Professional Documents

Culture Documents

Pile Integrity Test2 PDF

Uploaded by

Sima Datta DebOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pile Integrity Test2 PDF

Uploaded by

Sima Datta DebCopyright:

Available Formats

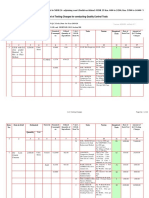

GUIDELINES FOR INTEGRITY TESTING OF PILES

2.0 SONIC ECHO TEST - LOW STRAIN INTEGRITY TESTING (IS 14893:2001) Sonic echo testing has been used successfully for quite sometime now for checking the integrity of piles after installation. It has been established that cast in situ piles in majority of the cases fail because of defective pile shaft necking, discontinuity of concrete, intrusion of foreign matter and improper toe formation due to contamination of concrete at base with soil particles, washing of concrete due to high water current, adoption of improper construction method, poor quality control on concreting etc.. Cracks developed while handling of precast piles can also be a cause of failure. If pile integrity can be assessed before completion of pile caps, then this will go a long way towards certification of pile integrity. Integrity testing is relatively quick and simple and enables number of piles to be examined in a single working day. The method does not identify all imperfections in a pile, but provides information about continuity, defects such as cracks, necking, soil incursions, changes in cross section and approximate pile lengths ( unless the pile is very long or the skin friction is too high ). Integrity testing result for a particular area may not be necessarily valid for another area. Detailed results in a particular area for a number of sites have to be collected and evaluated before interpretation of tests result of a new site in that area. Integrity tests provide an indication of soundness of concrete but they should be undertaken by persons experienced in the method and capable of interpreting the results with specific regard to piling. In this test, a small metal / hard rubber hammer is used to produce a light tap on the top of the pile. The shock traveling down the length of the pile is reflected back from the toe of the pile and recorded through a suitable transducer / accelerometer ( also held on the top of the pile close to the point of impact) in a computer disk for subsequent analysis. The primary shock wave which travels down the length of the shaft is reflected from the toe by change in density between the concrete and the sub strata. However, if the pile has any imperfections or discontinuities within its length these will set up secondary reflections which will be added to the return signal. By a careful analysis of the captured signal and a knowledge of the conditions of the ground, age of the concrete etc. a picture of the location of such problems can be built up.

2.1

2.2

2.3

2.4

2.5

2.6

2.7

GUIDELINES FOR INTEGRITY TESTING OF PILES

2.8 Normally more than one recording of signals is done until repeatability of signals is achieved. In case of large diameter piles, the tests are conducted at 5-6 places to cover the entire section of the pile. General Requirements of the tests i) ii) iii) iv) Pile shall be trimmed to cut off level or sound concrete level before the test with all laitance removed. The area surrounding the pile should be free from standing water and should be kept dewatered during the tests. The cast in situ piles should not normally be tested before 14 days of casting. The test piles, if available at site can be used for determination of pulse velocity and characteristic or reference signal generated. This can also be done from those piles whose depth is accurately recorded.

2.9 2.10

2.11

The following are the complimentary tests to the low strain integrity test method. These can be used to check the soundness of concrete at test level and to assess the stress wave velocity of pile concrete depending on concrete density and its in situ condition. a) Ultrasonic Pulse Velocity Test This test is carried out at the head

of the pile in order to arrive at the speed of sound propagation through the cast concrete of the pipe. b) Penetration Test The test is used to assess the strength of the concrete at the pile head to ensure that the pile is sufficiently cured and ready for NDT. Density Testing Of Cast Cubes In order to determine the density of concrete used each cube should be measured for density by weighing in air and water. Limitations i) ii) The present experience of NDT of piles is upto diameter of 1500 mm. This is applicable to cast in situ concrete bored and driven piles. The test cannot be conducted after provision / casting of pile cap.

c)

2.12

GUIDELINES FOR INTEGRITY TESTING OF PILES

iii) iv) v) This method is not suitable for piles surrounded by water as it may not give correct results. It does not provide information regarding verticality or displacement (in position) of the piles. Local loss of cover, small intrusions or type of conditions at the base of piles are undetectable.

You might also like

- Concrete Dispatch SlipDocument1 pageConcrete Dispatch SlipShesha ShayanNo ratings yet

- Field Density Test Sand Replacement Method: Employer: Chennai Metro Rail Limited Project: CMRL C4 ECV02Document1 pageField Density Test Sand Replacement Method: Employer: Chennai Metro Rail Limited Project: CMRL C4 ECV02zealbalaNo ratings yet

- WMM Plant Calibration (Fortune)Document12 pagesWMM Plant Calibration (Fortune)RSBIPL NH17 LABNo ratings yet

- Sieve Analysis Coarse Aggrigate (15-25) - 30!11!2022Document1 pageSieve Analysis Coarse Aggrigate (15-25) - 30!11!2022Mitendra Kumar ChauhanNo ratings yet

- California Bearing Ratio Test: (As Per IS 2720 (Part-16) )Document5 pagesCalifornia Bearing Ratio Test: (As Per IS 2720 (Part-16) )ஆதித்தன்No ratings yet

- C.B.R CombinedDocument9 pagesC.B.R Combinedusman ali usman aliNo ratings yet

- Quality TestDocument22 pagesQuality TestUmair Shaikh100% (1)

- Akhil Bharatvarshiya Marwari Aggarwal Jatiya Kosh: Plate Load Test ReportDocument2 pagesAkhil Bharatvarshiya Marwari Aggarwal Jatiya Kosh: Plate Load Test ReportGaneshNo ratings yet

- Bidirectional Sealing Ball Valves in Power ApplicationsDocument3 pagesBidirectional Sealing Ball Valves in Power Applicationsxisefengchuang100% (1)

- RMM CalibrationDocument18 pagesRMM CalibrationPrasanna S KulkarniNo ratings yet

- Test Report: Ultratech Cement Limited. (Concrete Division)Document3 pagesTest Report: Ultratech Cement Limited. (Concrete Division)rahulNo ratings yet

- Quality Control Format For MPR Ex Dsc-2Document7 pagesQuality Control Format For MPR Ex Dsc-2Rahmat mulyadiNo ratings yet

- Soil GSB WMM by Sand Replacement MethodDocument2 pagesSoil GSB WMM by Sand Replacement MethodBrahammanand BairwaNo ratings yet

- Introduction To Three Phase PowerDocument25 pagesIntroduction To Three Phase PowerSyed Raheel AdeelNo ratings yet

- Sand Replacement TestDocument8 pagesSand Replacement Testkrishna buildconNo ratings yet

- Work and Energy WorksheetsDocument8 pagesWork and Energy Worksheetsdddn1328No ratings yet

- Cement Concrtet Mix Design of M-20 Grade For RCC WorkDocument7 pagesCement Concrtet Mix Design of M-20 Grade For RCC WorkSandip Roy100% (1)

- Mesa (Maximum Entropy Spectral Analysis)Document9 pagesMesa (Maximum Entropy Spectral Analysis)Francis LinNo ratings yet

- Ulr - TC752121000004643FDocument16 pagesUlr - TC752121000004643FKishore KumarNo ratings yet

- Sc-Mix Design PDFDocument1 pageSc-Mix Design PDFjitendraNo ratings yet

- DCP Test Report ExampleDocument4 pagesDCP Test Report Exampledwi istNo ratings yet

- CMRL P2C401 Final Report 1-319-338Document20 pagesCMRL P2C401 Final Report 1-319-338Kishore KumarNo ratings yet

- Wing Finite Element Analysis1Document16 pagesWing Finite Element Analysis1usakalambaNo ratings yet

- Test Certificate of LabDocument4 pagesTest Certificate of LabR.S.No ratings yet

- Core Cutter TestDocument6 pagesCore Cutter TestMian M KhurramNo ratings yet

- Observation Sheet For Bitumen Extraction Test: Name of Division Name of Sub DivisionDocument2 pagesObservation Sheet For Bitumen Extraction Test: Name of Division Name of Sub DivisionramNo ratings yet

- Som Lab Manual NnceDocument39 pagesSom Lab Manual Nncelogeshboy007No ratings yet

- Ball Mill Performance & EfficiencyDocument7 pagesBall Mill Performance & EfficiencyVijay BhanNo ratings yet

- Absorption of Formaldehyde in WaterDocument135 pagesAbsorption of Formaldehyde in WaterBer GuzNo ratings yet

- ReportDocument34 pagesReportAjay MahaleNo ratings yet

- Self Compacting Concrete-Ce19s015 PDFDocument13 pagesSelf Compacting Concrete-Ce19s015 PDFmamthaNo ratings yet

- Date: 19.02.2020 CC Kerb Stone (Core) Test Report The Executive Engineer, Project Central 10, BBMP BangaloreDocument2 pagesDate: 19.02.2020 CC Kerb Stone (Core) Test Report The Executive Engineer, Project Central 10, BBMP BangaloreVithun PoojaryNo ratings yet

- Soil Report Sec-155Document16 pagesSoil Report Sec-155Sandeep SainiNo ratings yet

- 32 Bitumen MasticDocument4 pages32 Bitumen MasticArul Mozhi VarmanNo ratings yet

- Slump Test: Sourse /location:: CC Pavement Grade of Concrete:: M30 Water Cement Ratio:: 0.45Document37 pagesSlump Test: Sourse /location:: CC Pavement Grade of Concrete:: M30 Water Cement Ratio:: 0.45ChManikumarNo ratings yet

- RH & UPV FORMAT CGPPDocument19 pagesRH & UPV FORMAT CGPPImran KhanNo ratings yet

- Permeability Test-Double Packer Test - Template01Document1 pagePermeability Test-Double Packer Test - Template01Mohammed AliNo ratings yet

- Geotechnical Laboratory Measurements For Engineers: Unconsolidated Undrained Triaxial Compression TestDocument5 pagesGeotechnical Laboratory Measurements For Engineers: Unconsolidated Undrained Triaxial Compression TestYusi SulastriNo ratings yet

- TH ND: 2) The Results Are Related To The Test Performed at Location Shown by ClientDocument16 pagesTH ND: 2) The Results Are Related To The Test Performed at Location Shown by Clientakshay kothiyalNo ratings yet

- Chloride Migration Test: NORDTEST METHOD (NT BUILD 492 Approved 1999-11)Document8 pagesChloride Migration Test: NORDTEST METHOD (NT BUILD 492 Approved 1999-11)Sreenath Menon K100% (1)

- Irc Gov in SP 078 2008Document16 pagesIrc Gov in SP 078 2008surendraNo ratings yet

- Cube Test ReportDocument1 pageCube Test ReportSurajit SahaNo ratings yet

- Nitobond AR Std.Document4 pagesNitobond AR Std.Dinesh Kumar PatelNo ratings yet

- Module 18Document81 pagesModule 18Hemant YesajiNo ratings yet

- Admixture Chemical Tests: Chloride Ion Concentration Test (Is:6925 - 1973)Document3 pagesAdmixture Chemical Tests: Chloride Ion Concentration Test (Is:6925 - 1973)Sudhir MishraNo ratings yet

- Test Method - Soil2Document25 pagesTest Method - Soil2jitendraNo ratings yet

- M 40 PQC With GGBS 340-60Document6 pagesM 40 PQC With GGBS 340-60Er Dnyaneshwar PatilNo ratings yet

- Per Bore Hole Quotation - OU PDFDocument2 pagesPer Bore Hole Quotation - OU PDFNeelaNo ratings yet

- Authorized Signatory Aditya Gandhi (Technical Manager)Document1 pageAuthorized Signatory Aditya Gandhi (Technical Manager)dhwaniNo ratings yet

- Shear TestDocument3 pagesShear TestRajesh Kumar SrivastavaNo ratings yet

- Report-L & T-ALH-163-R3-okDocument32 pagesReport-L & T-ALH-163-R3-okShubham MauryaNo ratings yet

- Consolidation Test Specimen DataDocument6 pagesConsolidation Test Specimen DataSyafrizal ThaherNo ratings yet

- Proposed Structure of AGL at Dakor, Kheda PDFDocument13 pagesProposed Structure of AGL at Dakor, Kheda PDFjay_p_shahNo ratings yet

- Bitumen Lab Test ChargesDocument7 pagesBitumen Lab Test ChargesRenga PandiNo ratings yet

- Splash Works Water Parks Core Test Report PDFDocument1 pageSplash Works Water Parks Core Test Report PDFJahid HasanNo ratings yet

- Mix Design of Cement GroutDocument4 pagesMix Design of Cement GroutjitendraNo ratings yet

- Testpit Lithological Log: Project: Coordinates: Client: Site InchargeDocument1 pageTestpit Lithological Log: Project: Coordinates: Client: Site InchargeP Allen Samuel IgnatiusNo ratings yet

- Concrete Methods of Test Fresh ConcreteDocument4 pagesConcrete Methods of Test Fresh Concretecevivekt0% (1)

- IS 1528 Part 4 (2010)Document11 pagesIS 1528 Part 4 (2010)Gopal100% (1)

- Nandpur Mairi Road M-15 Mix Design of ConcreteDocument8 pagesNandpur Mairi Road M-15 Mix Design of ConcreteAnkush PatialNo ratings yet

- List of NABL Accredited Labs PDFDocument47 pagesList of NABL Accredited Labs PDFAdarsh Kumar ManwalNo ratings yet

- Mix Design FormatDocument3 pagesMix Design FormatAkshay MitraNo ratings yet

- Summary of Revised Codes For Concrete in 2018Document4 pagesSummary of Revised Codes For Concrete in 2018Vijayakrishna SingamsettiNo ratings yet

- Is 5529 1 2013 PDFDocument27 pagesIs 5529 1 2013 PDFAbhishek KumarNo ratings yet

- Results of Compressive Strength of Concrete / Grout CubesDocument1 pageResults of Compressive Strength of Concrete / Grout CubesSABEASNNo ratings yet

- Test Report: M/S Pcil & MBPCL Joint VentureDocument7 pagesTest Report: M/S Pcil & MBPCL Joint VentureImran KhanNo ratings yet

- Evaluation of Pile Intergrity Using Cross Hole Sonic Logging TestDocument5 pagesEvaluation of Pile Intergrity Using Cross Hole Sonic Logging TestDayah MahadiNo ratings yet

- Mutual Coupling in Antenna ArraysDocument48 pagesMutual Coupling in Antenna ArrayshomeiraNo ratings yet

- Cyclo BBB PDFDocument124 pagesCyclo BBB PDFNguyenHuanNo ratings yet

- Molecular Weight Distribution of LigninDocument26 pagesMolecular Weight Distribution of Ligninsamiw75No ratings yet

- Cone Tolerance PDFDocument21 pagesCone Tolerance PDFsosu_sorin3904No ratings yet

- Angular Wave Functions 11Document16 pagesAngular Wave Functions 11Rajeev GangwarNo ratings yet

- Bond Graph Modeling of Two Stage Reciprocating Air CompressorDocument54 pagesBond Graph Modeling of Two Stage Reciprocating Air CompressorSagar BhaveNo ratings yet

- A9. Fractional-Slot Concentrated-Windings Synchronous Permanent Magnet Machines Opportunities and ChallengesDocument15 pagesA9. Fractional-Slot Concentrated-Windings Synchronous Permanent Magnet Machines Opportunities and Challengeswalidghoneim1970No ratings yet

- Modern Optics - Lecture2Document27 pagesModern Optics - Lecture2chpmahdi07No ratings yet

- Final Exam - 2017 PDFDocument7 pagesFinal Exam - 2017 PDFOlla 8352No ratings yet

- ED-I Internal Test 04.08.2021Document2 pagesED-I Internal Test 04.08.2021Sandesh KaradNo ratings yet

- 1 Drawing Feynman DiagramsDocument5 pages1 Drawing Feynman DiagramsLachlan MacphersonNo ratings yet

- Class 11-Phy-Vectors-NumericalsDocument7 pagesClass 11-Phy-Vectors-Numericalss.karthick5583No ratings yet

- 10th Class Physics Notes Short Questions Mcqs English MediumDocument35 pages10th Class Physics Notes Short Questions Mcqs English MediumUn Knowns100% (2)

- Inviscid FlowDocument65 pagesInviscid Flowgerry apriliantoNo ratings yet

- CEN 512 Pile Capacity Under Axial Load and MomentDocument2 pagesCEN 512 Pile Capacity Under Axial Load and MomentGrace SantiagoNo ratings yet

- TAP 321-2: Calculating The Wavelength in Two-Slit InterferenceDocument6 pagesTAP 321-2: Calculating The Wavelength in Two-Slit InterferenceKevin DonnellyNo ratings yet

- Me201: Mechanics of Solids: End Semester ExamDocument1 pageMe201: Mechanics of Solids: End Semester ExamMuzammil MuhammedNo ratings yet

- Basic Principles of Plates and SlabsDocument148 pagesBasic Principles of Plates and SlabsMarin MariusNo ratings yet

- Airy FunctionDocument6 pagesAiry Functionmenonita89No ratings yet

- Table D.1 Example: Gujarati: Basic Econometrics, Fourth Edition Back Matter Appendix D: Statistical TablesDocument1 pageTable D.1 Example: Gujarati: Basic Econometrics, Fourth Edition Back Matter Appendix D: Statistical TablesventurabragaNo ratings yet

- Electrical Power Systems: Mohamed Taha MouwafiDocument12 pagesElectrical Power Systems: Mohamed Taha MouwafiAHMED BAKRNo ratings yet

- Hadassa HidrociclonesDocument14 pagesHadassa HidrociclonesHadassa Cabral Ribeiro GrippNo ratings yet

- Advances in Quantum TheoryDocument260 pagesAdvances in Quantum Theorymbox1286593100% (1)