Professional Documents

Culture Documents

Fixed Cutter - IADC Dull Grading

Uploaded by

César González CruzOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fixed Cutter - IADC Dull Grading

Uploaded by

César González CruzCopyright:

Available Formats

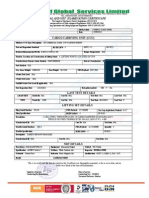

DriLL Bits

Fixed Cutter

IADC Dull Grading

Cutting Structure

Inner Rows

1

Outer Rows

2

Dull Char.

3

Location

4

Bearings/Seals X

Gauge

6

Other Dull Char.

7

Reason Pulled

8

Inner Area 2/3 Radius

Outer Area 1/3 Radius

1 2

Inner Cutting Structure Outer Cutting Structure

Location X All Areas Cone Gauge Nose Shoulder Taper

HAL9086

A measure of lost, worn and/or broken cutting structure. Linear Scale: 0-8 0 8

3

- No lost, worn and/or broken cutting structure - All of cutting structure lost, worn and/or broken Dull Characteristics Bond Failure Broken Cutters Balled Up Cored Chipped Cutters Delaminated Cutters Erosion Heat Checking Junk Damage Lost Matrix Lost Nozzle Lost Cutters No Dull Characteristics Not Rerunnable Plugged Nozzle/Flow Passage Ring Out Rerunnable Washed Out Worn Cutters

A C G N S T

5

Gauge Shoulder

HAL9085

Taper Nose

Cone

No Wear

Worn Cutter

Halliburton's fixed cutter bits are tip ground to exacting tolerances at gauge O.D. per API spec 7. Depending on the specific design and application as much as .080 of an inch of the cutter diameter may be ground flat. This can be mistaken for gauge wear if unfamiliar with our products. Please ensure that dull bits are in gauge with a calibrated PDC No Go ring gauge.

HAL9045

Lost Cutter

Delaminated

BF BT BU CR CT DL ER HC JD LM LN LT NO NR PN RO RR WO WT

6 Gauge (Measure in fractions of an inch) I - In Gauge 1 - 1/16" Out of Gauge 2 - 1/8" Out of Gauge 4 - 1/4" Out of Gauge 7

Other Dull Characteristics

(Refer to column 3 codes)

8

Reason Pulled or Run Terminated Change Bottomhole Assembly Condition Mud Core Point Downhole Motor Failure Drill Plug Drill String Failure Drill Stem Test Downhole Tool Failure Formation Change Hole Problems Hours on Bit Left in Hole Run Logs Pump Pressure Penetration Rate Rig Repair Total Depth/Casing Depth Torque Twist Off Weather Conditions Washout - Drill String

BHA CM CP DMF DP DSF DST DTF FM HP HR LIH LOG PP PR RIG TD TQ TW WC WO

HAL9045

DriLL Bits

FIXED CUTTER BITS - RING GAUGING

Any fixed cutter bit should be ring gauged prior to running in the hole. Stabilizers should also be calipered or gauged to verify they meet API-approved outside dimension tolerances as shown in the following table. Fixed cutter bits should not be larger than the nominal diameter. API Fixed Cutter Bit Tolerances

BIT SIZE (IN.) 6-3/4 and Smaller 6-25/32 to 9 9-1/32 to 13-3/4 13-25/32 to 17-1/2 17-17/32 and Larger FIXED CUTTER BIT O.D. TOLERANCE (IN.) -0.015 to +0.00 -0.020 to +0.00 -0.030 to +0.00 -0.045 to +0.00 -0.063 to +0.00

A no go gauge is used to ensure a bit is not smaller than allowed and, as the name implies, it should not go or slip down the entire length of the bit. A go gauge ensures a bit is not larger than allowed and should slip down the entire bit.

2009 Halliburton. All rights reserved. Sales of Halliburton products and services will be in accord solely with the terms and conditions contained in the contract between Halliburton and the customer that is applicable to the sale. H03086 9/09 www.halliburton.com

You might also like

- 17.5 XT1GRC 536283Document1 page17.5 XT1GRC 536283diegoilNo ratings yet

- Smith BitDocument4 pagesSmith BitRio RizkiNo ratings yet

- PDC - Terminology and MechanicsDocument17 pagesPDC - Terminology and MechanicsKaleem UllahNo ratings yet

- RC Product and Tech Tranining 2006Document226 pagesRC Product and Tech Tranining 2006amin peyvandNo ratings yet

- Catalogo de Punzones Dayton ProgreDocument28 pagesCatalogo de Punzones Dayton ProgreOdiseo Kratos SacuraguiNo ratings yet

- LG Wd1873rds Manual de UsuarioDocument76 pagesLG Wd1873rds Manual de UsuarioJosè Otoniel Osorio BarreraNo ratings yet

- Punjab Bye Laws For Commercial BuildingsDocument11 pagesPunjab Bye Laws For Commercial BuildingsAshween ManchandaNo ratings yet

- C32 Electronic Unit Injector - Adjust PDFDocument4 pagesC32 Electronic Unit Injector - Adjust PDFmanu luvunga100% (2)

- Iadc Bit GradingDocument1 pageIadc Bit GradinganarkasisNo ratings yet

- Steel Drill Collars: Quality Control and Ultrasonic Inspection Precision BoringDocument19 pagesSteel Drill Collars: Quality Control and Ultrasonic Inspection Precision BoringAshba13No ratings yet

- Bit GradingDocument17 pagesBit GradingnugratamaNo ratings yet

- PDC CatalogDocument32 pagesPDC Catalogruzzo2003No ratings yet

- International Limited: Rotary Shouldered Connection Inspection ReportDocument1 pageInternational Limited: Rotary Shouldered Connection Inspection ReportMichael OkwuwaNo ratings yet

- Oil Field: Main CatalogueDocument176 pagesOil Field: Main CatalogueM. Aguiar100% (1)

- Drilling Tools & Subs Inspection Report: Visual Body, Visual Connections, Blacklight Connections, Dimensional 3Document18 pagesDrilling Tools & Subs Inspection Report: Visual Body, Visual Connections, Blacklight Connections, Dimensional 3Michael OkwuwaNo ratings yet

- Visual Body, Visual Connections, Black Light Connections: International LimitedDocument6 pagesVisual Body, Visual Connections, Black Light Connections: International LimitedMichael OkwuwaNo ratings yet

- Brocas Varel PDFDocument24 pagesBrocas Varel PDFJunnior MoronNo ratings yet

- Mdi 813Document1 pageMdi 813pendexxNo ratings yet

- Drill BitDocument31 pagesDrill BitAboZaidNo ratings yet

- 2006-2007 Varel FixedCutterBitsCatalogDocument24 pages2006-2007 Varel FixedCutterBitsCatalogAndrzej KonopkaNo ratings yet

- Cutting Efficiency With PDC BitDocument6 pagesCutting Efficiency With PDC BitDanny RevillaNo ratings yet

- Dull GradingDocument2 pagesDull GradingRodrigo Black SegurondoNo ratings yet

- 6-1/2" Fxg74Di: Product SpecificationsDocument1 page6-1/2" Fxg74Di: Product SpecificationsdiegoilNo ratings yet

- Drill Bit Classifier 2007Document17 pagesDrill Bit Classifier 2007amin peyvandNo ratings yet

- Var-3704 - Performanceupdates-Me - Brochure-V1.0sm - ROP DATA PDFDocument12 pagesVar-3704 - Performanceupdates-Me - Brochure-V1.0sm - ROP DATA PDFamir_hayfaNo ratings yet

- Analisis Penggunaan Bit For ChevronDocument15 pagesAnalisis Penggunaan Bit For Chevronfaishal hafizhNo ratings yet

- 1475in Bit EMS11Document1 page1475in Bit EMS11eng20072007No ratings yet

- Reference Photo: 6 In. (152.4mm) HCD406ZDocument1 pageReference Photo: 6 In. (152.4mm) HCD406ZahmedNo ratings yet

- Visual Body, Visual Connections, Black Light Connections, Dimensional 3Document40 pagesVisual Body, Visual Connections, Black Light Connections, Dimensional 3Michael OkwuwaNo ratings yet

- Drill Pipe Inspection Tally Sheet: International LimitedDocument1 pageDrill Pipe Inspection Tally Sheet: International LimitedMichael OkwuwaNo ratings yet

- Data Sheet 15379Document1 pageData Sheet 15379Nur Rahim BimaNo ratings yet

- Catalogue: Products For Oil&gas IndustryDocument39 pagesCatalogue: Products For Oil&gas Industryfarid said errahmaniNo ratings yet

- International Limited: Drill Collar Inspection ReportDocument3 pagesInternational Limited: Drill Collar Inspection ReportMichael OkwuwaNo ratings yet

- Drill Bit Classifier 2006Document17 pagesDrill Bit Classifier 2006amin peyvandNo ratings yet

- 02IDPT Drill Bits #2Document48 pages02IDPT Drill Bits #2AboZaidNo ratings yet

- Fox Public Fox-Tp-M-101 Field InspectionDocument5 pagesFox Public Fox-Tp-M-101 Field InspectionJoseph MidouNo ratings yet

- CementingTools NS 1 A4 WatermarkedDocument7 pagesCementingTools NS 1 A4 Watermarkedislam atifNo ratings yet

- Deep Groove Ball Bearings: DimensionsDocument4 pagesDeep Groove Ball Bearings: Dimensionspradipbhosale81No ratings yet

- Bha & Drill ColarsDocument6 pagesBha & Drill Colarswasim78622No ratings yet

- DS-1 Volume 4 Addendum PDFDocument15 pagesDS-1 Volume 4 Addendum PDFMuhammad Bilal KhattakNo ratings yet

- Каталог инструмента 2017 eng PDFDocument128 pagesКаталог инструмента 2017 eng PDFmoreta18100% (1)

- 060 MSi611 - Er25036Document1 page060 MSi611 - Er25036ANo ratings yet

- 094 XS616Document1 page094 XS616AhmedNo ratings yet

- 10018611-Der 3CDocument1 page10018611-Der 3CNur Rahim BimaNo ratings yet

- 084 AT507X - Stylesheet PDFDocument1 page084 AT507X - Stylesheet PDFLeonardo BarriosNo ratings yet

- 174 V816pdg1xa2 Spec SheetDocument1 page174 V816pdg1xa2 Spec SheetMichaelNo ratings yet

- Reference Photo:: 6 In. (152.4mm) ATJ-4Document1 pageReference Photo:: 6 In. (152.4mm) ATJ-411tkt11No ratings yet

- Visual and NDT Examination Certificate: Cargo Carrying Unit (Ccu)Document1 pageVisual and NDT Examination Certificate: Cargo Carrying Unit (Ccu)Michael OkwuwaNo ratings yet

- Hole Openers NS 1 A4 WatermarkedDocument13 pagesHole Openers NS 1 A4 Watermarkedislam atifNo ratings yet

- Rotary Stem Threads GaugesDocument2 pagesRotary Stem Threads GaugesMarutpal MukherjeeNo ratings yet

- 5 5 DP-HT55-repDocument1 page5 5 DP-HT55-repChristopher Jones100% (1)

- Triton PDC BrochureDocument2 pagesTriton PDC BrochurediegoilNo ratings yet

- 1588-1326 Hyd Jar ...Document1 page1588-1326 Hyd Jar ...khalilNo ratings yet

- 12.25 MM75D 767489Document1 page12.25 MM75D 767489pendexxNo ratings yet

- 3-5 PDC Product OverviewDocument13 pages3-5 PDC Product OverviewMahmoud NassarNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name Daterohitbhat2345No ratings yet

- 011 StabilizersDocument2 pages011 StabilizersGonzalo Guzman Jaimes100% (1)

- Desgaste de BrocasDocument2 pagesDesgaste de Brocasjuliantobop181No ratings yet

- Iadc Bits PDFDocument3 pagesIadc Bits PDFconssu0820No ratings yet

- BitsstuffDocument13 pagesBitsstuffscrbdgharaviNo ratings yet

- DrillingDocument9 pagesDrillingHakan ÖzkaraNo ratings yet

- Iadc Bit GradingDocument1 pageIadc Bit GradingBilly WilsonNo ratings yet

- Dull Grading Fixed Cutter BitDocument14 pagesDull Grading Fixed Cutter BitChinyere NkereNo ratings yet

- Tutorial Questions and Answers - 2011Document10 pagesTutorial Questions and Answers - 2011Jan ScarNo ratings yet

- Lecture 1 - Intro and SolidWorks PCBDocument17 pagesLecture 1 - Intro and SolidWorks PCBmyturtle gameNo ratings yet

- Advanced Techniques in Power System Protective Relaying PDFDocument332 pagesAdvanced Techniques in Power System Protective Relaying PDFshashikant yadavNo ratings yet

- EC8093 - Digital Image Processing (Ripped From Amazon Kindle Ebooks by Sai Seena) PDFDocument102 pagesEC8093 - Digital Image Processing (Ripped From Amazon Kindle Ebooks by Sai Seena) PDFSivaramakrishnan Kanagaraj0% (1)

- Debug 1214Document2 pagesDebug 1214Faizah Ayulia NawitaNo ratings yet

- Computer Organization: - by Rama Krishna Thelagathoti (M.Tech CSE From IIT Madras)Document118 pagesComputer Organization: - by Rama Krishna Thelagathoti (M.Tech CSE From IIT Madras)iamy2ramsNo ratings yet

- Education Abbreviation by AffairsCloudDocument6 pagesEducation Abbreviation by AffairsCloudgsaijanardhanNo ratings yet

- SIMODUAL2 Industrial Double Containment Piping System - Dual Pipes For Double The ProtectionDocument32 pagesSIMODUAL2 Industrial Double Containment Piping System - Dual Pipes For Double The Protectionrade.paripovicNo ratings yet

- Thermophysical Properties of Containerless Liquid Iron Up To 2500 KDocument10 pagesThermophysical Properties of Containerless Liquid Iron Up To 2500 KJose Velasquez TeranNo ratings yet

- Aerospace MaterialsDocument68 pagesAerospace MaterialsAykut Üçtepe100% (1)

- Handling Tickets Is Called Issue Tracking System.: Sap SDDocument6 pagesHandling Tickets Is Called Issue Tracking System.: Sap SDNaveen KumarNo ratings yet

- No35-Inclined Roof SystemDocument24 pagesNo35-Inclined Roof SystemKitanovic NenadNo ratings yet

- One Pipe Steam DesignDocument44 pagesOne Pipe Steam Designreyes hernandezNo ratings yet

- CPU SchedulingDocument30 pagesCPU SchedulingHarsha OjhaNo ratings yet

- 02 - Student Lesson 2 Pile Driving SystemDocument91 pages02 - Student Lesson 2 Pile Driving SystemdannyzuanNo ratings yet

- 4-3 Deflection Due To Bending: 164 Mechanical Engineering DesignDocument10 pages4-3 Deflection Due To Bending: 164 Mechanical Engineering DesignSamawat AhsanNo ratings yet

- WinDNC - V05 - 02 English PDFDocument2 pagesWinDNC - V05 - 02 English PDFAnonymous XXKCjKnc0No ratings yet

- Amplitude Shift KeyingDocument3 pagesAmplitude Shift KeyingPurnendh ParuchuriNo ratings yet

- Introduccion To PhysicsDocument475 pagesIntroduccion To PhysicsLyvsNo ratings yet

- Stelzer Catalog PDFDocument12 pagesStelzer Catalog PDFlhphong021191No ratings yet

- Pavement Evaluation and Overlay Des - DR MSA - LatestDocument103 pagesPavement Evaluation and Overlay Des - DR MSA - LatestSreedhar BhuduruNo ratings yet

- Facts SeriesandshuntcompensationDocument56 pagesFacts SeriesandshuntcompensationIfranul HaqueNo ratings yet

- 101.S-4501 Steamer Cyclone Cleaning ProcedureDocument6 pages101.S-4501 Steamer Cyclone Cleaning ProcedureTRONGKIMNo ratings yet

- Astm A769 PDFDocument5 pagesAstm A769 PDFCristian OtivoNo ratings yet

- 02 MF Anchors PDFDocument13 pages02 MF Anchors PDFThaksenNo ratings yet

- Production ManagementDocument81 pagesProduction ManagementrrathoreNo ratings yet

- Fracture in Concrete and Reinforced ConcreteDocument23 pagesFracture in Concrete and Reinforced ConcreteNilay GandhiNo ratings yet