4.5 - Area Surface Pressure - Face Top (PA) - Tonf, m, C Units

17/40

EPRO MHENDSLK

SAP2000

10.21.10 16:33:41

SRARJ YK (SUKUNETTE)

-3.11

-2.87

-2.63

-2.39

-2.15

-1.91

-1.67

-1.44

-1.20

-0.96

-0.72

-0.48

-0.24

0.00

SAP2000 v14.1.0 - File:2.5x4.5 - Area Uniform (LLS) (Local - 3) - Tonf, m, C Units

18/40

EPRO MHENDSLK

SAP2000

10.21.10 16:34:08

SRARJ YK (AKTF)

-1.78

-1.64

-1.51

-1.37

-1.23

-1.10

-0.96

-0.82

-0.68

-0.55

-0.41

-0.27

-0.14

0.00

SAP2000 v14.1.0 - File:2.5x4.5 - Area Uniform (LLA) (Local - 3) - Tonf, m, C Units

19/40

EPRO MHENDSLK

SAP2000

6.28.10 13:31:47

DEPREML DURUM LAVE TOPRAK BASINCI

0.

76.

152.

228.

305.

381.

457.

533.

609.

685.

761.

838.

914.

990. E-3

SAP2000 v14.1.0 - File:2.5x4.5 - Area Surface Pressure - Face Top (PD) - Tonf, m, C Units

20/40

EPRO MHENDSLK

7.2. BETONARME HESAPLAR

Betonarme hesaplar hazrlanan bir exel program vastasyla yaplm olup, hesap detaylar ilerleyen

sayfalarda verilmitir.

21/40

EPRO MHENDSLK

SAP2000

10.21.10 17:04:38

UST TABLIYE ACIKLIK MOMENT

M11=40 tm

-25.0

-20.0

-15.0

-10.0

-5.0

0.0

5.0

10.0

15.0

20.0

25.0

30.0

35.0

40.0

SAP2000 v14.1.0 - File:2.5x4.5 - Resultant M11 Diagram (COMB4) - Tonf, m, C Units

22/40

EPRO MHENDSLK

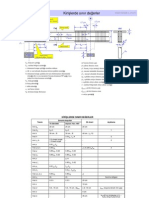

UST TABLIYE ELME HESABI (AIKLIK)

Kesitteki Faktrl Moment:

Mu = 4.00E+08 Nmm

Tama Gc Azaltma Katsays (AASHTO 8.16.1.2)

= 0.9

Kesit Genilii:

b= 1000 mm

Faydal Ykseklik:

d= 350 mm

eliin Karekteristik Dayanm:

fy= 420 MPa

Karekteristik Beton Basnc Dayanm

fc= 35 MPa

Paspay

d'= 50 mm

Gereken Eilme Donatsnn Alan

.Mn = . A s .fy da=

Mu=

Eilme Tama Gc

AASHTO 8.16.3.2

Edeger Basn Blou Derinlii

AASHTO 8.16.3.2

A s .fy

0.85.fc .b w

4.00E+08 Nmm

= = = >

Asgereken=

3234 mm2

Minumum Donat Oran

Salanan donat kopma modlne gre hesaplanan atlama momentinin (Mcr) en az 1.2 kat kadar

tama gc salamaldr. (AASHTO 8.17.1.1.1)

Kopma Modl:

fr= 3.11 MPa

Kesitin Geometrik Merkezine Gre Atalet Momenti:

Ig= 5.33E+09 mm4

Kesitin Arlk Merkezinin Alt Tabana Mesafesi:

d= 200 mm

atlama Momenti:

Mcr= 8.29E+07 Nmm

Asmin=

Mcr= fr.Ig/yt

(AASHTO 8.13.3)

1.2Mcr= 9.95E+07 Nmm

764 mm2

Kesitteki donat alan analiz sonucunda gereken donat alannn 1.33 katndan fazla ise minumum

donat art aranmaz. (AASHTO 8.17.1.2)

1.33Asgereken= 4302 mm2

Asmin =

Min ( 764

; 4302

) =

764 mm2

Dengeli Donat Oran

Kesitteki donat oran dengeli donat orannn %75 inden az olmaldr.

0.85.1.fc 599.843

b =

.

599.843+f

fy

y

Egilme Donats Alan:

Donat Alan:

As=

1= 0.85

b=

26 / 150

As= 3540 mm2

(AASHTO 8.16.3.1.1)

fc= 35 MPa

0.03541

0 / 200

3540 mm2

As,gereken=

3234 mm2

OK

As,min=

764 mm2

OK

>

0.01011

< 0.75* b= 0.0266

OK

23/40

EPRO MHENDSLK

SAP2000

10.21.10 17:05:04

UST TABLIYE MESNET MOMENT

M11=-25 tm

-25.0

-20.0

-15.0

-10.0

-5.0

0.0

5.0

10.0

15.0

20.0

25.0

30.0

35.0

40.0

SAP2000 v14.1.0 - File:2.5x4.5 - Resultant M11 Diagram (COMB3) - Tonf, m, C Units

24/40

EPRO MHENDSLK

UST TABLIYE ELME HESABI (MESNET)

Kesitteki Faktrl Moment:

Mu = 2.50E+08 Nmm

Tama Gc Azaltma Katsays (AASHTO 8.16.1.2)

= 0.9

Kesit Genilii:

b= 1000 mm

Faydal Ykseklik:

d= 350 mm

eliin Karekteristik Dayanm:

fy= 420 MPa

Karekteristik Beton Basnc Dayanm

fc= 35 MPa

Paspay

d'= 50 mm

Gereken Eilme Donatsnn Alan

.Mn = . A s .fy da=

Mu=

Eilme Tama Gc

AASHTO 8.16.3.2

Edeger Basn Blou Derinlii

AASHTO 8.16.3.2

A s .fy

0.85.fc .b w

2.50E+08 Nmm

= = = >

Asgereken=

1968 mm2

Minumum Donat Oran

Salanan donat kopma modlne gre hesaplanan atlama momentinin (Mcr) en az 1.2 kat kadar

tama gc salamaldr. (AASHTO 8.17.1.1.1)

Kopma Modl:

fr= 3.11 MPa

Kesitin Geometrik Merkezine Gre Atalet Momenti:

Ig= 5.33E+09 mm4

Kesitin Arlk Merkezinin Alt Tabana Mesafesi:

d= 200 mm

atlama Momenti:

Mcr= 8.29E+07 Nmm

Asmin=

Mcr= fr.Ig/yt

(AASHTO 8.13.3)

1.2Mcr= 9.95E+07 Nmm

764 mm2

Kesitteki donat alan analiz sonucunda gereken donat alannn 1.33 katndan fazla ise minumum

donat art aranmaz. (AASHTO 8.17.1.2)

1.33Asgereken= 2617 mm2

Asmin =

Min ( 764

; 2617

) =

764 mm2

Dengeli Donat Oran

Kesitteki donat oran dengeli donat orannn %75 inden az olmaldr.

0.85.1.fc 599.843

b =

.

599.843+f

fy

y

Egilme Donats Alan:

Donat Alan:

As=

1= 0.85

b=

20 / 150

As= 2094 mm2

(AASHTO 8.16.3.1.1)

fc= 35 MPa

0.03541

0 / 150

2094 mm2

As,gereken=

1968 mm2

OK

As,min=

764 mm2

OK

>

0.00598

< 0.75* b= 0.0266

OK

25/40

EPRO MHENDSLK

SAP2000

10.21.10 17:05:37

UST TABLIYE KESME KUVVET

V13=50 t

-45.0

-38.1

-31.2

-24.2

-17.3

-10.4

-3.5

3.5

10.4

17.3

24.2

31.2

38.1

45.0

SAP2000 v14.1.0 - File:2.5x4.5 - Resultant V13 Diagram (COMB4) - Tonf, m, C Units

26/40

EPRO MHENDSLK

UST TABLIYE KAYMA DONATISI HESABI

Tama Gc Azaltma Katsays (AASHTO 8.16.1.2)

= 0.85

Karakteristik Beton Basn Dayanm:

fc= 35 N/mm2

Kesit Genilii:

b= 1000 mm

Faydal Ykseklik:

d= 350 mm

Arttrlm (Faktrl) Kesme Kuvveti:

Vu= 500000 N

Beton Tarafndan Salanan Kesme Tama Gc:

Vc = 0.25. fc.d.bw

(AASHTO 8.16.6.3)

Vc= 517657 N

Vu= 500000 N

>

* Vc = 440008 N

KAYMA HESABI GEREKL

Kayma Donats:

20 /

250

Etriye Kolu Says:

a= 2

Boyuna Ynde Etriye Aral:

s=

eliin Karekteristik Dayanm:

fy= 420 N/mm2

Donat Tarafndan Salanan Kesme Tama Gc:

Vs =

250 mm

Av.fy.d

s

(AASHTO 8.16.6.3)

Vs= 369451 N

Kesme Tama Gc:

Vn=Vs+Vc

Vu <

Vu= 500000 N

<

* Vn = 754042 N

(AASHTO 8.16.6.1)

* Vn

OK

27/40

EPRO MHENDSLK

SAP2000

10.21.10 17:06:05

ALT TABLIYE ACIKLIK MOMENT

M11=-35 tm

-35.0

-30.4

-25.8

-21.2

-16.5

-11.9

-7.3

-2.7

1.9

6.5

11.2

15.8

20.4

25.0

SAP2000 v14.1.0 - File:2.5x4.5 - Resultant M11 Diagram (COMB4) - Tonf, m, C Units

28/40

EPRO MHENDSLK

ALT TABLIYE ELME HESABI (AIKLIK)

Kesitteki Faktrl Moment:

Mu = 3.50E+08 Nmm

Tama Gc Azaltma Katsays (AASHTO 8.16.1.2)

= 0.9

Kesit Genilii:

b= 1000 mm

Faydal Ykseklik:

d= 350 mm

eliin Karekteristik Dayanm:

fy= 420 MPa

Karekteristik Beton Basnc Dayanm

fc= 35 MPa

Paspay

d'= 50 mm

Gereken Eilme Donatsnn Alan

.Mn = . A s .fy da=

Mu=

Eilme Tama Gc

AASHTO 8.16.3.2

Edeger Basn Blou Derinlii

AASHTO 8.16.3.2

A s .fy

0.85.fc .b w

3.50E+08 Nmm

= = = >

Asgereken=

2804 mm2

Minumum Donat Oran

Salanan donat kopma modlne gre hesaplanan atlama momentinin (Mcr) en az 1.2 kat kadar

tama gc salamaldr. (AASHTO 8.17.1.1.1)

Kopma Modl:

fr= 3.11 MPa

Kesitin Geometrik Merkezine Gre Atalet Momenti:

Ig= 5.33E+09 mm4

Kesitin Arlk Merkezinin Alt Tabana Mesafesi:

d= 200 mm

atlama Momenti:

Mcr= 8.29E+07 Nmm

Asmin=

Mcr= fr.Ig/yt

(AASHTO 8.13.3)

1.2Mcr= 9.95E+07 Nmm

764 mm2

Kesitteki donat alan analiz sonucunda gereken donat alannn 1.33 katndan fazla ise minumum

donat art aranmaz. (AASHTO 8.17.1.2)

1.33Asgereken= 3729 mm2

Asmin =

Min ( 764

; 3729

) =

764 mm2

Dengeli Donat Oran

Kesitteki donat oran dengeli donat orannn %75 inden az olmaldr.

0.85.1.fc 599.843

b =

.

599.843+f

fy

y

Egilme Donats Alan:

Donat Alan:

As=

1= 0.85

b=

26 / 150

As= 3540 mm2

(AASHTO 8.16.3.1.1)

fc= 35 MPa

0.03541

0 / 200

3540 mm2

As,gereken=

2804 mm2

OK

As,min=

764 mm2

OK

>

0.01011

< 0.75* b= 0.0266

OK

29/40

EPRO MHENDSLK

SAP2000

10.21.10 17:06:36

ALT TABLIYE MESNET MOMENT

M11=25 tm

-35.0

-30.4

-25.8

-21.2

-16.5

-11.9

-7.3

-2.7

1.9

6.5

11.2

15.8

20.4

25.0

SAP2000 v14.1.0 - File:2.5x4.5 - Resultant M11 Diagram (COMB3) - Tonf, m, C Units

30/40

EPRO MHENDSLK

ALT TABLIYE ELME HESABI (MESNET)

Kesitteki Faktrl Moment:

Mu = 2.50E+08 Nmm

Tama Gc Azaltma Katsays (AASHTO 8.16.1.2)

= 0.9

Kesit Genilii:

b= 1000 mm

Faydal Ykseklik:

d= 350 mm

eliin Karekteristik Dayanm:

fy= 420 MPa

Karekteristik Beton Basnc Dayanm

fc= 35 MPa

Paspay

d'= 50 mm

Gereken Eilme Donatsnn Alan

.Mn = . A s .fy da=

Mu=

Eilme Tama Gc

AASHTO 8.16.3.2

Edeger Basn Blou Derinlii

AASHTO 8.16.3.2

A s .fy

0.85.fc .b w

2.50E+08 Nmm

= = = >

Asgereken=

1968 mm2

Minumum Donat Oran

Salanan donat kopma modlne gre hesaplanan atlama momentinin (Mcr) en az 1.2 kat kadar

tama gc salamaldr. (AASHTO 8.17.1.1.1)

Kopma Modl:

fr= 3.11 MPa

Kesitin Geometrik Merkezine Gre Atalet Momenti:

Ig= 5.33E+09 mm4

Kesitin Arlk Merkezinin Alt Tabana Mesafesi:

d= 200 mm

atlama Momenti:

Mcr= 8.29E+07 Nmm

Asmin=

Mcr= fr.Ig/yt

(AASHTO 8.13.3)

1.2Mcr= 9.95E+07 Nmm

764 mm2

Kesitteki donat alan analiz sonucunda gereken donat alannn 1.33 katndan fazla ise minumum

donat art aranmaz. (AASHTO 8.17.1.2)

1.33Asgereken= 2617 mm2

Asmin =

Min ( 764

; 2617

) =

764 mm2

Dengeli Donat Oran

Kesitteki donat oran dengeli donat orannn %75 inden az olmaldr.

0.85.1.fc 599.843

b =

.

599.843+f

fy

y

Egilme Donats Alan:

Donat Alan:

As=

1= 0.85

b=

20 / 150

As= 2094 mm2

(AASHTO 8.16.3.1.1)

fc= 35 MPa

0.03541

0 / 150

2094 mm2

As,gereken=

1968 mm2

OK

As,min=

764 mm2

OK

>

0.00598

< 0.75* b= 0.0266

OK

31/40

EPRO MHENDSLK

SAP2000

10.21.10 17:07:05

ALT TABLIYE KESME KUVVET

V13=50 t

-45.0

-38.1

-31.2

-24.2

-17.3

-10.4

-3.5

3.5

10.4

17.3

24.2

31.2

38.1

45.0

SAP2000 v14.1.0 - File:2.5x4.5 - Resultant V13 Diagram (COMB4) - Tonf, m, C Units

32/40

EPRO MHENDSLK

ALT TABLIYE KAYMA DONATISI HESABI

Tama Gc Azaltma Katsays (AASHTO 8.16.1.2)

= 0.85

Karakteristik Beton Basn Dayanm:

fc= 35 N/mm2

Kesit Genilii:

b= 1000 mm

Faydal Ykseklik:

d= 350 mm

Arttrlm (Faktrl) Kesme Kuvveti:

Vu= 500000 N

Beton Tarafndan Salanan Kesme Tama Gc:

Vc = 0.25. fc.d.bw

(AASHTO 8.16.6.3)

Vc= 517657 N

Vu= 500000 N

>

* Vc = 440008 N

KAYMA HESABI GEREKL

Kayma Donats:

20 /

250

Etriye Kolu Says:

a= 2

Boyuna Ynde Etriye Aral:

s=

eliin Karekteristik Dayanm:

fy= 420 N/mm2

Donat Tarafndan Salanan Kesme Tama Gc:

Vs =

250 mm

Av.fy.d

s

(AASHTO 8.16.6.3)

Vs= 369451 N

Kesme Tama Gc:

Vn=Vs+Vc

Vu <

Vu= 500000 N

<

* Vn = 754042 N

(AASHTO 8.16.6.1)

* Vn

OK

33/40

EPRO MHENDSLK

SAP2000

10.21.10 17:12:05

PERDE MOMENT

M11=-35 tm

-35.0

-33.1

-31.2

-29.2

-27.3

-25.4

-23.5

-21.5

-19.6

-17.7

-15.8

-13.8

-11.9

-10.0

SAP2000 v14.1.0 - File:2.5x4.5 - Resultant M11 Diagram (COMB3) - Tonf, m, C Units

34/40

EPRO MHENDSLK

PERDE ELME HESABI

Kesitteki Faktrl Moment:

Mu = 3.50E+08 Nmm

Tama Gc Azaltma Katsays (AASHTO 8.16.1.2)

= 0.9

Kesit Genilii:

b= 1000 mm

Faydal Ykseklik:

d= 350 mm

eliin Karekteristik Dayanm:

fy= 420 MPa

Karekteristik Beton Basnc Dayanm

fc= 35 MPa

Paspay

d'= 50 mm

Gereken Eilme Donatsnn Alan

.Mn = . A s .fy da=

Mu=

Eilme Tama Gc

AASHTO 8.16.3.2

Edeger Basn Blou Derinlii

AASHTO 8.16.3.2

A s .fy

0.85.fc .b w

3.50E+08 Nmm

= = = >

Asgereken=

2804 mm2

Minumum Donat Oran

Salanan donat kopma modlne gre hesaplanan atlama momentinin (Mcr) en az 1.2 kat kadar

tama gc salamaldr. (AASHTO 8.17.1.1.1)

Kopma Modl:

fr= 3.11 MPa

Kesitin Geometrik Merkezine Gre Atalet Momenti:

Ig= 5.33E+09 mm4

Kesitin Arlk Merkezinin Alt Tabana Mesafesi:

d= 200 mm

atlama Momenti:

Mcr= 8.29E+07 Nmm

Asmin=

Mcr= fr.Ig/yt

(AASHTO 8.13.3)

1.2Mcr= 9.95E+07 Nmm

764 mm2

Kesitteki donat alan analiz sonucunda gereken donat alannn 1.33 katndan fazla ise minumum

donat art aranmaz. (AASHTO 8.17.1.2)

1.33Asgereken= 3729 mm2

Asmin =

Min ( 764

; 3729

) =

764 mm2

Dengeli Donat Oran

Kesitteki donat oran dengeli donat orannn %75 inden az olmaldr.

0.85.1.fc 599.843

b =

.

599.843+f

fy

y

Egilme Donats Alan:

Donat Alan:

As=

1= 0.85

b=

26 / 150

As= 3540 mm2

(AASHTO 8.16.3.1.1)

fc= 35 MPa

0.03541

0 / 150

3540 mm2

As,gereken=

2804 mm2

OK

As,min=

764 mm2

OK

>

0.01011

< 0.75* b= 0.0266

OK

35/40

EPRO MHENDSLK

SAP2000

10.21.10 17:12:37

PERDE KESME KUVVET

V13=15 t

-15.0

-12.7

-10.4

-8.1

-5.8

-3.5

-1.2

1.2

3.5

5.8

8.1

10.4

12.7

15.0

SAP2000 v14.1.0 - File:2.5x4.5 - Resultant V13 Diagram (COMB3) - Tonf, m, C Units

36/40

EPRO MHENDSLK

PERDE KAYMA DONATISI HESABI

Tama Gc Azaltma Katsays (AASHTO 8.16.1.2)

= 0.85

Karakteristik Beton Basn Dayanm:

fc= 35 N/mm2

Kesit Genilii:

b= 1000 mm

Faydal Ykseklik:

d= 350 mm

Arttrlm (Faktrl) Kesme Kuvveti:

Vu= 150000 N

Beton Tarafndan Salanan Kesme Tama Gc:

Vc = 0.25. fc.d.bw

(AASHTO 8.16.6.3)

Vc= 517657 N

Vu= 150000 N

<

* Vc = 440008 N

KAYMA HESABI GEREKMYOR

37/40

EPRO MHENDSLK

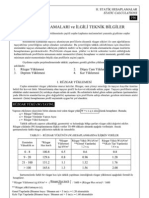

7.3. ZEMN EMNYET GERLMES KONROL

38/40

EPRO MHENDSLK

SAP2000

10.21.10 16:44:49

GERILME TAHKIKI

YATAK KATSAYISI = 10000 kN/m3

TEMEL DEPLASMANI = 0.0118 m.

GERILME = 0.0118 X 10000 = 118 kN/m2 < 150 kN/m2

SAP2000 v14.1.0 - File:2.5x4.5 - Deformed Shape (COMB2) - Tonf, m, C Units

39/40

EPRO MHENDSLK

8. SAP2000 PROGRAMI YN KABULLER

Shell Element

FINT = F intermediate

FVM ={1/2[(FMAX - FINT)^2+( FMAX - FMIN)^2+( FINT - FMIN)^2]}.

40/40

You might also like

- Menfez PolDocument6 pagesMenfez Polnihat karaNo ratings yet

- Kutu Menfez Hesabı EXCELDocument6 pagesKutu Menfez Hesabı EXCELHandeNo ratings yet

- Murt Deresi Hesap Hepsi PDFDocument82 pagesMurt Deresi Hesap Hepsi PDFMehmetDuran100% (2)

- Çobandede Köprüsü-Nihai RaporDocument74 pagesÇobandede Köprüsü-Nihai RaporAbdulkadir Cüneyt Aydın100% (1)

- Menfezlerin Tasarım MetoduDocument2 pagesMenfezlerin Tasarım MetoduKenan OzturkNo ratings yet

- MenfezlerDocument26 pagesMenfezlermkarasahinNo ratings yet

- Taş Ve Istinat DuvarlarıDocument64 pagesTaş Ve Istinat DuvarlarıAli Erkin Akyol50% (2)

- Sanat - Yapilari - Uygulama - Projeler - Yapim - İşi̇ Genel Tekni̇k - Şartnamesi̇Document51 pagesSanat - Yapilari - Uygulama - Projeler - Yapim - İşi̇ Genel Tekni̇k - Şartnamesi̇Merve DeğindaşNo ratings yet

- Yüzeysel Temeller YeniDocument33 pagesYüzeysel Temeller YeniAbdullah Mohibbi0% (1)

- 2013 Sanat Yapilari - OrjinalDocument113 pages2013 Sanat Yapilari - OrjinalAlyanNo ratings yet

- Kutu Menfez Stati̇k-AashtoDocument16 pagesKutu Menfez Stati̇k-AashtoMahzun Araratlı50% (2)

- Tünel KazisiDocument40 pagesTünel Kazisiozgur kılıcNo ratings yet

- Hesap AciklamaDocument3 pagesHesap AciklamaOrhan KızmazNo ratings yet

- Kutu Menfez Stati K AashtoDocument8 pagesKutu Menfez Stati K AashtoCoşkun AteşNo ratings yet

- Kutu Menfez Hesab ExcelDocument12 pagesKutu Menfez Hesab ExcelSOPHİENo ratings yet

- Betonarme Kopru HesabiDocument23 pagesBetonarme Kopru HesabiYasin Topçu100% (1)

- Box Kutu MenfezDocument23 pagesBox Kutu MenfezEFECAN100% (1)

- Istinat Duvarlarinin Statik Ve Dinamik Yukler Altindaki Davranisinin Analizi Behaviour of Retaining Walls Under Static and Dynamic LoadsDocument103 pagesIstinat Duvarlarinin Statik Ve Dinamik Yukler Altindaki Davranisinin Analizi Behaviour of Retaining Walls Under Static and Dynamic LoadsVefa OkumuşNo ratings yet

- ZeminDocument3 pagesZeminSeyfi BarutNo ratings yet

- KoprulerDocument41 pagesKoprulerCan AydoğmuşNo ratings yet

- Deprem Etkisi Altında BA Yapılar - N AydınogluDocument62 pagesDeprem Etkisi Altında BA Yapılar - N AydınoglusertackocdagNo ratings yet

- Karayollarında Zayıf Zemin Problemleri Ve Önlemler Yayın No 266Document25 pagesKarayollarında Zayıf Zemin Problemleri Ve Önlemler Yayın No 266EmrePınarcıNo ratings yet

- Islah Sekileri Tersip BentleriDocument108 pagesIslah Sekileri Tersip BentleriserhatNo ratings yet

- IMO Dinamik Temel - BSDocument63 pagesIMO Dinamik Temel - BSonurumanNo ratings yet

- Karayollari Sanat Yapilari Araştirma Şartname PDFDocument14 pagesKarayollari Sanat Yapilari Araştirma Şartname PDFMetin AzaNo ratings yet

- Karayolu MenfezDocument25 pagesKarayolu MenfezFurkan YılmazNo ratings yet

- 6.drenaj TasarimiDocument49 pages6.drenaj TasarimiOnur Furkan CakıllıNo ratings yet

- Tünel ŞaftDocument120 pagesTünel ŞaftHarun KologluNo ratings yet

- Betonarme 1 5Document16 pagesBetonarme 1 5turusan94256No ratings yet

- Kolon Hesabi-Mizan Dogan PDFDocument52 pagesKolon Hesabi-Mizan Dogan PDFayhanNo ratings yet

- Guclendirme PDFDocument88 pagesGuclendirme PDFOktayNo ratings yet

- İMO - İnşaat Mühendisliği El KitabıDocument206 pagesİMO - İnşaat Mühendisliği El KitabıHasim ErenNo ratings yet

- B 1. Beton Ile Betonarme Davranışı Ve Hesap Için Temel İlkelerDocument52 pagesB 1. Beton Ile Betonarme Davranışı Ve Hesap Için Temel İlkelerAyberk KocaNo ratings yet

- İnşaat İşleri Projelendirme Genel ŞartnamesiDocument24 pagesİnşaat İşleri Projelendirme Genel ŞartnamesiOktayNo ratings yet

- Palplanş Örnek RaporDocument17 pagesPalplanş Örnek RaporCelal Ünal100% (1)

- KuTu Menfez TipLeriDocument28 pagesKuTu Menfez TipLeribinanc100% (1)

- Açik Kanallar SonDocument36 pagesAçik Kanallar SonRamazanNo ratings yet

- ALHAN MO Yap Kaz K Zemin Sunum 1637844776Document42 pagesALHAN MO Yap Kaz K Zemin Sunum 1637844776nisfibolahenkNo ratings yet

- Su Kaynakları Vize PDFDocument7 pagesSu Kaynakları Vize PDFPuncover0% (1)

- Açık İşletmelerde Şev Stabilite Analizi Ve Nurkireç Kalker Sahasına UygulanmasıDocument106 pagesAçık İşletmelerde Şev Stabilite Analizi Ve Nurkireç Kalker Sahasına UygulanmasıUmur Sönmez0% (1)

- Toprak İşleriDocument21 pagesToprak İşleriPsemenos GleftesNo ratings yet

- Bitirme Tezi1Document184 pagesBitirme Tezi1selooooNo ratings yet

- Baret TemellerDocument87 pagesBaret TemellercengizNo ratings yet

- Kopru-3 Yukkilavuzu 201510 PDFDocument163 pagesKopru-3 Yukkilavuzu 201510 PDFYeliz KircaNo ratings yet

- Doseme HesabiDocument68 pagesDoseme HesabigokhanNo ratings yet

- Ödev 1Document1 pageÖdev 1isensa symposiumNo ratings yet

- Yapı Malzemelerinin Tarihsel GelişimiDocument7 pagesYapı Malzemelerinin Tarihsel GelişimiErkan ŞamhalNo ratings yet

- 3.2 Karayolu Geometrik Standartlar 2006Document251 pages3.2 Karayolu Geometrik Standartlar 2006HÜSEYİN DEMİRNo ratings yet

- Celik Yapilarin Tasarim Ve Boyutlama Esaslari - TUCSADocument34 pagesCelik Yapilarin Tasarim Ve Boyutlama Esaslari - TUCSAmsenerNo ratings yet

- Geçiş EğrileriDocument60 pagesGeçiş EğrileriNazim ManicNo ratings yet

- Giydirme Cephe Statik HesaplamalarDocument11 pagesGiydirme Cephe Statik HesaplamalarKemal OmurluogluNo ratings yet

- 2010-Poli̇feni̇lenvi̇ni̇len (PPV) Bazli Konjuge Poli̇merlerle Hazirlanan Organi̇k Fotovoltai̇k HücrelerDocument69 pages2010-Poli̇feni̇lenvi̇ni̇len (PPV) Bazli Konjuge Poli̇merlerle Hazirlanan Organi̇k Fotovoltai̇k HücrelerBeyza Nur AKBOLATNo ratings yet

- Otoparklar İçin Jet Fanli Havalandirma Hesabi: SeçilenDocument9 pagesOtoparklar İçin Jet Fanli Havalandirma Hesabi: SeçilenUğur AydemirNo ratings yet

- BolumII C Ornek13 NurayAydinogluDocument25 pagesBolumII C Ornek13 NurayAydinoglutolgaNo ratings yet

- Asenkron Motor SürücüDocument84 pagesAsenkron Motor Sürücüerkulrecep01No ratings yet

- CCS3.1.KK - TR Ver1.501Document27 pagesCCS3.1.KK - TR Ver1.501akdagendustriyelNo ratings yet

- Öngerme Kiriş HesabıDocument61 pagesÖngerme Kiriş HesabıozgurdogerNo ratings yet

- Pistona Etki Eden Gerilmelerin Analizi PDFDocument111 pagesPistona Etki Eden Gerilmelerin Analizi PDFBurak YılmazNo ratings yet

- TS 5711Document3 pagesTS 5711GB TrdNo ratings yet