Professional Documents

Culture Documents

Pile Cap Design 1

Uploaded by

kjpatel2Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pile Cap Design 1

Uploaded by

kjpatel2Copyright:

Available Formats

DAR GROUP

Project

The Pearl

Job Ref.

Q09077

Section

QQ

Sheet no./rev.

1

Calc. by

Eng.TK

Date

09-Mar-08

Chk'd by

Eng.IC

Date App'd by

Dr.AE

Date

e

w1

e

w2

dpile

Ldiag

Loaded area ac, bc

P1

P2 P3

s

s

s

b

L

0.866s

0.288s

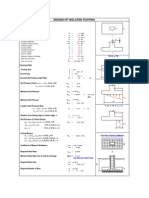

3 Pile Pile Cap,

height h

ac

X

X

Y

bc

Y

PILE CAP DESIGN

DESIGN INPUT - 3-PILE PILE CAP - CONCENTRICALLY LOADED

Pile details

; Pile diameter; dpile = 450.0 mm

; Pile capacity (service); Pcap = 750.00 kN

; Pile spacing; s = 1350.0 mm

Pile spacing OK

; Pile cap overhang ; e = 500.0 mm

Edge distance OK

Pile cap details

Pile cap dimensions

dimension in x-x axis direction ; L = sin(60) s+ dpile +2 e = 2.619 m

dimension in y-y axis direction ; b = s + dpile +2 e = 2.800 m

w1 = dpile+ 2 e = 1.450 m

w2 = dpile+ 2 e = 1.450 m

Diagonal length of sides; Lside_diag = \( (L-w1)

2

+ ((b-w2)/2)

2

) = 1.350 m

;Overall thickness of pile cap; h = 750.0 mm

;Pile embedment distance; ec = 160.0 mm

Embedment distance OK

; Concrete cover; dc = 75.0 mm

; Trial bar diameter; dbar = 19.1 mm

DAR GROUP

Project

The Pearl

Job Ref.

Q09077

Section

QQ

Sheet no./rev.

2

Calc. by

Eng.TK

Date

09-Mar-08

Chk'd by

Eng.IC

Date App'd by

Dr.AE

Date

Effective depth;

dbx = h - ec - dc - dbar/2 = 505 mm

dby = dbx - 1.0 dbar = 486 mm

db = (dbx + dby) / 2 = 496 mm

Column details

; Column width along x-x axis; ac = 400.0 mm

; Column width along y-y axis; bc = 600.0 mm

Material properties

; Yield strength of tension reinforcement; fy = 415 N/mm

2

; Concrete strength; fc = 40.000 N/mm

2

; Concrete density; c = 24.0 kN/m

3

Loading details

Note: The following calculations assume that the centroid of the pile cap coincides with that of the pile group.

; Column axial dead load; Pdl = 1250.000 kN

Area of pile cap; Acap = L b - sin(60) Lside_diag

2

/2 = 6.54 m

2

Weight of pile cap

Pwt = (Acap h - 3 t dpile

2

ec/4) c = 115.967 kN

; Surcharge pressure on cap; psur = 0.000 N/mm

2

Surcharge load;

Psur = psur (L b - (sin(60) Lside_diag

2

)/2 - ac bc ) = 0.000 kN

; Column axial live load; Pll = 425.000 kN

Total column load (unfactored); Pn = Pdl + Pll = 1675.000 kN

The service load per pile; Pn_pile = (Pn + Pwt + Psur)/3 = 596.989 kN

Pile capacity OK

Total column load (factored); Pu = 1.2 Pdl + 1.6 Pll = 2180.000 kN

The ultimate load per pile; Pu_pile = (Pu + 1.2 (Pwt + Psur))/3 = 773.054 kN

PILE CAP FORCES TIED ARCH METHOD

CRSI Fig. 13-13

dcl_pl = \((s/2)

2

+ (0.288*s)

2

) = 778.968 mm

xcl_pl = \(dcl_pl

2

+ db

2

) = 923.448 mm

u = atan(dcl_pl/(db)) = 57.516 deg

u1 = acos((\(db

2

+ (0.288 * s)

2

))/xcl_pl) = 46.967 deg

Compression within pile cap; Cmax = Pu_pile / cos(u) = 1439.409 kN

Tension within pile cap; T = Cmax * sin(u1)/2 = 526.072 kN

COMPRESSION IN PILE CAP - SUGGESTED ADDITIONAL CHECKS

Check compression diagonal as an unreinforced column, using a core equivalent to 2 pile diameters

DAR GROUP

Project

The Pearl

Job Ref.

Q09077

Section

QQ

Sheet no./rev.

3

Calc. by

Eng.TK

Date

09-Mar-08

Chk'd by

Eng.IC

Date App'd by

Dr.AE

Date

;;; Pc = 0.55 0.60 fc t ((2 dpile)

2

)/4 = 8397.477 kN

Compression - OK

ACI 22.5.2

Check bearing capacity of pilecap over piles

A1 = t dpile

2

/4 = 159043 mm

2

; A2 = Acap = 6544410 mm

2

; Pbrg = 0.55 0.85 fc A1 min(2, sqrt( A2 / A1 )) = 5948.213 kN

Bearing - OK

ACI 22.5.5

Check bearing capacity of pilecap under column

;;; A1 = ac bc = 240000 mm

2

Pbrg = 0.65 0.85 fc A1 min(2, sqrt( A2 / A1 )) = 10608.000 kN

Column Bearing - OK

ACI 10.17.1

TENSION STEEL IN PILE CAP

Area of tension steel required for tied-arch behavior

;; As_T = T / (0.75 fy) = 1690 mm

2

Moment at face of column

;;; Distance from pile to face of column; xface = max(.577 s - min(ac,bc) / 2, 0 mm) = 579.0 mm

;;; Pressure due to pile cap selfweight and surcharge; qu = 1.2 (psur + Pwt / Acap) = 0.021 N/mm

2

;;; ;Width at column face; bw = if( xface< L - w1, w2 + 2 .577 xface, b ) = 2.12 m

; Ultimate moment at column face

Muy = Pu_pile xface - qu (w2 xface

2

/ 2 + 2 .577 xface

3

/3)= 440.8 kNm

Area of tension steel required for flexure

; |1 = if(fc < 27.58 N/mm

2

, 0.85, max( .65, 0.85 - 0.05 (fc - 27.58 N/mm

2

) / 6.89 N/mm

2

)) = 0.760

et = 0.319 |1 = 0.242

Ru = et (1 0.588 et) = 0.208

; Rreqd = Muy / ( fc db

2

) / bw = 0.021153

Section dimensions are OK to be tension-controlled;

J = sqrt(max(.25 - Rreqd / 0.85 / 2.,0) ) + .5 = 0.9874

Asflex = Muy / ( 0.90 fy J db ) = 2410 mm

2

; Minimum ratio of tension reinforcement for temperature and shrinkage

ACI 7.12.1

min = 0.001800

ACI 10.5.1

As_min = max( 3 \(fc ) b db / fy, 200 b db / fy )

As_min = 5272 mm

2

As_43 = (4/3 max(As_T,Asflex))

Ast_min = if(As_min > As_43, max(min b h, As_43), max(min b h, As_min))

DAR GROUP

Project

The Pearl

Job Ref.

Q09077

Section

QQ

Sheet no./rev.

4

Calc. by

Eng.TK

Date

09-Mar-08

Chk'd by

Eng.IC

Date App'd by

Dr.AE

Date

Ast_min = 3780 mm

2

As_req_normal = max(Asflex, Ast_min, As_T) = 3780 mm

2

As_req = As_req_normal / (2 cos(30)) = 2182 mm

2

; Try 9 No #6 bar(s);

Each set of bars should be placed in the direction of axis connecting center of piles (triangular pattern)

As_prov = 2565 mm

2

dbar = Dt = 19.0 mm

acon = As_prov fy / (0.85 fc b) = 11.182 mm

ccon = acon / |1 = 0.048

ct = 0.003 ((dbx ccon) / ccon) = 0.100

Pass - Ductility OK at ultimate strength.;

Area of bars - OK;

CLEAR DISTANCE BETWEEN BARS IN TENSION (ACI 7.6)

;;;; Assume reinforcing is put into a strip with a width equal to 3 pile diameters

Bar spacing, c-c; spcc = max(0 mm, (3 dpile - dbar)/(Lnt - 1)) = 166.4 mm

Clear spacing; spclear = max(0 mm, (spcc - dbar)) = 147.3 mm

spmin = max(dbar, 25.4 mm) = 25.4 mm

ACI 7.6.1

spmax = 457.2 mm

ACI 7.6.5

Bar spacing - OK

DEVELOPMENT OF TENSION STEEL

All bars must be provided with standard 180 end hooks.

Check hook development length (ACI 12.5)

;;;;;;;;; ldh_1 = (0.02 | fy / \(fc)) dbar = 301.076 mm

mod1 = if(((dbar<=35.814 mm)&&(dc>=63.5 mm)),0.7, 1.0 ) = 0.7

ldh = max(ldh_1 mod1, 152.4 mm, 8 dbar) = 210.8 mm

Hook development length OK

SHEAR ACI 15.5

Shear checks

;;;;;;;;;

Punching of single pile must be checked

Punching of pile at corner must be checked

Punching of overlapping piles must be checked

One way shear @d distance in the section parallel to y-y axis is not applicable

One way shear @d distance in the section parallel to x-x axis is not applicable

Punching shear @ d/2 from column face is not applicable

One way shear @ column face in the section parallel to y-y axis direction must be checked

One way shear @ column face in the section parallel to x-x axis must be checked

Punching shear @ column face must be checked

DAR GROUP

Project

The Pearl

Job Ref.

Q09077

Section

QQ

Sheet no./rev.

5

Calc. by

Eng.TK

Date

09-Mar-08

Chk'd by

Eng.IC

Date App'd by

Dr.AE

Date

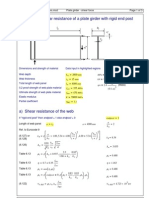

CHECK PUNCHING OF SINGLE PILE (ACI 11.12.2)

;;;; bo = t (dpile + db) = 2971.8 mm

Vc = 4 \(fc) bo db = 3096.086 kN

Vs = 0 kN

|Vn = 0.75 (Vc + Vs) = 2322.065 kN

Vup = Pu_pile = 773.1 kN

Pile punching capacity - OK

CHECK PUNCHING OF SINGLE PILE AT CORNER (ACI 11.12.2)

;;;;; bo = t (dpile + db)/4 + 2 (e + dpile / 2) = 2192.9 mm

Vc = 4 \(fc) bo db = 2284.669 kN

Vs = 0 kN

|Vn = 0.75 (Vc + Vs) = 1713.502 kN

Vup = Pu_pile = 773.1 kN

Pile punching capacity at corner - OK

CHECK PUNCHING OF OVERLAPPING PILES (ACI 11.12.2)

;;;;; bo = t (dpile + db) + 2 s = 5671.8 mm

Vc = 4 \(fc) bo db = 5909.015 kN

Vs = 0 kN

|Vn = 0.75 (Vc + Vs) = 4431.762 kN

Vup = 2 Pu_pile = 1546.1 kN

Pile punching capacity at overlap - OK

ONE-WAY (BEAM) SHEAR THREE PILE CAP (ACI 11.12, 15.5)

Design ultimate shear force @ column face

;;;;;;;;;;;;;;;

xd = max( (L - e - dpile/2 - .288 s - ac/2), 0 mm ) = 1305.3 mm

bx = min((w2 + 2 (e+dpile/2) * tan(30)),(\(2w1

2

)))

bx = 2050.6 mm

Vu_face = Pu_pile = 773.054 kN

VMrat = Muy / (Vu_face db) = 1.150

Section shear capacity

Concrete strength; fc = 40.000 N/mm

2

; w = As_prov / ( bx db ) = 0.002522

f1 = (db/xface) (3.5 - 2.5 VMrat) = 0.536

f2 = 1.9 \(fc) = 0.998 N/mm

2

f3 = 2500 w/ VMrat = 0.038 N/mm

2

Vc1 = f1 (f2 + f3) bx db = 564.493 kN

DAR GROUP

Project

The Pearl

Job Ref.

Q09077

Section

QQ

Sheet no./rev.

6

Calc. by

Eng.TK

Date

09-Mar-08

Chk'd by

Eng.IC

Date App'd by

Dr.AE

Date

Vc2 = min( Vc1, 10 \(fc) bx db ) = 564.493 kN

CRSI Eq. 13-2

Vc = max( Vc2, 2 \(fc) bx db ) = 1068.189 kN

Vs = 0 kN

|Vn = 0.75 (Vc + Vs) = 801.142 kN

One-way shear capacity - OK

TWO-WAY (PUNCHING) SHEAR CHECK (ACI 11.12.2)

Total length of shear perimeter at column face (CRSI Design Handbook)

;;;;;;; Perimeter (@d/2); bo = 2 (bc + db + ac + db) = 3983.8 mm

Perimeter (@face); bs = 2 (ac + bc) = 2000.0 mm

Concrete strength; fc = 40.000 N/mm

2

Punching shear; Vup = Pu + (Psur + Pwt) (smin(b,s))/L

2

= 2210.810 kN

Shear capacity of concrete

w = max(if(N==3, .577 s, s/2 ) - ac/2, s/2 - bc/2, .001 mm) = 579.0 mm

Vc1 = (db/w) (bo/bs) 2 \(fc) bs db = 1777.704 kN

Vc2 = min( Vc1, 32 \(fc) bs db ) = 1777.704 kN

Vc = max( Vc2, 4 \(fc) bo db ) = 4150.500 kN

Vs = 0 kN

|Vn = 0.75 (Vc + Vs) = 3112.875 kN

Two-way shear capacity - OK

;;

You might also like

- Pile CAP Design Example + 2 PilesDocument3 pagesPile CAP Design Example + 2 PilesTharanga Pradeep100% (1)

- Design of Pile CapDocument120 pagesDesign of Pile Capcivilaskar100% (3)

- Pile Cap For 1 PilesDocument5 pagesPile Cap For 1 Pileshemantkle2u80% (5)

- Pile Cap For 4 PilesDocument4 pagesPile Cap For 4 Pileshemantkle2u100% (2)

- Pile Cap For 3 PileDocument3 pagesPile Cap For 3 Pilehemantkle2u50% (2)

- Pile Cap DesignDocument6 pagesPile Cap DesignSree Arvind Harish SomasundaramNo ratings yet

- 3 PilesDocument37 pages3 PilesAnonymous nwByj9LNo ratings yet

- Design for Pile Cap Calculation SheetDocument3 pagesDesign for Pile Cap Calculation Sheetbhaskardharani50% (2)

- Pile Cap Design (4-Piles)Document4 pagesPile Cap Design (4-Piles)Uttam Kumar GhoshNo ratings yet

- Design of Footing 091807Document1 pageDesign of Footing 091807Albert Dimayuga0% (1)

- RC Pile Cap Design (ACI318)Document4 pagesRC Pile Cap Design (ACI318)topukuet75% (4)

- Pile Cap For 2 PilesDocument5 pagesPile Cap For 2 Pileshemantkle2uNo ratings yet

- 600MM Pile Cap DesignDocument2 pages600MM Pile Cap DesignVishal Nanavare0% (1)

- Kda - Factory Ii (Gen - Trias, Cavite) Design of MicropilesDocument4 pagesKda - Factory Ii (Gen - Trias, Cavite) Design of MicropilesRoda Cadiz100% (4)

- Combined Footing Analysis and DesignDocument20 pagesCombined Footing Analysis and DesignNeil SonNo ratings yet

- Design of Isolated Footing With Vertical Load Only - According To ACI-318-99Document3 pagesDesign of Isolated Footing With Vertical Load Only - According To ACI-318-993cesNo ratings yet

- Long Term Deflection DesignDocument1 pageLong Term Deflection DesignklynchelleNo ratings yet

- View Topic - Pile Cap Design Using SafeDocument5 pagesView Topic - Pile Cap Design Using SafeParameswaran GanesanNo ratings yet

- Cantilever Footing Design CalculationsDocument8 pagesCantilever Footing Design CalculationsHafiz Kamarudin100% (2)

- Double Dragon Octagon Pile Cap DesignDocument228 pagesDouble Dragon Octagon Pile Cap Designraymond80% (5)

- Reinforced Concrete Pile Cap Design CalculationsDocument14 pagesReinforced Concrete Pile Cap Design CalculationsHoihogo Hoi100% (1)

- Design of isolating footing subjected to moment and shear forcesDocument4 pagesDesign of isolating footing subjected to moment and shear forcesashisheckNo ratings yet

- 2 Piles Cap Design bs8110Document3 pages2 Piles Cap Design bs8110Faizal ImranNo ratings yet

- Pile Cap DesignDocument25 pagesPile Cap DesignGanesh Konar100% (5)

- Design of eccentric footing and beam projectDocument5 pagesDesign of eccentric footing and beam projectJagadeesh Sundaram100% (1)

- Design of Pile FoundationDocument17 pagesDesign of Pile FoundationNarnindi Venkata Ramananda SagarNo ratings yet

- Combined Strap FootingDocument8 pagesCombined Strap FootingNoman Khan100% (2)

- Foundation Analysis and Design: Michael Valley, S.EDocument52 pagesFoundation Analysis and Design: Michael Valley, S.Esalahaddinsharif100% (3)

- Isolated Footing Design by SefianDocument6 pagesIsolated Footing Design by SefianManoj Kumar Pal80% (5)

- Pile Cap Design For 3-Piles Pattern Based On ACI 318-14Document18 pagesPile Cap Design For 3-Piles Pattern Based On ACI 318-14VikasVarmaNo ratings yet

- Design of Raft FoundationDocument9 pagesDesign of Raft FoundationAnonymous ciKyr0tNo ratings yet

- Composite Floor BeamDocument6 pagesComposite Floor BeamAhmed Ben Hmida50% (2)

- Pile Cap ForDocument3 pagesPile Cap ForSunil SinghNo ratings yet

- EXAMPLE: - Calculation of Design Seismic Force by Static Analysis Method DataDocument17 pagesEXAMPLE: - Calculation of Design Seismic Force by Static Analysis Method DataNikhil100% (1)

- Pile Cap DesignDocument2 pagesPile Cap DesignsivaNo ratings yet

- Combined FootingDocument2 pagesCombined Footingsantosh-a-biraj-330750% (6)

- Pile Cap Design - 3-PileDocument6 pagesPile Cap Design - 3-PileParth DaxiniNo ratings yet

- Design of Eccentric Footing - F5Document3 pagesDesign of Eccentric Footing - F5Nikita MeshramNo ratings yet

- Strap Footing Sample PDFDocument6 pagesStrap Footing Sample PDFRegan Tandukar44% (9)

- Footing and beam design for column layoutDocument65 pagesFooting and beam design for column layoutarif_rubinNo ratings yet

- Pile Cap Design Calculations With CSI SAFEDocument7 pagesPile Cap Design Calculations With CSI SAFEMiguel J.No ratings yet

- Eccentric FootingDocument5 pagesEccentric Footingdaddakoli007No ratings yet

- Design of Beams & Slab (ACI 318-14)Document354 pagesDesign of Beams & Slab (ACI 318-14)emonwre100% (1)

- Crack Width Design - IS456-2000Document1 pageCrack Width Design - IS456-2000Nitesh SinghNo ratings yet

- Design of STRIP FoundationDocument21 pagesDesign of STRIP FoundationPremasiri Karunarathna100% (5)

- Strip Footing 3 Columns Bsi 8110 - 2Document11 pagesStrip Footing 3 Columns Bsi 8110 - 2Magdy Bakry100% (2)

- RC Column Design (ACI318-05)Document5 pagesRC Column Design (ACI318-05)Rizwan MirzaNo ratings yet

- EC2 Continuous Beam DesignDocument14 pagesEC2 Continuous Beam Designikanyu79No ratings yet

- Steel Column BeamDocument6 pagesSteel Column Beamdharul khairNo ratings yet

- 6 Pile GroupDocument4 pages6 Pile GroupAnonymous nwByj9L100% (1)

- FinalDocument42 pagesFinalVishnu Kumar0% (1)

- Indrumator Metal - EGDocument37 pagesIndrumator Metal - EGhooky1100% (1)

- RC MEMBER DESIGN CALCULATIONSDocument3 pagesRC MEMBER DESIGN CALCULATIONS郑 凯伦 Tey Kai LoonNo ratings yet

- SEO-Optimized Beam Design CalculationDocument169 pagesSEO-Optimized Beam Design CalculationabuzahrauNo ratings yet

- Gorakhpur Bypass RobDocument9 pagesGorakhpur Bypass RobvivekNo ratings yet

- EC2 Beam DesignDocument4 pagesEC2 Beam Designikanyu79No ratings yet

- Ec9 Ex61 Shear No StiffenersDocument3 pagesEc9 Ex61 Shear No StiffenersimotalpNo ratings yet

- Sloped FootingDocument19 pagesSloped FootingBala ChandarNo ratings yet

- Gantry CraneDocument18 pagesGantry Craneamirthraj7494% (16)

- Aegis Padlock 3 ManualDocument21 pagesAegis Padlock 3 Manualkjpatel2No ratings yet

- Dresser Blackhawk Hot Tap-Line Stop ProductsDocument20 pagesDresser Blackhawk Hot Tap-Line Stop Productskjpatel2No ratings yet

- Okonite Engineering HandbookDocument65 pagesOkonite Engineering Handbooktomgilmartin100% (1)

- AutopipeDocument53 pagesAutopipeAlfonso ChipaNo ratings yet

- Dresser Blackhawk Hot Tap-Line Stop ProductsDocument20 pagesDresser Blackhawk Hot Tap-Line Stop Productskjpatel2No ratings yet

- CB&I Horton SpheresDocument6 pagesCB&I Horton Sphereskjpatel2No ratings yet

- Dresser Blackhawk Hot Tap-Line Stop ProductsDocument20 pagesDresser Blackhawk Hot Tap-Line Stop Productskjpatel2No ratings yet

- Dresser Blackhawk Hot Tap-Line Stop ProductsDocument20 pagesDresser Blackhawk Hot Tap-Line Stop Productskjpatel2No ratings yet

- Rebar Info - SizesDocument1 pageRebar Info - Sizeskjpatel2No ratings yet

- UA Seismic ParametersDocument1 pageUA Seismic Parameterskjpatel2No ratings yet

- Center Line Plan & Mat Foundation Detail 10.02.12-ModelDocument1 pageCenter Line Plan & Mat Foundation Detail 10.02.12-Modelkjpatel2No ratings yet

- Design Guide For Floor VibrationsDocument56 pagesDesign Guide For Floor Vibrations_at_to_No ratings yet

- Section DesignerDocument191 pagesSection DesignergreatwellwisherNo ratings yet

- Analysis and DesignDocument8 pagesAnalysis and Designkjpatel2No ratings yet

- StateadoptionsDocument2 pagesStateadoptionskjpatel2No ratings yet

- STAADetcDocument8 pagesSTAADetckjpatel2No ratings yet

- Section 13206 - Pressurized Steel Tanks City of San Diego, CWP Guidelines Part 1 - GeneralDocument5 pagesSection 13206 - Pressurized Steel Tanks City of San Diego, CWP Guidelines Part 1 - Generalkjpatel2No ratings yet

- Anchoring in Cracked ConcreteDocument11 pagesAnchoring in Cracked Concretekjpatel2No ratings yet

- Ad Case StudyDocument74 pagesAd Case StudyShreya AndeNo ratings yet

- Plumbing code requirements for piping dimensionsDocument50 pagesPlumbing code requirements for piping dimensionsChristine Joyce RoseteNo ratings yet

- Automatic Self-Climbing Formwork PeriDocument2 pagesAutomatic Self-Climbing Formwork PeriSivaram KottaliNo ratings yet

- Cement & Sand Coefficient CalculationDocument10 pagesCement & Sand Coefficient Calculationmallikarjuna ketheNo ratings yet

- Installation and maintenance tips for engineered quartz surfacesDocument1 pageInstallation and maintenance tips for engineered quartz surfacesSuresh JainNo ratings yet

- CavitationDocument1 pageCavitationmcsfuvNo ratings yet

- Choke PerformanceDocument18 pagesChoke PerformanceJúlio César Nascimento100% (2)

- Standard Design of Wazu (Wadu) KhanaDocument3 pagesStandard Design of Wazu (Wadu) KhanaSohail ShaikhNo ratings yet

- Boq For Level 02 & Level 52Document47 pagesBoq For Level 02 & Level 52Aneesh YohannanNo ratings yet

- HDPE-100 Catalogue PDFDocument9 pagesHDPE-100 Catalogue PDFkumar sandeepNo ratings yet

- Design Principles: Crane Sheave BasicDocument6 pagesDesign Principles: Crane Sheave BasicUsman GhaniNo ratings yet

- 2014-09-09 Construction Meeting Minutes PDFDocument3 pages2014-09-09 Construction Meeting Minutes PDFIthacaVoiceNo ratings yet

- Damage Temperature Inspection MonitoringDocument11 pagesDamage Temperature Inspection MonitoringRaghavan Venkatraman100% (1)

- Analysis and Design of Hollow Reinforced Concrete ColumnsDocument5 pagesAnalysis and Design of Hollow Reinforced Concrete ColumnsEditor IJRITCC100% (1)

- Ground-Mount Solar Array FoundationsDocument12 pagesGround-Mount Solar Array FoundationsimamtaNo ratings yet

- Assignment On Consolidation IVsemDocument2 pagesAssignment On Consolidation IVsemRockey100% (1)

- Retaining Wall Design (Final)Document6 pagesRetaining Wall Design (Final)ifylasyNo ratings yet

- #4 Retainer Wall Design (DRAFT 12012021)Document97 pages#4 Retainer Wall Design (DRAFT 12012021)Seek n DestroyNo ratings yet

- Lesson 3Document15 pagesLesson 3ahmedsabercgNo ratings yet

- Industrial Bearing Price List 2017Document88 pagesIndustrial Bearing Price List 2017gaurav guptaNo ratings yet

- Tunnel Form Construction Technique and ProcessDocument5 pagesTunnel Form Construction Technique and ProcessManish ShashikantNo ratings yet

- Characteristic Performance of PEB Vs CSBDocument19 pagesCharacteristic Performance of PEB Vs CSBAyon SenguptaNo ratings yet

- Arches and Vaults: Building Structure VDocument45 pagesArches and Vaults: Building Structure VRachana MuppalaNo ratings yet

- Introduction Tribology ViscosityDocument13 pagesIntroduction Tribology ViscosityMadan MohanasundaramNo ratings yet

- Roof purlin design and stress analysisDocument1 pageRoof purlin design and stress analysis_jessecaNo ratings yet

- Anite WorkDocument4 pagesAnite WorkShenbagaraja PandianNo ratings yet

- Construction Materials Sample Exit Exam QuestionsDocument120 pagesConstruction Materials Sample Exit Exam QuestionsSemereNo ratings yet

- 1992 Chana & DesaiDocument6 pages1992 Chana & DesaiMarcus FreitasNo ratings yet

- Ce 602 Set CDocument9 pagesCe 602 Set CJade Paul D. BesanaNo ratings yet

- Gas Dynamics Question BankDocument3 pagesGas Dynamics Question BankChanduNo ratings yet