Professional Documents

Culture Documents

RM Silo Ocp3

Uploaded by

Mahata PriyabrataOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RM Silo Ocp3

Uploaded by

Mahata PriyabrataCopyright:

Available Formats

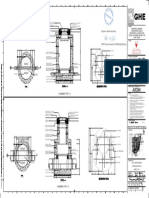

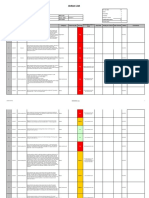

Design of Raw Meal Silo Based on BS EN 1991-4:2006 for Obajana Cement Line 3, Nigeria

1. Material =

Raw Meal

2. Weight of Material Stored in Storage Silo

3. Thickness of RCC Wall of Storage Silo

4. Average thickness of Top Slab of Silo

5. thickness of Inverted Cone

=

=

=

400

150

500

EL. of Flat Slab Btoom above GL

EL. of Top of Top Slab above GL

Max. Level of Filling below Silo Top

Height of av. Material Storage from Flat Slab

Internal Diameter of Storage silo

D

Angle of Repose

fr

12. Mean Angle of Internal Friction

fm

=

=

=

=

=

=

21.02

70.00

0.15

46.18

22.5

25

25

13. Slenderness Ratio (hc / dc)

2.05

14. Silo Type

15. Temperature of Hot Material inside

Ti

= Slender silo

=

120 oC

16. Temperature of Outside Atmosphere

T0

17.

18.

19.

20.

Bulk Density of Stored Material

Maximum ht of Flat Slab

Seismic Zone III

Live Loads on Operating Floors

=

=

=

=

21.

22.

23.

24.

25.

26.

27.

28.

29.

Basic Wind speed

Grade of Conc. for wall (Characteristic Strength)

El. of Top of Flat Slab above GL

Angle of Inverted Cone

a

Thickness of RCC Wall below Cone Support

Axial Force Imposed on Ftop

Yield Stress of Reinfocement

Grade of Conc. For foundation

ef

Maximum eccentricity of filling

30. Maximum eccentricity of outlet

e0

=

=

=

=

=

=

=

=

=

=

20000 Ton

46.18

22.50

0

0

C

1.4 T/M3

0.000 M

0.16

1

T/M2

41

M/sec

25

N/mm2

21.016 M

60 o

500 mm

20

Ton

300 N/mm2

25

N/mm2

0

M

0

dc

0.4

M

M

M

M

M

21.016

-0.6

mm

mm

mm

13.675

6.

7.

8.

9.

10.

11.

0.15

2.80

A. SILO CONFIGURATION

0.500

FGL

B. CAPACITY CALCULATION

Volume above cone

= 18363 M3

TOTAL

= 18363 M3

Weight of material

= 22036 T Considering density of material

Weight of material

= 25708 T Considering density of material

C. DESIGN OF SILO WALL

Design parameters to determine Silo Forces

(a)

= Plan Cross-sectional area of the Silo

A

(b)

= Internal Diameter of the Silo ( Bin )

D

(c)

= Max. Dia. of the Circle that can be inscribed in the Bin

d

(d)

= Height of the Bin

h

(e)

= Internal perimeter of the Silo

U

(f)

= A/U

R

(g)

= Bulk Density of Stored Material

l

(h)

= Maximum depth below the Equivalent Surface of the Solid

Z

fim

(i)

= Mean angle of internal friction

(j) f (max) = Maximum angle of internal friction (af X fim)

(k) f (min) = Minimum angle of internal friction (fim / af))

1 of 7

1.2

1.4

T/M3

T/M3

=

=

=

=

=

=

=

=

=

=

=

from capacity consideration

for structural design

397.608

22.50

22.50

48.98

70.69

5.63

1.40

46.18

25

30.50

20.49

M2

M

M

M

M

M

T/M3

M

O

O

O

Design of Raw Meal Silo Based on BS EN 1991-4:2006 for Obajana Cement Line 3, Nigeria

Km

(l)

= Mean lateral pressure ratio

=

0.54

(m) K (max) = Maximum lateral pressure ratio (Km X ak)

=

0.648

(n) K (min) = Minimum lateral pressure ratio (Km / ak)

=

0.450

mm

(o)

= Mean wall friction coefficient for solid sliding on the vertical wall

=

0.56

(p) m (max) = Maximum wall friction coefficient (mm X am)

=

0.599

(q) m (min) = Minimum wall friction coefficient (mm / am)

=

0.523

cop

(r)

= Patch load solid reference factor

=

0.5

Note: 1) For maximum normal pressure on vertical wall m (min), K (max) & f (min) shall be used

2) For maximum frictional traction on vertical wall m (max), K (max) & f (min) shall be used

3) For maximum vertical load on silo bottom m (min), K (min) & f (max) shall be used

1. Determination of Lateral pressure, Vertical pressure and Frictional traction for Symmetrical filling load condition

Phf (z)

Pwf (z)

Pvf (z)

nzSk

zo

Pho

Yj (z)

zo

zo

zo

Pho

Pho

Pho

=

=

=

=

=

=

=

=

=

=

=

=

=

Z

(M)

2.80

6.98

9.98

12.98

15.98

18.98

21.98

24.98

27.98

30.98

33.98

36.98

39.98

42.98

48.98

Horizontal pressure at depth Z

= Pho*Yj(z)

(T/M2)

Wall friction traction at depth Z

= m*Pho*Yj(z)

(T/M2)

Vertical pressure at depth Z

= (Pho / K)*Yj(z) (T/M2)

The resulting characteristic value of the vertical force in the wall after filling at depth Z

(1 / (K*m))*(A / U) M

l*K*zo

(T/M2)

1 - e(-Z / Zo)

16.59 M

14.49 M

23.8839 M

15.0469 (T/M2)

13.14 (T/M2)

15.0469 (T/M2)

Z / Z0

Normal

0.000

0.252

0.433

0.614

0.795

0.976

1.156

1.337

1.518

1.699

1.880

2.061

2.242

2.423

2.785

( for maximum normal pressure calculation )

( for maximum frictional traction calculation )

( for maximum vertical load calculation )

( for maximum normal pressure calculation )

( for maximum frictional traction calculation )

( for maximum vertical load calculation )

Z / Z0 1 -e(Z/Zo) 1 -e(Z/Zo) 1 -e(Z/Zo)

Friction Vertical Normal Friction Vertical

0.000

0.000

0.000

0.000

0.000

0.289

0.175

0.223

0.251

0.161

0.496

0.301

0.351

0.391

0.260

0.703

0.426

0.459

0.505

0.347

0.910

0.552

0.548

0.597

0.424

1.117

0.677

0.623

0.673

0.492

1.324

0.803

0.685

0.734

0.552

1.531

0.929

0.737

0.784

0.605

1.738

1.054

0.781

0.824

0.652

1.945

1.180

0.817

0.857

0.693

2.152

1.305

0.847

0.884

0.729

2.359

1.431

0.873

0.906

0.761

2.566

1.557

0.894

0.923

0.789

2.774

1.682

0.911

0.938

0.814

3.188

1.934

0.938

0.959

0.855

Z / Z0

Phf

Pwf

2

(T/M )

0.00

3.35

5.29

6.90

8.25

9.37

10.31

11.10

11.75

12.30

12.75

13.13

13.45

13.71

14.12

Pvf

2

(T/M )

0.00

1.97

3.08

3.97

4.70

5.30

5.78

6.17

6.49

6.75

6.96

7.13

7.27

7.38

7.55

=

=

=

=

=

=

Thick walled circular silo

Filling outward patch pressure

= Cpf*Phf

Filling inward patch pressure

= Ppf/7

0.21*Cop*(1+2E2)*(1-e(-1.5*((hc/dc)-1)))

2*ef / dc =

0.00

Maximum eccentricity of surface pole during filling

2 of 7

0.0

nzSk

2

(T/M )

0.00

5.37

8.68

11.60

14.18

16.45

18.46

20.23

21.79

23.16

24.37

25.44

26.39

27.22

28.60

2. Determination of Lateral patch pressure in wall for filling patch load condition

Silo Type

Ppf

Ppfi

Cpf

E

ef

= m*Pho*(z-zo*Yj(z)) T/M

(T/M)

0.00

3.78

10.44

19.72

31.13

44.26

58.79

74.47

91.07

108.43

126.40

144.87

163.74

182.95

222.13

Design of Raw Meal Silo Based on BS EN 1991-4:2006 for Obajana Cement Line 3, Nigeria

Phf

Cop

s

Phf,u

Z

(M)

2.80

6.98

9.98

12.98

15.98

18.98

21.98

24.98

27.98

30.98

33.98

36.98

39.98

42.98

48.98

=

=

=

=

=

Local filling pressure

0.50

Patch load solid reference factor

=

The length of the zone on which the patch load is applied

Resulting symmetrical horizontal pressure for filling

Maximun(0.5+0.01*(dc/t) or 1)

Cpf

Phf

Ppf

Ppfi

Phf,u

0.083

0.083

0.083

0.083

0.083

0.083

0.083

0.083

0.083

0.083

0.083

0.083

0.083

0.083

0.083

Normal

0.00

3.35

5.29

6.90

8.25

9.37

10.31

11.10

11.75

12.30

12.75

13.13

13.45

13.71

14.12

(T/M2)

0.000

0.279

0.441

0.575

0.688

0.781

0.860

0.925

0.979

1.025

1.063

1.094

1.121

1.143

1.177

(T/M2)

0.000

0.040

0.063

0.082

0.098

0.112

0.123

0.132

0.140

0.146

0.152

0.156

0.160

0.163

0.168

(M)

4.418

4.418

4.418

4.418

4.418

4.418

4.418

4.418

4.418

4.418

4.418

4.418

4.418

4.418

4.418

(T/M2)

0.000

3.649

5.755

7.513

8.980

10.204

11.226

12.079

12.790

13.384

13.880

14.293

14.639

14.927

15.368

4.418

= p*dc/16

=

= Phf,u*(1+*Cpf)

1.06

=

3. Determination of Lateral pressure, Vertical pressure and Frictional traction for Symmetrical discharge load condition

= Horizontal pressure at depth Z

= Ch*Phf (T/M2)

= Wall friction traction at depth Z

= Cw*Pwf (T/M2)

= The resulting characteristic value of the vertical force in the wall during discharge at depth Z

1.15

= Discharge factor for horizontal pressure

=

= C0

1.10

= Discharge factor for wall frictional traction

=

= Discharge factor for all solids

Phe (z)

Pwe (z)

nzSk

Ch

Cw

C0

Z

(M)

2.80

6.98

9.98

12.98

15.98

18.98

21.98

24.98

27.98

30.98

33.98

36.98

39.98

42.98

48.98

Phe

2

(T/M )

0.00

3.85

6.08

7.94

9.49

10.78

11.86

12.76

13.51

14.14

14.66

15.10

15.46

15.77

16.24

Pwe

2

(T/M )

0.00

2.17

3.39

4.37

5.17

5.83

6.36

6.79

7.14

7.42

7.66

7.84

8.00

8.12

8.31

nzSk

(T/M)

0.00

4.15

11.49

21.70

34.24

48.69

64.67

81.92

100.18

119.27

139.04

159.36

180.12

201.24

244.35

3 of 7

= Cw*m*Pho*(z-zo*Yj(z))

(T/M)

Design of Raw Meal Silo Based on BS EN 1991-4:2006 for Obajana Cement Line 3, Nigeria

4. Determination of Lateral patch pressure in wall for discharge patch load condition

Silo Type

Ppe

Ppei

hc / dc

Cpe

E

e

Phe

Cop

s

Phe,u

Z

(M)

2.80

6.98

9.98

12.98

15.98

18.98

21.98

24.98

27.98

30.98

33.98

36.98

39.98

42.98

48.98

=

=

=

=

=

=

=

=

=

=

=

=

Thick walled circular silo

Discharge outward patch pressure

Discharge inward patch pressure

2.05

= Cpe*Phe

= Ppe / 7

0.42*Cop*(1+2*E2)*(1-exp(-1.5*((hc/dc)-1)))

2*e / dc

0.0

=

Max(ef,e0)

0.0

=

M

Local discharge pressure

0.50

Patch load solid reference factor

=

The length of the zone on which the patch load is applied

Resulting symmetrical horizontal pressure for discharge

Maximun(0.5+0.01*(dc/t) or 1)

Cpe

Phe

Ppe

Ppei

Phe,u

0.167

0.167

0.167

0.167

0.167

0.167

0.167

0.167

0.167

0.167

0.167

0.167

0.167

0.167

0.167

Normal

0.00

3.85

6.08

7.94

9.49

10.78

11.86

12.76

13.51

14.14

14.66

15.10

15.46

15.77

16.24

(T/M2)

0.000

0.643

1.014

1.323

1.581

1.797

1.977

2.127

2.252

2.357

2.444

2.517

2.578

2.629

2.706

(T/M2)

0.000

0.092

0.145

0.189

0.226

0.257

0.282

0.304

0.322

0.337

0.349

0.360

0.368

0.376

0.387

(M)

4.418

4.418

4.418

4.418

4.418

4.418

4.418

4.418

4.418

4.418

4.418

4.418

4.418

4.418

4.418

(T/M2)

0.000

4.497

7.094

9.260

11.068

12.577

13.837

14.888

15.765

16.497

17.108

17.617

18.043

18.398

18.942

4.418

= p*dc/16

=

= Phe,u*(1+*Cpe)

1.00

=

5. Discharge loads for silos with large outlet eccentricities

e0

0.0

=

M

ef

0.0 M

=

This procedures is not applicable

6. Pressure due to reduction in ambient atmospheric temperature

Temperature DIFFERENTIAL calculation

(Ref. Annex D of BS EN 1991-1-5-: 2003

Material temperature inside silo (Tin) oC=

Minimum temperature of outside environment (Tout) 0C=

Thickness of silo wall (hi) m=

The thermal conductivity of concrete (i) (W/(mK))=

The thermal resistance Rin (m2K/W)=

Thermal resistance Rout (m2K/W)=

Total thermal resistance (m2K/W)

120

-0.6

0.4

1.71

0.17

0.04

Rtot=Rin+(hi/i)+Rout

Temperature differential [(Tin-Tout)/Rtot]*(h/i) 0C=

0.444

63.55

4 of 7

Design of Raw Meal Silo Based on BS EN 1991-4:2006 for Obajana Cement Line 3, Nigeria

Temperature DIFFERENTIAL calculation

(Ref. clause 6.10 of Reynolds handbook, 10th edition)

h = thickness of wall (m) =

Inside material/hot liquid/flue gas (TG) temperature (0C) =

0.4

120

External air temperature/temperature (TA)at other face of wall (0C) =

-0.6

Thermal conductivity (kc) of RCC wall(watt/sqm/ C) =

1.71

ai = Resistance at the internal face (watt/sqm/0C)

0.17

aa = Resistance due to cavity (watt/sqm/ C)

ao = Resistance at the external face (watt/sqm/0C)

0.04

Co-efficient of linear expansion of concrete (c) (/0C) =

Modulus of elasticity of concrete (Ec) (N/mm 2) =

Moment of inertia (Ic) of concrete section (m4)

Resistance to the transmission of heat (k) through wall (watt/sqm/0C) =

h

+

k=

ai+aa+ao

kc

0

The change in temperature (T C) through concrete wall =

T = (TG-TA)*k*hc/kc

0.00001

21000

0.0053333

2.25

63.5

a) Tension due to Temperature

PhT

= Normal pressure

= CT*aw*DT*Ew/((r / t)+(1-v)*(Ew/EsU))

o

o

120

15

Ti =

To =

C

C

= 0.400 m

t = Thickness of silo wall

CT

3.0

= Temperature load multiplier

=

per degree centigrade

0.0000011

aw

= Coefficient of thermal expansion of the silo wall

=

o

DT

= Temperature differential

=

63.5 C

r

11.45 M

= Silo radius (dc / 2)

=

Ew

= Elastic modulus of the silo wall

= 5500*SQRT(fck)

= 27500.0 N/mm2

v

0.3

= Poisson's ration

=

EsU

= Inloading effective elastic modulus at depth Z

= *Pvft

= 10487.8 T/M2

Pvft

28.60 T/M2

= Vertical stress at the base of the vertical walled section =

5 of 7

Design of Raw Meal Silo Based on BS EN 1991-4:2006 for Obajana Cement Line 3, Nigeria

= 7*l3/2

= Modulus contiguity coefficient

PhT

2.72

366.68

(T/M2)

7. Design against Hoop Tension due to Load P h

Dead Load Factor

Kd

Height Symmetrical filling

(Phf)

from top

Kl =

1.4

live Load Factor

Lateral Pressure ( Ph)

Unsymmetrical

Symmetrical

Unsymmetrical

filling (Phf,u)

discharge. (Phe) discharge. (Phe,u)

1.20

Pvft

Esu

Design Factored Design Factored Design Factored Design Factored

(M)

2.80

6.98

9.98

12.98

15.98

18.98

21.98

24.98

27.98

30.98

33.98

36.98

39.98

42.98

48.98

T/M

0.00

3.35

5.29

6.90

8.25

9.37

10.31

11.10

11.75

12.30

12.75

13.13

13.45

13.71

14.12

T/M

0.00

4.69

7.40

9.66

11.55

13.12

14.44

15.53

16.45

17.21

17.85

18.38

18.83

19.20

19.76

T/M

0.00

3.65

5.76

7.51

8.98

10.20

11.23

12.08

12.79

13.38

13.88

14.29

14.64

14.93

15.37

T/M

0.00

5.11

8.06

10.52

12.57

14.29

15.72

16.91

17.91

18.74

19.43

20.01

20.49

20.90

21.51

T/M

0.00

3.85

6.08

7.94

9.49

10.78

11.86

12.76

13.51

14.14

14.66

15.10

15.46

15.77

16.24

T/M

0.00

5.40

8.51

11.11

13.28

15.09

16.60

17.86

18.92

19.80

20.53

21.14

21.65

22.08

22.73

T/M

0.00

4.50

7.09

9.26

11.07

12.58

13.84

14.89

15.76

16.50

17.11

17.62

18.04

18.40

18.94

Hoop Tension due Steel Reqd. Steel Reqd.

to Temperature from Filling &

from

(T = PhT*D/2)

Discharge Temperature

Height

from top

Maximum Hoop

Tension

(T = Ph*D/2)

(M)

T/M of Height

T/M of Height

mm2/m

mm2/m

2.80

6.98

9.98

12.98

15.98

18.98

21.98

24.98

27.98

30.98

33.98

36.98

39.98

42.98

48.98

0.00

72.09

113.71

148.44

177.43

201.62

221.80

238.65

252.71

264.44

274.23

282.41

289.23

294.92

303.63

0.00

9.18

14.60

19.22

23.18

26.59

29.53

32.08

34.29

36.21

37.89

39.35

40.62

41.74

43.57

0.00

2763.56

4358.92

5690.30

6801.39

7728.64

8502.47

9148.26

9687.20

10136.96

10512.31

10825.55

11086.97

11305.12

11639.31

0.00

352.09

559.56

736.69

888.56

1019.26

1132.09

1229.75

1314.49

1388.17

1452.34

1508.31

1557.21

1599.97

1670.24

6 of 7

T/M

0.00

6.30

9.93

12.96

15.50

17.61

19.37

20.84

22.07

23.10

23.95

24.66

25.26

25.76

26.52

Temperature

pressure (PhT)

Design Factored

T/M

0.00

5.37

8.68

11.60

14.18

16.45

18.46

20.23

21.79

23.16

24.37

25.44

26.39

27.22

28.60

T/M

0.00

1968.5

3183.4

4254.9

5200.0

6033.4

6768.5

7416.8

7988.6

8492.9

8937.7

9330.0

9675.9

9981.1

10487.8

T/M2

T/M2

0.57

0.91

1.20

1.45

1.66

1.84

2.00

2.14

2.26

2.36

2.45

2.53

2.60

2.72

0.80

1.27

1.68

2.02

2.32

2.58

2.80

2.99

3.16

3.31

3.44

3.55

3.65

3.81

Design of Raw Meal Silo Based on BS EN 1991-4:2006 for Obajana Cement Line 3, Nigeria

Level (m) Height Rebars(IF) for hoop tension

from top

s reqd. s prov.

f

(M)

mm mm (c/c) mm (c/c)

2.80

22

200

6.98

22

275

120

63.016

9.98

25

225

120

25

173

130

57.016 12.98

15.98

25

144

130

25

127

110

51.016 18.98

21.98

25

115

110

25

107

100

45.016 24.98

27.98

25

101

100

25

97

100

39.016 30.98

33.98

25

93

100

25

91

90

33.016 36.98

39.98

25

89

90

25

87

90

27.016 42.98

25

84

90

21.016 48.98

Check

OK

OK

OK

OK

OK

OK

OK

OK

Revise

Revise

OK

Revise

Revise

Revise

Rebars(OF) for hoop tension

s reqd. s prov. Check

f

mm mm (c/c) mm (c/c)

22

150

OK

22

219

120

OK

25

179

120

OK

25

137

65

OK

25

114

65

OK

25

101

55

OK

25

91

55

OK

25

85

50

OK

25

80

50

OK

25

76

50

OK

25

73

50

OK

25

71

45

OK

25

69

45

OK

25

68

45

OK

25

66

45

7 of 7

You might also like

- Calculation For D12m SiloDocument3 pagesCalculation For D12m SiloHaftamu Tekle80% (10)

- Silo Design CementDocument4 pagesSilo Design Cementkvamshi_1971100% (7)

- Silo Design WebDocument1 pageSilo Design Weblecongdinh100% (1)

- Silos DesignDocument7 pagesSilos Designaloyssberg100% (4)

- Example 3 Rectangular SiloDocument7 pagesExample 3 Rectangular SiloAhmed Said50% (2)

- Silo SizeDocument1 pageSilo Sizeuvarajmecheri100% (1)

- Silo Design Final For Mombasa - Is - NiladriDocument9 pagesSilo Design Final For Mombasa - Is - NiladriMahata Priyabrata100% (1)

- Design Examples 1 2 of Circular Silo PDFDocument7 pagesDesign Examples 1 2 of Circular Silo PDFAnicet Vincent70% (10)

- Structural Design of Steel Bins and SilosDocument36 pagesStructural Design of Steel Bins and Silosyoussefayay92% (12)

- Steel Silo's DesignDocument2 pagesSteel Silo's Designemad sabri100% (1)

- Silo Design Final For Mombasa Is NiladriDocument18 pagesSilo Design Final For Mombasa Is NiladrijnmanivannanmechNo ratings yet

- Silo VoDocument2 pagesSilo Vosuntoshsalvi4859No ratings yet

- Design of Hopper BottomDocument1 pageDesign of Hopper Bottomamir1911411No ratings yet

- Silo Structure Rev 3Document176 pagesSilo Structure Rev 3saadyamin2821100% (3)

- Silo DesignDocument12 pagesSilo Designraju_420034520No ratings yet

- Silo Data SheetDocument4 pagesSilo Data SheetZoran Danilov100% (1)

- 1000 m3 Ash Silo Calculation ReportDocument15 pages1000 m3 Ash Silo Calculation Reporttranceintt0% (1)

- Tel: (978) 649-3300 Fax: (978) 649-3399 Tel: (805) 541-0901 Fax: (805) 541-4680Document48 pagesTel: (978) 649-3300 Fax: (978) 649-3399 Tel: (805) 541-0901 Fax: (805) 541-4680gkdora57489% (9)

- Concrete Silo Design According To EuroCodeDocument14 pagesConcrete Silo Design According To EuroCodeJay Ryan Santos50% (2)

- Silo WallDocument5 pagesSilo WallMunish GaurNo ratings yet

- Calculation For D12m SiloDocument4 pagesCalculation For D12m SiloJuan Carlos Quispe Chara0% (1)

- Prestressed Silo DesignDocument11 pagesPrestressed Silo DesignmahakNo ratings yet

- Silo Design: Mech D (4'2) Roll No: 16311A03M4 16311A03M7 16311A03P7Document44 pagesSilo Design: Mech D (4'2) Roll No: 16311A03M4 16311A03M7 16311A03P7Akhilprasad SadigeNo ratings yet

- Silo Design Kit PP013Document42 pagesSilo Design Kit PP013cris_2010100% (4)

- IS 9178 (Part 1) - 1978Document39 pagesIS 9178 (Part 1) - 1978bhustlero0o100% (2)

- DIN-1055-6 2005silosDocument195 pagesDIN-1055-6 2005silosTunisian Mentalist75% (4)

- Design Calculation For Fly Ash Storage Silo Stage-II - Rev.2 - Z1660 TalcherDocument135 pagesDesign Calculation For Fly Ash Storage Silo Stage-II - Rev.2 - Z1660 TalcherSwapan Kumar BoseNo ratings yet

- Ring Beam StressesDocument12 pagesRing Beam StressesjdkelleyNo ratings yet

- Silo GuideDocument14 pagesSilo GuideMd. Mynul Hossain100% (2)

- Design of Silos 2010Document21 pagesDesign of Silos 2010Topaca Paec100% (3)

- ASh Silo Sizing CalculationDocument7 pagesASh Silo Sizing CalculationDurjoy Chakraborty100% (3)

- Structural Design of Steel Bins - Gerard XavierDocument77 pagesStructural Design of Steel Bins - Gerard XavierNicolas Valle100% (9)

- Silos Design With Different Aspect RatiosDocument9 pagesSilos Design With Different Aspect Ratiosmrnaeem100% (1)

- BS 8110:part 1: 1985, Section Three, Table 3.9: C S V 1/3 1/4 MDocument7 pagesBS 8110:part 1: 1985, Section Three, Table 3.9: C S V 1/3 1/4 MnaconnetNo ratings yet

- Inze TankDocument9 pagesInze TankHabib Ur RahmanNo ratings yet

- Box+Culvert+by+R S VasneyDocument10 pagesBox+Culvert+by+R S VasneyfwrconsultantNo ratings yet

- Box Culvert by R.S.vasneyDocument10 pagesBox Culvert by R.S.vasneyShreedhar33% (3)

- IsolatedFdn-1 BS8110Document8 pagesIsolatedFdn-1 BS8110Shaikh Muhammad AteeqNo ratings yet

- Thrust Block CalculationsDocument5 pagesThrust Block CalculationsNiño Erick Castañares86% (7)

- Isolated Sloped FootingDocument9 pagesIsolated Sloped Footingarif_rubinNo ratings yet

- Cement Silo Design As Per IsDocument12 pagesCement Silo Design As Per Issoumi bhattacharyaNo ratings yet

- Base PlateDocument12 pagesBase PlateD SRINIVAS100% (1)

- Fire Water Tank FoundationDocument18 pagesFire Water Tank Foundationcholan100% (2)

- Design of FoundationDocument66 pagesDesign of FoundationShaikh Muhammad Ateeq100% (2)

- Civil Cad Lab PDFDocument49 pagesCivil Cad Lab PDFArun RajNo ratings yet

- On Ground TankDocument24 pagesOn Ground TankSanjoy Sanyal100% (1)

- Cant Ret DesignDocument48 pagesCant Ret DesigndsanandaNo ratings yet

- Baseplate DesignDocument14 pagesBaseplate DesignmaheshbandhamNo ratings yet

- Abut DesignDocument32 pagesAbut DesignSubir Kunda100% (2)

- Pile DesignDocument5 pagesPile DesignKanu PreiyaNo ratings yet

- Water TankDocument22 pagesWater TankSamik SenNo ratings yet

- API 650 Design TanksDocument39 pagesAPI 650 Design TanksAhmedAli25% (4)

- Filter Water TankDocument8 pagesFilter Water TankHemant Sonawadekar100% (1)

- Trafo Found DesignDocument6 pagesTrafo Found DesignIrshad Khan100% (1)

- Design of Steel Chimney According To Is:6533/1989 No. Chimney Specifications Units Value RemarksDocument24 pagesDesign of Steel Chimney According To Is:6533/1989 No. Chimney Specifications Units Value RemarksG S Deshpande100% (1)

- Linkbox Chamber Structural Calculation - TypicalDocument5 pagesLinkbox Chamber Structural Calculation - TypicalMohamed ImranNo ratings yet

- Design of Thrust BlocksDocument20 pagesDesign of Thrust BlocksBalaji Rao Ch100% (1)

- Box Culvert at Chainage 83 10 M XLSX Depth 4 1 MDocument18 pagesBox Culvert at Chainage 83 10 M XLSX Depth 4 1 MMario Sajulga Dela Cuadra100% (1)

- Chamber Type - G: Master Planning, Infrastructure & Residential Design For Social Housing Project at East SitraDocument1 pageChamber Type - G: Master Planning, Infrastructure & Residential Design For Social Housing Project at East SitraMahata PriyabrataNo ratings yet

- Master Planning, Infrastructure & Residential Design For Social Housing Project at East SitraDocument1 pageMaster Planning, Infrastructure & Residential Design For Social Housing Project at East SitraMahata PriyabrataNo ratings yet

- Master Planning, Infrastructure & Residential Design For Social Housing Project at East SitraDocument1 pageMaster Planning, Infrastructure & Residential Design For Social Housing Project at East SitraMahata PriyabrataNo ratings yet

- Chamber Type - E: Master Planning, Infrastructure & Residential Design For Social Housing Project at East SitraDocument1 pageChamber Type - E: Master Planning, Infrastructure & Residential Design For Social Housing Project at East SitraMahata PriyabrataNo ratings yet

- Q 1115 - Pile Design For Sheet Piling WorksDocument10 pagesQ 1115 - Pile Design For Sheet Piling WorksMahata PriyabrataNo ratings yet

- MS - Dewatering PDFDocument46 pagesMS - Dewatering PDFMahata PriyabrataNo ratings yet

- Master Planning, Infrastructure & Residential Design For Social Housing Project at East SitraDocument1 pageMaster Planning, Infrastructure & Residential Design For Social Housing Project at East SitraMahata PriyabrataNo ratings yet

- Part A (Main Villa Remedial Works) : Sl. No Description Action Date RemarksDocument1 pagePart A (Main Villa Remedial Works) : Sl. No Description Action Date RemarksMahata PriyabrataNo ratings yet

- Al Marassi MCP - Headwall - Section 1Document20 pagesAl Marassi MCP - Headwall - Section 1Mahata PriyabrataNo ratings yet

- Thermal Cracking of ConcreteDocument2 pagesThermal Cracking of ConcreteChatchai ManathamsombatNo ratings yet

- Road CrossingDocument5 pagesRoad CrossingMahata PriyabrataNo ratings yet

- MC 175 SB 16 A Heights 32.9mDocument33 pagesMC 175 SB 16 A Heights 32.9mMahata PriyabrataNo ratings yet

- BS 4283Document26 pagesBS 4283Mahata Priyabrata100% (1)

- Al Marassi MCP - Headwall - Section 1Document20 pagesAl Marassi MCP - Headwall - Section 1Mahata PriyabrataNo ratings yet

- Gulf Plastic ECatalogDocument38 pagesGulf Plastic ECatalogMahata PriyabrataNo ratings yet

- Concrete Industrial Ground Floor Slab Desig1Document3 pagesConcrete Industrial Ground Floor Slab Desig1Mahata PriyabrataNo ratings yet

- ESR FDN DesignDocument161 pagesESR FDN DesignMahata PriyabrataNo ratings yet

- Sample Consultancy AgreementDocument15 pagesSample Consultancy AgreementMahata PriyabrataNo ratings yet

- sTAAD FOR TEMP. SUPPORTDocument5 pagessTAAD FOR TEMP. SUPPORTMahata PriyabrataNo ratings yet

- A-Indian Contract ActDocument57 pagesA-Indian Contract ActAntony SebastianNo ratings yet

- Solider ResultsDocument1 pageSolider ResultsMahata PriyabrataNo ratings yet

- 3A1 Lecture 13Document46 pages3A1 Lecture 13apurvajahagirdarNo ratings yet

- Silo Design Final For Mombasa - Is - NiladriDocument9 pagesSilo Design Final For Mombasa - Is - NiladriMahata Priyabrata100% (1)

- QuestionsddDocument1 pageQuestionsddMahata PriyabrataNo ratings yet

- Analysis of ForceDocument4 pagesAnalysis of ForceMahata PriyabrataNo ratings yet

- Design of Monorail BeamDocument6 pagesDesign of Monorail BeamMahata Priyabrata100% (2)

- Syllabus Waste Heat Recovery: Classification, Advantages and Applications, CommerciallyDocument18 pagesSyllabus Waste Heat Recovery: Classification, Advantages and Applications, Commerciallyalzewam152100% (2)

- Biaxial Stress SystemDocument12 pagesBiaxial Stress SystemMahata PriyabrataNo ratings yet

- 9 Cswip 3.1 Question Answers SPECIMEN WRITTEN EXAMINATION QUESTIONS Question Answers Solved Past Papers Cswip 3.1Document32 pages9 Cswip 3.1 Question Answers SPECIMEN WRITTEN EXAMINATION QUESTIONS Question Answers Solved Past Papers Cswip 3.1Mohammed Amjad AliNo ratings yet

- Chemical Storage ShelterDocument18 pagesChemical Storage ShelterManoj Kumar PalNo ratings yet

- Partical TechnologyDocument54 pagesPartical TechnologyEhtisham ZiaNo ratings yet

- Pneumatic Conveying Systems and Components For Bulk Material HandlingDocument8 pagesPneumatic Conveying Systems and Components For Bulk Material HandlingmseifNo ratings yet

- Paragloss Production DCA06 - Internal - V1Document16 pagesParagloss Production DCA06 - Internal - V1Animal Memes100% (1)

- Betim Company Profile 2022Document47 pagesBetim Company Profile 2022Zeynel OzkayaNo ratings yet

- Ssci Plant LayoutDocument1 pageSsci Plant LayoutCristina AbañoNo ratings yet

- Grain Storage and Handling PDFDocument13 pagesGrain Storage and Handling PDFAnonymous 5oLTGeONo ratings yet

- Dry Bulk Product Safety SOPDocument14 pagesDry Bulk Product Safety SOPWan Sek ChoonNo ratings yet

- 16 Pneumatic Conveying ConceptsDocument36 pages16 Pneumatic Conveying ConceptsUroš ČampragNo ratings yet

- Operation & Maintenance Guide For Dry Ash Evacuation & Transportation System - OperationDocument24 pagesOperation & Maintenance Guide For Dry Ash Evacuation & Transportation System - OperationArun RajNo ratings yet

- Checklist For Approval of Ready Mix Concrete PlantDocument23 pagesChecklist For Approval of Ready Mix Concrete PlantRamyash YadavNo ratings yet

- Supersax Trans PodDocument2 pagesSupersax Trans PodW MoralesNo ratings yet

- Design Mech DryersDocument5 pagesDesign Mech DryersBrandon DouglasNo ratings yet

- HAMBURGDocument9 pagesHAMBURGВиталий СвятскийNo ratings yet

- DK0209E22 - Software PH Manual For PV350... PV1500 BurnersDocument17 pagesDK0209E22 - Software PH Manual For PV350... PV1500 BurnersPauls KrūmiņšNo ratings yet

- Industrial Vacuum LoaderDocument2 pagesIndustrial Vacuum LoaderryanvlopezNo ratings yet

- 2-SHG, HGC, HGC-VD - Manuel de Maintenance V1.0 ENDocument48 pages2-SHG, HGC, HGC-VD - Manuel de Maintenance V1.0 ENdungdhtsNo ratings yet

- 2017 Combustible Dust Incident ReportDocument22 pages2017 Combustible Dust Incident ReportBob JohnsonNo ratings yet

- HNK065 3 Action List PDFDocument7 pagesHNK065 3 Action List PDFhenrique silvaNo ratings yet

- Course 4 EDocument45 pagesCourse 4 ESzabolcs KovacsNo ratings yet

- BVH2086GB-Multicor K40 Installation ManualDocument15 pagesBVH2086GB-Multicor K40 Installation ManualWangNo ratings yet

- Ash PresentationDocument19 pagesAsh PresentationRichard Peters100% (1)

- Ash HandlingDocument24 pagesAsh HandlingpksvnsNo ratings yet

- Curriculum Vitae Kota Khageswararao Contact: +91 8496043202Document4 pagesCurriculum Vitae Kota Khageswararao Contact: +91 8496043202venkat santhoshNo ratings yet

- S120Document14 pagesS120praveena61No ratings yet

- Design and Construction of Silos and Bunkers Sargis S SafarianDocument482 pagesDesign and Construction of Silos and Bunkers Sargis S SafarianFatima tuz ZohraNo ratings yet

- Pneumatic ConveyingDocument16 pagesPneumatic ConveyingIrwan Sattu100% (1)

- Industrial Training VenkatDocument48 pagesIndustrial Training Venkat25 VIGNESH DASARINo ratings yet

- Bulk Material HandlingDocument5 pagesBulk Material HandlingPrasenjit BhuiyaNo ratings yet

- Bulk Bag Filler Brochure WWDocument8 pagesBulk Bag Filler Brochure WWTran Anh LeNo ratings yet

- Design Criteria For Structural Design of Silage Silo Walls: July 2012Document7 pagesDesign Criteria For Structural Design of Silage Silo Walls: July 2012Bayari ArNo ratings yet