Professional Documents

Culture Documents

Isolation of Flavonoids From Mulberry (L.) Leaves With Macroporous Resins

Uploaded by

Nina AnindyawatiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Isolation of Flavonoids From Mulberry (L.) Leaves With Macroporous Resins

Uploaded by

Nina AnindyawatiCopyright:

Available Formats

African Journal of Biotechnology Vol. 7 (13), pp. 2147-2155, 4 July, 2008 Available online at http://www.academicjournals.

org/AJB ISSN 16845315 2008 Academic Journals

Full Length Research Paper

Isolation of flavonoids from mulberry (Morus alba L.) leaves with macroporous resins

Jun Wang, Fu An Wu*, Hui Zhao, Li Liu and Qiu Sheng Wu

College of Biotechnology and Environmental Engineering, Jiangsu University of Science and Technology, Sericultural Research Institute, Chinese Academy of Agricultural Sciences Zhenjiang 212018, P.R. China.

Accepted 20 May, 2008

Flavonoids are major active constituents in mulberry (Morus alba L.) leaves and possess various pharmacological activities. In the present study, the extraction technology and preparative separation of total flavonoids (TFs) in mulberry leaves extracts by macroporous resins were studied systematically, and the column packed with selected resin was used to perform dynamic adsorption and desorption tests to optimize the separation process. The research results indicated that the maximal yield of TFs was achieved when mulberry leaves were extracted under the optimized conditions of a pH of 8, a o solid-liquid ratio of 1:40, a temperature of 90 C and a time of 4 h. H103 resin is the most appropriate for the separation of TFs from other components in mulberry leaves extracts, which adsorption behavior can be described with Langmuir and Freundlich isotherms and two-step adsorption kinetics model. The optimum parameters for TFs separation by H103 were achieved, after one run treatment. The recovery and purity of TFs in the final product were 90.57 and 76.33%, respectively. In conclusion, the preparative separation of TFs in mulberry leaves can be easily and effectively done by H103 resin. Key words: Optimization, isolation, flavonoids, Morus alba (L.), mulberry leaves, macroporous resin. INTRODUCTION Mulberry, Morus alba L., as a non-toxic natural therapeutic agent, belongs to the family of Moraceae, and has been cultivated in many Asian countries such as China, India, Korea, Japan and Thailand where the leaves were used as food for silkworms (Nuengchamnong et al., 2007). There is an increasing interest on mulberry leaves because the leaves were found to have hypoglycemic, hypotensive, diuretic, bacteriostatic and antivirotic properties and they have been applied widely in clinic, which has important values to gerontal diseases and delayed consenescence (Chu et al., 2006). The mulberry leaves are rich in flavonoids, alkaloids and polysaccharides components which are known as the most potently major active compounds by chemical constituent investigations. Among those, the TFs in mulberry leaves were contained rutin, quercetin, isoquercitrin and quercetin 3-(6-malonylglucoside) (Lee et al., 2007). Flavonoids have found applications in food and pharmaceutical industries for their valuable properties, and adsorbent resins have been utilized to separate and concentrate these products from the natral matrixes (Fu et al., 2005; Qi et al., 2007).In particular, the medical applications of total flavoniods of mulberry leaves have provoked much interest, and its leaves have been brought to market as a product of traditional Chinese medicine (TCM) that possesses notable biological activities. Nowadays, the traditional separation methods about the flavonoids of mulberry leaves used so far were limited to simple techniques such as extraction and precipitation leading to low recoveries. Hence a more efficient and simple purification method for TFs in mulberry leaves is required. The purification method of macroporous resin is a new promising technology in bioengineering, and has successfully applied in the preparative separation of TFs in natural products (Aehle et al., 2004; Fu et al., 2005; Zhang and Li, 2006; Qi et al., 2007).Similarly, such a method is extremely useful for the extraction and separation of the TFs from mulberry leaves. Therefore, the objectives of the present study were to investigate the adsorption and desorption properties of TFs from mulberry leaves on different macroporous resins, and

*Corresponding author. E-mail: fuword@163.com.. Tel: 86-5118561-6571

2148

Afr. J. Biotechnol.

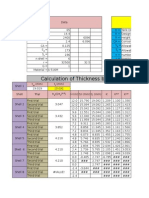

Table 1. Extraction of TFs from mulberry leaves by L9 (34).

Level 1 2 3 4 5 6 7 8 9 T1 T2 T3 X1 X2 X3 R

Temperature ( C) 70 70 70 80 80 80 90 90 90 9.90 10.71 11.01 3.30 3.57 3.67 0.37

Factors Solid-liqid ratio Extraction time (h) 1:20 2 1:30 4 1:40 6 1:20 4 1:30 6 1:40 2 1:20 6 1:30 2 1:40 4 9.83 10.13 10.32 11.34 11.47 10.15 3.28 3.38 3.44 3.78 3.82 3.38 0.55 0.41

pH 7 8 9 9 7 8 8 9 7 10.11 11.38 10.13 3.37 3.79 3.38 0.42

Yield of TFs (%) 2.78 3.77 3.35 3.47 3.22 4.02 3.58 3.32 4.10

develop an efficient method for the preparative separation of TFs from mulberry leaves with the resin. The results in this study are significant for the preparative separation of TFs from other plants in general.

MATERIALS AND METHODS Chemicals and reagents Rutin standard was brought from National Institute for Control of Pharmaceutical and Biological Products (Beijing, China). All other reagents were of analytical grade and deionized water was purified by a Milli-Q water-purification system from Millipore (Bedford, MA, USA). Appropriate amount of standard was dissolved in ethanol to yield the stock solutions at concentration of 0.5 mg/ml for rutin. Adsorbents Macroporous resins including AB-8, X-5, S-8, H103, NKA, NKA-9, NKA-II, D101, D4020 and D3520 were purchased from Nankai Hecheng Science and Technology (Tianjin, China). The adsorbent beads were pre-treated to remove the monomers and porogenic agents trapped inside the pores during the synthesis process. All resins were soaked in 95% ethanol, shaken for 24 h and washed by deionized water thoroughly (Juang and Shiau, 1999). The moisture contents of the test resins were determined by drying the beds at 60 to constant weight in dry oven. C Optimization of extraction technology of TFs from mulberry leaves Mulberry leaves were collected during the summer season in West campus, Jiangsu University of Science and Technology, Jiangsu province, China. The material was dried at 60 powered by a herb C, disintegrator (Qinzhou Sanyang Package Equipment Co., Ltd) and then sieved (60 mesh). As shown in Table 1, the extraction technology of TFs from

mulberry leaves was optimized by orthogonal experiments L9 (34). Mulberry leaves powder (500 g) was extracted under optimum process conditions. The extracts were purified by membrane filtration and then transferred to a rotary evaporator device (R200, Bchi, Switzerland) and concentrated under vacuum to the contents of TFs 6.05 mg/ml (pH 6), stored at 4 C. Static adsorption and desorption tests The static adsorption tests of mulberry leaves extracts on macroporous resins were performed as follows: 1 g sample of hydrated test resins were placed in flasks with a lid; then 50 ml of sample solutions of mulberry leaves extracts (TFs concentration 6.05 mg/ml) were added. The flasks were then shaken (100 rpm) for 24 h at 25 C. The solutions after adsorption were analyzed by chromatometry. The desorption processes were performed as follows: after reaching adsorption equilibrium, the resins were first washed by deionized water and then desorbed with 30 ml ethanol water (30:70, 60:40, 100:0) solutions, respectively. The flasks were then shaken (100 rpm) for 24 h at 25 The desorption solutions were analyzed C. by chromatometry. The selectivity of resins was based on the capacities of adsorption and desorption, and radio of desorption. The adsorption kinetic curves of TFs on the preliminarily selected H103 resin was studied according to the method described above; the respective concentrations in the sample solutions were monitored at certain time intervals till equilibrium. The test for equilibrium adsorption isotherms on H103 and AB-8 resins were conducted by mixing 50 ml sample solutions of mulberry leaves extracts at different concentrations with 0.5 g (dry weight) resins, and then shaking for 6 h at a temperature of 25, 30 and 35 C. The initial and equilibrium concentrations at different temperatures were determined by chromatometry. The test for adsorption kinetics on H103 resin were conducted by mixing 75 ml sample solutions of mulberry leaves extracts (the concentration of TFs 6.05 mg/ml) with 1 g (dry weight) resin, and then shaking (100 rpm) for 10 h at a temperature of 25 The C. remaining concentrations at different times were determined by chromatometry.

Wang et al.

2149

The adsorption and desorption properties of the selected H103 resin under different conditions including initial concentration of sample solution, temperature, and concentration of ethanol for desorption were also evaluated. Dynamic adsorption and desorption tests Dynamic adsorption and desorption experiments were carried out on glass columns (25 400 mm) wet-packed with 16 g (dry weight) of selected H103 resin, and the packed length of resin was 80 mm. Sample solution flowed through the glass column at the flow rate of 1 ml/min and the concentration of TFs in the effluent liquid were monitored at certain time intervals by chromatometry. For adsorptive equilibrium, the adsorbated column was washed first by deionized water, and then eluted by ethanol water (60:40) solution. The flow rate was 1 ml/min, and the concentration of TFs in desorption solution was determined by chromatometry. Determination of TFs The TFs content was determined by the aluminum trichloride method of Wang et al. (2008). Adsorption capacities, adsorption radio, desorption radio and recovery The following equations were used to quantify the capacities of adsorption and desorption as well as the ratio of desorption. Adsorption evaluation:

Adsorption kinetics models The experimental data of adsorption rate constant were fitted to the two-step adsorption kinetics model to describe the adsorption kinetic property of solutes with the resin:

qt = qe A1e k1t A2 e k2t

dqt / dt = ki (qe qt ) + ci i =1, 2

(5)

(6)

where A1 and A2 are frequency factors; k1 and k2 are adsorption rate constants; qt is the adsorption quantity (mg/g) (Nagaoka and Imae, 2003).

RESULTS AND DISCUSSION Optimum process conditions for extracting TFs from mulberry leaves As can be seen from Table 1, the results showed the influence order of different factors on the yield of TFs from mulberry leaves: solid-liqid ratio > pH > extraction time > extraction temperature. The optimum technological conditions for extracting TFs from mulberry leaves were: pH 8; solid-liquid ratio, 1:40; temperature, 90 and time, C; 4 h. the maximal yield of TFs was 4.77% when mulberry leaves were extracted under the optimized conditions. Adsorption capacity, adsorption ratio, desorption radio and recovery

qe =

(C0 Ce )V0 m

(1)

E (%) =

C0 Ce 100% C0

(2)

where qe is the adsorption capacity at adsorption equilibrium (mg/g resin); E the adsorption ratio (%); C0 and Ce the initial and equilibrium concentrations of solute in the solution, respectively (mg/ml); V0 the volume of the initial sample solution (ml) and m is the weight of dry resin (g). Desorption evaluation:

R=

CdVd 100% C0V0

(3)

D=

CdVd 100% ( C0 Ce ) V0

(4)

where R is the recovery (%); Cd the concentration of the solute in the desorption solution (mg/ml); Vd the volume of the desorption solution (ml); D the desorption ratio (%); C0 ,Ce and V0 are the same as described above. Adsorption equations The equilibrium experimental data were fitted to the Henry, Langmuir and Freundlich equations to describe the interaction of solutes with the resin (Jung et al., 2001).

The adsorption capacities of S-8, H103 and AB-8 resins toward TFs of mulberry leaves were considerably higher than those of other resins (Figure 1). However, the recovery and desorption ratio of S-8 resin was the lowest in all resins (Figure 2). On the contrary, although the ad-sorption capacities of H103 and AB-8 resins were not the highest, the recovery and desorption ratio were higher, which correlates with the capacities of the resins and the chemical features of the adsorbed substance. Therefore, H103 and AB-8 resins were selected to further investigate their adsorption behavior toward TFs of mulberry leaves. Different concentrations of ethanol solutions were used to perform desorption tests in order to choose proper desorption solution. With the increasing of the ethanol concentration, the desorption ratios on all resins increased accordingly and reached their peak value at the concentration of 60%, then decreased with the concentration of ethanol (Figure 2). Therefore, ethanol water (40:60) solution was selected as the appropriate desorption solution and was used in the subsequent assays. Adsorption isotherms on AB-8 and H103 resin Equilibrium adsorption isotherms were conducted at tem-

2150

Afr. J. Biotechnol.

600

100

500

Adsorption capacity Adsorption ratio

80

Adsorption capacity (mg/g)

Adsorption ratio (%)

400 60 300 40 200 20

100

0

AB-8 X-5 S-8 H103 D101 NKA NKA-9NKA-II D4020 D3520 --

Resin trade name

Figure 1. Adsorption capacity and adsorption ratio of TFs in mulberry leaves on different resins.

Recovery_30% Ethanol Recovery_60% Ethanol Recovery_100% Ethanol

100 90 80 70

Desorption ratio_30% Ethanol Desorption ratio_60% Ethanol Desorption ratio_100% Ethanol

100 90

70 60 50 40 30 20 10 0

AB-8 X-5 S-8 H103 D101 NKA NKA-9NKA-II D4020 D3520 --

Recovery (%)

60 50 40 30 20 10 0

Resin trade name

Figure 2. Recovery and desorption ratio of TFs in mulberry leaves on different resins.

peratures of 25, 30 and 35 For the two resins, the C. adsorption capacity increased with the initial concentration of TFs in mulberry leaves, and reached the saturation plateau when the initial concentrations of TFs in mulberry leaves were 3.0 and 4.4 mg/ml, respectively

(Figure 3). It can also be seen from Figure 3, within the temperatures investigated, at the same initial concentration, the adsorption capacities decreased with the increasing temperature; the adsorptive speed was slower than desorptive speed for TFs in mulberry leaves, which

Desorption ratio (%)

80

Wang et al.

2151

450

H103 25 r=0.9772 H103 30 r=0.9765 H103 35 r=0.9554 AB -8 25 r=0.9738 AB -8 30 r=0.9526 AB -8 35 r=0.9127

300

qe

150 0

Ce

(a) Henry isotherm

0.012

0.010 0.008

H103 25 r=0.9979 H103 30 r=0.9907 H103 35 r=0.9863 AB-8 25 r=0.9979 AB-8 30 r=0.9707 AB-8 35 r=0.9801

1/qe

0.006 0.004 0.002 0.000 0.0

0.4

0.8

1.2

1.6

2.0

1/C e

(b) Langmuir isotherm

2.5

lgqe

0.0

0.2

(c) Freundlich isotherm

Figure 3. Adsorption isotherms for TFs in mulberry in mulberry leaves on H103 and AB-8 resins.

2.0

H103 25 H103 30 H103 35 AB-8 25 AB-8 30 AB-8 35

r=0.9962 r=0.9861 r=0.9777 r=0.9964 r=0.9652 r=0.9522

0.4

0.6

lgC e

2152

Afr. J. Biotechnol.

400

800

simulation value

200

simulation value

400

100

200

10

t (h)

Figure 4. Adsorption kinetics and adsorption rate curves of TFs from mulberry leaves.

indicated that the adsorption was a thermopositive process. Therefore, 25 was used in the subsequent C assays. The Henry, Langmuir and Freundlich isotherms are the best known and the most often used isotherms for the adsorption of solutes from a solution in the bio-separation process. The Henry, Langmuir and Freundlich parameters were obtained from the Henry, Langmuir and Freundlich equations, and summarized in Figure 3. The correlation coefficients of the Henry, Langmuir and Freundlich equations on H103 resin were slightly higher than AB-8 resin, especially the equilibrium adsorption isotherm of H103 that highly fit to the Langmuir and Freundlich models. The Langmuir model assumes monomolecular layer adsorption with a homogeneous distribution of adsorption energies and without mutual interaction between adsorbed molecules, while the Freundlich model can be used to describe the adsorption behavior of monomolecular layer as well as that of the muli-molecular layer (Fu et al., 2005).The equilibrium adsorption behavior of H103 fit both models. In the comprehensive consideration of the adsorption capacity and desorption ratio, H103 resin was selected as the most suitable resin for the separation of TFs in mulberry leaves and was used in the subsequent assays. Adsorption kinetics on H103 resin The adsorption capacity of H103 resin increased with adsorption time, reaching equilibrium at about 5 h (Figure

4). In first 2 h, the adsorption capacity increased rapidly, after 2 h the slopes, at different times which indicate the adsorption ratio, varied little. Experimental and theoretical studies of adsorption kinetics in various solute-solution systems have been the subject of so many papers; one of the most famous is probably the pioneering paper published by Lagergren in 1898 (Lagergren et al., 1898).Since that time, a variety of theoretical expressions have been proposed to describe the observed adsorption kinetics. Some of them were purely empirical and some were based on certain physical models of adsorption kinetics. Although one may face a variety of physical situations, such a two-step kinetic mechanism should be very typical of many adsorption systems, because the kinetics of molecule sorption from aqueous solutions by solids can be considered as a two-step process (Rudzinski and Plazinski, 2008). The adsorption process is the distribution of the solute molecules between the adsorbents and the liquid phase (Scordino et al., 2003). In the current paper, we apply two-step adsorption kinetics to the analysis of the above kinetics data. The analytical curves of the kinetics were calculated, and computer simulations were carried out to interpret the experimental data of TFs adsorption on H103. The adsorption rate constants were obtained from twostep adsorption kinetics model; the kinetics parameters were described as Table 2. As can be seen from Figure 5, for the two steps, the adsorption rate constants k1 > k2. The results demonstrated a similar two-step adsorption kinetics model as "fast followed by slow" in the adsorption process of TFs on H103 resin.

dq/dt(mg/min)

300

experimental value

600

qt

Wang et al.

2153

Table 2. Adsorption Kinetics parameters in the two-step adsorption kinetics model.

Parameters qe A1 k1 A2 K2

Value 447.63 207.89 0.46 239.77 2.88

Std Error 0.67 4.48 0.01 4.98 0.09

t-value 669.53 46.39 39.33 48.15 32.08

95% CLs 446.21 449.04 198.39 217.39 0.43 0.48 229.21 250.32 2.69 3.07

P>|t| 0.00 0.00 0.00 0.00 0.00

300

65 60

800

250

q D

55 50 45

600

200

dq / dt

400

k2=0.47 0.46-0.48 2 r =0.9993 y=k2x+c2

y=k1x+c1

q(mg/g)

150 40 100 35 30 50 25 0 2 4 6 8 10 20

D(%)

200

k1=2.31 0.73-3.88 r =0.9971

2

measured value

100

200

300

400

500

C(mg/ml)

qe-qt

Figure 5. Adsorption rate constants in two-step adsorption kinetics model on H103 resin.

Figure 6. Adsorption capacity and desorption ratio of H103 resin under different TFs concentration.

There are two adsorption mechanisms that should be considered in the adsorption kinetics of TFs on H103 resin: In the first mechanism, the surface coverage by the adsorbed TFs molecules increases relatively rapid at early stage due to the formation of first adlayer and then gradually at longer time scale by the formation of the second adlayer. The total coverage depends on the degree of the contribution of two adsorption processes. On the other hand, in the second mechanism, the maximum coverage happens by the excess adsorption at the early stage. The excess TFs molecules are desorbed at the long time scale, accompanying with the rearrangement to the monolayer (Nagaoka and Imae, 2003). Therefore, adsorption kinetics process for TFs in mulberry leaves on H103 resin fitted to two-step adsorption kinetics model. Effect of concentration of sample solution on H103 resin The concentration of sample solution influences the adsorption capacity and adsorption ratio on H103 resin (Figure 6). For TFs in mulberry leaves, the highest ad-

sorption capacity appeared at the concentration of sample solution of 6.02 mg/ml, and then decreased with the increase of the concentration of sample solution. Hence, the concentration of sample solution was adjusted to about 6.02 mg/ml for the subsequent assays. Dynamic leakage curve on H103 resin The dynamic leakage curves on H103 resin were obtained for TFs in mulberry leaves based on the volume of effluent liquid and the concentration of solute therein. The flow rate of sample solution is one of the important factors influencing the dynamic leakage curves; there was a linear relationship between ln[C/(C0-C)] and t (Wang et al., 2008), as shown in Figure 7. As the flow rate of sample solution increased, the dynamic leakage time decreased (Figure 7); on the contrary, the adsorption capacity increased. In the comprehensive consideration of the dynamic leakage time, adsorption capacity and regression coefficient of linear relationship between ln[C/(C0-C)] and t, 9.0 ml/min was selected the most suitable flow rate of sample solution for the dynamic adsorption of TFs in mulberry leaves and was used in the subsequent assays.

2154

Afr. J. Biotechnol.

Table 3. Dynamic desorption process parameters in the Pearson IV equation.

Flow rate of desorption solution (ml/min 4.5 7.5

r 0.9957 0.9826

DF Adj r 0.9943 0.9746

Fit Std Err 21.33 48.29

F-value 923.21 158.34

1200

4.5mL/min experimental value

1000 800

7.5mL/min experimental value 4.5mL/min simulation value 7.5mL/min simulation value

ln C/C0-C

P (mg)

4.5 mL/min r=0.9812 9.0 mL/min r=0.9955 13.0 mL/min r=0.9811

Dynamic desorption curve on H103 resin The dynamic desorption curves on H103 resin were obtained based on desorption time and quality of solute therein. The flow rate of desorption solution is one of the important factors influencing the dynamic desorption curves, and the recovery and purity of TFs in mulberry leaves decreased with the flow rate of desorption solution (Figure 8). From the figure, it is shown that the data of dynamic desorption curves fitted to Pearson IV equation which parameters were described in Table 3. The experiment results shown that when the flow rate of desorption solution was 4.5 ml/min, the recovery and purity of TFs in the final product were 90.57 and 76.33%, respectively. The dynamic desorption curves equation 2 e was: y = a + b (1 + n )- exp (-f (atan (n) + atan (f / (2e)))) / 2 2 e (1 + f / (4e ))- , where n = (x-df /(2e) - c) /d, a = -14.53, b 2 = 1113.87, c = 19.28, d = 5.14, e = 0.96, f = -2.35, r = 0.9957. In the comprehensive consideration of the dynamic desorption time, the stimulated results by Pearson IV equation, recovery and purity of TFs in mulberry leaves, 4.5 ml/min was selected the most suitable flow rate of desorption solution for the dynamic desorption of TFs in mulberry leaves. Conclusions The preconcentration and separation method of TFs from

Figure 8. Dynamic desorption curves of TFs in mulberry leaves on column packed with H103 resin under different flow rate of 60% ethanol.

mulberry leaves with macroporous resins was successfully achieved in this study. The maximal yield of TFs was obtained when mulberry leaves were extracted under the optimized conditions of pH of 8, a solid-liquid ratio of 1:40, a temperature of 90 and a time of 4 h. Among the ten C resins investigated, H103 resin offers the best separation capacity for TFs from other components in mulberry leaves extracts. Process parameters including concentration and flow rate of sample solution, concentration and flow rate of desorption solution, temperature, etc., were optimized for the most effective separation of TFs in mulberry leaves on H103 resin. The equilibrium experimental data of adsorption of TFs in mulberry leaves on H103 resin at different temperatures fitted to Langmuir and Freundlich isotherms. The adsorption kinetics proocess for TFs in mulberry leaves on H103 resin fitted to two-step adsorption kinetics model. Through one run treatment on the column packed with H103 resin under optimal conditions, the recovery and purity of TFs in the final product were 90.57 and 76.33%, respectively. The adsorption method is more advanced than the traditional methods in the separation of TFs in mulberry leaves extracts, because of its lower cost and high efficiency. The techniques in this study can be applied for the separation of other flavonoids in other natural products.

Figure 7. Linear relationship between ln[C/(C0-C)] and t in dynamic leakage process of TFs in mulberry leaves on column packed with H103 resin under different flow rate of 6.05 mg/ml TFs solution

600 400 200 0

-3

-6

100

200

300

t/min

20

40

60

80

100

120

140

time min)

Wang et al.

2155

REFERENCES Aehle E, Raynaud-Le Grandic S, Ralainirina R, Baltora-Rosset S, Mesnard F, Prouillet C, Maziere J, Fliniaux M (2004). Development and evaluation of an enriched natural antioxidant preparation obtained from aqueous spinach (Spinacia oleracea) extracts by an adsorption procedure. Food Chem. 86(4): 579-585. Chu Q, Lin M, Tian X, Ye J (2006). Study on capillary electrophoresis-amperometric detection profiles of different parts of Morus alba L. J. Chromatogr., A 1116 (1-2): 286-290. Fu B, Liu J, Li H, Li L, Lee FSC, Wang X (2005). The application of macroporous resins in the separation of licorice flavonoids and glycyrrhizic acid. J. Chromatogr., A 1089 (1-2): 18-24. Juang R, Shiau J (1999). Adsorption isotherms of phenols from water onto macroreticular resins. J. Hazard. Mater. 70(3): 171-183. Jung M, Ahn K, Lee Y, Kim K, Rhee Paeng I, Rhee J, Tae Park J, Paeng K (2001). Evaluation on the adsorption capabilities of new chemically modified polymeric adsorbents with protoporphyrin IX. J. Chromatogr., A 917 (1-2): 87-93. Lee CY, Sim SM, Cheng HM (2007). Systemic absorption of antioxidants from mulberry (Morus alba L) leaf extracts using an in situ rat intestinal preparation. Nutr. Res. (N. Y., NY, U. S.) 27 (8): 492-497. Nagaoka H, Imae T (2003). Analytical investigation of two-step adsorption kinetics on surfaces. J. Colloid Interface Sci. 264 (2): 335-342. Nuengchamnong N, Ingkaninan K, Kaewruang W, Wongareonwanakij S, Hongthongdaeng B (2007). Quantitative determination of 1-deoxynojirimycin in mulberry leaves using liquid chromatography-tandem mass spectrometry. J. Pharm. Biomed. Anal. 44(4): 853-858.

Qi Y, Sun A, Liu R, Meng Z, Xie H (2007). Isolation and purification of flavonoid and isoflavonoid compounds from the pericarp of Sophora japonica L. by adsorption chromatography on 12% cross-linked agarose gel media. J. Chromatogr., A 1140 (1-2): 219-224. Rudzinski W, Plazinski W (2008). Kinetics of Dyes Adsorption at the Solid-Solution Interfaces: A Theoretical Description Based on the Two-Step Kinetic Model. Environ. Sci. Technol. 42(7): 2470-2475. Lagergren S (1898). About the theory of so-called adsorption of soluble substances. Vetenskapsakad Handl. 24 (4): 1-39. Scordino M, Di Mauro A, Passerini A, Maccarone E (2003). Adsorption of flavonoids on resins: Hesperidin. J. Agric. Food Chem. 51(24): 6998-7004. Wang J, Zhao H, Wu F, Yang K (2008). Separation and purification of total flavones from mulberry leaves. Ion Exchange And Adsorption. 24 (2): 139-147. Zhang L, Li C (2006). Study on separation and purification of total flavones of Hawthorn leaves by macroporous adsorption resins. Chem. Ind. For. Prod. 26(1): 87-90.

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Adavances in Positioning and FramesDocument407 pagesAdavances in Positioning and Framesoliwia.tolloczkoNo ratings yet

- NotDocument47 pagesNotAnup MauryaNo ratings yet

- Chul Park The Limits of Two-Temperature ModelDocument13 pagesChul Park The Limits of Two-Temperature ModellazharNo ratings yet

- Analysis and Design of Asynchronous Sequential CircuitsDocument30 pagesAnalysis and Design of Asynchronous Sequential CircuitsBeulah JacksonNo ratings yet

- PhysicsDocument28 pagesPhysicsamritam yadavNo ratings yet

- Lecture 24 - Strength Analysis of FuselagesDocument6 pagesLecture 24 - Strength Analysis of FuselagesgavinNo ratings yet

- Tank Design CalculationDocument20 pagesTank Design CalculationHairil HerliansyahNo ratings yet

- Sieve Analysis of Soil: By: Muhammad Firdaus, ST, MTDocument12 pagesSieve Analysis of Soil: By: Muhammad Firdaus, ST, MTdaus_parisi100% (1)

- AISI S913-13 - SDocument18 pagesAISI S913-13 - SEdison BecerraNo ratings yet

- How To Design Roof Purlins - A Solved Example - StructvilleDocument16 pagesHow To Design Roof Purlins - A Solved Example - StructvilleLavanyanNo ratings yet

- Logistic Regression EBayDocument10 pagesLogistic Regression EBayPrateek ShuklaNo ratings yet

- 06 Advanced MOSFET PDFDocument153 pages06 Advanced MOSFET PDFmayurNo ratings yet

- 02-02 Dam FormworkDocument20 pages02-02 Dam FormworkJae Min HwangNo ratings yet

- 03 Chapter 1Document45 pages03 Chapter 1hymerchmidt100% (1)

- Mathematics (T) Coursework: Title: Mathematical Investigation (Am - GM)Document1 pageMathematics (T) Coursework: Title: Mathematical Investigation (Am - GM)Elil MathhyNo ratings yet

- CNTH Skema Fizik Paper 3Document3 pagesCNTH Skema Fizik Paper 3Norfadila Mat JusofNo ratings yet

- CC Relief DoorDocument7 pagesCC Relief DoorHim SatiNo ratings yet

- Lab 2Document5 pagesLab 2Adeem Hassan KhanNo ratings yet

- Material Chap 7Document24 pagesMaterial Chap 7chemicaly12No ratings yet

- Centrifugal Pump Test RigDocument4 pagesCentrifugal Pump Test RigSameer Tamboli100% (1)

- Kim Lighting B30 Series Bollard Brochure 1985Document20 pagesKim Lighting B30 Series Bollard Brochure 1985Alan MastersNo ratings yet

- Boilere Solare Cu Serpentina Elbi Combi Quick Fisa PrezentareDocument2 pagesBoilere Solare Cu Serpentina Elbi Combi Quick Fisa PrezentaresilvercristiNo ratings yet

- Bed Plate Main Engine BedplateDocument52 pagesBed Plate Main Engine BedplateSuhas KassaNo ratings yet

- Fire Resisting Properties of Common Building MterialsDocument2 pagesFire Resisting Properties of Common Building MterialssuryakantameNo ratings yet

- Semikron Datasheet Skiip 23ac126v1 25231080Document4 pagesSemikron Datasheet Skiip 23ac126v1 25231080Antonio Carlos CardosoNo ratings yet

- Engineering Syllabus of First Year EE, ECE, PWE, AEIE, EEE, IC, Apparel 2007Document37 pagesEngineering Syllabus of First Year EE, ECE, PWE, AEIE, EEE, IC, Apparel 2007Anish LahiriNo ratings yet

- 6226 e CTM Second EditionDocument228 pages6226 e CTM Second EditionNuriaReidNo ratings yet

- 4x & 6x Night Vision Weapon Sights Operator ManualDocument15 pages4x & 6x Night Vision Weapon Sights Operator Manualakms1982No ratings yet

- Compact Heat Exchanger DesignDocument52 pagesCompact Heat Exchanger DesignoperationmanagerNo ratings yet

- Engine Control SystemDocument7 pagesEngine Control SystemFaisal Al HusainanNo ratings yet