Professional Documents

Culture Documents

Formula Table Solid Mechanics

Uploaded by

mechfunOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Formula Table Solid Mechanics

Uploaded by

mechfunCopyright:

Available Formats

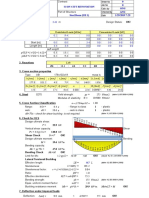

Formulas in Solid Mechanics

Tore Dahlberg

Solid Mechanics/IKP, Linkping University

Linkping, Sweden

This collection of formulas is intended for use by foreign students in the course TMHL61,

Damage Mechanics and Life Analysis, as a complement to the textbook Dahlberg and

Ekberg: Failure, Fracture, Fatigue - An Introduction, Studentlitteratur, Lund, Sweden, 2002.

It may be use at examinations in this course.

Contents Page

1. Definitions and notations 1

2. Stress, Strain, and Material Relations 2

3. Geometric Properties of Cross-Sectional Area 3

4. One-Dimensional Bodies (bars, axles, beams) 5

5. Bending of Beam Elementary Cases 11

6. Material Fatigue 14

7. Multi-Axial Stress States 17

8. Energy Methods the Castigliano Theorem 20

9. Stress Concentration 21

10. Material data 25

Version 03-09-18

1. Definitions and notations

Definition of coordinate system and loadings on beam

Loaded beam, length L, cross section A, and load q(x), with coordinate system (origin at the

geometric centre of cross section) and positive section forces and moments: normal force N,

shear forces T

y

and T

z

, torque M

x

, and bending moments M

y

, M

z

Notations

Quantity Symbol SI Unit

Coordinate directions, with origin at geometric centre of x, y, z m

cross-sectional area A

Normal stress in direction i (= x, y, z)

i

N/m

2

Shear stress in direction j on surface with normal direction i

ij

N/m

2

Normal strain in direction i

i

Shear strain (corresponding to shear stress

ij

)

ij

rad

Moment with respect to axis i M, M

i

Nm

Normal force N, P N (= kg m/s

2

)

Shear force in direction i (= y, z) T, T

i

N

Load q(x) N/m

Cross-sectional area A m

2

Length L, L

0

m

Change of length m

Displacement in direction x u, u(x), u(x,y) m

Displacement in direction y v, v(x), v(x,y) m

Beam deflection w(x) m

Second moment of area (i = y, z) I, I

i

m

4

Modulus of elasticity (Youngs modulus) E N/m

2

Poissons ratio

Shear modulus G N/m

2

Bulk modulus K N/m

2

Temperature coefficient

x

y

z

T

T

M

M

N

y

z

y

z

x

M

T

z

M

z

M

y

N

x

M

T

y

L

A

q x ( )

K

1

1

2. Stress, Strain, and Material Relations

Normal stress

x

N = fraction of normal force N

A = cross-sectional area element

Shear stress

xy

(mean value over area A in the y direction)

Normal strain

x

Linear, at small deformations ( << L

0

)

= change of length

L

0

= original length

u(x) = displacement

Non-linear, at large deformations

L = actual length (L = L

0

+ )

Shear strain

xy

Linear elastic material (Hookes law)

Tension/compression

T = change of temperatur

Lateral strain

Shear strain

Relationships between G, K, E and

x

N

A

or

x

lim

A 0

N

A

_

xy

T

y

A

(

mean

)

x

L

0

or

x

du(x)

dx

x

ln

L

L

0

_

xy

u(x, y)

y

+

v(x, y)

x

x

x

E

+ T

y

x

xy

xy

G

G

E

2 ( 1 + )

K

E

3 ( 1 2 )

2

3. Geometric Properties of Cross-Sectional Area

The origin of the coordinate system Oyz is

at the geometric centre of the cross section

Cross-sectional area A

dA = area element

Geometric centre (centroid)

e =

gc

= distance from axis to geometric

centre

f =

gc

distance from axis to geometric

centre

First moment of area

A = the sheared area (part of area A)

Second moment of area

I

y

= second moment of area with respect to

the y axis

I

z

= second moment of area with respect to

the z axis

I

yz

= second moment of area with respect to

the y and z axes

Parallel-axis theorems

First moment of area

Second moment of area

O

y

z

e

f

dA

A

A

dA

e A

A

dA

f A

A

dA

S

y

A

zdA and S

z

A

ydA

I

y

A

z

2

dA

I

z

A

y

2

dA

I

yz

A

yzdA

S

A

(z + e) dA eA and S

A

(y + f) dA fA

I

A

(z + e)

2

dA I

y

+ e

2

A , I

A

(y + f)

2

dA I

z

+ f

2

A ,

I

A

(z + e) (y + f) dA I

yz

+ ef A

3

Rotation of axes

Coordinate system has been rotated

the angle with respect to the coordinate

system Oyz

Principal moments of area

I

1

+ I

2

= I

y

+ I

z

Principal axes

A line of symmetry is always a principal

axis

Second moment of area with respect to axes through geometric centre for some

symmetric areas (beam cross sections)

Rectangular area, base B, height H

Solid circular area, diameter D

Thick-walled circular tube, diameters D

and d

y

z

z

y

dA

I

2

dA I

y

cos

2

+ I

z

sin

2

2I

yz

sin cos

I

2

dA I

y

sin

2

+ I

z

cos

2

+ 2I

yz

sin cos

I

A

dA (I

y

I

z

) sin cos + I

yz

(cos

2

sin

2

)

I

y

I

z

2

sin2 + I

yz

cos 2

I

1, 2

I

y

+ I

z

2

t R where R

I

y

I

z

2

_

,

2

+ I

yz

2

sin 2

I

yz

R

or cos 2

I

y

I

z

2R

y

z

H

B

I

y

BH

3

12

and I

z

HB

3

12

y

z

D

I

y

I

z

D

4

64

y

z

D d

I

y

I

z

64

( D

4

d

4

)

4

Thin-walled circular tube, radius R and

wall thickness t (t << R)

Triangular area, base B and height H

Hexagonal area, side length a

Elliptical area, major axis 2a and minor

axis 2b

Half circle, radius a (geometric centre at e)

4. One-Dimensional Bodies (bars, axles, beams)

Tension/compression of bar

Change of length

N, E, and A are constant along bar

L = length of bar

N(x), E(x), and A(x) may vary along bar

Torsion of axle

Maximum shear stress

M

v

= torque = M

x

W

v

= section modulus in torsion (given

below)

Torsion (deformation) angle

M

v

= torque = M

x

K

v

= section factor of torsional stiffness

(given below)

y

z

R

t

I

y

I

z

R

3

t

y

z

H

2 B/ 2 B/

I

y

BH

3

36

and I

z

HB

3

48

y

z

a

a

a

a

a

I

y

I

z

5

3

16

a

4

y

z

2a

b 2

I

y

ab

3

4

and I

z

ba

3

4

y

z

a

e

I

y

8

8

9

_

,

a

4

0, 110 a

4

and e

4a

3

NL

EA

or

0

L

(x)dx

0

L

N(x)

E(x)A(x)

dx

max

M

v

W

v

M

v

L

GK

v

5

Section modulus W

v

and section factor K

v

for some cross sections (at torsion)

Torsion of thin-walled circular tube, radius

R, thickness t, where t << R,

Thin-walled tube of arbitrary cross section

A = area enclosed by the tube

t(s) = wall thickness

s = coordinate around the tube

Thick-walled circular tube, diameters D

and d,

Solid axle with circular cross section,

diameter D,

Solid axle with triangular cross section,

side length a

Solid axle with elliptical cross section,

major axle 2a and minor axle 2b

Solid axle with rectangular cross section b

by a, where b a

for k

Wv

and k

Kv

, see table below

y

z

R

t

W

v

2R

2

t K

v

2R

3

t

t(s)

(s)

A Area

s

W

v

2At

min

K

v

4A

2

s

[t(s)]

1

ds

y

z

D d

W

v

16

D

4

d

4

D

K

v

32

(D

4

d

4

)

y

z

D

W

v

D

3

16

K

v

D

4

32

y

z

a

/ 2 a / 2 a

W

v

a

3

20

K

v

a

4

3

80

y

z

2a

b 2

W

v

2

a b

2

K

v

a

3

b

3

a

2

+ b

2

y

z

a

b

W

v

k

Wv

a

2

b K

v

k

Kv

a

3

b

6

Factors k

Wv

and k

Kv

for some values of ratio b / a (solid rectangular cross section)

b

/

a k

Wv

k

Kv

1.0 0.208 0.1406

1.2 0.219 0.1661

1.5 0.231 0.1958

2.0 0.246 0.229

2.5 0.258 0.249

3.0 0.267 0.263

4.0 0.282 0.281

5.0 0.291 0.291

10.0 0.312 0.312

0.333 0.333

Bending of beam

Relationships between bending moment M

y

= M(x), shear force T

z

= T(x), and load q(x) on

beam

Normal stress

I (here I

y

) = second moment of area (see

Section 12.2)

Maximum bending stress

W

b

= section modulus (in bending)

Shear stress

S

A

= first moment of area A (see Section

12.2)

b = length of line limiting area A

gc

= shear stress at geometric centre

= the Jouravski factor

The Jouravski factor for some cross sections

rectangular 1.5

triangular 1.33

circular 1.33

thin-walled circular 2.0

elliptical 1.33

ideal I profile A

/

A

web

dT(x)

dx

q(x) ,

dM(x)

dx

T(x) , and

d

2

M(x)

dx

2

q(x)

N

A

+

Mz

I

max

M

W

b

where W

b

I

z

max

TS

A

Ib

gc

T

A

7

Skew bending

Axes y and z are not principal axes:

I

y

, I

z

, I

yz

= second moment of area

Axes y and z are principal axes:

I

1

, I

2

= principal second moment of area

Beam deflection w(x)

Differential equations

when EI(x) is function of x

when EI is constant

Homogeneous boundary conditions

Clamped beam end

where * is the coordinate of beam end

(to be entered after differentiation)

Simply supported beam end

Sliding beam end

Free beam end

N

A

+

M

y

(zI

z

yI

yz

) M

z

(yI

y

zI

yz

)

I

y

I

z

I

yz

2

N

A

+

M

1

z

I

1

M

2

y

I

2

d

2

dx

2

'

EI(x)

d

2

dx

2

w(x)

q(x)

EI

d

4

dx

4

w(x) q(x)

x x=L

w(*) 0 and

d

dx

w(*) 0

x x=L

w(*) 0 and EI

d

2

dx

2

w(*) 0

x x=L

d

dx

w(*) 0 and EI

d

3

dx

3

w(*) 0

x x=L

EI

d

2

dx

2

w(*) 0 and EI

d

3

dx

3

w(*) 0

8

Non-homogeneous boundary conditions

(a) Displacement prescribed

(b) Slope prescribed

(c) Moment M

0

prescribed

(d) Force P prescribed

Beam on elastic bed

Differential equation

EI = constant bending stiffness

k = bed modulus (N/m

2

)

Solution

Boundary conditions as given above

Beam vibration

Differential equation

EI = constant bending stiffness

m = beam mass per metre (kg/m)

t = time

Assume solution w(x,t) = X(x)T(t). Then the standing wave solution is

where

4

=

2

m

/EI

Boundary conditions (as given above) give an eigenvalue problem that provides the

eigenfrequencies and eigenmodes (eigenforms) of the vibrating beam

w(*)

x x=L

x

x=L

O

z

O

0 0

M M

x x=L

P P

(a)

(b)

(c)

(d)

d

dx

w(*)

EI

d

2

dx

2

w(*) M

0

EI

d

3

dx

3

w(*) P

EI

d

4

dx

4

w(x) + kw(x) q(x)

w(x) w

part

(x) + w

hom

(x) where

w

hom

(x) {C

1

cos (x) + C

2

sin (x)} e

x

+ {C

3

cos (x) + C

2

sin (x)} e

x

;

4

k

4EI

EI

4

x

4

w(x, t) + m

2

t

2

w(x, t) q(x, t)

T(t) e

i t

and X(x) C

1

cosh (x) + C

2

cos (x) + C

3

sinh (x) + C

4

sin (x)

9

Axially loaded beam, stability, the Euler cases

Beam axially loaded in tension

Differential equation

N = normal force in tension (N > 0)

Solution

New boundary condition on shear force (other boundary conditions as given above)

Beam axially loaded in compression

Differential equation

P = normal force in compression (P > 0)

Solution

New boundary condition on shear force (other boundary conditions as given above)

Elementary cases: the Euler cases (P

c

is critical load)

Case 1 Case 2a Case 2b Case 3 Case 4

EI

d

4

dx

4

w(x) N

d

2

dx

2

w(x) q(x)

w(x) w

part

(x) + w

hom

(x) where

w

hom

(x) C

1

+ C

2

N

EI

x + C

3

sinh

N

EI

x

_

,

+ C

4

cosh

N

EI

x

_

,

T(*) EI

d

3

dx

3

w(*) + N

d

dx

w(*)

EI

d

4

dx

4

w(x) + P

d

2

dx

2

w(x) q(x)

w(x) w

part

(x) + w

hom

(x) where

w

hom

(x) C

1

+ C

2

P

EI

x + C

3

sin

P

EI

x

_

,

+ C

4

cos

P

EI

x

_

,

T(*) EI

d

3

dx

3

w(*) P

d

dx

w(*)

P

L, EI L, EI

P

L, EI

P

L, EI

P

L, EI

P

P

c

2

EI

4L

2

P

c

2

EI

L

2

P

c

2

EI

L

2

P

c

2.05

2

EI

L

2

P

c

4

2

EI

L

2

10

5. Bending of Beam Elementary Cases

Cantilever beam

x

z w(x)

L, EI

P

w(x)

PL

3

6EI

3

x

2

L

2

x

3

L

3

_

,

w(L)

PL

3

3EI

d

dx

w(L)

PL

2

2EI

x

z w(x)

L, EI

M

w(x)

ML

2

2EI

x

2

L

2

_

,

w(L)

ML

2

2EI

d

dx

w(L)

ML

EI

x

z w(x)

L, EI

q = Q/L

w(x)

qL

4

24EI

x

4

L

4

4

x

3

L

3

+ 6

x

2

L

2

_

,

w(L)

qL

4

8EI

d

dx

w(L)

qL

3

6EI

x

z w(x)

L, EI

q

0

w(x)

q

0

L

4

120EI

x

5

L

5

10

x

3

L

3

+ 20

x

2

L

2

_

,

w(L)

11 q

0

L

4

120EI

d

dx

w(L)

q

0

L

3

8EI

x

z w(x)

L, EI

q

0

w(x)

q

0

L

4

120EI

x

5

L

5

+ 5

x

4

L

4

10

x

3

L

3

+ 10

x

2

L

2

_

,

w(L)

q

0

L

4

30EI

d

dx

w(L)

q

0

L

3

24EI

11

Simply supported beam

Load applied at x = L ( < 1), = 1

w(x)

PL

3

6EI

(1

2

)

x

L

x

3

L

3

_

,

for

x

L

x

z w(x) L, EI

L L

P + = 1

w(L)

PL

3

3EI

2

2

. When > one obtains

w

max

w

1

2

3

_

,

w(L)

1 +

3

1 +

3

d

dx

w(0)

PL

2

6EI

(1 + )

d

dx

w(L)

PL

2

6EI

(1 + )

x

z w(x) L, EI

M

A

M

B

w(x)

L

2

6EI

'

M

A

2

x

L

3

x

2

L

2

+

x

3

L

3

_

,

+ M

B

x

L

x

3

L

3

_

d

dx

w(0)

M

A

L

3 EI

+

M

B

L

6 EI

d

dx

w(L)

M

A

L

6 EI

M

B

L

3 EI

w(x)

ML

2

6EI

(1 3

2

)

x

L

x

3

L

3

_

,

for

x

L

x

z w(x) L, EI

L L

M

d

dx

w(0)

ML

6EI

(1 3

2

)

d

dx

w(L)

ML

6EI

(1 3

2

)

w(x)

QL

3

24EI

x

4

L

4

2

x

3

L

3

+

x

L

_

,

x

z w(x) L, EI

Q

w(L/2)

5 QL

3

384 EI

d

dx

w(0)

d

dx

w(L)

QL

2

24EI

w(x)

QL

3

180EI

3

x

5

L

5

10

x

3

L

3

+ 7

x

L

_

,

d

dx

w(0)

7 QL

2

180EI

d

dx

w(L)

8 QL

2

180EI

x

z w(x) L, EI

Q

w(x)

QL

3

180EI

3

x

5

L

5

+ 15

x

4

L

4

20

x

3

L

3

+ 8

x

L

_

,

d

dx

w(0)

8 QL

2

180EI

d

dx

w(L)

7 QL

2

180EI

x

z w(x) L, EI

Q

12

Clamped simply supported beam and clamped clamped beam

Load applied at x = L ( < 1), = 1

Only redundant reactions are given. For deflections, use superposition of solutions

for simply supported beams.

x

z L, EI

M

A

L L

P + = 1

M

A

PL

2

(1

2

)

x

z L, EI

M

A

M

B

M

A

M

B

2

x

z L, EI

M

A

M

L L

+ = 1

M

A

M

2

(1 3

2

)

x

z

L, EI

M

A

Q

M

A

QL

8

x

z

L, EI

M

A

Q

M

A

2 QL

15

x

z

L, EI

M

A

L L

+ = 1

M

B

P M

A

PL

2

M

B

PL

2

x

z

L, EI

M

A

M

L L

+ = 1

M

B

M

A

M (1 3) M

B

M (1 3 )

x

z

L, EI

M

A

Q

M

B

M

A

M

B

QL

12

x

z

L, EI

M

A

Q

M

B

M

A

QL

10

M

B

QL

15

13

6. Material Fatigue

Fatigue limits (notations)

Load Alternating Pulsating

Tension/compression

Bending

Torsion

The Haigh diagram

a

= stress amplitude

m

= mean stress

Y

= yield limit

U

= ultimate strenght

u

,

up

= fatigue limits

, , = factors reducing fatigue limits

(similar diagrams for

ub

,

ubp

and

uv

,

uvp

)

Factors reducing fatigue limits

Surface finish

Factor reducing the fatigue limit due to

surface irregularities

(a) polished surface ( = 1)

(b) ground

(c) machined

(d) standard notch

(e) rolling skin

(f) corrosion in sweet water

(g) corrosion in salt water

t

u

up

t

up

t

ub

ubp

t

ubp

t

uv

uvp

t

uvp

u

a

m

up

up

up

u

Y U

Y

300 600 900 1200 MPa

(a)

(b)

(c)

(d)

(e)

(f)

(g)

U

1.0

0.8

0.6

0.4

0.2

14

Volume factor (due to process)

Factor reducing the fatigue limit due to

size of raw material

(a) diameter at circular cross section

(b) thickness at rectangular cross section

Volume factor (due to geometry)

Factor reducing the fatigue limits

ub

and

uv

due to loaded volume.

Steel with ultimate strength

U

=

(a) 1500 MPa

(b) 1000 MPa

(c) 600 MPa

(d) 400 MPa

(e) aluminium

Factor = 1 when fatigue notch factor K

f

>

1 is used.

Fatigue notch factor K

f

(at stress concentration)

K

t

= stress concentration factor (see Section

12.8)

q = fatigue notch sensitivity factor

Fatigue notch sensitivity factor q

Fatigue notch sensitivity factor q for steel

with ultimate strength

U

=

(a) 1600 MPa

(b) 1300 MPa

(c) 1000 MPa

(d) 700 MPa

(e) 400 MPa

20 40 60 80

10 20 30 40

(a)

(b)

100mm

50mm

1.0

0.8

40 80 120 0

(a)

(b)

(c)

(d)

(e)

Diameter or thickness in mm

1.0

0.9

0.8

K

f

1 + q (K

t

1)

1 10 2 5

(a)

(b)

(c)

(d)

(e)

q

r

1.0

0.8

0.6

0.4

0.2

0.1 0.5

Fillet radius in mm

15

Whler diagram

ai

= stress amplitude

N

i

= fatigue life (in cycles) at stress

amplitude

ai

Damage accumulation D

n

i

= number of loading cycles at stress

amplitude

ai

N

i

= fatigue life at stress amplitude

ai

Palmgren-Miners rule

Failure when n

i

= number of loading cycles at stress

amplitude

ai

N

i

= fatigue life at stress amplitude

ai

I = number of loading stress levels

Fatigue data (cyclic, constant-amplitude loading)

The following fatigue limits may be used only when solving exercises. For a real

design, data should be taken from latest official standard and not from this table.

1

Material Tension Bending Torsion

alternating pulsating alternating pulsating alternating pulsating

MPa MPa MPa MPa MPa MPa

Carbon steel

141312-00 110 110 110 170 150 150 100 100 100

141450-1 140 130 130 190 170 170 120 120 120

141510-00 230

141550-01 180 160 160 240 210 210 140 140 140

141650-01 200 180 180 270 240 240 150 150 150

141650 460

Stainless steel 2337-02,

Aluminium SS 4120-02, ; SS 4425-06,

1

Data in this table has been collected from B Sundstrm (editor): Handbok och Formelsamling i

Hllfasthetslra, Institutionen fr hllfasthetslra, KTH, Stockholm, 1998.

1 2 3 4 5 6 7 0

a

log N

ai

D

n

i

N

i

i 1

I

n

i

N

i

1

t t t t t t

t t t t t t

t

t t t t t t

t t t t t t

t

u

t 270 MPa

ub

t 110 MPa

u

t 120 MPa

16

7. Multi-Axial Stress States

Stresses in thin-walled circular pressure vessel

t

= circumferential stress

x

= longitudinal stress

p = internal pressure

R = radius of pressure vessel

t = wall thickness (t << R)

Rotational symmetry in structure and load (plane stress, i.e.

z

= 0)

Differential equation for rotating circular plate

u = u(r) = radial displacement

= density

= angular rotation (rad/s)

Solution

Stresses

where

Boundary conditions

r

or u must be known on inner and outer boundary of the circular plate

Shrink fit

= difference of radii

p = contact pressure

u = radial displacement as function of p

Plane stress and plane strain (plane state)

Plane stress (in xy-plane) when

z

= 0,

xz

= 0, and

yz

= 0

Plane strain (in xy-plane) when

xz

= 0,

yz

= 0, and

z

= 0 or constant

Stresses in direction (plane state)

() = normal stress in direction

() = shear stress on surface with normal in direction

t

p

R

t

and

x

p

R

2t

(

z

0)

d

2

u

d r

2

+

1

r

d u

d r

u

r

2

1

2

E

2

r

u(r) u

hom

+ u

part

A

0

r +

B

0

r

1

2

8E

2

r

3

r

(r) A

B

r

2

3 +

8

2

r

2

and

(r) A +

B

r

2

1 + 3

8

2

r

2

A

E A

0

1

and B

E B

0

1 +

u

outer

(p) u

inner

(p)

()

x

cos

2

() +

y

sin

2

() + 2

xy

cos()sin()

y

x

( )

( )

() (

x

y

) sin()cos() +

xy

(cos

2

() sin

2

())

17

Principal stresses and principal directions at plane stress state

1

= angle from x axis (in xy plane) to

direction of principal stress

1

Strain in direction (plane state)

() = normal strain in direction

() = shear strain of element with normal in direction

Principal strains and principal directions (plane state)

1

= angle from x axis (in xy plane) to

direction of principal strain

1

Principal stresses and principal directions at three-dimensional stress state

The determinant

gives three roots (the principal stresses)

(contains the nine stress components

ij

)

Direction of principal stress

i

(i = 1, 2, 3) is given by

n

ix

, n

iy

and n

iz

are the elements of the unit

and vector n

i

in the direction of

i

(

T

means transpose)

1, 2

1, 2

c

t R

x

+

y

2

t

x

y

2

_

,

2

+

xy

2

sin(2

1

)

xy

R

or cos(2

1

)

x

y

2R

()

x

cos

2

() +

y

sin

2

() +

xy

sin()cos()

y

x

() (

y

x

) sin(2) +

xy

cos(2)

1, 2

c

t R

x

+

y

2

t

x

y

2

_

,

2

+

xy

2

_

,

2

sin(2

1

)

xy

2R

or cos(2

1

)

x

y

2R

Stress matrix S

x

xy

xz

yx

y

yz

zx

zy

z

1

1

1

1

]

S I 0

Unit matrix I

1 0 0

0 1 0

0 0 1

1

1

1

]

(S

i

I) n

i

0

n

i

T

n

i

1

18

Principal strains and principal directions at three-dimensional stress state

Use shear strain

The determinant

gives three roots (the principal strains)

I = unit matrix

Direction of principal strain

i

(i = 1, 2, 3) is given by

n

ix

, n

iy

and n

iz

are the elements of the unit

and vector n

i

in the direction of

i

(

T

means transpose)

Hookes law, including temperature term (three-dimensional stress state)

= temperature coefficient

T = change of temperature (relative to

temperature giving no stress)

Effective stress

The Huber-von Mises effective stress (the deviatoric stress hypothesis)

The Tresca effective stress (the shear stress hypothesis)

ij

ij

/ 2 for i j

Strain matrix E

x

xy

xz

yx

y

yz

zx

zy

z

1

1

1

1

]

E I 0

(E

i

I) n

i

0

n

i

T

n

i

1

x

1

E

[

x

(

y

+

z

)] + T

y

1

E

[

y

(

z

+

x

)] + T

z

1

E

[

z

(

x

+

y

)] + T

xy

xy

G

yz

yz

G

zx

zx

G

e

vM

x

2

+

y

2

+

z

2

x

y

y

z

z

x

+ 3

xy

2

+ 3

yz

2

+ 3

zx

2

1

2

{(

1

2

)

2

+ (

2

3

)

2

+ (

3

1

)

2

}

e

T

max[

1

2

,

2

3

,

3

1

]

max

pr

min

pr

(pr = principal stress)

19

8. Energy Methods the Castigliano Theorem

Strain energy u per unit of volume

Linear elastic material and uni-axial stress

Total strain energy U in beam loaded in tension/compression, torsion, bending, and

shear

M

t

= torque = M

x

K

v

= section factor of torsional stiffness

M

bend

= bending moment = M

y

= shear factor, see below

Cross section Shear factor

is given for some cross sections in the

table ( is the Jouravski factor, see Section

12.3 One-Dimensional Bodies)

Elementary case: pure bending

Only bending momentet M

bend

is present.

The moment varies linearly along the beam

with moments M

1

and M

2

at the beam ends.

One has

M

bend

(x) = M

1

+ (M

2

M

1

)x

/L, which gives

The second term is negative if M

1

and M

2

have different signs

The Castigliano theorem

= displacement in the direction of force P

of the point where force P is applied

= rotation (change of angle) at moment

M

u

2

U

tot

0

L

'

N(x)

2

2EA(x)

+

M

t

(x)

2

2GK

v

(x)

+

M

bend

(x)

2

2EI(x)

+

T(x)

2

2GA(x)

dx

6/5 3/2

10/9 4/3

2 2

A/A A/A

web web

A

I

2

S

A

b

_

,

2

dA

L, EI

M M

1 2

M

1

M

M

2

x

U

tot

L

6EI

{M

1

2

+ M

1

M

2

+ M

2

2

}

U

P

and

U

M

20

9. Stress Concentration

Tension/compression

Maximum normal stress at a stress concentration is

max

= K

t

nom

, where K

t

and

nom

are given in the diagrams

Tension of flat bar with shoulder fillet Tension of flat bar with notch

Tension of circular bar with shoulder Tension of circular bar with U-shaped

fillet groove

K

t

0

B b

P

nom

=

bh

P

P

r

r/b

B/b

thickness h

3.0

2.5

2.0

1.5

1.0

2.0

1.5

1.2

1.1

1.05

1.01

0.1 0.2

K

t

0

nom

=

bh

P

r

r/b

B/b

P P

B b

thickness h

3.0

2.5

2.0

1.5

1.0

2.0

1.2

1.1

1.05

1.01

0.1 0.2 0.3 0.4 0.5 0.6

K

t

0

nom

=

r

P P

D d

r/d

d

2

D/d

4P

3.0

2.5

2.0

1.5

1.0

2.0

1.5

1.2

1.1

1.05

1.01

0.1 0.2 0.3

K

t

0

nom

=

r

P P

D d

r/d

d

2

D/d

4 P

3.0

2.5

2.0

1.5

1.0

1.2

1.1

1.05

1.01

0.1 0.2 0.3 0.4 0.5 0.6

21

Tension of flat bar with hole

Bending

Maximum normal stress at a stress concentration is

max

= K

t

nom

, where K

t

and

nom

are given in the diagrams

Bending of flat bar with hole Bending of circular bar with hole

2

3

5 B/a=

nom

B

=

0

0 0

K

t

r/a

a

B

0

2r

2r

B -

2.5

2.25

0.1 0.2 0.3 0.4

2.0

2.2

2.4

2.6

2.8

3.0

3.2

K

t

0

nom

=

M M

d

M

b b

b

B

(B-d)h

2

6

d/B

d/h

thickness h

3.0

2.5

2.0

1.5

1.0

0.25

0.5

1.0

2.0

= 0

0.2 0.4 0.6

K

t

0

nom

=

d

M M

3

D

d

d/D

M

D D

6

2

b b

b

32

3.0

2.5

2.0

1.5

1.0

0.1 0.2 0.3

22

Bending of flat bar with shoulder fillet Bending of flat bar with notch

Bending of circular bar with shoulder Bending of circular bar with U-shaped

fillet groove

K

t

0

B b

nom

=

r

r/b

B/b

M

b

M

b

M

b

6

hb

2

thickness h

3.0

2.5

2.0

1.5

1.0

6.0

2.0

1.2

1.05

1.02

1.01

0.1 0.2

K

t

0

nom

=

r

r/b

B/b

B b

M

b

M

b

M

b

6

hb

2

thickness h

3.0

2.5

2.0

1.5

1.0

1.2

1.1

1.05

1.02

1.01

0.1 0.2 0.3 0.4 0.5 0.6

K

t

0

nom

=

r

D d

r/d

d

D/d

3

M

b

M

b

M

b

32

3.0

2.5

2.0

1.5

1.0

6.0

2.0

1.2

1.05

1.02 1.01

0.1 0.2 0.3

K

t

0

nom

=

r

D d

r/d

d

D/d

M

b

M

b

M

b

32

3

3.0

2.5

2.0

1.5

1.0

1.2

1.05

1.02

1.01

0.1 0.2 0.3 0.4 0.5 0.6

23

Torsion

Maximium shear stress at stress concentration is

max

= K

t

nom

, where K

t

and

nom

are

given in the diagrams

Torsion of circular bar with shoulder Torsion of circular bar with notch

fillet

Torsion of bar with longitudinal keyway Torsion of circular bar with hole

K

t

0

nom

=

r

D d

r/d

d

D/d

M M

3

v v

M

v

16

3.0

2.5

2.0

1.5

1.0

2.0

1.3

1.2

1.1

0.1 0.2 0.3

K

t

0

nom

=

r

D d

r/d

d

M M

3

D/d

v v

v

M 16

3.0

2.5

2.0

1.5

1.0

1.2

1.05

1.01

0.1 0.2 0.3 0.4 0.5 0.6

K

t

0 r/d

r

d

8

d

3

nom

=

v

/4

7

d

d

16M

4.0

3.5

3.0

2.5

2.0

0.05 0.10

K

t

0

nom

=

d

M M

3

D

d

d/D

M

v v

v

D

16

D

6

2

2.0

1.5

1.0

0.1 0.2 0.3

24

10. Material data

The following material properties may be used only when solving exercises. For a real

design, data should be taken from latest official standard and not from this table (two values

for the same material means different qualities).

1

Material Youngs 10

6

Ultimate Yield limit

modulus strength tension/ bending torsion

E compression

GPa K

-1

MPa MPa MPa MPa

Carbon steel

141312-00 206 0.3 12 360 >240 260 140

460

141450-1 205 0.3 430 >250 290 160

510

141510-00 205 0.3 510 >320

640

141550-01 205 0.3 490 >270 360 190

590

141650-01 206 0.3 11 590 >310 390 220

690

141650 206 0.3 860 >550 610

Offset yield strength R

p0.2

(

0,2

)

Stainless steel

2337-02 196 0.29 16.8 >490 >200

Aluminium

SS 4120-02 70 23 170 >65

215

SS 4120-24 70 23 220 >170

270

SS 4425-06 70 23 >340 >270

1

Data in this table has been collected from B Sundstrm (editor): Handbok och Formelsamling i

Hllfasthetslra, Institutionen fr hllfasthetslra, KTH, Stockholm, 1998.

25

You might also like

- Solid Mechanics FormulasDocument26 pagesSolid Mechanics FormulasLindi NewmanNo ratings yet

- DX E X A X P: Axial LoadsDocument5 pagesDX E X A X P: Axial LoadsvijshahNo ratings yet

- Formulas in Solid Mechanics - Division of Solid Mechanics PDFDocument26 pagesFormulas in Solid Mechanics - Division of Solid Mechanics PDF陳琮方No ratings yet

- Understanding Stresses in BeamsDocument15 pagesUnderstanding Stresses in BeamsdonjazonNo ratings yet

- Effect of Winkler Foundation On Frequencies and Mode Shapes of Rectangular Plates Under Varying In-Plane Stresses by DQMDocument17 pagesEffect of Winkler Foundation On Frequencies and Mode Shapes of Rectangular Plates Under Varying In-Plane Stresses by DQMSalam FaithNo ratings yet

- Static Equilibrium: M M M F F FDocument41 pagesStatic Equilibrium: M M M F F FINMENo ratings yet

- Beam 6 PDFDocument9 pagesBeam 6 PDFLuis MoranNo ratings yet

- Sébastien Neukirch - Elastic KnotsDocument56 pagesSébastien Neukirch - Elastic KnotsDopameNo ratings yet

- Section III: Load and Stress AnalysisDocument29 pagesSection III: Load and Stress Analysisrameshaarya99No ratings yet

- Free Vibration Analysis of Beams by Using A Third-Order Shear Deformation TheoryDocument13 pagesFree Vibration Analysis of Beams by Using A Third-Order Shear Deformation TheoryalokjietNo ratings yet

- Basic Stress EquationDocument5 pagesBasic Stress EquationtankimsinNo ratings yet

- Large Deflection Static Analysis of Rectangular Plates On Two Parameter Elastic FoundationsDocument9 pagesLarge Deflection Static Analysis of Rectangular Plates On Two Parameter Elastic FoundationsAnonymous wWOWz9UnWNo ratings yet

- ME2061 - Strain GaugesDocument19 pagesME2061 - Strain GaugesJethro JeyarajNo ratings yet

- MD 2Document33 pagesMD 2Wilfredo Nieves OsoriaNo ratings yet

- Dinamika StrukturDocument25 pagesDinamika StrukturErik Wahyu PradanaNo ratings yet

- Torsion in Structural DesignDocument73 pagesTorsion in Structural Designjakeer7100% (1)

- 05-State of Stress in 3D 8.4.16 (8 Files Merged) PDFDocument347 pages05-State of Stress in 3D 8.4.16 (8 Files Merged) PDFChandra Bhushan Choubey100% (1)

- Analysis of hollow-core slab floors finite element procedureDocument13 pagesAnalysis of hollow-core slab floors finite element procedureFrancisco GoFlesNo ratings yet

- Nota Bending MoementDocument47 pagesNota Bending MoementAfiq NajmiNo ratings yet

- L51-Vector Fields and Line IntegralsDocument37 pagesL51-Vector Fields and Line IntegralsQuynh-AnhNo ratings yet

- Waves Scattering Induced by An Interface Crack in A Coated MaterialDocument6 pagesWaves Scattering Induced by An Interface Crack in A Coated MaterialDarioLampaNo ratings yet

- Mass Moment of Inertia Formulas and ApplicationsDocument7 pagesMass Moment of Inertia Formulas and ApplicationsdearsaswatNo ratings yet

- Vibration Analysis of Plates With Cutouts by The Modified Rayleigh-Ritz MethodDocument12 pagesVibration Analysis of Plates With Cutouts by The Modified Rayleigh-Ritz Methodkrisbhaskar22-1No ratings yet

- DYNAMIC ANALYSIS OF LAMINATED CROSS-PLY PANEL UNDER LOCALIZED MOMENT by Ali Be IglooDocument6 pagesDYNAMIC ANALYSIS OF LAMINATED CROSS-PLY PANEL UNDER LOCALIZED MOMENT by Ali Be Iglooantony1993No ratings yet

- INTRODUCTION TO DYNAMIC ANALYSIS OF SIMPLE STRUCTURESDocument37 pagesINTRODUCTION TO DYNAMIC ANALYSIS OF SIMPLE STRUCTURESyuchunieNo ratings yet

- Calculation of Cross Sectional Properties: ArticleDocument7 pagesCalculation of Cross Sectional Properties: ArticleEng TrNo ratings yet

- D. Magnetic Flux and Magnetic Flux DensityDocument5 pagesD. Magnetic Flux and Magnetic Flux Densityjoseph5689No ratings yet

- Structural Element Stiffness Matrices and Mass Matrices: 1 PreliminariesDocument28 pagesStructural Element Stiffness Matrices and Mass Matrices: 1 PreliminariesnetkulaNo ratings yet

- Handouts D8 1Document8 pagesHandouts D8 1ozzy22No ratings yet

- Milano LecturesDocument60 pagesMilano LecturesSkiptippNo ratings yet

- Numerical Analysis of Free Vibrations of Laminated Composite Conical and Cylindrical Shells: Discrete Singular Convolution (DSC) ApproachDocument21 pagesNumerical Analysis of Free Vibrations of Laminated Composite Conical and Cylindrical Shells: Discrete Singular Convolution (DSC) ApproachjssrikantamurthyNo ratings yet

- Flexural Analysis of Thick Beams Using Single Variable Shear Deformation TheoryDocument13 pagesFlexural Analysis of Thick Beams Using Single Variable Shear Deformation TheoryIAEME PublicationNo ratings yet

- MECH3310 Mechanics of Solids 2: The University of SydneyDocument8 pagesMECH3310 Mechanics of Solids 2: The University of SydneyJim LettermanNo ratings yet

- Strength of Materials FinalDocument11 pagesStrength of Materials FinalRenel Alucilja100% (6)

- Lec40 PDFDocument7 pagesLec40 PDFJason DrakeNo ratings yet

- Discretisation: Use of Symmetry: - TypesDocument6 pagesDiscretisation: Use of Symmetry: - TypesShamar JamesNo ratings yet

- Mec Sol 15Document30 pagesMec Sol 15Vinícius GonçalvesNo ratings yet

- Lin Stab AnalysisDocument7 pagesLin Stab AnalysisMohammad RameezNo ratings yet

- Torsion of Orthotropic Bars With L-Shaped or Cruciform Cross-SectionDocument15 pagesTorsion of Orthotropic Bars With L-Shaped or Cruciform Cross-SectionRaquel CarmonaNo ratings yet

- 1013 1877 1 SMDocument7 pages1013 1877 1 SMAgus Hendri WahyudiNo ratings yet

- MANE 4240 & CIVL 4240 Introduction To Finite Elements: Constant Strain Triangle (CST)Document33 pagesMANE 4240 & CIVL 4240 Introduction To Finite Elements: Constant Strain Triangle (CST)Jason MillerNo ratings yet

- MANE 4240 & CIVL 4240 Introduction to Finite ElementsDocument33 pagesMANE 4240 & CIVL 4240 Introduction to Finite ElementsM.Saravana Kumar..M.ENo ratings yet

- Polar Coordinates: Axi-Symmetric ProblemsDocument8 pagesPolar Coordinates: Axi-Symmetric ProblemsalshaijiNo ratings yet

- Engineering Beam Theory For The First Order Analysis With Finite Element MethodDocument46 pagesEngineering Beam Theory For The First Order Analysis With Finite Element MethodPredatator90No ratings yet

- Solution To The Static Stability Problem of Three-Layered Annular Plates With A Soft CoreDocument24 pagesSolution To The Static Stability Problem of Three-Layered Annular Plates With A Soft CoreAssefa NigussieNo ratings yet

- Mech MatDocument11 pagesMech MatDwie OktavianaNo ratings yet

- 06gm CurvesDocument11 pages06gm CurvesRajesh MahapatraNo ratings yet

- Reading Assignment: Logan 6.2-6.5 + Lecture Notes SummaryDocument32 pagesReading Assignment: Logan 6.2-6.5 + Lecture Notes Summarym_er100No ratings yet

- O-H. Kim, Y.C. Kim: 2. TheoryDocument4 pagesO-H. Kim, Y.C. Kim: 2. Theoryjainrakeshj4987No ratings yet

- Propagation of Love Waves in An Elastic Layer With Void PoresDocument9 pagesPropagation of Love Waves in An Elastic Layer With Void PoresAnshul GroverNo ratings yet

- MECH3310 Mechanics of Solids 2: The University of SydneyDocument8 pagesMECH3310 Mechanics of Solids 2: The University of SydneyJim LettermanNo ratings yet

- Vibration Analysis of Cross-Ply Laminated Beams With General Boundary Conditions by Ritz MethodDocument16 pagesVibration Analysis of Cross-Ply Laminated Beams With General Boundary Conditions by Ritz MethodHakim KaciNo ratings yet

- SIF For Cracks in Notched Plates in Biaxial LoadingDocument24 pagesSIF For Cracks in Notched Plates in Biaxial LoadingArun KumarNo ratings yet

- 1.138J/2.062J/18.376J, Wave PropagationDocument2 pages1.138J/2.062J/18.376J, Wave PropagationwenceslaoflorezNo ratings yet

- Linear plate bending and laminate theoryDocument32 pagesLinear plate bending and laminate theorysebastianmatiasNo ratings yet

- Green's Function Estimates for Lattice Schrödinger Operators and Applications. (AM-158)From EverandGreen's Function Estimates for Lattice Schrödinger Operators and Applications. (AM-158)No ratings yet

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- Proving Ring ExperimentDocument7 pagesProving Ring ExperimentPrateek AggarwalNo ratings yet

- 3-D Sheet Metal FormingDocument15 pages3-D Sheet Metal FormingDan WolfNo ratings yet

- Review of Wear Mechanisms in Hip Implants Paper 1 GeneralDocument9 pagesReview of Wear Mechanisms in Hip Implants Paper 1 GeneralCesar EscobarNo ratings yet

- Classification of Composite MaterialsDocument4 pagesClassification of Composite Materialsthasarathanr1993_939No ratings yet

- On Stress Measures in Deformed Solids: by Nasser M. AbbasiDocument57 pagesOn Stress Measures in Deformed Solids: by Nasser M. AbbasircmmrcNo ratings yet

- Replica Metallography and Penetrant TestingDocument14 pagesReplica Metallography and Penetrant TestingBala Singam100% (1)

- Stress and StrainDocument7 pagesStress and StrainAnonymous mXicTi8hBNo ratings yet

- Strain Based Design of PipelineDocument137 pagesStrain Based Design of PipelinejangdiniNo ratings yet

- Article On Brittle Failures by K.K.Parthiban, Boiler Expert, IndiaDocument12 pagesArticle On Brittle Failures by K.K.Parthiban, Boiler Expert, Indiaparthi20065768No ratings yet

- Exam - 5Document13 pagesExam - 5Stanley AlexNo ratings yet

- Steel Beam Design CalculationsDocument45 pagesSteel Beam Design CalculationsOng George SammyNo ratings yet

- Failure Analysis of W e L D Repaired Turbine RotorDocument6 pagesFailure Analysis of W e L D Repaired Turbine RotorAli AlyaniNo ratings yet

- Metal To Plastic ChoiceDocument4 pagesMetal To Plastic ChoicealdozenNo ratings yet

- CSWIP Question Answers PDFDocument32 pagesCSWIP Question Answers PDFAnonymous SA40GK6100% (2)

- Corrosion Resistance of Austenitic and Duplex Stainless Steels in EnvironmentsDocument58 pagesCorrosion Resistance of Austenitic and Duplex Stainless Steels in Environmentssajay2010No ratings yet

- Load Cell Troubleshooting Tips PDFDocument38 pagesLoad Cell Troubleshooting Tips PDFThong Kin MunNo ratings yet

- C. Molecular Forces or Thermal Behavior: FibersDocument14 pagesC. Molecular Forces or Thermal Behavior: FibersKuldeep singh ChandelNo ratings yet

- Mechanical QuizDocument56 pagesMechanical QuizsigmasundarNo ratings yet

- AER 520 Chapter 6 BendingDocument55 pagesAER 520 Chapter 6 BendingzaidNo ratings yet

- Cyclic Behavior of Concrete Bridge Bents: Aci Structural Journal Technical PaperDocument11 pagesCyclic Behavior of Concrete Bridge Bents: Aci Structural Journal Technical PaperpicottNo ratings yet

- Beam End ForcesDocument5 pagesBeam End ForceskalkulaNo ratings yet

- 8552Document6 pages8552yigitilgazNo ratings yet

- MapeWrap EQ NetDocument2 pagesMapeWrap EQ NetdraganugNo ratings yet

- Band Theory of SolidsDocument29 pagesBand Theory of SolidsMohammed Ali KazmiNo ratings yet

- Fundamentals of Friction - Macroscopic and Microscopic ProcessesDocument637 pagesFundamentals of Friction - Macroscopic and Microscopic ProcessesAditi Sen100% (1)

- Casting RefDocument20 pagesCasting RefNavdeep GillNo ratings yet

- High Throughput Production of Nanoscale Liposomes Using Extreme Aspect Ratio Hydrodynamic Flow FocusingDocument3 pagesHigh Throughput Production of Nanoscale Liposomes Using Extreme Aspect Ratio Hydrodynamic Flow Focusingmrh2767No ratings yet

- Jurnal AluminiumDocument14 pagesJurnal AluminiumTyaFattyaNo ratings yet

- Asimen cmt630Document3 pagesAsimen cmt630Fatin HashimNo ratings yet

- ACI Strut and Tie Model Examples-1Document64 pagesACI Strut and Tie Model Examples-1aihr7886% (7)