Professional Documents

Culture Documents

M11 - 9 - Feedlip Kit Installation Instructions

Uploaded by

browar444Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

M11 - 9 - Feedlip Kit Installation Instructions

Uploaded by

browar444Copyright:

Available Formats

STAINLESS STEEL FEEDLIP INSTALLATION INSTRUCTIONS

M-11/9 ZYTEL MAGAZINE

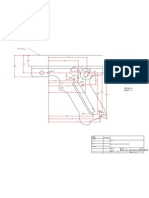

This procedure requires average skills. Read instructions completely before proceeding. In general the procedure is to clean and abrade the magazine, apply epoxy to one side and affix one feedlip, clamp, clean excess epoxy and let dry for 4 hours before proceeding with the other feedlip. Be patient, take your time and you will end up with a high quality, reliable, trouble-free magazine. NOTE: It is very important to use the J-B WELD epoxy specified below. This epoxy meets the strength and temperature range required. Using a different adhesive may result in failure of the inserts to adhere to the magazine during operation. Tools and materials: J-B WELD two part epoxy, part no. 8265-S Isopropyl Alcohol Stiff Toothbrush Paper Towel 80 grit emery paper 220 grit wet/dry sand paper Craft Sticks/Popsicle Stick for mixing Flat toothpicks 1" C-clamp Mixing container Procedure: 1) 2) 3) 4) Disassemble magazine. Remove baseplate, spring and follower. Thoroughly clean feedlip area with alcohol and toothbrush. Wipe area with a paper towel and insure magazine is dry. Abrade magazine feedlips with 80 grit emery paper in areas shown in Figure 1. Wrapping emery paper around craft stick for use as a file may help abrade inside magazine. Thoroughly clean feedlip area with alcohol and toothbrush to remove sanding dust and debris. Abrade both metal feedlips with 80 grit emery paper in area to be epoxied. Clean metal feedlips with alcohol and dry. Mix two part epoxy. Dispense equal parts of epoxy in a mixing container. Only dispense enough required for one feed lip. Only a dab is required. Using a craft stick, mix thoroughly! Take your time mixing, the epoxy takes a while to start to set. Liberally apply epoxy to one side of the magazine feedlips abraded in step 4.

FIGURE 1

5) 6) 7) 8)

FIGURE 2

9)

10) Position one feedlip and clamp with a 1" c-clamp as shown in figure 2. Insure the top of the feedlip is pressed flush with the top of the magazine while tightening. Use enough pressure on the c-clamp to firmly hold the feedlip, but make sure you do not crush or deform the magazine. Epoxy should seep out from the edges. 11) Using a toothpick, carefully remove excess epoxy. 12) Let cure for 4 hours minimum. 13) Remove c-clamp. 14) Repeat steps 8 through 13 for the other side. 15) Using 80 grit emery paper, carefully remove any remaining epoxy protrusions, internally and externally. 16) Using 220 grit wet/dry sanding paper, wet sand metal feedlips and surrounding epoxy to magazine junction. 17) Clean with alcohol and toothbrush and dry. 18) Reassemble magazine.

Manufacturer and/or Seller assume no liability for this product or its use. Keep out of reach of children. Kit contains small parts that pose a choking hazard. No warranty is implied or stated. Installer assumes all liabilities for any damages to firearm, property or persons. This is not a factory installed component.

You might also like

- STAINLESS STEEL FEEDLIP INSTALLATIONDocument1 pageSTAINLESS STEEL FEEDLIP INSTALLATIONJorge Mercado NajeraNo ratings yet

- JT 59 PDFDocument2 pagesJT 59 PDFAndone AnutuNo ratings yet

- Sika AnchorFix 1 PDSDocument8 pagesSika AnchorFix 1 PDSSkerdi MucoNo ratings yet

- Fiber Optic Cable TerminationDocument16 pagesFiber Optic Cable TerminationStephenNo ratings yet

- Carbon Fibre Skinning Starter KitDocument8 pagesCarbon Fibre Skinning Starter KitcraigbonnymanNo ratings yet

- Epoxy Application GuideDocument24 pagesEpoxy Application GuideAhmed Emad AhmedNo ratings yet

- Fi - SCST Multimode Singlemode Connector - II PDFDocument4 pagesFi - SCST Multimode Singlemode Connector - II PDFmirkofedorNo ratings yet

- Thin Section CookbookDocument5 pagesThin Section CookbookTara QuitiLen OngNo ratings yet

- Advent 200 Manual 2005Document20 pagesAdvent 200 Manual 2005Cristian Pedraza Beltran100% (1)

- Introduction To 8 Inc Pressure VesselsDocument23 pagesIntroduction To 8 Inc Pressure VesselsAckmonNo ratings yet

- KAYAK MAINTENANCE AND REPAIR GUIDEDocument5 pagesKAYAK MAINTENANCE AND REPAIR GUIDEScott NelsonNo ratings yet

- Conley Corporation Fabrication Seminar Trainee Sign-Off SheetDocument3 pagesConley Corporation Fabrication Seminar Trainee Sign-Off SheetDieguitoOmarMoralesNo ratings yet

- Jewelry Box: Woodworks: Beginner Project 2009-2010Document7 pagesJewelry Box: Woodworks: Beginner Project 2009-2010Sal GNo ratings yet

- Tender "Fritz": PlansDocument15 pagesTender "Fritz": Plansİspir YazılımNo ratings yet

- How To Install The Insert: Alpha Q Tutorial Bert Hull Feb 8, 2005Document9 pagesHow To Install The Insert: Alpha Q Tutorial Bert Hull Feb 8, 2005prasannam407No ratings yet

- Epoxy ResinDocument7 pagesEpoxy ResinAtiq JamNo ratings yet

- Grain Structure Observation of Mild SteelDocument8 pagesGrain Structure Observation of Mild SteelAshok ChowdaryNo ratings yet

- Grain Structure Observation of Mild SteelDocument8 pagesGrain Structure Observation of Mild SteelAshok ChowdaryNo ratings yet

- Interzone 101Document0 pagesInterzone 101hennawijayaNo ratings yet

- Sikadur AnchorFix-1Document3 pagesSikadur AnchorFix-1Adam GreenlawNo ratings yet

- Alfa Laval Regasketing Plares HeatersDocument9 pagesAlfa Laval Regasketing Plares Heatersvaleriy100% (1)

- Rocket Motor Construction TutorialDocument19 pagesRocket Motor Construction TutorialAzher Uddin100% (1)

- Nitobond Ep..Document4 pagesNitobond Ep..budhikurniawanNo ratings yet

- Durapipe ABS Jointing Instructions.Document2 pagesDurapipe ABS Jointing Instructions.Stuart GoodswenNo ratings yet

- Republic of the Philippines Materials and Engineering Lab ManualDocument40 pagesRepublic of the Philippines Materials and Engineering Lab ManualBenjie flor CalayegNo ratings yet

- Mould Making Kit (For Use With Carbon Fibre)Document7 pagesMould Making Kit (For Use With Carbon Fibre)eyewired2000100% (1)

- 55 Watt Gas CO2 Laser TubeDocument66 pages55 Watt Gas CO2 Laser TubeFitzwalter100% (1)

- Cerakote Training ManualDocument21 pagesCerakote Training ManualJames Ó CuinneagainNo ratings yet

- GAP-015 - Rev D (2015 - 06 - 02 18 - 24 - 57 UTC)Document2 pagesGAP-015 - Rev D (2015 - 06 - 02 18 - 24 - 57 UTC)Epuran Liviu100% (2)

- Canoe Plans Part 2Document20 pagesCanoe Plans Part 2cockybundooNo ratings yet

- Pentax 240 OPCDocument4 pagesPentax 240 OPCOswaldo nuñezNo ratings yet

- Carbon Fibre Fishing Pole Repair Kit InstructionsDocument4 pagesCarbon Fibre Fishing Pole Repair Kit InstructionsdaveagriffNo ratings yet

- DL50 Discus Launch GliderDocument16 pagesDL50 Discus Launch GliderAri SutiknoNo ratings yet

- TDS - R FlexDocument2 pagesTDS - R FlexDivyanshu GuptaNo ratings yet

- Grout AlternatesDocument2 pagesGrout AlternatesAnonymous ua66zYwrpNo ratings yet

- Postand Core ProtocolDocument4 pagesPostand Core ProtocolDontoNo ratings yet

- Modellherstellungsfibel en PDFDocument45 pagesModellherstellungsfibel en PDFcontinentdriftNo ratings yet

- Intermediate Project Charging StationDocument6 pagesIntermediate Project Charging StationGultainjeeNo ratings yet

- Jazeera Anti-Skid EpoxyDocument3 pagesJazeera Anti-Skid EpoxyAhmad BougeisNo ratings yet

- DevCon 5 Minute Epoxy Technical Data SheetDocument2 pagesDevCon 5 Minute Epoxy Technical Data Sheetjohn432questNo ratings yet

- Nitobond EP : Constructive SolutionsDocument4 pagesNitobond EP : Constructive SolutionsmilanbrasinaNo ratings yet

- Vacuum Chuck InstructionsDocument1 pageVacuum Chuck Instructionsapi-52301964No ratings yet

- C&B Impression Materials Classification & TechniquesDocument7 pagesC&B Impression Materials Classification & TechniquesruchikaNo ratings yet

- CarbonFiberHowTo2 PDFDocument20 pagesCarbonFiberHowTo2 PDFSolidWorksNo ratings yet

- T2 Global-CP03-C&S-MSB-XX-019941-B - W0 - T0 - 12974-3Document7 pagesT2 Global-CP03-C&S-MSB-XX-019941-B - W0 - T0 - 12974-3Areaya mahetemNo ratings yet

- Bostik 1782 - TDSDocument3 pagesBostik 1782 - TDSZack AsentistaNo ratings yet

- Technical Data Epoxy Tile GroutDocument2 pagesTechnical Data Epoxy Tile GroutMeliany SariNo ratings yet

- Ceramic resin shop primer protects steel from corrosionDocument2 pagesCeramic resin shop primer protects steel from corrosionTrịnh Minh KhoaNo ratings yet

- Pinholehasselblad PDFDocument8 pagesPinholehasselblad PDFYanina Arizaga80% (5)

- Section Cutting and Staining: A practical introduction to histological methods for students and practitionersFrom EverandSection Cutting and Staining: A practical introduction to histological methods for students and practitionersNo ratings yet

- Family Handyman Quick & Easy ProjectsFrom EverandFamily Handyman Quick & Easy ProjectsFamily HandymanNo ratings yet

- The Nail technician’s Career Guide - The blueprint to a successful nail salon businessFrom EverandThe Nail technician’s Career Guide - The blueprint to a successful nail salon businessNo ratings yet

- Fantastic Origami Sea Creatures: 20 Incredible Paper ModelsFrom EverandFantastic Origami Sea Creatures: 20 Incredible Paper ModelsRating: 2.5 out of 5 stars2.5/5 (3)

- Fantastic Origami Flying Creatures: 24 Amazing Paper ModelsFrom EverandFantastic Origami Flying Creatures: 24 Amazing Paper ModelsRating: 5 out of 5 stars5/5 (3)

- M 1911 A 1Document62 pagesM 1911 A 1Michael C. Burgess88% (16)

- Mechanism of Action of Presynaptc Neurotoxins. Annual Report 1985 PDFDocument34 pagesMechanism of Action of Presynaptc Neurotoxins. Annual Report 1985 PDFbrowar444No ratings yet

- A 518298Document19 pagesA 518298browar444No ratings yet

- Firearms - Blueprint - Owen MK II, H&R Reising Submachine Guns and Springfield M60 RifleDocument12 pagesFirearms - Blueprint - Owen MK II, H&R Reising Submachine Guns and Springfield M60 Riflebrowar44484% (19)

- Firearms - Blueprint - Ruger 10-22 Rifle Receiver 2Document1 pageFirearms - Blueprint - Ruger 10-22 Rifle Receiver 2browar444100% (2)

- Stinger Rifles FamilyDocument7 pagesStinger Rifles Familybrowar44467% (9)

- MAC 10 CookbookDocument90 pagesMAC 10 Cookbookbrowar44472% (32)

- Ruger 10-22 Rifle Receiver 1 - BlueprintDocument1 pageRuger 10-22 Rifle Receiver 1 - BlueprintAride4ever100% (2)

- UZI SMG ReceiverDocument7 pagesUZI SMG Receiverbrowar444100% (6)

- 223 Silencer DesignDocument1 page223 Silencer DesignFlavio MarçalNo ratings yet

- Post-14-01138-M 14 Receiver Ordnance PrintsDocument5 pagesPost-14-01138-M 14 Receiver Ordnance PrintsJustus Pradana AdityawanNo ratings yet

- Home Workshop - Vol 5 - AR-15, M-16 - Bill Holmes - Paladin Press PDFDocument110 pagesHome Workshop - Vol 5 - AR-15, M-16 - Bill Holmes - Paladin Press PDFCarlaAndrade100% (2)

- Beretta 38A 38-44 SMG Receiver BlueprintDocument1 pageBeretta 38A 38-44 SMG Receiver Blueprinth762x39100% (3)

- PPSH41 Assault Rifle BlueprintDocument12 pagesPPSH41 Assault Rifle Blueprinth762x3992% (12)

- UZI ReceiverDocument7 pagesUZI Receiverbrowar444No ratings yet

- SVT40 ManualDocument23 pagesSVT40 Manualandy2205No ratings yet

- Metal Casting Basics Book 1Document57 pagesMetal Casting Basics Book 1browar444100% (1)

- Machinist Drawings For SMG Frames - MAC10, MAC11, Cobray M11-9, CobrayM12Document13 pagesMachinist Drawings For SMG Frames - MAC10, MAC11, Cobray M11-9, CobrayM12Aride4ever89% (73)

- TM-9-1005-301-30 Repair Wood Fibre Plastic Components of Weapons Part1Document19 pagesTM-9-1005-301-30 Repair Wood Fibre Plastic Components of Weapons Part1browar444No ratings yet

- Spring RatingDocument6 pagesSpring Ratingbrowar444No ratings yet

- Full Auto Volume Three Semi Auto Mac 10 SMG Modification ManualDocument29 pagesFull Auto Volume Three Semi Auto Mac 10 SMG Modification ManualJerry Becraft85% (13)

- Ruger Mk1 Right Side Grip FrameDocument1 pageRuger Mk1 Right Side Grip Framebrowar444No ratings yet

- Ruger Mk1 Grip Frame Left SideDocument1 pageRuger Mk1 Grip Frame Left Sidebrowar444100% (1)

- TM-9-1005-301-30 Repair Wood Fibre Plastic Components of Weapons Part2Document18 pagesTM-9-1005-301-30 Repair Wood Fibre Plastic Components of Weapons Part2browar444No ratings yet

- Shotgun Based Pistol BlueprintDocument6 pagesShotgun Based Pistol BlueprintGonzoGranello0% (1)

- Metal Casting Basics Book 2Document67 pagesMetal Casting Basics Book 2browar444100% (2)

- MAC-11 9mm Construction Conversion Iron Wulf PublishingDocument86 pagesMAC-11 9mm Construction Conversion Iron Wulf PublishingJordan Voller100% (5)

- Mac-10 SMG Lower-Upper Receiver - BlueprintsDocument2 pagesMac-10 SMG Lower-Upper Receiver - Blueprintsbrowar44489% (9)

- Ruger Mk1 Grip Frame Left Hole DetailDocument1 pageRuger Mk1 Grip Frame Left Hole Detailbrowar444100% (1)

- Nangant Pistol HistoryDocument67 pagesNangant Pistol Historygorlan100% (1)

- Motori Industriali Serie ASC Da 160 A 315mmDocument52 pagesMotori Industriali Serie ASC Da 160 A 315mmdungga1No ratings yet

- SW - Animal-Spec-GuideDocument20 pagesSW - Animal-Spec-GuideMohindra PersadNo ratings yet

- Luxepoxy STL: Solventless Epoxy Tank Lining PC 246Document2 pagesLuxepoxy STL: Solventless Epoxy Tank Lining PC 246livefreakNo ratings yet

- Painting Coating Selection Guide PDFDocument1 pagePainting Coating Selection Guide PDFNageswara Rao BavisettyNo ratings yet

- Technomelt LoctiteDocument16 pagesTechnomelt LoctitePanya PurahongNo ratings yet

- Iclp 2016LPofCFRPID256Document9 pagesIclp 2016LPofCFRPID256daniel govantesNo ratings yet

- Epoxy Catalogue 2007 PDFDocument24 pagesEpoxy Catalogue 2007 PDFbreno_gcNo ratings yet

- Intercure 420: Rapid Recoat EpoxyDocument4 pagesIntercure 420: Rapid Recoat EpoxyA. FauziNo ratings yet

- 2374 - Technical Specification of Flooring Works PDFDocument17 pages2374 - Technical Specification of Flooring Works PDFKarthikeyan PanchatcharamNo ratings yet

- 3m IATD CatalogueDocument25 pages3m IATD Catalogueapi-3725857100% (2)

- Engineering GuideDocument34 pagesEngineering GuideNandhakumaran RajagopalanNo ratings yet

- Gandhinagar Road & Bridge Sor 2011-2012Document58 pagesGandhinagar Road & Bridge Sor 2011-2012Zankar R ParikhNo ratings yet

- Vol VII - PG B0 2 - Corrosion Protection and PaintingDocument27 pagesVol VII - PG B0 2 - Corrosion Protection and PaintingSameer khanNo ratings yet

- External - PDSDocument10 pagesExternal - PDSfaisalfaiNo ratings yet

- Silquest Silanes Selector and Handling GuideDocument11 pagesSilquest Silanes Selector and Handling GuideAmit KumarNo ratings yet

- ReArm Bond EBADocument2 pagesReArm Bond EBARajesh GiriNo ratings yet

- Composite - Design ProjectDocument6 pagesComposite - Design ProjectSomen DasNo ratings yet

- United States Patent (19) 11 Patent Number: 5,985,454Document10 pagesUnited States Patent (19) 11 Patent Number: 5,985,454KatNo ratings yet

- Chapter 1 Final DefenseDocument10 pagesChapter 1 Final DefenseasdfghjklNo ratings yet

- Loctite MaintenanceDocument44 pagesLoctite MaintenancemmkattaNo ratings yet

- Guentner Material Selection 2011 EnglishDocument8 pagesGuentner Material Selection 2011 EnglishHoang100% (1)

- Pultrusion Process - Composite ManufacturingDocument25 pagesPultrusion Process - Composite ManufacturingChetan100% (8)

- Composite Materials Journal of ThermoplasticDocument12 pagesComposite Materials Journal of ThermoplasticMehmet ÖzdemirNo ratings yet

- Jotachar JF750Document17 pagesJotachar JF750samet çelikNo ratings yet

- Epo-Tek H20eDocument2 pagesEpo-Tek H20edigiarkanandNo ratings yet

- 3M Infrastructure Coating - EMD Overview For Indonesia TeamDocument38 pages3M Infrastructure Coating - EMD Overview For Indonesia TeamYohanes Dimas PriambodhoNo ratings yet

- Aqua Epoxy PDFDocument2 pagesAqua Epoxy PDFAhKimNo ratings yet

- Document PDFDocument134 pagesDocument PDFOoj GenNo ratings yet

- EP2620419A1 - Polyamide Based Sizing Composition For Glass Fibres - Google PatentsDocument9 pagesEP2620419A1 - Polyamide Based Sizing Composition For Glass Fibres - Google Patentsمهدی عارفخانیNo ratings yet

- Compression and Injection Molding Techniques For Natural Fiber CompositesDocument17 pagesCompression and Injection Molding Techniques For Natural Fiber CompositesRakesh KanakamNo ratings yet