Professional Documents

Culture Documents

New Model Variable Frequency Transformer (NMVFT) - A Technology For V/F Control of Induction Motors

Uploaded by

IDESOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

New Model Variable Frequency Transformer (NMVFT) - A Technology For V/F Control of Induction Motors

Uploaded by

IDESCopyright:

Available Formats

ACEEE Int. J. on Electrical and Power Engineering, Vol. 02, No.

01, Feb 2011

New Model Variable Frequency Transformer (NMVFT) A Technology for V/f Control of Induction Motors

Farhad Ilahi Bakhsh, Mohammad Irshad, and Shirazul Islam

Department of Electrical Engineering, A.M.U, Aligarh, India Email: farhad.engg@gmail.com Email: 87.irshad@gmail.com Email: shiraz.zhcet@yahoo.com

Abstract Variable frequency transformer (VFT) is used as a controllable bidirectional transmission device that can transfer power between asynchron ous networks and f unctionally is similar to back-to-back HVDC. This paper describes the basic concept of a New M odel Variable Frequency Transformer (NMVFT). NMVFT is a new technology which is used for v/f control of induction motors. A digital simulation model of NM VFT and its control system are developed using MATLAB. The out power thus generated in v/f mode has been practically verified for the speed control of a three-phase induction motor. Thus constant speed-torque characteristics were achieved. In de x Term s Va ria b le f req u en cy tra n sf or me r (V F T) , Asynchronous, New Model Variable Frequency Transformer (NMVFT), V/f control, M ATLAB.

I. I NTRODUCTION Variable frequency transformer (VFT) is a controllable bidirectional transmission device that can transfer power between asynchronous networks. The construction of VFT is similar to conventional asynchronous machines, where the two separate electrical networks are connected to the stator and rotor respectively. One power system is connected with the rotor side of the VFT via the electrical brush rings and step-up transformers. And another power system is connected with the stator side of the VFT directly via a stepup transformer. Electrical power is exchanged between the two networks by magnetic coupling through the air gap of the VFT. A motor and drive system are used to adjust the rotational position of the rotor relative to the stator, thereby controlling the magnitude and direction of the power flowing through the VFT [1, 2]. Both the winding currents of the stator and rotor induce a rotary magnetic field Fstator and Frotor respectively. In the steady state, the two rotary magnetic fields are rotating with the same angular speed i.e. Fstator is standstill to Frotor. The composite magnetic fields Fstator_rotor will rotate with a speed of system-stator, cutting the stator coils with the same speed, and cutting the rotor coils with a speed of system_rotor. And the angle frequency of the resulting inductive potential at stator and rotor windings is synchronous with their currents respectively. A stable power exchange between the two asynchronous systems is possible. The transferred power and its direction are controlled by the torque applied to the rotor,

2011 ACEEE

which is supplied by the dc drive motor. If torque is applied in one direction, then power flows from the stator winding to the rotor winding. If torque is applied in the opposite direction, then power flows from the rotor winding to the stator winding. If no torque is applied, then no power flows through the rotary transformer [3, 4]. The worlds first VFT, which was manufactured by GE, installed and commissioned in Hydro-Quebecs Langlois substation, where it will be used to exchange power up to 100 MW between the asynchronous power grids of Quebec (Canada) and New York (USA). Figure 1 shows a simplified one-line diagram of the Langlois VFT, which is comprised of the following: a rotary transformer for power exchange, a drive motor to control the movement of the rotor and to transfer power, a collector to connect the rotor windings with the outside system via electric brushes [5 - 7].

Figure 1. Photograph of Langlois 100 MW VFT

II. NMVFT MODEL AND SYSTEM DESCRIPTION A. NMVFT Model In the model, NMVFT is a three phase singly fed slip ring type induction machine. The stator winding is energized with three phase ac source and the rotor winding is kept open. The rotor is coupled to a controllable constant speed drive i.e. dc shunt motor via mechanical coupler and 11

DOI: 01.IJEPE.02.01.50

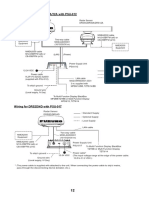

ACEEE Int. J. on Electrical and Power Engineering, Vol. 02, No. 01, Feb 2011 scope is connected to measure the magnitude of voltage and frequency of voltage across the rotor winding. Figure 2 shows the circuit diagram of NMVFT. across the rotor winding as well as its frequency becomes double the rated value. Thus a constant V/f characteristics is achieved. This operation of NMVFT is verified digitally by MATLAB Simulation and practically. III. DIGITAL SIMULATION OF VFT A. MATLAB Simulation In the view of MATLAB simulink, NMVFT is a type of machi ne which can be simulated wit h the asynchronous machine SI units. The asynchronous machine SI units having a three-phase excitation system on stator side. The constant speed achieved from dc shunt motor is simulated by using a constant block. And then we could use this simulated model, as shown as Figure 3, to solve electric system of NMVFT.

Figure 2. NMVFT circuit diagram

B. NMVFT Operation The three phase ac supply is applied to the stator winding of the three phase four poles singly fed slip ring type induction machine. The rotor is coupled with the dc shunt motor through a mechanical coupler. When the 220V dc supply is applied to the dc shunt motor the NMVFT comes in operation. The induced emf Er in the rotor circuit is given by Er = sV (1) where, V = Supply voltage per phase, s = Slip of Induction Motor and Er = Emf induced in the rotor circuit per phase And the frequency of the induced voltage in the rotor circuit is given by fr = sf (2) where, f = Supply frequency, s = Slip of Induction Motor and fr = frequency of the induced voltage in the rotor circuit The operation of NMVFT includes the following: i) If the rotational speed of dc shunt motor is zero then the value of slip is equal to one as a result the emf induced across the rotor winding is the rated rotor terminal voltage and the frequency of voltage is the rated frequency. ii) If the dc shunt motor rotates in a)The direction of the rotating air gap flux then the relative motion between them decreases results in decrease in slip as a result the emf induced across the rotor winding as well as its frequency decreases. When the speed of rotation of dc shunt motor is equal to synchronous speed then the slip becomes zero as a result the emf induced a) across the rotor winding as well as its frequency becomes zero. b)The direction opposite to the rotating air gap flux then the relative motion between them increases results in increase in slip as a result the emf induced across the rotor winding as well as its frequency increases. When the speed of rotation of dc shunt motor is equal to synchronous speed then the slip becomes double as a result the emf induced

Figure 3. MATLAB Simulation diagram of NMVFT

B. Simulation Figures and Results When the rotational speed of dc shunt motor is zero.

2011 ACEEE

12

DOI: 01.IJEPE.02.01.50

ACEEE Int. J. on Electrical and Power Engineering, Vol. 02, No. 01, Feb 2011 b) The direction of rotation of rotor is opposite to the air gap field:-

a)

The direction of rotation of rotor is same as that of the air gap field:-

When the rotational speed of dc shunt motor is equal to the synchronous speed i.e. relative speed is double of synchronous speed.

-50*pi

1000

500

When the rotational speed of dc shunt motor is equal to the synchronous speed i.e. relative speed is zero.

-500

-1000 0 200

0.5

1.5

2.5

3.5 x 10

4

100

0 -100

-200

In this way we can control output voltage from rated voltage to twice of rated voltage and frequency from rated frequency to twice the rated frequency i.e. 50 100 Hz in India. The emf induced across the rotor winding versus its frequency graph achieved is shown as:

0 0.5 1 1.5 2 2.5 3 x 104

-300

In this way we can control output voltage from zero volts to rated voltage and frequency from zero Hertz to rated frequency i.e. 50 Hz in India. The emf induced across the rotor winding versus its frequency graph achieved is shown as:

Figure 4. MATLAB Simulation results showing variation of rotor circuit voltages with time and voltage versus frequency graphs.

2011 ACEEE

13

DOI: 01.IJEPE.02.01.50

ACEEE Int. J. on Electrical and Power Engineering, Vol. 02, No. 01, Feb 2011 IV. PRACTICAL ANALYSIS Figure 6 showing the variation of rotor voltage with its frequency of table I.

Figure 6. Voltage versus Frequency curve (table I)

b) The direction of rotation of rotor is opposite to the air gap field:-

Figure 5. Mechanical and electrical parameters used during experiment.

While performing the experiment the rotor of dc shunt motor is mechanically coupled to the rotor of the induction motor. The three phase ac supply is given to the stator winding of three phase four poles slip ring type induction motor through an auto transformer. The rotor windings are kept open circuited and voltmeter is connected across the rotor winding. The 220V dc is applied to the dc shunt motor through a rheostat. A tachometer is used to measure the speed of the dc shunt motor. With the help of auto transformer the input voltage of induction motor is maintained constant and through rheostat the voltage of the dc shunt motor is varied which varies the current in shunt winding and as a result the flux of dc shunt winding varies, resulting in variation of speed of dc shunt motor. Since the rotor of dc shunt motor is mechanically coupled with the rotor of induction motor, thus the speed of the induction motor varies accordingly. The voltage induced across the rotor winding and its frequency is given in the table: a) The direction of rotation of rotor is same as that of the air gap field:-

Figure 7 shows the variation of rotor voltage with its frequency of table II.

V. INDUCTION MOTOR V/F CONTROL The output power of the NMVFT is applied to three phase induction motor of 1HP, 420V, 2A, 50Hz, 1430rpm. A linear torque-speed characteristics is achieved. The torque-speed characteristics for different magnitude of voltage and different frequency of voltage i.e. 50Hz, 40Hz and 30Hz, with and without boost up voltage, are shown as:

2011 ACEEE

14

DOI: 01.IJEPE.02.01.50

ACEEE Int. J. on Electrical and Power Engineering, Vol. 02, No. 01, Feb 2011

Figure 11. D.C Shunt motor mechanically coupled with Induction motor

CONCLUSIONS Using NMVFT we can vary voltage from zero volts to twice the rated voltage and frequency from zero hertz to twice the rated frequency. Thus a constant V/f is achieved by NMVFT and is harmonics free. This is a new alternative for v/f control of Induction Motor. It eliminates the use of conventional v/f power supply using a MOSFET or IGBT based inverter. Therefore the reliability of the system is high and the proposed system can be used at MW level of power. MATLAB based si mulation is done for the overall performance of the NMVFT system. Moreover, a satisfactory performance of a three-phase induction motor is also obtained, when energized form the NMVFT supply. It showed almost linear torque-speed characteristics. REFERENCES

[1] E.Larsen, R .Piw ko, D.M cLaren , D .McNabb, M.Granger, M.D usseau lt,L-P.Rollin , J .Primeau, Variable-Frequ ency Transformer - A New Alternative for Asynchronous Power Tra ns fer, C an ad a Po we r, To ront o,On ta rio, C an ada , September 28-30,2004. [2] P.Doyon, D.McLaren, M.White, Y.Li, P.Truman, E.Larsen, C.Wegner, E.Pratico, R.Piwko, Development of a 100 MW Variable Frequency Transformer, Canada Power, Toronto, Ontario, Canada, September 28-30, 2004. [3] M . D u ssea u lt , J.M .Gag non , D .Ga libo is , M .Gra nger, D.McNabb, D.Nadeau, J. Primeau, S.Fiset, E.Larsen, G.Drobniak, I.McIntyre, E.Pratico, C.Wegner, First V FT Application and Commissioning, Canada Power, Toronto, Ontario, CANADA, September 28-30, 2004.

[4] D. McLaren, J. Michalec, The Variable Frequency Transformer (VFT) A Rotating Machine. GE Energy and American Electric Power (AEP) Doble, 2006.

Figure 9. Torque versus Speed characteristics (with boost-up voltage)

[5] A. Merkhouf, S. Upadhyay and P. Doyon, Variable frequency transformer - an overview, in Proc. of the 2006 IEEE Power Engineering Society General Meeting, June 18-22, 2006 pp. [6] Geson g Chen, and Xiaoxin Zhou, D igital Simulation of Var iable Fre qu en cy Tr an sfor me rs Fo r Asyn ch ron ou s Interconnection in Power System, 2005. [7] Arezki M erkh ouf, Pierre Doyon and Sanjoy Upadh yay , Va riable Fr eq ue nc y Tra ns form er C on cep t an d Electromagnetic Design Evaluation, IEEE Transactions on Energy Conversion, vol. 23, no. 4, December 2008.

2011 ACEEE

15

DOI: 01.IJEPE.02.01.50

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- 产 品 型 号 : HCYD 产 品 规 格 : 23-XX-AG2/S3 使 用 说 明 书 V1.1: Elevator power-off leveling deviceDocument15 pages产 品 型 号 : HCYD 产 品 规 格 : 23-XX-AG2/S3 使 用 说 明 书 V1.1: Elevator power-off leveling deviceAndrés LemosNo ratings yet

- Section E Volume 07 HV TransformersDocument26 pagesSection E Volume 07 HV TransformersRigoberto UrrutiaNo ratings yet

- The Konzen Pulse MotorDocument35 pagesThe Konzen Pulse MotorRODRIGO TROCONIS50% (2)

- Line Losses in The 14-Bus Power System Network Using UPFCDocument6 pagesLine Losses in The 14-Bus Power System Network Using UPFCIDESNo ratings yet

- 1010Document6 pages1010Wil LamNo ratings yet

- Power System State Estimation - A ReviewDocument9 pagesPower System State Estimation - A ReviewIDESNo ratings yet

- Study of Structural Behaviour of Gravity Dam With Various Features of Gallery by FEMDocument8 pagesStudy of Structural Behaviour of Gravity Dam With Various Features of Gallery by FEMIDESNo ratings yet

- Design and Performance Analysis of Genetic Based PID-PSS With SVC in A Multi-Machine System Considering Detailed ModelDocument9 pagesDesign and Performance Analysis of Genetic Based PID-PSS With SVC in A Multi-Machine System Considering Detailed ModelIDESNo ratings yet

- Various OSI Layer Attacks and Countermeasure To Enhance The Performance of WSNs During Wormhole AttackDocument6 pagesVarious OSI Layer Attacks and Countermeasure To Enhance The Performance of WSNs During Wormhole AttackIDESNo ratings yet

- Secure Multi-Party Negotiation: An Analysis Forelectronic Payments in Mobile ComputingDocument8 pagesSecure Multi-Party Negotiation: An Analysis Forelectronic Payments in Mobile ComputingIDESNo ratings yet

- Optimal Placement of DG For Loss Reduction and Voltage Sag Mitigation in Radial Distribution Systems Using ABC AlgorithmDocument6 pagesOptimal Placement of DG For Loss Reduction and Voltage Sag Mitigation in Radial Distribution Systems Using ABC AlgorithmIDESNo ratings yet

- Responsive Parameter Based An AntiWorm Approach To Prevent Wormhole Attack in Ad Hoc NetworksDocument8 pagesResponsive Parameter Based An AntiWorm Approach To Prevent Wormhole Attack in Ad Hoc NetworksIDESNo ratings yet

- Artificial Intelligence Technique Based Reactive Power Planning Incorporating FACTS Controllers in Real Time Power Transmission SystemDocument7 pagesArtificial Intelligence Technique Based Reactive Power Planning Incorporating FACTS Controllers in Real Time Power Transmission SystemIDESNo ratings yet

- Selfish Node Isolation & Incentivation Using Progressive ThresholdsDocument8 pagesSelfish Node Isolation & Incentivation Using Progressive ThresholdsIDESNo ratings yet

- Permutation of Pixels Within The Shares of Visual Cryptography Using KBRP For Enhanced SecurityDocument9 pagesPermutation of Pixels Within The Shares of Visual Cryptography Using KBRP For Enhanced SecurityIDESNo ratings yet

- Cloud Security and Data Integrity With Client Accountability FrameworkDocument13 pagesCloud Security and Data Integrity With Client Accountability FrameworkIDESNo ratings yet

- Comparative Study of Morphological, Correlation, Hybrid and DCSFPSS Based Morphological & Tribrid Algorithms For GFDDDocument10 pagesComparative Study of Morphological, Correlation, Hybrid and DCSFPSS Based Morphological & Tribrid Algorithms For GFDDIDESNo ratings yet

- Enhancing Data Storage Security in Cloud Computing Through SteganographyDocument7 pagesEnhancing Data Storage Security in Cloud Computing Through SteganographyIDESNo ratings yet

- Low Energy Routing For WSN'sDocument4 pagesLow Energy Routing For WSN'sIDESNo ratings yet

- High Density Salt and Pepper Impulse Noise RemovalDocument10 pagesHigh Density Salt and Pepper Impulse Noise RemovalIDESNo ratings yet

- Genetic Algorithm Based Layered Detection and Defense of HTTP BotnetDocument12 pagesGenetic Algorithm Based Layered Detection and Defense of HTTP BotnetIDESNo ratings yet

- Texture Unit Based Monocular Real-World Scene Classification Using SOM and KNN ClassifierDocument8 pagesTexture Unit Based Monocular Real-World Scene Classification Using SOM and KNN ClassifierIDESNo ratings yet

- Band Clustering For The Lossless Compression of AVIRIS Hyperspectral ImagesDocument14 pagesBand Clustering For The Lossless Compression of AVIRIS Hyperspectral ImagesIDESNo ratings yet

- Rotman Lens Performance AnalysisDocument6 pagesRotman Lens Performance AnalysisIDESNo ratings yet

- Optimized Neural Network For Classification of Multispectral ImagesDocument6 pagesOptimized Neural Network For Classification of Multispectral ImagesIDESNo ratings yet

- Blind Source Separation of Super and Sub-Gaussian Signals With ABC AlgorithmDocument10 pagesBlind Source Separation of Super and Sub-Gaussian Signals With ABC AlgorithmIDESNo ratings yet

- Microelectronic Circuit Analogous To Hydrogen Bonding Network in Active Site of - LactamaseDocument8 pagesMicroelectronic Circuit Analogous To Hydrogen Bonding Network in Active Site of - LactamaseIDESNo ratings yet

- Mental Stress Evaluation Using An Adaptive ModelDocument8 pagesMental Stress Evaluation Using An Adaptive ModelIDESNo ratings yet

- 3-D FFT Moving Object Signatures For Velocity FilteringDocument5 pages3-D FFT Moving Object Signatures For Velocity FilteringIDESNo ratings yet

- Genetic Algorithm Based Mosaic Image Steganography For Enhanced SecurityDocument12 pagesGenetic Algorithm Based Mosaic Image Steganography For Enhanced SecurityIDESNo ratings yet

- Efficient Architecture For Variable Block Size Motion Estimation in H.264/AVCDocument9 pagesEfficient Architecture For Variable Block Size Motion Estimation in H.264/AVCIDESNo ratings yet

- Opportunities and Challenges of Software CustomizationDocument11 pagesOpportunities and Challenges of Software CustomizationIDESNo ratings yet

- Ontology-Based Semantic Approach For Learning Object RecommendationDocument10 pagesOntology-Based Semantic Approach For Learning Object RecommendationIDESNo ratings yet

- MCQ in Philippine Electrical Code PEC Part 2 REE Board ExamDocument19 pagesMCQ in Philippine Electrical Code PEC Part 2 REE Board ExamManuel DizonNo ratings yet

- Laney: Service Information CPC12 Powered MonitorDocument9 pagesLaney: Service Information CPC12 Powered MonitorLeonardo de SouzaNo ratings yet

- Ccfl-Inverter DS-1307WKDocument14 pagesCcfl-Inverter DS-1307WKsachinNo ratings yet

- SEC Automatic Transfer Switch SpecificationsDocument27 pagesSEC Automatic Transfer Switch SpecificationsI CNo ratings yet

- Starting Methods For Induction MotorsDocument3 pagesStarting Methods For Induction MotorsKrishnamoorthy Ayyasami100% (1)

- 74HCT32Document4 pages74HCT32Horst MumpitzNo ratings yet

- DRS2D Installation Manual (PG12)Document1 pageDRS2D Installation Manual (PG12)Rob SNo ratings yet

- Diode N BJP CKT Quiestion N SolutionDocument11 pagesDiode N BJP CKT Quiestion N SolutionMeezan ChandNo ratings yet

- PANEL BadjoDocument11 pagesPANEL BadjoArry ArekKulonanNo ratings yet

- En Acs880 Q971 Atex Ag G A4Document52 pagesEn Acs880 Q971 Atex Ag G A4Romildo FernandesNo ratings yet

- VI Characteristics of DiodeDocument5 pagesVI Characteristics of DiodeMUDABBIR RASHIDNo ratings yet

- Chapter 7 - Electrical UtilizationDocument21 pagesChapter 7 - Electrical UtilizationKamaruz DanialNo ratings yet

- EMEC Important QuestionsDocument3 pagesEMEC Important QuestionsHarish KumarNo ratings yet

- Question Bank Ac MachinesDocument4 pagesQuestion Bank Ac Machinesashwin paulNo ratings yet

- Phase Relay Control RM17TG SchneiderDocument2 pagesPhase Relay Control RM17TG SchneiderSevtunus BangunNo ratings yet

- Vol12 Tab13 PDFDocument99 pagesVol12 Tab13 PDFJuanFuentesBecerraNo ratings yet

- Manual de Maquina de Humo Magnum2000Document12 pagesManual de Maquina de Humo Magnum2000Octavio BarbozaNo ratings yet

- RU7088 Mosfet: N-Channel Advanced Power MOSFETDocument11 pagesRU7088 Mosfet: N-Channel Advanced Power MOSFETCelso SáNo ratings yet

- 174B-MCC Boiler - As BuiltDocument33 pages174B-MCC Boiler - As BuiltDharun KumarNo ratings yet

- Panel de Alarmas Al8-2 DeifDocument8 pagesPanel de Alarmas Al8-2 Deifcyrus6_998128100% (1)

- Dokumen - Tips - Jetta No 1311 Wiring Diagram Justanswercom NBSPPDF File5282009wiringDocument22 pagesDokumen - Tips - Jetta No 1311 Wiring Diagram Justanswercom NBSPPDF File5282009wiringAlfredo GracidaNo ratings yet

- Junction Leakage and GIDLDocument3 pagesJunction Leakage and GIDLThabasum Aara SNo ratings yet

- Cabluri Monofilare Fara Manta Unsheathed Single-Core Cables: Test Voltage: 3 KV, 50 HZ, 5 Minutes in WaterDocument2 pagesCabluri Monofilare Fara Manta Unsheathed Single-Core Cables: Test Voltage: 3 KV, 50 HZ, 5 Minutes in WaterCirtiu SandaNo ratings yet

- B 80 B 84 A 03 AdasdasdDocument2 pagesB 80 B 84 A 03 AdasdasdAdhitz D RavenzNo ratings yet

- BLDNG Utilities RSW 3-1Document29 pagesBLDNG Utilities RSW 3-1Steven PadillaNo ratings yet

- Mov ManualDocument32 pagesMov Manualpriyabubun1986No ratings yet

- DC - AC ConverterDocument10 pagesDC - AC ConverterLukman Hakim BaharuddinNo ratings yet