Professional Documents

Culture Documents

Annexure-I (Sprinkler System)

Uploaded by

ashilvantOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Annexure-I (Sprinkler System)

Uploaded by

ashilvantCopyright:

Available Formats

SPRINKLER SYSTEM FOR STOCKPILES (DSS-1) TECHNICAL PROPOSAL INTRODUCTION It is proposed to provide the Sprinkler System to prevent lift

off of dust from Stockpiles. In this System, plain water is sprayed over the material by installing a number of Sprinklers around the Stockpiles in a ring manner to cover the entire projected area of the Stockpile. The Sprinkler break-up the water into small droplets simulating natural rainfall. The water sprayed on the Stockpile will wet the material and prevent lift off of dust due to wind etc.

1.0

DESIGN CONSIDERATION The design of the Dust suppression is mainly depend upon the stockpile dimension. Here three Nos. of stockpile which are of different dimension. These are as follows:-

Dimension of Stockpile 1 & 3 Dimension of Stockpile 2 Total Number of Stockpiles Operating Conditions

- 415 M X 52 M (L X W) - 415 M X 78 M (L X W) 03Nos. Two sprinkler shall operate at a time in Each of the stockpiles 1 & 3, while sprinkler of stockpile 2 are closed. Alternatively 2 Nos sprinkler of Stockpile No 2 will operate and sprinkler of stockpile 1 & 3 are closed.

Pump House Location

Near Transfer Tower TT-10.

EQUIPMENT DETAILS: 2.0 WATER PUMPING STATION Water Storage Tank Duplex Stariner Water Pumps

2.1

Water Storage Tank (BY client ) In order to store water for the Sprinkler System for the Stockpile Area and Aquadyne without chemical Dust Suppression System for various transfer Point a Water Storage Tank of capacity of 220 Cu.M(one hour of maximum pumping capacity) in reinforcement cement concrete shall be constructed by the client. The water tank shall be complete with accessories such as inlet pipe, valve, float valve, over flow pipe, drawing valve, etc . our organization shall provide a high and low level switch with indication for the fitment in the Tank.

The Tank Shall be common for Both the System. 2.2 Duplex Strainer A Duplex Strainer shall be provided at the inlet of water pump. The Duplex Strainer shall consist of Two Strainer in parallel with diverter valves,one strainer to be used at a time.The strainer shall have a MS body with ss strainer A differential pressure switch is installed to provide a Audio-visual signal when the pressure drop across the filter Exceeds the pre-set value to allow the operator to divert the flow to the second strainer. 2.3 Water Pumps 2 Nos. Water Pumps {one operating + one standby} rated as 180 Cu.M/hr at 110 mtrs. head fitted with 180 HP - 4 Pole Motor shall be provided to supply water to the Sprinklers system in stockpiles. The Pump capacity has been selected on the consideration that a Maximum 02 opposite Sprinklers in each of the stockpile 1 & 3 will be operating at a time. While the sprinkler system of stockpile No-2 will remain closed. Alternatively two opposite sprinkler in Stockpile 2 will operate while the sprinkler of stockpile 1 & 3 will remain closed. The operation of these Water Pumps shall be interlocked with the Low Level Switch in the Water Storage Tank to ensure that the Pumps do not operate when the water level of the tank is below the minimum level. A re-circulation / by-pass line shall be provided to cater for any variation in the requirement of water in the Sprinklers System and to avoid built-up of pressure in the line. 3.0 3.1 SPRAY SYSTEM Sprinklers (For stockpile 1 & 3) The Sprinklers are single / twin Jet Hydrodynamic type with Oscillating Arm, covering a segment of the circle. The Sprinkler shall have a discharge capacity of 26~27 Cu.M./Hr. at 5.0 Bar pressure with a throw of 37 Mtrs .Sprinkler shall be installed on both sides of the stock pile at a distance of approximately 40 M i.e. 11 sprinklers on each sides of stock pile total 44sprinklers for two stockpile 1 & 3. 3.2 Sprinklers (For stockpile 2) The Sprinklers are single / twin Jet Hydrodynamic type with Oscillating Arm, covering a segment of the circle. The Sprinkler shall have a discharge capacity of 77~80 Cu.M./Hr. at 5.0 Bar pressure with a throw of 56 Mtrs .Sprinkler shall be installed on both sides of the stock pile at a distance of approximately 40 M i.e. 11 sprinklers on each sides of stock pile total 22sprinklers for stockpile 2. 3.2 Flow Activation Stations ( Solenoid Box ) Each Sprinkler is provided with a Flow Activation Station(FAS) for ON / OFF control of the Sprinkling Operation. The Flow Activation Station consists of a

Globe Valve and a Solenoid Valve housed in an enclosure. The height of the sprinkler shall be 2.5 M~ 3.0 M above the ground. The sprinkler post shall be supported on both sides. 4.0 PIPELINE SYSTEM The Water Pipeline System shall consist of MS / GI Medium Grade pipes with fittings & valves from the water pumps in the pump house to the various sprinklers. Pipe of 50 NB and below shall be in GI with threaded joints and pipes of 50 NB and above shall be in MS. All valves up to 50 NB shall be with Gun body with threaded joints, whereas for pipes 65 NB and above , the valve shall be Cast Iron Body with Flanged. All the pipe line from the pump house to the stockpile area shall be below ground and will be provided with wrapping coating as per IS 10221. 5.0 TAKE-OFF POINTS We shall provide take-off points at 50 Meters centre for the filling of make-up water tanks of dust suppression system on each stacker / re-claimer. The takeoff points shall be providing on the pipe along the length of the stockpile No. 2 only. The Take-off point shall consist of 25mm quick coupling(female part) and a ball valves. The Total number of Take-off points shall be 16 Nos. i.e. 8 on each line.

6.0

Water Requirement The water requirement for sprinkler system depend upon a large number of factors such as type and size of material, ambient condition such as temperature, humidity and wind condition which can widely vary during day and season to season. However for the purpose of estimate it is presumed that the total projected area of the stockpile shall be sprinkled with water equivalent to 5~8 mm of rainfall three times a days, based on above assumption the total water requirement shall be each sprinkler cycle or 1800CuM/day

7.0 7.1

ELECTRICAL WORKS Starter Panel One No. Starter Panel is provided to feed power to the LT Motors of water pumps, sequential controller and FAS. The Starter Panel shall be located in the Pump House. The Starter shall be designed with incoming MCCB and the necessary number of switch fuse unit for outgoing feeders of the various loads. Control circuits of Starter will be 110 V, 1-phase, 50 Hz. Provision will be made for one Control Transformer of 415 /110V.

7.2

Local Push Button Stations for Water Pumps Local Push Button Stations shall be provided for the Two Nos. Water Pump Motors.

7.3

Controller 3 Nos. Controller ( one for each stock pile ) is provided for sequential operation of the sprinkler. The Controller are Microprocessor based capable of fully automatic or manual operation. The Controller shall be housed in a weather resistant cabinet suitable for either indoor or outdoor installation. The Controller shall be capable of operating two Solenoid Valves per Station in a sequential manner. The operation of Controller is through Electronic Timer with facility for programming of timing between the Sprinklers.

7.4

Power and Control Cables The Power and Control Cable shall include: -

(i)

Power & Control Cabling from the Starter to the Electric Motors of the Water Pumps, Controller and Low Level Switch of the Water Storage Tank in the Pump House. Power & Control Cabling from the Controllers in the Pump House to the various flow activation system.

(ii)

8.0

EXCLUSIONS / CLIENTS SCOPE The following works are excluded from our Scope of work: -

8.1

Civil & Structural Works The Work shall include construction pump House, Pump foundations, cable trenches, water storage tank with accessories, retaining/toe wall pedestal supports for installation of sprinkler posts, pedestals for laying of pipes over ground and underground works for installation of the pipeline system etc.

8.2

Water Supply Continuous supply of filtered water at the inlet of the RCC Storage Tank.

8.3

Electrical Works 415 V AC, 3 phase power connection at the Incomer of TPS Starter Panel in pump Houses . The List of Equipment included in the Proposal is attached as Annexure-IB

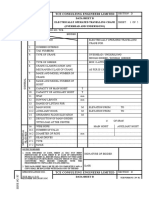

SPRINKLER SYSTEM FOR STOCKPILE (DSS-1) EQUIPMENT LIST SL. 1.0 1.1 1.2 1.3 DESCRIPTION Water Pumping Station to include: Low and high for Water Tank Duplex Stariner Water Pumps of capacity 180 cu.m/hr. at 110 mtrs. Head fitted 180 HP 4 pole Electric Motor Spray System to include: Sprinklers a)Discharge Capacity 26~27 CuM/Hr for Stockpile 1 &3 b) Discharge Capacity 77~80 CuM/Hr for Stockpile 2 Flow Activation Station (Solenoid boxes) a) For Discharge of 26~27 CuM/Hr Stockpile 1 &3 b) For Discharge of 77~80 CuM/Hr Stockpile 2 Water Pipeline System Take-off Point 25 NB ball valve with Coupling Electrical to include: Starter Panel for Water Pumps with arrangement for power distribution and starters for water pumps etc. Local Push Button Station for Water Pump Controller Power & Control Cabling from the Starter to the Electric Motors of the Water Pumps, Controllers and Low Level Switch of the Water Storage Tank in the Pump House Power & Control Cabling from the Controllers in the Pump House to the various flow activation system. 01 No. 02 Nos. 03 Nos. Lot 44 Nos. 22 Nos. 01 Set 01 No 02 Nos. (1 working + 1 stand by ) QTY.

2.0 2.1

2.2

44 Nos. 22 Nos. Lot

3.0 4.0 5.0 5.1 5.2 5.3 5.4

16 Nos.

5.5

Lot

You might also like

- SBCA Sprinkler Loads On TrussesDocument7 pagesSBCA Sprinkler Loads On TrussesDale HansenNo ratings yet

- Nfpa Codes PDFDocument12 pagesNfpa Codes PDFphe zenNo ratings yet

- 3 - Brother Odd - Dean KoontzDocument213 pages3 - Brother Odd - Dean KoontzJustinSnow50% (2)

- Intro To Auto Sprinkler 2020Document69 pagesIntro To Auto Sprinkler 2020MuhammedNo ratings yet

- Agente Limpio PDFDocument112 pagesAgente Limpio PDFREYINA OTZNo ratings yet

- Fire Sprinkler HangarDocument88 pagesFire Sprinkler HangarAce Glen GarciaNo ratings yet

- CPVC Fire Sprinkler Products: Installation Instructions & Technical HandbookDocument106 pagesCPVC Fire Sprinkler Products: Installation Instructions & Technical HandbookMark FessendenNo ratings yet

- Inspect & Test Fire Sprinkler Flow & Tamper Switches Every 6 MonthsDocument8 pagesInspect & Test Fire Sprinkler Flow & Tamper Switches Every 6 Monthsm.sofiqur rahmanNo ratings yet

- Method Statement For Drainage Pipe SystemDocument15 pagesMethod Statement For Drainage Pipe SystemaNo ratings yet

- Fire Sprinkler System NFPA 13 Plan Review Checklist PDFDocument10 pagesFire Sprinkler System NFPA 13 Plan Review Checklist PDFAshik HasanNo ratings yet

- NTC Nicet ReviewerDocument132 pagesNTC Nicet ReviewerJerick JavelosaNo ratings yet

- Introduction To Wet Chemical Fire Suppression SystemsDocument47 pagesIntroduction To Wet Chemical Fire Suppression SystemsCarlos AllueNo ratings yet

- Fire Protection 101Document126 pagesFire Protection 101Isabel CarolinaNo ratings yet

- Managing Stress Piping SystemsDocument4 pagesManaging Stress Piping SystemsisyentNo ratings yet

- FMDS0834Document119 pagesFMDS0834Oliver SanchezNo ratings yet

- Plumbing CalculationDocument2 pagesPlumbing Calculationsenghy75% (8)

- Ubc 1979Document734 pagesUbc 1979Nguyen DuyNo ratings yet

- Vertical Turbine Fire PumpsDocument6 pagesVertical Turbine Fire PumpsSérgio Gnipper100% (1)

- Flexible ConnectionsDocument118 pagesFlexible ConnectionsMuzaffarNo ratings yet

- Eil Spec Bo16-000-80-44-Ol-S001 Rev ADocument2 pagesEil Spec Bo16-000-80-44-Ol-S001 Rev AjaganNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Deluge Sprinkler SystemsDocument3 pagesDeluge Sprinkler Systemsfalconcrest320% (1)

- Fire Water Demand Calculation DocumentDocument16 pagesFire Water Demand Calculation DocumentHSEI Jatim - NSU 2020100% (2)

- Fire Service Underground Standards 2017 PDFDocument4 pagesFire Service Underground Standards 2017 PDFMathiyalakan RengasamyNo ratings yet

- Reactor piping design guideDocument19 pagesReactor piping design guidesyedahmad39No ratings yet

- NFPA 11 Tank Fire Protection ChartDocument1 pageNFPA 11 Tank Fire Protection ChartTjay NóniiNo ratings yet

- Bataraja Training-Water SystemDocument28 pagesBataraja Training-Water SystemYooankuNo ratings yet

- Maximum Distance Between HangersDocument2 pagesMaximum Distance Between HangersAhmed Ali100% (1)

- 3844 - Installation of Internal Hydrants & Hose ReelDocument22 pages3844 - Installation of Internal Hydrants & Hose ReelSiyaram PatidarNo ratings yet

- Fire Sprinkler Systems InstallationDocument6 pagesFire Sprinkler Systems InstallationSachin DarneNo ratings yet

- Easyheat s27 - 02 SarcoDocument8 pagesEasyheat s27 - 02 SarcoMarcelo ResckNo ratings yet

- FSX-A Deluge Valve (Jan 2021)Document12 pagesFSX-A Deluge Valve (Jan 2021)Mohammed ElmakNo ratings yet

- Corken Underground Tank Installation GuideDocument8 pagesCorken Underground Tank Installation GuideDayo Idowu100% (1)

- Outside Screw and Yoke (OS&Y) Gate Valve - Flanged: Technical FeaturesDocument42 pagesOutside Screw and Yoke (OS&Y) Gate Valve - Flanged: Technical FeaturesayaNo ratings yet

- Fire Pump InstallationDocument4 pagesFire Pump InstallationFrancis Owusu100% (1)

- NFPA 13 2016 Edition (Old File)Document4 pagesNFPA 13 2016 Edition (Old File)raigoukiNo ratings yet

- As 2118.8-1997 Automatic Fire Sprinkler Systems Minor ModificationsDocument7 pagesAs 2118.8-1997 Automatic Fire Sprinkler Systems Minor ModificationsSAI Global - APAC50% (2)

- Technical Data: 1. DescriptionDocument6 pagesTechnical Data: 1. DescriptiondimchienNo ratings yet

- Is 15105-2002Document60 pagesIs 15105-2002Siddharth GupteNo ratings yet

- Part 1 - General: SECTION 21 13 13 Wet-Pipe Sprinkler SystemsDocument16 pagesPart 1 - General: SECTION 21 13 13 Wet-Pipe Sprinkler SystemsNelson VargasNo ratings yet

- OH-900 Oxygen Hydrogen AnalyserDocument6 pagesOH-900 Oxygen Hydrogen AnalyserPham DuyetNo ratings yet

- HVWS SystemDocument1 pageHVWS Systemabhinay02meNo ratings yet

- How To Calculate Surge Forces On Piping Systems - Intergraph CADWorx & AnalysisDocument4 pagesHow To Calculate Surge Forces On Piping Systems - Intergraph CADWorx & Analysissammar_10No ratings yet

- Chemtrol PVC CPVCDocument60 pagesChemtrol PVC CPVCWakko20IPNNo ratings yet

- Booster Pump-TechPart - 2of2 BDocument71 pagesBooster Pump-TechPart - 2of2 BKatie RamirezNo ratings yet

- Forbes Marshall Consultancy specifications for compressed air accessoriesDocument2 pagesForbes Marshall Consultancy specifications for compressed air accessoriessppatilNo ratings yet

- GW SprinklersDocument18 pagesGW SprinklersmajdirossrossNo ratings yet

- TrueUnion - True Union Ball ValveDocument4 pagesTrueUnion - True Union Ball ValveKarthick VenkateshNo ratings yet

- Disclosure To Promote The Right To InformationDocument45 pagesDisclosure To Promote The Right To Informationrajeshtak05No ratings yet

- Compressor Inlet Piping - Compressed Air Best PracticesDocument10 pagesCompressor Inlet Piping - Compressed Air Best PracticesBehroozRaadNo ratings yet

- Green PPR Pipe FittingDocument12 pagesGreen PPR Pipe FittinggeorgeNo ratings yet

- 6206 Guide For Selection Installation andDocument32 pages6206 Guide For Selection Installation andakbavra80% (5)

- Standard Sprinkler InstallationDocument161 pagesStandard Sprinkler Installationzul ireanaNo ratings yet

- Document 53192 3/2/2011 Rev:: P/N 53192:D1 ECN 11-159Document172 pagesDocument 53192 3/2/2011 Rev:: P/N 53192:D1 ECN 11-159Aob AprilNo ratings yet

- PH008 - Grease Interceptor Sizing REVISEDDocument8 pagesPH008 - Grease Interceptor Sizing REVISEDcoolth2No ratings yet

- Steam Separator and Steam Trap Are Almost Same in FunctionDocument7 pagesSteam Separator and Steam Trap Are Almost Same in FunctionTHEOPHILUS ATO FLETCHERNo ratings yet

- Viking Tabela PreçosDocument377 pagesViking Tabela PreçosleonelNo ratings yet

- What Is A Deluge Fire System PDFDocument1 pageWhat Is A Deluge Fire System PDFmister_no34No ratings yet

- Water Meter Installation GuidelinesDocument10 pagesWater Meter Installation GuidelinesVinish HARIDAS NAIRNo ratings yet

- Ethio Telecom HQ Building Fire Suppression ValvesDocument6 pagesEthio Telecom HQ Building Fire Suppression ValvesdiribaNo ratings yet

- Standard Parts of Pipe SupportsDocument5 pagesStandard Parts of Pipe SupportsMohit BauskarNo ratings yet

- Jacketed Piping DesignDocument6 pagesJacketed Piping DesignManuel Vivian SouzaNo ratings yet

- ASME/ANSI B16.1 - 1998 - Cast Iron Pipe Flanges and Flanged FittingsDocument17 pagesASME/ANSI B16.1 - 1998 - Cast Iron Pipe Flanges and Flanged FittingsVinit DhandeNo ratings yet

- Asme B31.8Document8 pagesAsme B31.8deepndeepsi100% (1)

- Pipeline Stress Analysis with Caesar IIDocument16 pagesPipeline Stress Analysis with Caesar IISharbel WgNo ratings yet

- MIFAB Control Flo Roof DrainsDocument5 pagesMIFAB Control Flo Roof DrainsjavedwestNo ratings yet

- Eot Crane Datasheet-BDocument5 pagesEot Crane Datasheet-Bbashok20No ratings yet

- Pipe Expansion and Support - International Site For Spirax SarcoDocument8 pagesPipe Expansion and Support - International Site For Spirax SarcoSandi ApriandiNo ratings yet

- Jci 2017072Document15 pagesJci 2017072Toretta AdrianNo ratings yet

- POWER PLANT RAW WATER SYSTEMDocument21 pagesPOWER PLANT RAW WATER SYSTEMAniesh MahajanNo ratings yet

- Storm Water DesignDocument2 pagesStorm Water DesignashilvantNo ratings yet

- Storm Water DesignDocument1 pageStorm Water DesignashilvantNo ratings yet

- Storm Water DesignDocument2 pagesStorm Water DesignashilvantNo ratings yet

- Is 4984 PVC PipesDocument21 pagesIs 4984 PVC PipesKathiravan ManimegalaiNo ratings yet

- 428.00 Meters: A) Bihari Pump StationDocument1 page428.00 Meters: A) Bihari Pump StationashilvantNo ratings yet

- Strainer DesignDocument1 pageStrainer DesignashilvantNo ratings yet

- Thrust Ventilation System Description: Novenco Car ParkDocument16 pagesThrust Ventilation System Description: Novenco Car ParkOtelea StefanNo ratings yet

- Technical Data: 1. DescriptionDocument6 pagesTechnical Data: 1. Descriptionh2odavidNo ratings yet

- Exhaust+Duct+Design R5Document16 pagesExhaust+Duct+Design R5syammcNo ratings yet

- MX Zonecheck PDFDocument2 pagesMX Zonecheck PDFNarendra Reddy BhumaNo ratings yet

- As 4118.1.7-1996 Fire Sprinkler Systems Components - Alarm Valves (Dry)Document7 pagesAs 4118.1.7-1996 Fire Sprinkler Systems Components - Alarm Valves (Dry)SAI Global - APACNo ratings yet

- Small BuildingDocument5 pagesSmall BuildingasddasswxlNo ratings yet

- Coverage Area Sprinkler Head NFPA 13, 2013 EditionDocument4 pagesCoverage Area Sprinkler Head NFPA 13, 2013 EditionSopheareak ChhanNo ratings yet

- Fire Protection Systems: Continuing Education From Plumbing Systems & DesignDocument25 pagesFire Protection Systems: Continuing Education From Plumbing Systems & DesignKyi TharNo ratings yet

- Thana DCRDocument383 pagesThana DCRAtul Kulkarni50% (2)

- Giacomini PDFDocument52 pagesGiacomini PDFLavzNo ratings yet

- Singapore Building Code 2013 Chapter 3 CompartmentalisationDocument284 pagesSingapore Building Code 2013 Chapter 3 CompartmentalisationyokeleetanNo ratings yet

- Water Mist Fire Protection Systems - System Design, Installation and Commissioning - Code of PracticeDocument36 pagesWater Mist Fire Protection Systems - System Design, Installation and Commissioning - Code of PracticeInyamul HasanNo ratings yet

- Tyco TY3531 TFP181 - 08 - 2022Document5 pagesTyco TY3531 TFP181 - 08 - 2022First LAstNo ratings yet

- NestleDocument25 pagesNestlehzqazmn100% (2)

- Firedos: Proportioners For Stationary Extinguishing SystemsDocument12 pagesFiredos: Proportioners For Stationary Extinguishing SystemsJhon FrediNo ratings yet

- Traning Report 3309Document65 pagesTraning Report 3309ayeshmanthabroNo ratings yet

- 191210-01 CommentsDocument7 pages191210-01 CommentsMoriyasu NguyenNo ratings yet

- WSN 102 (2018) 17-29 PDFDocument13 pagesWSN 102 (2018) 17-29 PDFBuddy EkoNo ratings yet

- Stand Alone Food Court UpgradesDocument5 pagesStand Alone Food Court UpgradesLester Bug-osNo ratings yet

- FMDS0750-Compressed Gas CylynderDocument11 pagesFMDS0750-Compressed Gas CylynderAnanto WardonoNo ratings yet

- Courseware in Iws: Industry Workplace and Safety PracticesDocument36 pagesCourseware in Iws: Industry Workplace and Safety PracticesKarenSantiago-Villanueva100% (1)