Professional Documents

Culture Documents

Charge Controller Circuit

Uploaded by

Singam SridharOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Charge Controller Circuit

Uploaded by

Singam SridharCopyright:

Available Formats

Project 1

Here is a schematic of the new charge controller circuit. Click on it for a larger, clearer version. I was careful to use only easy to find parts. The NE555 is probably the most popular IC in history. Billions of them are made every year. It should be easy to find just about anywhere in the world. I also switched to a 5 Volt regulator from the 8 Volt regulator the earlier version used. People were complaining they couldn't find it. The transistor is a 2N2222, NTE123, 2N3904, or other similar general purpose small NPN transistor. The MOSFET is an IRF540 or similar power MOSFET. I just happen to have a bunch of IRF540s on hand, left over from other projects. So I used one of them rather than buying something else. Use whatever you can find. All the resistors are 1/8 watt. 1/4 watt or higher resistors can be substituted if you don't have 1/8

Watt resistors. The two trimpots, R1 and R2, should ideally be multi-turn units, but ordinary single-turn units can be substituted, with a slight loss of precision in the tuning. I used 10K trimpots because I already had them on hand. Any value between 10K and 100K ought to work just fine. 10% tolerance is plenty good enough on all the passive components. There is no need for any precision parts in this circuit.

The relay is a general purpose SPDT automotive relay rated at 40 amps. It should be very easy to find. Get one from an auto parts store, or salvage one from a junked car in a scrap yard. I have included a pinout for the relay for ease of connection. 40 Amps may seem like overkill, but it allows for expansion in the future. You may start with only one small solar panel, then add a few more later, possibly a wind turbine, and a bigger battery bank. Eventually the charge controller will need to switch some serious current. Why not build in the capability from day one? All other parts are specified below.

Most of the parts can be purchased at your local Radio Shack. The rest of the parts can be found at auto parts stores, and online electronics suppliers like Digi-Key, Newark, etc. You might find the online suppliers to be much cheaper, especially if you plan on building several units and need multiples of each part. You could also try looking for deals on parts on Amazon.com. I buy my automotive relays on Ebay. Even with shipping it is cheaper than the auto parts store, and they are delivered right to my mail box. IC1 - 7805 5 Volt positive Voltage Regulator IC2 - NE555 Timer Chip PB1, PB2 - NO Momentary Contact Push Buttons LED1 - Green LED LED2 - Yellow LED RLY1 - 40 Amp SPDT Automotive Relay D1 - 1N4001 or similar R1, R2 - 10K Multi-Turn Trim-Pots R3, R4, R5 - 1K Ohm 1/8 Watt 10% R6 - 330 Ohm 1/8 Watt 10% R7 - 100 Ohm 1/8 Watt 10% Q1 - 2N2222 Or Similar NPN Transistor Q2 - IRF540 Or Similar Power MOSFET C1 - 0.33uF 35V 10% C2 - 0.1uF 35V 10%

Once I had the prototype working on the breadboard, I built another unit on a piece of Radio Shack Protoboard for use in the field. It came together in only a couple of hours, and again, worked the first time (I must be living right lately). This more rugged version will get mounted in a box and given a thorough testing in the field. Note that on this board I have chosen to use the 78L05 version of the 5 Volt regulator. It is in a tiny TO92 package, the same size as the 2N2222 transistor. It is the small, black rectangle on the upper left corner of the board. It saves a lot of board space. It can only handle 100 mA, but that is plenty enough to power this circuit. If you can't find the little 78L05, you can use the full size TO-220 version of the 7805, which is much more common. There will be no penalty other than using up a little more board real estate. I just happened to have a few of the 78L05s left over from another project.

Once you have the circuit built, it is time to tune or calibrate it. I use 11.9V and 14.9V as my low and high set points for the controller. These are the points where it switches from sending power to the batteries to dumping power into a dummy load, and vice versa (a dummy load is only needed if you are using a wind turbine, if using only solar panels, the dummy load line can be left open). Probably the best way to tune the circuit is to attach a variable DC power supply to the battery terminals. Set the power supply to 11.9V. Measure the voltage at Test Point 1. Adjust R1 until the voltage at the test point is as close to 1.667V as you can get it. Now set your variable power supply to 14.9V and measure the voltage at Test Point 2. Adjust R2 until the voltage at the test point is as close to 3.333V as you can get it. Test the operation of the charge controller by running the input voltage up and down between about 11.7 and 15.1 Volts. You should hear the relay pull in at about 14.9 Volts and open at about 11.9 Volts. In between the two set points the controller should stay in whichever state it is in. The Charge and Dump buttons can be used to change the state of the controller when the input Voltage is between the two set points. Before you write to me and tell me that my lower set point is too low and I am over-discharging my batteries, consider that the battery voltage isn't normally going to get that low except under

load. If the load were removed, the voltage would recover over time back up to well over 12V. So the batteries aren't as deeply discharged as you might think at first glance. Once I had the circuit working, I mounted it inside a semi-weatherproof enclosure. The relay is on the left side. I used a barrier strip to make wiring everything together easier. I used heavy gage wire for all the high-current connections. This thing was designed to switch up to 40 Amps after all. I also included a fuse in line with the solar/wind input line. Click on the image for a larger view.

Here is another view with the lid in place. I used this enclosure because I happened to already have it on hand, not because it is the best one for the job. For permanent outdoor use I would prefer to use a more rugged and weather-proof enclosure like I did for my original charge controller design. However, I like the fact that I can see the LEDs through the translucent lid and tell which state the charge controller is in at a glance, and I didn't have to drill any extra holes in the box for the LEDs. This box will work for field testing purposes. Click on the image for a larger view.

Here is a side view of the unit showing the feedthrough barrier strip with all the connections to the outside. There are connections for the positive side of the battery(s), the positive input from a solar panel or wind turbine, the positive side of an optional dummy load, and three ground connections. When hooking up the charge controller, the battery should be connected first. That way the electronics will have a stable source of power. If a solar panel or wind turbine is connected first, the controller is liable to wildly oscillate between states. I should explain about dummy loads. The type of wind turbines I build have no real provision for braking or furling in high winds. It is only the presence of a constant load on them that prevents them from over-reving in high winds. So when the charge controller senses that the batteries are fully charged and switches them out of the circuit, it switches in a dummy load (just a big external bank of high-wattage resistors) to soak up the power output of the wind turbine and keep it under load. If you are using a commercially made wind turbine with built-in over-rev protection, or using only solar panels, then the dummy load isn't necessary and you can leave the dummy line unconnected. You can learn more about dummy loads on my wind turbine page.

Here is another side view showing the charge and dump buttons. The charge controller will automatically switch between charge and dump when the battery voltage reaches the low and high set points. Between the set points the controller will remain in whichever state it is in. These buttons allow me to manually toggle the charge controller between the two states.

dumping Click

power on

so the

as

not photo

to

over-charge for a

Here is a photo of the first real field test of the new charge controller design. It seemed to be working good in my bench tests, but I wanted to make sure it worked right under realworld conditions. So I set up one of my home-made 60 Watt solar panels outside my workshop and used it to charge up a deep-cycle battery using the new charge controller. It worked great. The charge controller let power run into the battery until it was fully charged and then switched to the battery. Perfect! larger version.

highly

successful

Here is a closer photo of the setup. The battery is a 36 AH deep-cycle unit often used in personal mobility scooters and motorized wheel chairs. I find that they work well in small-scale wind and solar power systems. The Volt meter is showing 12.64 volts on the battery, which is essentially fully charged. The battery was nearly fully charged when I started this test. It took only a short time for the solar panel to top it off and the charge controller to switch over to dumping. A test.

The only issue I had during the test was seeing which of the LEDs was on in the bright sunlight.

In normal use though the charge controller would be mounted in a sheltered and shady spot out of the direct sunlight.

Project 2

ou need a regulator circuit to ensure that the voltage output never goes above 14V (a good 12V battery charging rule of thumb) and that current never travels back from the battery into the solar panel at night. I nabbed the following circuit (used without permission, sorry) from ETI and built it.

This regulator circuit achieves 3 things: battery cannot discharge into the panel, panel voltage can never go above 14.3V and even when the panel voltage output is as low as 6-7 volts it is still capable of charging a 12V battery. Here's my personal quick rundown of the circuit:

D3 stops current from flowing out of the battery and back into the circuit. Cost is a continous 0.7V off the top of the operating voltage (from using a didode) but it's the only way. ZD2 clamps the voltage at 14.3V (ie 15-0.7 of D3). If the batteries are fully charged the solar panel will try to bring them above 14.3V. Instead of that juice cooking the batteries it is burned off as heat in the 5W rated zener. Yep, it gets hot, potentially useful solar power is wasted to nothing. You get that. Pretty much the rest of the circuit is a capacitive doubling charge pump into C4. The 555 hard switches Q1 at T= (R2+R3)*C2 = 3.1kHz. Looking at the arrangement of C3, D1,

D2 and C4 you can see when Q1 is on the negative plate of C3 is held close to ground and thus charges up to close to Vcc via D1. C4 also charges up to close to Vcc. Now when Q1 turns off the negative plate of C3 is forced to Vcc through R5 but it still has a charge of Vcc across it. Because of D1 does not allow current back to Vcc, C4 now has 2xVcc across it, and thus the voltage is doubled. Now this will find a stable level at the battery voltage but you can see that if Vcc drops to 6-7 volts (ie a cloud goes across the panel) the output on the battery is still 12-14V. This is a nice feature, without it any solar panel output below the battery voltage would have no effect - but in this case that voltage is still useful. As you can see I grabbed a couple of meters and "neatly" mounted them on a bit of placcy. I'd pefer it to be continuously logging data to my PC, but for now an instantaneous readout was fine.

Readout pictured was 0.2A @ 14V = 2.8W. Best I've seen is 0.32 @ 13.8V = 4.4W. I calculated the loss due to the regulator at 0.4W. A couple of old car batteries lying around serve as the "battery bank". Car batteries are *not* suitable for solar sites. Car batteries do not like to be flattened, in fact they don't even like losing any charge. What you want are batteries that don't mind a deep cycle. Specially made lead acid batteries such as marine and gelcels can handle many deep cycles; where a deep cycle is defined as 50% charge used. Anything less is detrimental to the battery's health. Nicads/ NiMH/ etc are much more suited as they actually don't mind being fully flattened - due in part to the fact that they do not consume the anode. However a better way of using solar power is to not use batteries at all - for example solar water pumping. For now they are keeping the first spinoff solar project alive - the solar guitar amp.

Parallel those old car batteries...

Project 3

You might also like

- MID Question PaperDocument5 pagesMID Question PaperSingam SridharNo ratings yet

- Improve Power Quality With Mitigation TechniquesDocument171 pagesImprove Power Quality With Mitigation TechniquesSingam Sridhar80% (15)

- Sustainability 11 05355 v2Document24 pagesSustainability 11 05355 v2Singam SridharNo ratings yet

- LicenseDocument1 pageLicenseSingam SridharNo ratings yet

- Inverter Applications: - Motor DrivesDocument49 pagesInverter Applications: - Motor DrivesrajapeeeNo ratings yet

- Power Quality Presentation SingamDocument368 pagesPower Quality Presentation SingamSingam SridharNo ratings yet

- Mewar University Chittorgarh Ph.D. Program Guidelines: S. No. Stage Standard Operating Procedures Frequency StageDocument3 pagesMewar University Chittorgarh Ph.D. Program Guidelines: S. No. Stage Standard Operating Procedures Frequency StageSingam SridharNo ratings yet

- Energy Devices – The wind (Lecture 4Document8 pagesEnergy Devices – The wind (Lecture 4MarcLinigerNo ratings yet

- Teaching Styles For Teaching EffectivenessDocument6 pagesTeaching Styles For Teaching EffectivenessSingam SridharNo ratings yet

- Design and Analysis of A Low Cost VI Analyzer Using Arduino UNO and Matlab Interface For A Buck ConverterDocument1 pageDesign and Analysis of A Low Cost VI Analyzer Using Arduino UNO and Matlab Interface For A Buck ConverterSingam SridharNo ratings yet

- Detection of Driver Drowsiness Using Eye Blink SensorDocument10 pagesDetection of Driver Drowsiness Using Eye Blink SensorSingam SridharNo ratings yet

- World's Largest Science, Technology & Medicine Open Access Book PublisherDocument19 pagesWorld's Largest Science, Technology & Medicine Open Access Book PublisherSingam SridharNo ratings yet

- Msp430G2553 Launchpad™ Development Kit (MSP Exp430G2Et) : User'S GuideDocument26 pagesMsp430G2553 Launchpad™ Development Kit (MSP Exp430G2Et) : User'S GuideSingam SridharNo ratings yet

- Design and Analysis of A Low Cost VI Analyzer Using Arduino UNO and Matlab Interface For A Buck ConverterDocument1 pageDesign and Analysis of A Low Cost VI Analyzer Using Arduino UNO and Matlab Interface For A Buck ConverterSingam SridharNo ratings yet

- Creating Graphical User Interfaces (GUI's) With Matlab: by Jeffrey A. Webb OSU Gateway Coalition MemberDocument44 pagesCreating Graphical User Interfaces (GUI's) With Matlab: by Jeffrey A. Webb OSU Gateway Coalition MemberSingam SridharNo ratings yet

- Control Robot Motion Using Bluetooth & Android AppDocument1 pageControl Robot Motion Using Bluetooth & Android AppSingam SridharNo ratings yet

- Sample Course Overview - TemplateDocument2 pagesSample Course Overview - TemplateSingam SridharNo ratings yet

- EcrDocument36 pagesEcrSingam SridharNo ratings yet

- Msp430intro 170625172931 PDFDocument40 pagesMsp430intro 170625172931 PDFSingam SridharNo ratings yet

- ASSIGNMENTDocument2 pagesASSIGNMENTSingam SridharNo ratings yet

- Hve Unit test-IIDocument1 pageHve Unit test-IISingam SridharNo ratings yet

- Msp430intro 170625172931 PDFDocument40 pagesMsp430intro 170625172931 PDFSingam SridharNo ratings yet

- Syllabus JntuhDocument2 pagesSyllabus JntuhSingam SridharNo ratings yet

- 03 Chapter1Document6 pages03 Chapter1Singam SridharNo ratings yet

- Test of Robo: MajorDocument4 pagesTest of Robo: MajorSingam SridharNo ratings yet

- FINAL LabDocument4 pagesFINAL LabSingam SridharNo ratings yet

- Energy 2Document12 pagesEnergy 2Bertram Nirmal PhilipNo ratings yet

- Genie NX1Document2 pagesGenie NX1Singam SridharNo ratings yet

- Msp430intro 170625172931 PDFDocument40 pagesMsp430intro 170625172931 PDFSingam SridharNo ratings yet

- IMPRINT II C Technology Development ThemesDocument4 pagesIMPRINT II C Technology Development ThemesSingam Sridhar0% (1)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Dreams PDFDocument8 pagesDreams PDFapi-266967947No ratings yet

- RUN ON SENTENCES AND FRAGMENTS GUIDEDocument17 pagesRUN ON SENTENCES AND FRAGMENTS GUIDEWAHEED-UL -ISLAMNo ratings yet

- Sanjay Chandra Vs Cbi On 23 November, 2011Document21 pagesSanjay Chandra Vs Cbi On 23 November, 2011SaiBharathNo ratings yet

- Ds Mini ProjectDocument12 pagesDs Mini ProjectHarsh VartakNo ratings yet

- Pan AfricanismDocument12 pagesPan AfricanismOscar MasindeNo ratings yet

- 1.MIL 1. Introduction To MIL Part 2 Characteristics of Information Literate Individual and Importance of MILDocument24 pages1.MIL 1. Introduction To MIL Part 2 Characteristics of Information Literate Individual and Importance of MILBernadette MendozaNo ratings yet

- Logic and Its Metatheory: Instructor InformationDocument6 pagesLogic and Its Metatheory: Instructor InformationMarco StoroniMazzolani Di MaioNo ratings yet

- Perspective in PharmacyDocument3 pagesPerspective in PharmacyAgniez Hannah Permites100% (4)

- Gauteng Grade 6 Maths ExamDocument14 pagesGauteng Grade 6 Maths ExamMolemo S MasemulaNo ratings yet

- Seismic Aspects of Dam Design PDFDocument12 pagesSeismic Aspects of Dam Design PDFAlokNo ratings yet

- ICT File Management ExerciseDocument3 pagesICT File Management ExercisebrightonNo ratings yet

- Xerox 6030 PDFDocument663 pagesXerox 6030 PDFРумен ИвановNo ratings yet

- Netscaler 10 With Citrix Triscale™ Technology: Download This SlideDocument40 pagesNetscaler 10 With Citrix Triscale™ Technology: Download This SlidePhong TrầnNo ratings yet

- Tango With DjangoDocument191 pagesTango With DjangoZachary JamesNo ratings yet

- Vector DifferentiationDocument2 pagesVector DifferentiationJayashree MisalNo ratings yet

- Relación Entre Séneca y MaquiaveloDocument14 pagesRelación Entre Séneca y MaquiaveloJuan Pablo TorresNo ratings yet

- SAP Training Program Proposal for StudentsDocument2 pagesSAP Training Program Proposal for StudentsAjay KumarNo ratings yet

- Conquest of The Americas (Eakin-2002)Document81 pagesConquest of The Americas (Eakin-2002)GregNo ratings yet

- ICTMS 2013 - Program ScheduleDocument3 pagesICTMS 2013 - Program ScheduleSantanu DasNo ratings yet

- Sic 789 ADocument19 pagesSic 789 AFlorinMacoveiNo ratings yet

- English (Step Ahead)Document33 pagesEnglish (Step Ahead)ry4nek4100% (1)

- Ablutophobia Fear of Bathing and HomoeopathyDocument8 pagesAblutophobia Fear of Bathing and HomoeopathyDr. Rajneesh Kumar Sharma MD Hom100% (1)

- Chapter 8Document3 pagesChapter 8sasafoadjeiNo ratings yet

- A History Analysis and Performance Guide To Samuel Barber?Document117 pagesA History Analysis and Performance Guide To Samuel Barber?giorgio planesioNo ratings yet

- Irish Chapter 6 Causes of DeathDocument8 pagesIrish Chapter 6 Causes of DeathIrish AlonzoNo ratings yet

- Unit 1 DinosaurDocument5 pagesUnit 1 DinosaurAnamika ShabnamNo ratings yet

- The Bible in Picture and Story (1889)Document250 pagesThe Bible in Picture and Story (1889)serjutoNo ratings yet

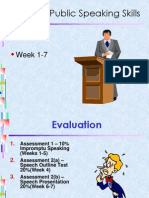

- TOPIC 1 - Public Speaking SkillsDocument72 pagesTOPIC 1 - Public Speaking SkillsAyan AkupNo ratings yet

- E-Portfolio Rubric For HHS4C: Criteria Level 1 Level 2 Level 3 Level 4 Overall Expectation ADocument4 pagesE-Portfolio Rubric For HHS4C: Criteria Level 1 Level 2 Level 3 Level 4 Overall Expectation Aapi-312895913No ratings yet