Professional Documents

Culture Documents

Rigging JSA Safety

Uploaded by

aQiLGunawanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rigging JSA Safety

Uploaded by

aQiLGunawanCopyright:

Available Formats

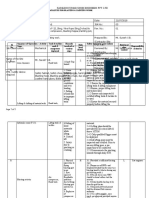

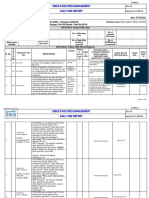

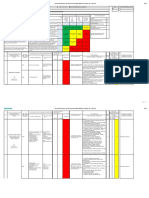

Document Number HG-Rig-012 Issued by, Rigging Department Approved by, Director

HaGun Institute

SAFETY RIGGING RESPONSIBILITY PROCEDURE

1 SAFETY RIGGING RESPONSIBILITY PROCEDURE

1.1 Supervisors:

1.1.1 Shall ensure that personnel safety, preservation of equipment and materials, is considered in the plan of lifting operation 1.1.2 Personnel shall be taught to rig-up loads correctly and carefully. 1.1.3 Personal protective equipment shall be worn; Safety helmets / hard hat Safety Glasses / goggles Respiratory / hearing protections Safety gloves Safety shoes

1.2 Equipment:

1.2.1 Ropes / chain / fibber Hitching equipment must be checked before and after each use. Worn ropes and broken chains cannot be used safely; frequent inspection should concentrate on finding broken links, strands, or fibbers. Frayed, loose, or cut strands used as signs to detect excessive wear in slings. Watch for fixed kinks. Any sign of corrosion is a signal that the sling is probably defective. Chain links must work freely within one another. Look for cracks, flaws, cold shuts, cut, nicks, stretching, etc. Whenever sling inspection uncovers a defect, the sling must be withdrawn immediately from service and marked or tagged conspicuously to ensure against its use. Using the wrong sling can be dangerous. It is wrong to assume that all chain slings, wire rope slings, or fibber rope slings have the same capacity and are correct for all lifting tasks. Frequently, only the manufacturer is capable of repairing a defective sling. Hooks will show wear by straightened tines, as well as cracks and flaws. Check for these, get replacements for load hooks that are bend open. Once a hook has been overloaded, it can no longer be used safely. Any heavy lifting job calls for the proper size hoist capacity.

1.2.2 Hooks

Revised: 0 Page 1 of 5 Date: 28 September 2012

Document Number HG-Rig-012 Issued by, Rigging Department Approved by, Director

HaGun Institute

SAFETY RIGGING RESPONSIBILITY PROCEDURE

Using the wrong sling can be dangerous. It is wrong to assume that all chain slings, wire rope slings, or fibber rope slings have the same capacity and are correct for all lifting tasks. Consider the angle of inclination of chain sling branches. Using a sling that is too short, thus reducing the angle of inclination will cut down your safety margin. Use the Chain Capacity Chart Reference. Always place pads or softeners on sharp corners with which slings and chains might otherwise come into contact, especially in cases where the slings might slide during the lifting operation. Shake out twists and kinks before loading: dont permit kinky slings to be used. Dont use a sling where a kink cannot be removed. Be careful to avoid placing a chain or sling so that the weight of the load is carried on the point of the hook. Load slings with the weight on the main portion (bowl) of hooks. Never use a single wire sling when hooked by a spliced eye. When the weight is sufficient, the sling is liable to untwist, allowing the slices to open and slip. Splicing chains or shortening chains with bolts, etc. is prohibited. In using slings of any kind, ensure that slings are properly laid; to make sure that one lay does not lie on top of the other; this will prevent proper equalization, thus putting an undue strain on the outer member. Try to keep pull on sling legs in a straight line. Choker and basket hitches may be used as slings but only after a careful check of safe load limits has been made. Foreign substances such as grit, bits of metal, and glass particles are harmful to cables and ropes. Never drag slings and ropes across the floor or ground.

1.2.3 Rigging signalling Standard crane signalling shall handle by one designated person only. During signalling, the crane rigger shall ensure his position is visible by the crane operator, if not visible than communications through handy talky shall be provided. When multi-lifts (two or more) hoists are being used, the crane rigger must stand in between, to ensure the crane operator can see and understand clearly the signal for each hoist. Before signalling the crane operator to hoist, the crane rigger shall ensure that the crane block is in-line 90 directly over the load to avoid swinging. Avoid unbalanced loads. If hooks are beyond reach, ask for assistance, and never force a hook or chain into place by hammering. Avoid sudden jerking when lifting or lowering, as this can increase the stress put on the chain or hook far beyond the actual weight of the load.

Revised: 0 Page 2 of 5 Date: 28 September 2012

Document Number HG-Rig-012 Issued by, Rigging Department Approved by, Director

HaGun Institute

SAFETY RIGGING RESPONSIBILITY PROCEDURE

If it is necessary to walk alongside a suspended or elevated load, stand or walk clear of the load never underneath it. Use a tag line to guide or hold the load. Be certain that your path of travel is free of obstructions before you begin. Material being piled should be properly placed and blocked, ensure that it shall not slip or over balance. Stack material neatly. Cross tie and step back where necessary. Avoid crushing slings when lowering loads. Use cribbing blocks under the load to remove slings. Roll or bend cables in one direction. Never bend first in one direction then another. Hitching equipment not in use shall not remain loose on hoisting devices but should be removed from crane hooks, hoists and loads.

1.2.4 Storing / maintaining equipment: Chains should be hung over the top of the A-Frame storage rack and looped so that no part of them touches the floor when in use. This method will permit easy examination of the most frequently damaged areas of slings, i.e., the hook, the lower 1/3 of the sling, and the master link where you can check the ID tag. Also, the crane operator will not need a rigger to unhook and the rigger will not have to lift much to hook on. Good housekeeping throughout the operation will help to control the hazards of mechanical lifting. SPECIAL NOTE: Before lifting dangerous or unusual lifts or fittings, make certain that the immediate supervisor is notified and present.

Revised: 0 Page 3 of 5 Date: 28 September 2012

Document Number HG-Rig-012 Issued by, Rigging Department Approved by, Director

HaGun Institute

SAFETY RIGGING RESPONSIBILITY PROCEDURE

2 OPERATOR - RIGGER RESPONSIBILITIES:

2.1 The crane must not be operated by anyone except an authorized person.

2.1.1 Never use any lifting machine or device unless you have been instructed in its use and fully understand all details of its operation. 2.1.2 The crane should be moved only upon the proper signal from one designated person, particularly where a group is involved. 2.1.3 All signals should be clear and unmistakable.

2.2 The crane rigger and the crane operator are a team handling a valuable piece of equipment.

2.2.1 Improper handling; this machine can be a dangerous machine if not properly handled. 2.2.2 Defective lifting equipment of any kind must be taken out of service for repair or adjustment. 2.2.3 Do not attempt to repair ant defective equipment unless the supervisor specifically authorizes to do so. 2.2.4 Do not walk or stand under a suspended load. 2.2.5 Allow on one else to do so. 2.2.6 Lifting machinery, including hooks, slings, etc., is not designed to carry personnel. 2.2.7 Do not permit anyone to ride on equipment. 2.2.8 Never load any equipment beyond its established capacity. 2.2.9 Careful when handling small pieces! Many accidents occur because of thoughtlessness when handling small pieces. 2.2.10 Remove all loose pieces that may be laying on work that is to be lifted.

2.3 Before starting to hoist, the operator should place the block directly over the load to avoid swinging the load during hoisting.

2.3.1 He shall carefully watch long hitches and the position of the hoisting hook and shall exercise extreme care to avoid running the hook above the limit. 2.3.2 If the chain has been strained in anyway, he shall notify his supervisor at once. 2.3.3 The location of the main circuit breaker for the crane electrical feed lines must be known. Revised: 0 Page 4 of 5 Date: 28 September 2012

Document Number HG-Rig-012 Issued by, Rigging Department Approved by, Director

HaGun Institute

SAFETY RIGGING RESPONSIBILITY PROCEDURE

2.3.4 Safe load factors for each piece of lifting equipment must be known. 2.3.5 Never overload slings, attempt to lift material too heavy for the equipment, or exceed the height limits for which the lifting equipment is designed. 2.3.6 Check the area where material is to be moved. 2.3.7 If the route is not well lighted or has obstructions, a supervisor should be advised so the situation can be corrected. 2.3.8 Break in wire rope gradually; when it is new, wire rope shouldnt be used at its maximum capacity rating. 2.3.9 Avoid haste, plan thoroughly and proceed cautiously with the work. 2.3.10 Adaptation of equipment to unusual uses should be avoided. 2.3.11 Any change in operating procedures must be approved by a supervisor. 2.3.12 Know the established emergency procedures for personal injury, fire, weather extremes, power failure, etc.

Revised: 0 Page 5 of 5 Date: 28 September 2012

You might also like

- Is 3177-2020Document92 pagesIs 3177-2020pawanbit80% (5)

- Basic Rigging EngineerDocument1 pageBasic Rigging EngineerGunawan HaGun86% (7)

- LEEA Academy MCE Module Quiz Paper - ANSWERS Mar20Document39 pagesLEEA Academy MCE Module Quiz Paper - ANSWERS Mar20Rana Danish100% (1)

- Electric Power Plant III TM-9-6115-669-13 and PDocument572 pagesElectric Power Plant III TM-9-6115-669-13 and PJeffrey GrayNo ratings yet

- JHA Maintenance Tech HVACDocument2 pagesJHA Maintenance Tech HVACMdavaNo ratings yet

- JSA Formet New Blasting & PaintingDocument5 pagesJSA Formet New Blasting & Paintingsakthi venkatNo ratings yet

- IG2, Hendry Lukas Timothy, 00663146, Redhat Safety TrainingDocument39 pagesIG2, Hendry Lukas Timothy, 00663146, Redhat Safety Trainingjashuva lenka88% (8)

- Norsok R-003, Safe Use of Lifting EquipmentDocument58 pagesNorsok R-003, Safe Use of Lifting EquipmentPatranNo ratings yet

- Ports and Marines FacilitiesDocument36 pagesPorts and Marines Facilities허윤호No ratings yet

- HydrospecDocument16 pagesHydrospecg665013No ratings yet

- Installation Method of The M&e WorksDocument27 pagesInstallation Method of The M&e WorksMạnh Hùng100% (2)

- Manual Grúa Liebherr 11200Document54 pagesManual Grúa Liebherr 11200jessie morales100% (1)

- Lifting Equipment PDFDocument2 pagesLifting Equipment PDFcityofdarwingisNo ratings yet

- JHA 02 Lifting and SlingingDocument4 pagesJHA 02 Lifting and Slingingadil khanNo ratings yet

- JSA Formet New Structural Steel FabricationDocument7 pagesJSA Formet New Structural Steel Fabricationsakthi venkatNo ratings yet

- EHS Alert 010 - Concrete Placing Boom OperationDocument1 pageEHS Alert 010 - Concrete Placing Boom OperationAbdulKatherNo ratings yet

- SOP SOP0007 Hitachi Electric Jack HammerDocument3 pagesSOP SOP0007 Hitachi Electric Jack HammerWidya BungaNo ratings yet

- JSA Format Erection of Column 903-C-02,03Document5 pagesJSA Format Erection of Column 903-C-02,03sakthi venkat100% (1)

- Instructions For Using The Risk Assessment FormDocument9 pagesInstructions For Using The Risk Assessment FormMalik Khuram ShazadNo ratings yet

- Work Method Statement: Confined SpaceDocument3 pagesWork Method Statement: Confined SpaceKarthik babu0% (1)

- Manual & Mechanical ChecklistDocument7 pagesManual & Mechanical ChecklistMartine OtienoNo ratings yet

- Risk Assessment For Braket Scaffolding: Construction of Lubricating Oil Blending Plant (LOBP)Document3 pagesRisk Assessment For Braket Scaffolding: Construction of Lubricating Oil Blending Plant (LOBP)AmeerHamzaWarraichNo ratings yet

- Steel Shield Temporary Fencing Risk Assessment and Method Statement For ErectionDocument7 pagesSteel Shield Temporary Fencing Risk Assessment and Method Statement For ErectionIrfan Prima AldiNo ratings yet

- Job Safety Analysis: S.No Activities Hazard Risk Control MeasuresDocument2 pagesJob Safety Analysis: S.No Activities Hazard Risk Control Measureskhaja asifuddinNo ratings yet

- Suspended Scaffold Inspection ChecklistDocument3 pagesSuspended Scaffold Inspection ChecklistSamantha Meril PandithaNo ratings yet

- RiggingDocument2 pagesRiggingpruncu.alianmNo ratings yet

- JSA For Pressure Test 2ND REVISIONDocument10 pagesJSA For Pressure Test 2ND REVISIONMuthu AlaguRaj100% (1)

- Akk Jha Installation of Diesel TankDocument3 pagesAkk Jha Installation of Diesel TankDouglas Delly0% (1)

- 09 JSA For Excavation and Blinding at Pump House 1 & 3Document4 pages09 JSA For Excavation and Blinding at Pump House 1 & 3Hilbrecht De Pedro100% (1)

- 04, Use of Hand ToolsDocument2 pages04, Use of Hand ToolsFrancis K BonfulNo ratings yet

- Risk Assesment - Floor Chasing and ScreedingDocument3 pagesRisk Assesment - Floor Chasing and Screedingirfan vpNo ratings yet

- 3 Safe Use of Crawler CranesDocument2 pages3 Safe Use of Crawler CranesSiewkuan LeeNo ratings yet

- Job Safety Analysis Sheet: Activity Potential Hazard Likely Causes Control MeasureDocument2 pagesJob Safety Analysis Sheet: Activity Potential Hazard Likely Causes Control MeasureM Waqas HabibNo ratings yet

- Jsa Fueling Equipment On DeckDocument2 pagesJsa Fueling Equipment On DeckIlya BordonosovNo ratings yet

- JSA - Batching Plant OperationDocument3 pagesJSA - Batching Plant OperationNisith SahooNo ratings yet

- JSA Scaffolding Erection and Dismentling New 2021Document5 pagesJSA Scaffolding Erection and Dismentling New 2021Captain ChickenNo ratings yet

- Job Safety Analysis - Clinker StorageDocument4 pagesJob Safety Analysis - Clinker StorageMohammed MinhajNo ratings yet

- Safe Operating Procedures 03 Chainsaw OperationDocument2 pagesSafe Operating Procedures 03 Chainsaw OperationVictorNo ratings yet

- F-49 Full Body Harness Inspection ChecklistDocument1 pageF-49 Full Body Harness Inspection ChecklistSKH Culture100% (1)

- Project:: SWP For Safe Use of MewpsDocument3 pagesProject:: SWP For Safe Use of MewpsVaradaraju Thirunavukkarasan100% (1)

- Hse Induction: Welcome To UMM AL HAYMAN-W 300/132/11 KV SubstationDocument61 pagesHse Induction: Welcome To UMM AL HAYMAN-W 300/132/11 KV SubstationJinadNo ratings yet

- Lifting Operations Risk Assessment Crane Risk AssessmentDocument13 pagesLifting Operations Risk Assessment Crane Risk Assessment9853318441No ratings yet

- Job Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityDocument2 pagesJob Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityJayendra PatelNo ratings yet

- Jsa PolypipeDocument2 pagesJsa PolypipeHow Chin Engineering Sdn BhdNo ratings yet

- TieDocument5 pagesTieshinto LawrenceNo ratings yet

- Job Safety Analysis Worksheet: Short Descriptive Title of Task: New Revised ReviewedDocument2 pagesJob Safety Analysis Worksheet: Short Descriptive Title of Task: New Revised ReviewedZulfokar FahdawiNo ratings yet

- Sogetrap JSA Lifting Cabin by ForkliftDocument2 pagesSogetrap JSA Lifting Cabin by ForkliftTSP HSENo ratings yet

- Nasda Wind Power Project: Sub-Station Excavation Job Safety Analysis WorksheetDocument2 pagesNasda Wind Power Project: Sub-Station Excavation Job Safety Analysis WorksheetRaza Muhammad SoomroNo ratings yet

- Fan InstallationDocument2 pagesFan InstallationKrishna PatilNo ratings yet

- RMDJV-PJ74-HIRADC-SUBE 03 (Installation of Outdoor Equipment)Document2 pagesRMDJV-PJ74-HIRADC-SUBE 03 (Installation of Outdoor Equipment)myn maliQueNo ratings yet

- Building De-Dusting JSADocument3 pagesBuilding De-Dusting JSAJayesh J PillaiNo ratings yet

- TRA 58 Unloading and Rigging Up Test EquipmentDocument4 pagesTRA 58 Unloading and Rigging Up Test EquipmentPirlo PoloNo ratings yet

- JSA #28 - Use of Hand ToolsDocument1 pageJSA #28 - Use of Hand ToolsSubham SohalNo ratings yet

- Hse JsaDocument22 pagesHse JsaAnonymous y1pIqcNo ratings yet

- Job Safety Analysis (Jsa) : Fabrication Works, Welding Works Using Power Tools, Hand Tools, Welding Machine WapstechDocument3 pagesJob Safety Analysis (Jsa) : Fabrication Works, Welding Works Using Power Tools, Hand Tools, Welding Machine WapstechMohamedSaidNo ratings yet

- Ev02 - Brief Program For New Work at Height CampaignDocument2 pagesEv02 - Brief Program For New Work at Height CampaignFrancis Enriquez TanNo ratings yet

- Construction Job Hazards Analysis: This Is A TEMPLATEDocument1 pageConstruction Job Hazards Analysis: This Is A TEMPLATETamNo ratings yet

- Generic TRA For Mobile Elevating Work PlatformDocument4 pagesGeneric TRA For Mobile Elevating Work PlatformKhawaja Arslan Ahmed100% (1)

- Risk Assessment IIIDocument1 pageRisk Assessment IIIJosh Booth100% (2)

- DIL AW 201601 Global FallsDocument3 pagesDIL AW 201601 Global Fallsvikrant911100% (1)

- Site Inspection Workplace Trasport ChecklistDocument6 pagesSite Inspection Workplace Trasport ChecklisttipuNo ratings yet

- Crane Hoist Sling Safety ProgramDocument14 pagesCrane Hoist Sling Safety Programomar sadiqNo ratings yet

- Daily HSE ReportDocument5 pagesDaily HSE ReportSayeed MalikNo ratings yet

- JSA Forklift PDFDocument2 pagesJSA Forklift PDFfauziNo ratings yet

- SOP-34 Ladders SafetyDocument3 pagesSOP-34 Ladders SafetyBoiler ScrubberNo ratings yet

- Job Safety Analysis Pre-Task Briefing: Reviewed / Approved By: Safety PersonnelDocument2 pagesJob Safety Analysis Pre-Task Briefing: Reviewed / Approved By: Safety Personnelmahammed saleemNo ratings yet

- Ra & Jsa FormatDocument19 pagesRa & Jsa Formatspecpro50% (2)

- MachineGuardingSopTech 31Document1 pageMachineGuardingSopTech 31muthuswamy77No ratings yet

- Genie E Series Slab Scissor Lift Operation PDFDocument11 pagesGenie E Series Slab Scissor Lift Operation PDFRajesh gpNo ratings yet

- TaiLing by Duo CraneDocument9 pagesTaiLing by Duo CraneHaGun Gunawan100% (1)

- Rigging JSA RiggerDocument12 pagesRigging JSA RiggeraQiLGunawanNo ratings yet

- Rigging JSA ScaffolderDocument30 pagesRigging JSA ScaffolderaQiLGunawanNo ratings yet

- Grafik Sondir 2010Document7 pagesGrafik Sondir 2010aQiLGunawanNo ratings yet

- Grafik Sondir 2007Document7 pagesGrafik Sondir 2007Gunawan HaGunNo ratings yet

- Cutting PLan Pipe & Ducting PDFDocument91 pagesCutting PLan Pipe & Ducting PDFHaGun Gantry100% (1)

- Grua Hidraulica Rt880e PDFDocument967 pagesGrua Hidraulica Rt880e PDFGustavo100% (1)

- Khandala - Pipe - Line - Work - Phase 1 PDFDocument23 pagesKhandala - Pipe - Line - Work - Phase 1 PDFborkarsd007No ratings yet

- Transport Manual V90Document28 pagesTransport Manual V90cungondaNo ratings yet

- Magnetek Mondel MBT BrakesDocument36 pagesMagnetek Mondel MBT BrakesNo-No-NoNo ratings yet

- Job Safety Analysis: (Risk Assessment)Document9 pagesJob Safety Analysis: (Risk Assessment)MarhendraNo ratings yet

- Study On Erection Control Scheme For Long Span Steel Arch Bridge and Its Application On Chaotianmen Yangtze River BridgesDocument14 pagesStudy On Erection Control Scheme For Long Span Steel Arch Bridge and Its Application On Chaotianmen Yangtze River BridgesMiguel PerezNo ratings yet

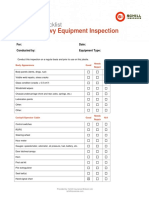

- Heavy Equipment Inspection ChecklistDocument9 pagesHeavy Equipment Inspection ChecklistAbhishek ShahNo ratings yet

- Sample of Method StatementDocument13 pagesSample of Method StatementMohammadImranRazaNo ratings yet

- Crane PDFDocument102 pagesCrane PDFBrook KingNo ratings yet

- List of TBT Agendas: S.# TBT Topic Reference NumberDocument31 pagesList of TBT Agendas: S.# TBT Topic Reference NumberRabban100% (1)

- Bridgeconstructionpartner 01 2014Document36 pagesBridgeconstructionpartner 01 2014Harianto RamadhanNo ratings yet

- Lifting and Rigging ProcedureDocument8 pagesLifting and Rigging ProcedureKluKlux Land100% (2)

- Nebosh IGC2 Part 3Document38 pagesNebosh IGC2 Part 3MuhammadAkram100% (7)

- Gantry Girder 2020Document18 pagesGantry Girder 2020madhavi prajapatiNo ratings yet

- Product CatalougDocument68 pagesProduct CatalougMohamed HarbNo ratings yet

- PMS BrochureDocument6 pagesPMS BrochureOsama KashkoushaNo ratings yet

- Liebherr SC OverviewDocument11 pagesLiebherr SC Overviewnicolasq francescaNo ratings yet

- Service Manual SM00-000-000.00: How To Use This Manual, General Service Instructions, and Safety ProceduresDocument6 pagesService Manual SM00-000-000.00: How To Use This Manual, General Service Instructions, and Safety ProcedureseduardoNo ratings yet

- For Heavy-Duty Truck: Truck-Mounted UNIC Crane SeriesDocument3 pagesFor Heavy-Duty Truck: Truck-Mounted UNIC Crane SeriesSaleh Mohammad TahsinNo ratings yet

- GOOGLE SketchUp - Film and Stage InstructionsDocument3 pagesGOOGLE SketchUp - Film and Stage InstructionsXaverius NandaNo ratings yet

- Company Profile Kiri & CompanyDocument5 pagesCompany Profile Kiri & CompanyMr. LALIT KUMAR KIRINo ratings yet