Professional Documents

Culture Documents

DLW Varanasi

Uploaded by

Priyesh Kumar SinghOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DLW Varanasi

Uploaded by

Priyesh Kumar SinghCopyright:

Available Formats

Diesel Locomotive Works

Varanasi, one of the oldest populated cities in the world and has a promising place in the international ground both as a hub of traditions and technology. One side the humming of divine and holy bells of the temples brings the city to life; on other side Diesel Locomotive Works (DLW) Varanasi is one of the largest industrial unit in eastern part of the nation. DLW catch the attention of lot of foreign tourist students to observer on going amazing locomotive manufacturing process in Varanasi. Diesel Locomotive works Varanasi is located at the North end of the city and about 8 Km away from the Holy River Ganges Ghats. DLW is an ISO 9002, ISO 14001 & OHS 18001 Certified Organization of diesel electric locomotive.

Diesel Locomotive Works, Varanasi (DLW) is one of the main manufacturing units run by the Indian Railways. This manufacturing unit came into existence in year 1961, as a Green Field Project in industrial association with ALCO, USA. This unit generate all the Diesel Electric Locomotives. In year 1964, the first locomotive was manufactured and it was devoted to the country. Diesel Locomotive Works, Varanasi produces only Electric Diesel locomotives and auxiliary parts of locomotives. However it is an Indian corporation but it has supplied locomotives to some foreign countries also, includes Angola, Bangladesh, Malaysia, Myanmar, Sri Lanka, Vietnam and Tanzania.

Diesel Locomotive manufacturing Works, Varanasi is works into three main sections that include Engine section Vehicle section Block section

Engine section manufacture more than 2000 machinery, which comprise ALCO turbo superchargers, cylinder heads, connecting rods, camshafts, lubricating oil pumps, chrome plated cylinder liners and many different types of gears

Vehicle section of DLW unit works on different fields that include Bogie Manufacturing, Component Fabrication, Locomotive Assembly, under frame Fabrication, and many more.

Currently, Diesel Locomotive Works, Varanasi constructs locomotives and DG sets. In locomotives section, again it manufactures two different types of products, one is EMD and another is ALCO.

Classification of Locomotives

In India, locomotives are classified according to their track gauge, motive power, the work they are suited for and their power or model number. The class name includes this information about the locomotive. It comprises 4 or 5 letters. The first letter denotes the track gauge. The second letter denotes their motive power (Diesel or Electric) and the third letter denotes the kind of traffic for which they are suited (goods, passenger, mixed or shunting).One of the earliest pictures of railways in India The fourth letter used to denote locomotives' chronological model number. However, from 2002 a new classification scheme has been adopted. Under this system, for newer diesel locomotives, the fourth letter will denote their horsepower range. Electric locomotives don't come under this scheme and even all diesel locos are not covered. For them this letter denotes their model number as usual. A locomotive may sometimes have a fifth letter in its name which generally denotes a technical variant or subclass or subtype. This fifth letter indicates some smaller variation in the basic model or series, perhaps different motors, or a different manufacturer. With the new scheme for classifying diesel locomotives (as mentioned above) the fifth item is a letter that further refines the horsepower indication in 100 hp increments: 'A' for 100 hp, 'B' for 200 hp, 'C' for 300 hp, etc. So in this scheme, a WDM-3A refers to a 3100 hp loco, while a WDM-3F would be a 3600 hp loco.

The classification syntaxes

The first letter (gauge)

W-Indian broad gauge (The "W" Stands for Wide Gauge - 5 Feet 6 inches) Y-metre gauge (The "Y" stands for Yard Gauge - 3 Feet or 1000mm) Z-narrow gauge(2 ft 6 in) N-narrow gauge (2 ft)

The second letter (motive power)

D-Diesel C-DC electric (can run under DC traction only) A-AC electric (can run under AC traction only) CA-Both DC and AC (can run under both AC and DC tractions), 'CA' is considered a single letter B-Battery electric locomotive (rare)

The third letter (job type)

G-goods P-passenger M-mixed; both goods and passenger S-Used for shunting (Also known as switching engines or switchers in United states and some other countries) U-Electric multiple units (used as commuters in city suburbs) R-Railcars

For example, in "WDM 3A":

"W" means broad gauge "D" means diesel motive power "M" means suitable for mixed(for both goods and passenger)service "3A" means the locomotive's power is 3,100 hp ('3' stands for 3000 hp, 'A' denotes 100 hp more)

Or, in "WAP 5":

"W" means broad gauge "A" mean AC electric traction motive power "P" means suitable for Passenger service "5" denotes that this locomotive is chronologically the fifth electric locomotive model used by the railways for passenger service.

Different Types of locosDiesel traction

WDM - Wide Diesel Mixed WDP - Wide Diesel Passenger WDG - Wide Diesel Goods WDS - Wide Diesel Shunter

Mixed type locomotives:

WDM 1 (First mainline diesel electric locomotives used in India. Introduced in 1957. Imported from ALCO. Out of service now. 1950 hp) WDM 2 (Most widely used and first homemade mainline diesel-electric locomotives in India. Original prototypes were made by ALCO. Introduced in 1962. More than 2700 have been made. Rated at 2600 hp) WDM 2A,WDM 2B (Technical variants of WDM 2) WDM 3 (Only 8 were imported. They used hydraulic transmission and are currently nonfunctional) WDM 3A (Formerly WDM 2C. Another WDM 2 variant. It is not related to WDM 3. 3100 hp) WDM 3A R (Formerly WDM 2. It is a rebuilt with DBR fitted on Short Hood. It is not related to WDM 3. 3100 hp) WDM 3C, WDM 3D (higher powered versions of WDM 3A) WDM 4 (Entered service along with WDM 2. Prototypes designed by General Motors. Though considered superior to WDM 2 in many ways, these locomotives weren't chosen as General Motors did not agree to a technology transfer agreement. 2600 hp) WDM 6 (Very rare class; only two were made; one is being used by Puttalam Cement Factory in Sri Lanka. Rated at 1200 HP) WDM 7 (Fifteen of these locos were built from June 1987 through 1989, they were designed for branch-line duties, but they are now used mostly for shunting. Rated at 2000 hp)

Passenger locomotives:

WDP 1 WDP 2 (New class name WDP 3A. Dedicated passenger diesel locomotive. Entered service in 1998. Powerful locomotive. 3100 hp) WDP 3 (This locomotives are actually prototypes of the class WDP 1 and never entered serial production.) WDP 4 (EMD (former GM-EMD) GT46PAC, fundamentally a passenger version of the WDG 4 (GT46MAC). 4000 hp) WDP 4B (EMD (former GM-EMD) GT46PAC, An improved version of the WDP 4, this is a more powerful version and has 6 traction motors, just like the WDG 4. Also comes with wider cabin to aid visibility and minor exterior design changes. 4500 hp) WDP 4D (EMD (former GM-EMD) GT46PAC, This is basically a WDP 4B with twin cabs. Minor changes were made to the locomotive to facilitate the addition of a second cabin. This locomotive comes with LCD instrument display and toilet for the drivers. As of now, two units have been made and are expected to enter full-time service soon. 4500 hp)

Goods locomotives:

DG 2 (New class name WDG 3A. These class is actually a technically upgraded form of WDM 2) WDG 3B, WDG 3C, WDG 3D (Technical upgraded forms of WDG 2 or WDG 3A) WDG 4 (New dedicated goods locomotives. These are General motors' GT46MAC models. First units were imported in 1999. They are numbered from #12000 upward. Local production started on 2002. 4000 hp) WDG 5 (Another Freight dedicated Locomotive developed by Diesel Locomotive Works and Supported by Electro Motive Diesels. First unit was rolled out from DLW on 25 February 2012. They are numbered from #50001 upward. Rated at 5500 hp. Equipped with Fire Control System, TFT Display and Driver's Toilet.)Loco is still under trials in DLW, Varanasi. The locomotive/series is named 'BHEEM', after the strong Pandav brother from epic of Mahabharat.

Shunting locomotives (Also known as switching engines):

WDS 1 (First widely deployed and successful diesel locomotives used in India. Imported in 1944-45. currently out of service. 386 hp) WDS 2 (currently out of service.) WDS 3 (All locomotives of this class were rebuilt and reclassified as WDS 4C in 197678. 618 hp) WDS 4,WDS 4A,WDS 4B,WDS 4D (Designed by Chittaranjan Locomotive Works. 600-700 hp) WDS 4C (Rebuilt WDS 3 locos as mentioned above) WDS 5 (Some of these locomotives are used for industrial shunting. A few are used on Indian Railways. Rated at 1065 hp) WDS 6 (Heavy-haul shunters made in large numbers for industrial concerns as well as for Indian Railways Rated at 1200/1350 hp) WDS 8 (Only five of these were made, and all were transferred to steel works 800 hp)

Products manufactured at DLW VaranasiDLW manufactures two different types of products EMD ALCO

EMD WDG4 - 4000 HP GOODS LOCOMOTIVE Broad Gauge freight traffic Co-Co diesel electric locomotive with 16 Cylinder 4000 HP engine, AC-AC transmission, microprocessor controlled propulsion and braking with high traction high speed cast steel trucks. First turned out in 1999 with transfer of technology from General Motor (USA), this locomotive has exceptional fuel efficiency and very low maintenance requirements. It is specifically designed for heavy haul freight traffic requirements of Indian Railways for the 21st Century. The heart of loco Traction Control Converter uses the GTO devices (obsolete technology). Now the IGBT devices, has been introduced from Oct2006. It is the latest technology and will be cost effective and gives higher reliability. The locomotive power has been upgraded to 4500 BCV and the first Loco (Loco No 12114) was manufactured in May07 Diesel Engine

Transmission

16 Cylinder 710 G3B, 2 stroke, turbocharged after cooled Fuel Efficient Engine Injection System Direct Unit Injector Governor Woodward Compression Ratio- 16:1 Lube Oil Sump Capacity 950 Lts

Electrical AC-AC 6 Traction motor ( 3 in parallel per bogie) Suspension Axle hung / taper roller bearing Gear Ratio 90:17

Truck

Brakes

High adhesion HTSC ( High Tensile Steel Cast) truck of bogie Adhesion 0.42

Electronic Air Brake System ( KNORR-NYAB-Computer Controlled Braking) Air , hand , dynamic brake Pure air brake

General Characteristic

Installed Power Axle Load Gauge Wheel arrangement Wheel diameter Height Width Overall Length (Over Buffer Beam)

4000 HP 21 T 1676 mm Co-Co 1092 mm 4201 mm 3127 mm 19964 mm 126 T 54 T 100 Kmph 6000 lts EM 2000 with SIBAS-16

Weight Max tractive effort Maximum speed Fuel tank capacity Locomotive Control

Traction Control

WDG4-4000 LOCOMOTIVE

HP

GOODS TRACTIVE CHART

EFFORT

&

POWER

WDP4 4000 HP PASSENGER LOCOMOTIVE State-of-Art, Microprocessor controlled AC-AC, Passenger Locomotive

Powered with 16-710G3B 4000HP Turbo charged Two stroke Engine. Fabricated rigid design Under frame, two stage suspension, High Traction High Speed 3 axle (HTSC) light weight cast truck frame attribute to high adhesion performance. First turned out in 2003, this locomotive has exceptional fuel efficiency and very low maintenance requirements. It is specifically designed for heavy haul passenger traffic requirements for Indian Railways The WDP4 fleet is being upgraded by provision of hotel load feature along with power upgradation to 4500 HP. The prototype will be manufactured in the year 2007. Diesel Engine

Transmission

16 Cylinder 710 G3B, 2 stroke, turbocharged after cooled Fuel Efficient Engine Injection System Direct Unit Injector Governor Woodward Compression Ratio- 16:1 Lube Oil Sump Capacity 1073 Lts

Electrical AC-AC 4 Traction motor ( 3 in parallel per bogie) Suspension Axle hung / taper roller bearing Gear Ratio 77:17

Truck

Brakes

High adhesion HTSC ( High Tensile Steel Cast) truck or bogie Adhesion 0.42

Electronic Air Brake System ( KNORR-NYAB-Computer Controlled Braking) Air , hand , dynamic brake with fully blended with automatic brakes Pure air brake

General Characteristic

Installed Power Axle Load Gauge Wheel arrangement Wheel diameter Height Width Overall Length (Over Buffer Beam)

4000 HP 19.5 T 1676 mm A-A-I I-A-A 1092 mm 4201mm 3127 mm 19964 mm 117 T 27 T 160 Kmph 4000 lts EM 2000 with SIBAS-16 Traction Control

Weight Max tractive effort Maximum speed Fuel tank capacity Locomotive Control

ALCO

1350 VDM

HP

CAPE

GAUGE

LOCOMOTIVE 4

TECHNICAL INFORMATION 1350 HP Locomotive having fabricated cape gauge Co-Co bogie. hese locomotives have been supplied to Angola and Sudan. Wheel Arrangement Co - Co Track Gauge 1067 mm Cape gauge Weight 72 t Overall Length 15600 mm

921 mm 18: 93 90 Kmph Type : ALCO 251 D 6 Cyl. in line. HP 1350 Transmission Electrical AC/DC Brake 28LAV-1 system Loco Air, dynamic, parking Train Air & Vacuum Fuel Tank Capacity 3000 Litres Contact Details for Product Purchase 2300 HP CAPE GAUGE LOCOMOTIVE

Wheel Diameter Gear Ratio Maximum Speed Diesel Engine

TECHNICAL INFORMATION 2300 HP Main Line Locomotive, having fabricated cape gauge Co-Co bogies. These are provided with two drivers cabs, one at each end. These locomotives have been supplied to Angola and Sudan. Wheel Arrangement Co-Co Track Gauge 1067 mm Cape Gauge Weight 102 t Overall Length 17620 mm Wheel Diameter 921 mm Gear Ratio 18 : 93 Maximum Speed 100 Kmph Diesel Engine Type : ALCO 251-B 12 Cyl. VEngine HP 2300 Transmission Electrical AC/DC

Brake IRAB-1 Loco Air, Dynamic, parking Train Air Fuel Tank Capacity 3000 Litres Contact Details for Product Purchase 2300 HP METER GAUGE LOCOMOTIVE

TECHNICAL INFORMATION 2300 HP Main Line Locomotive, having fabricated meter gauge Co-Co bogies. These are provided with two drivers cabs, one at each end. These locos have been supplied to Malaysia, Senegal and Mali. Wheel Arrangement Co-Co Track Gauge 1000 mm Meter Gauge Weight 102 t Overall Length 17620 mm Wheel Diameter 921 mm Gear Ratio 18 : 93 Maximum Speed 100 Kmph Diesel Engine Type : ALCO 251-B 12 Cyl. VEngine HP 2300 Transmission Electrical AC/DC Brake IRAB-1 Loco Air, Dynamic, parking Train Air Fuel Tank Capacity 3000 Litres Contact Details for Product Purchase 3000 HP CAPE GAUGE LOCOMOTIVE

TECHNICAL INFORMATION ( Provisional Specifications) 3000 HP Micro Processor Controlled, Main Line, Cape Gauge Locomotive with improved Cab, under development for Mozambique Railway. Wheel Arrangement Co-Co Track Gauge 1067 mm Cape Gauge Weight 114 t Overall Length 18632 mm Wheel Diameter 1000 mm Gear Ratio 19 : 92 Maximum Speed 100 Kmph Diesel Engine Type : ALCO 251-C 16 Cyl. VEngine HP 3000 Transmission Electrical AC/DC Brake IRAB-1 Loco Air, Dynamic Train Air Fuel Tank Capacity 6000 Litres Contact Details for Product Purchase 1350 YDM4 HP METER GAUGE LOCOMOTIVE

TECHNICAL INFORMATION 1350 HP Locomotive having cast / fabricated meter Gauge Co-Co bogie. Such locomotives have been supplied to Vietnam and Myanmar. Wheel Arrangement Co - Co

IRAB 1 system / 28LAV-1 Loco Air, dynamic, parking Train Air / Dual (Air and Vacuum) Fuel Tank Capacity 3000 Litres Contact Details for Product Purchase BROAD WDG 3A GAUGE MAIN LINE FREIGHT LOCOMOTIVE

Track Gauge Weight Overall Length Wheel Diameter Gear Ratio Maximum Speed Diesel Engine HP Transmission Brake

1000 mm 72 t 15600 mm 965 mm 18: 93 96 Kmph ALCO 251 D 6 Cyl. in line. 1350 Electrical AC/DC

TECHNICAL INFORMATION Diesel Electric main line, heavy duty goods service locomotive, with 16 cylinder ALCO engine and AC/DC traction with micro processor controls. Wheel Arrangement Co-Co Track Gauge 1676 mm Weight 123 t Length over Buffers 19132 mm Wheel Diameter 1092 mm Gear Ratio 18 : 74 Min radius of Curvature 117 m Maximum Speed 105 Kmph Diesel Engine Type : 251 B,16 Cyl.V HP 3100

Brake IRAB-1 Loco Air, Dynamic Train Air Fuel Tank Capacity 6000 litres Contact Details for Product Purchase BROAD WDM 3D GAUGE MAIN LINE MIXED SERVICE LOCOMOTIVE

TECHNICAL INFORMATION Diesel Electric Locomotive with micro processor control suitable for main line mixed Service train operation. Wheel Arrangement Co-Co Track Gauge 1676 mm Weight 117 t Max. Axle Load 19.5 t Length over Buffer 18650 mm Wheel Diameter 1092 mm Gear Ratio 18 : 65 Maximum Speed 120 Kmph Diesel Engine Type : 251 B-16 Cyl. V type (uprated) HP 3300 HP (standard UIC condition) Transmission Electric AC / DC Brake IRAB-1 system Loco Air, Dynamic, Hand Train Air Fuel Tank Capacity 5000 litres BROAD GAUGE SHUNTING LOCOMOTIVE WDS 6AD

TECHNICAL INFORMATION A heavy duty shunting Diesel Electric Locomotive for main line and branch line train operation. This locomotive is very popular with Steel Plants and Port Trusts. Wheel Arrangement Co-Co Track Gauge 1676 mm Weight 113 t Length over Buffer 17370 mm Wheel Diameter 1092 mm Gear Ratio 74 : 18 Maximum Speed 50 Kmph Diesel Engine Type : 251 D-6 Cyl. in-line HP 1350 / 1120 HP (std.) Transmission Electric AC / DC Brake IRAB-1 Loco Air Train Air Fuel Tank Capacity 5000 litres Dlw Have 3 divisions BLOCK DIVISION ENGINE DIVISION LOCO DIVISION

BLOCK DIVISION

Flame Cutting of Components Steel plates of sizes up to 80 mm thickness are ultrasonically tested before being precision cut by numerically controlled flame cutting machines, Plasma Cutting Machine. Components are straightened and machined prior to fitting & tacking on fixture designed specially for engine block fabrication to ensure close tolerance on engine block.

Fabrication of Engine Block/ Crankcase Components after flame cutting and various machining operations are fit and tack welded before taking on rollovers. Heavy Argon-CO2 welding is done on these rollovers. High quality of welding is done by qualified welders. Weld joints are subjected to various tests like ultrasonic, X-rays, Visual etc. Down-hand welding is ensured using specially designed positioners. Fabrication of engine block is completed by submerged arc welding using semi-automatic welding machines. Special fixtures are used for making down-hand welding possible in inaccessible areas. Critical welds are subjected to radiographic examination. All welders are periodically tested and re-qualified for the assigned. After complete welding weldment is stress relieved and marking is done for subsequent machining. Portal Milling Machine Engine block machining is done on Portal Milling Machine which is a 5 axis CNC machine with SIEMENs 840-D state of art system control with dedicated tool management system. This machine performs milling, drilling, tapping and boring operations in single setting. The machine accuracy of 10enables adhering to the tolerance required on engine block. Angular Boring Machine Angular boring "V" boring is done of special purpose machine which is a special purpose machine, which has two high precision angular boring bars on which different boring inserts are mounted. The cutting inserts on boring bars to achieve evenly distributed cutting load during boring operation. This contributes to accuracy while machining. Boring bars are mounted on high precision bearings which provide control on size during angular boring. The machine is capable of boring and drilling to different sizes.

ENGINE DIVISION

COMPONENT MACHINING Over 2000 components are manufactured in-house at DLW. These include ALCO turbo super chargers, lubricating oil pumps, cam shafts, cylinder heads, laser hardened cylinder liners, connecting rods and various gears. Our well-equipped Machine Shops have dedicated lines for operations like turning, milling, gear hobbing, drilling, grinding and planning etc. In addition, DLW is equipped with a variety of special purpose machines and a large number of state-of-the-art CNC machines to ensure quality and precision. Associated manufacturing process like heat treatment and induction hardening are also carried out in-house. A new eco friendly laser hardening machine has been setup which is designed to laser harden the inner bore of engine cylinder liner and this feature advantages such as low running cost, state of the art controls to provide reliable and versatile laser power for ultimate quality requirements. Engine Assembly & Testing

Pre-inspected engine block, crankshaft, cylinder liners, pistons, connecting rods, cylinder heads, exhaust manifold, turbo supercharger and all related piping are used in assembly of engine. Electrical machines like traction alternator, auxiliary generator and exiter are thereafter coupled on the engine. The complete power pack with electrics are tested on computerized Engine Test Bed to verify prescribed horsepower output. Vital parameters of engine health are checked to assure the quality of product. Only after the engine parameters are found perfect the power pack are cleared for application on locomotives.

LOCO DIVISION

Component Fabrication Precision cutting and forming of sheet metalis utilised for manufacture of superstructures including drivers cab engine hoods, and compartments for housing electrical equipment. All activities connected with pipes like pickling, bending, cutting, forming and threading of pipes of various sizes are undertaken in another well-equipped work area. All electrical equipment is assembled in the fabricated control compartments and driver's control stands are done in another work area. Underframe Fabrication Under frames are fabricated with due care to ensure designed weld strength. Requisite camber to the under frame is provided during fabrication itself. Critical welds are tested radio-graphically. Welder training and their technical competence are periodically reviewed. High Horse Power (HHP) under frame is fabricated using heavy fixtures, positioners to ensure down hand welding. Fixtures are used to ensure proper fitting of components and quality welding in subsequent stages. BOGIE MANUFACTURING Special purpose machines are utilized for machining cast and fabricated bogie frames. Axle and wheel disc machining is undertaken on sophisticated CNC machines. Inner diameter of wheel discs are matched with the outer diameter of axles and assembled on wheel press. The complete truck (bogie), including bogie frames, wheels and axles, brake rigging and traction motors are assembled which is ready for application to locomotive. LOCOMOTIVE ASSEMBLY Tested engines are receive from Engine Division. Similarly under frames are received from Loco frame shop and assembled trucks from Truck machine shop. Superstructure compartments and contractor compartment are received from Respective manufacturing and assembly shops of Vehicle Division. Important alignments like crank shaft deflection, compressor alignment and Eddy Current clutch/radiator fan alignment are done during assembly stage. Electrical control equipments are fitted and control cable harnessing is undertaken. The complete locomotive is thus assembled before being sent onwards for final testing and spray painting. All locomotive are rigorous tested as per laid down test procedures before the locomotive is taken up for final painting and dispatch for service.

You might also like

- The Key To Metal Bumping (Panel Beating, Auto Body Repair Bible)Document69 pagesThe Key To Metal Bumping (Panel Beating, Auto Body Repair Bible)wulfgang2498100% (11)

- Carboguard 703 GFDocument2 pagesCarboguard 703 GFlhanx2100% (2)

- Part List WDS6 PDFDocument198 pagesPart List WDS6 PDFmajjisatNo ratings yet

- Maintain Diesel Locomotive FiltersDocument22 pagesMaintain Diesel Locomotive FiltersmajjisatNo ratings yet

- Emex PDFDocument4 pagesEmex PDFWolf LillyNo ratings yet

- Toshiba X-ray Generator ManualDocument125 pagesToshiba X-ray Generator ManualFrancisco Diaz100% (9)

- Locomotives in IndiaDocument18 pagesLocomotives in IndianelanandNo ratings yet

- Intro To DSL LocoDocument26 pagesIntro To DSL Locokr_abhijeet72356587100% (2)

- Summer Training-Diesel Loco Shed 2014, TughlakabadDocument53 pagesSummer Training-Diesel Loco Shed 2014, TughlakabadSHAHFAHADJAMIA80% (10)

- Indian Locomotive Class WDM-2 - Wikipedia, The Free EncyclopediaDocument4 pagesIndian Locomotive Class WDM-2 - Wikipedia, The Free Encyclopediasassyboy4uNo ratings yet

- Six Weeks Training Report DLWDocument20 pagesSix Weeks Training Report DLWvinaykumaryadav75% (4)

- How Powerful Is A Railway Engine?: 192 Upvotes by Kunal Sharma, Ramanuja Chakraborty, Ronak Jain, (More)Document3 pagesHow Powerful Is A Railway Engine?: 192 Upvotes by Kunal Sharma, Ramanuja Chakraborty, Ronak Jain, (More)Ajay Kumar75% (4)

- GM Locomotive STCDocument39 pagesGM Locomotive STCMUKESH KUMAR100% (1)

- Summer Traning DLW ReportDocument55 pagesSummer Traning DLW ReportRavi Sagar83% (6)

- Diesel Locomotive ShedDocument8 pagesDiesel Locomotive ShedDrSumedha SarmaNo ratings yet

- Draft Maintenance Manual For Non AC LHB CoachesDocument511 pagesDraft Maintenance Manual For Non AC LHB CoachesBharat ki rail Bharat ki jeevan rekha100% (1)

- Technical Specification For APU - EMD LocomotivesDocument16 pagesTechnical Specification For APU - EMD LocomotivesBoora Rajashekher0% (1)

- Latest Circuit Description of WDS6 Loco With WW GovernorDocument13 pagesLatest Circuit Description of WDS6 Loco With WW GovernormajjisatNo ratings yet

- Diesel Locomotive Power PackDocument43 pagesDiesel Locomotive Power PackME Tool Design CITDNo ratings yet

- DLW Varanasi 2Document8 pagesDLW Varanasi 2Jalaj ChaudharyNo ratings yet

- ALCO Loco BreakersDocument2 pagesALCO Loco BreakersmajjisatNo ratings yet

- List SpecDocument7 pagesList Specdivisional electrical engg100% (1)

- EmuDocument18 pagesEmuKundan KumarNo ratings yet

- Spec Hotel Load Conv P4 - Rev 0 - Aug 12Document35 pagesSpec Hotel Load Conv P4 - Rev 0 - Aug 12divisional electrical enggNo ratings yet

- Traction Motor 1Document47 pagesTraction Motor 1IC QUEENNo ratings yet

- Engine Erection ShopDocument2 pagesEngine Erection ShopSmriti MehraNo ratings yet

- Railways Project (Final)Document40 pagesRailways Project (Final)Arka Nandy100% (1)

- Vdocument - in - Air Brake System of LocomotiveDocument65 pagesVdocument - in - Air Brake System of LocomotiveNaveenkondiNo ratings yet

- All Systems - ALCO LocoDocument56 pagesAll Systems - ALCO Locochandu mohamedNo ratings yet

- Spart: Under Floor MountedDocument4 pagesSpart: Under Floor MountedVijay AnandNo ratings yet

- Mainenace Guidelines For LHB Cocahes.Document7 pagesMainenace Guidelines For LHB Cocahes.Parthaprotim Nath0% (1)

- Maintenance Manual 1400 HP DEMUs PDFDocument556 pagesMaintenance Manual 1400 HP DEMUs PDFSunil Jadhav58% (12)

- DLW 4 Weeks Internship ReportDocument25 pagesDLW 4 Weeks Internship Reportanshaj singhNo ratings yet

- Why Turbo Super Charger Is Used in Diesel LocomotiveDocument5 pagesWhy Turbo Super Charger Is Used in Diesel LocomotiveDrSumedha SarmaNo ratings yet

- HOG Operation Presentation On HOGDocument12 pagesHOG Operation Presentation On HOGdivisional electrical engg100% (1)

- 1.introduction To Carriage Workshop LallagudaDocument28 pages1.introduction To Carriage Workshop Lallagudavenkatesh naniNo ratings yet

- LHB Coach GuideDocument21 pagesLHB Coach Guide4179309100% (1)

- Maintenance Handbook For Traction Motor TAO-659 PDFDocument45 pagesMaintenance Handbook For Traction Motor TAO-659 PDFsumitNo ratings yet

- MJR MSE LLL DSL BookDocument147 pagesMJR MSE LLL DSL Bookbalaji817150No ratings yet

- Must Change Item in PohDocument23 pagesMust Change Item in Pohmailbkrao100% (1)

- BHEL Summer Training Report 2019Document53 pagesBHEL Summer Training Report 2019SubscribeNo ratings yet

- Final-Draft Spec of AC-AC System For HHP LocosDocument101 pagesFinal-Draft Spec of AC-AC System For HHP LocosRahul KumarNo ratings yet

- Revised Maintenance Manual For LHB AC and Non AC CoachesDocument261 pagesRevised Maintenance Manual For LHB AC and Non AC CoachesAjay KumarNo ratings yet

- Railway Internship FINAL REPORTDocument62 pagesRailway Internship FINAL REPORTsubhendu sardarNo ratings yet

- WDG4D 4500 HP (Mp-Misc-312) Jan-2016Document17 pagesWDG4D 4500 HP (Mp-Misc-312) Jan-2016raja shekarNo ratings yet

- Bogie Container Flat Wagon Type Blca & BLCBDocument5 pagesBogie Container Flat Wagon Type Blca & BLCBRaj ThakurNo ratings yet

- Handbook On WDP4 WDG4 Locomotives For Maintenance Staff PDFDocument125 pagesHandbook On WDP4 WDG4 Locomotives For Maintenance Staff PDFabhinav lohia100% (2)

- HHP Locomotive's BogiesDocument47 pagesHHP Locomotive's BogiesSAI KRISHNAN LNo ratings yet

- Alternator RewindDocument39 pagesAlternator RewindanwarNo ratings yet

- Report Vocational TrainingDocument43 pagesReport Vocational Traininghbyubuybiu ubbhybNo ratings yet

- Railways Dee (G)Document41 pagesRailways Dee (G)Piyush RanjanNo ratings yet

- 8w-Detc Maintenance ManualDocument87 pages8w-Detc Maintenance Manualarun100% (1)

- ALCO Loco Auto Flasher Light - 0Document6 pagesALCO Loco Auto Flasher Light - 0majjisatNo ratings yet

- Booklet On Roof Mounted Package Unit of LHB Coaches-30 - 03 - 2021Document61 pagesBooklet On Roof Mounted Package Unit of LHB Coaches-30 - 03 - 2021praveen_01236No ratings yet

- Air Conditioning and Train Lighting SystemsDocument109 pagesAir Conditioning and Train Lighting SystemsDipankar SinghNo ratings yet

- Mechanical Question BankDocument22 pagesMechanical Question Bankmustafa67% (3)

- DBOOK wdg4Document13 pagesDBOOK wdg4RUDHRESH KUMAR SNo ratings yet

- Bringing Joy Through Dependable Business SolutionsDocument19 pagesBringing Joy Through Dependable Business SolutionsjaikolangaraparambilNo ratings yet

- Report On Summer Training at DLW, VaranasiDocument35 pagesReport On Summer Training at DLW, VaranasiHimanshu Singh43% (7)

- Final Training Report (Turbocharger)Document31 pagesFinal Training Report (Turbocharger)Jack Williams75% (4)

- Diesel Locomotive All Series (Report)Document24 pagesDiesel Locomotive All Series (Report)sandeep kumar vishwakarmaNo ratings yet

- Industrial Visit Report To Shakurbasti and TRTCDocument46 pagesIndustrial Visit Report To Shakurbasti and TRTCRachit Goel0% (1)

- Summer Training Report On DLW VaransiDocument36 pagesSummer Training Report On DLW VaransiAmit B Chauhan64% (11)

- Unit 3 Production and Cost AnalysisDocument6 pagesUnit 3 Production and Cost Analysismanjunatha TK100% (1)

- Keywords: Sanitary Napkins, Chlorine, Uv-Vis SpectrophotometryDocument10 pagesKeywords: Sanitary Napkins, Chlorine, Uv-Vis SpectrophotometryFajar PriyonoNo ratings yet

- Unit 2 Me1203Document20 pagesUnit 2 Me1203Muthuvel MNo ratings yet

- Valorizing Spent Coffee GroundsDocument15 pagesValorizing Spent Coffee GroundsJorge ZapataNo ratings yet

- Command: V C CV18-CV26, CV620-CV750Document24 pagesCommand: V C CV18-CV26, CV620-CV750Jim AndrewsNo ratings yet

- GATE 2005 - Question Paper TF: Textile Engineering and Fiber ScienceDocument25 pagesGATE 2005 - Question Paper TF: Textile Engineering and Fiber ScienceChandra Deep Mishra100% (1)

- Esteem SeminarDocument83 pagesEsteem SeminarTK LauNo ratings yet

- Diagnostic Exam for Aeronautical Engineering StudentsDocument4 pagesDiagnostic Exam for Aeronautical Engineering StudentsBerns DulamNo ratings yet

- Premier R' Series Generator: Operator'S Manual For YourDocument37 pagesPremier R' Series Generator: Operator'S Manual For YourRon SchmittNo ratings yet

- Variable Injection TimingDocument2 pagesVariable Injection Timingvran770% (1)

- Assignment: Q.N.1. in A Turning Operation, It Was Observed That The Tool Life Was 150 Minutes When The CuttingDocument7 pagesAssignment: Q.N.1. in A Turning Operation, It Was Observed That The Tool Life Was 150 Minutes When The CuttingAnkesh KapilNo ratings yet

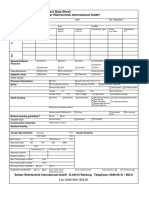

- Agitator Data Sheet Stelzer Rührtechnik International GMBH: CompanyDocument1 pageAgitator Data Sheet Stelzer Rührtechnik International GMBH: CompanyDeepikaNo ratings yet

- NSH KBR Skop e 009 - Bus Duct Installation and TestingDocument7 pagesNSH KBR Skop e 009 - Bus Duct Installation and TestingFrancisco Severino Gatoc Jr.No ratings yet

- QweqDocument2 pagesQweqPraYush RajbhandariNo ratings yet

- Crane Packing ListDocument2 pagesCrane Packing Listmanas3sNo ratings yet

- Insulating Systems For High-Voltage Rotating MachinesDocument16 pagesInsulating Systems For High-Voltage Rotating MachinesNikulin JoelNo ratings yet

- Fin FANDocument2 pagesFin FANNorman Morales100% (1)

- DONE ElectSpeciBook PDFDocument35 pagesDONE ElectSpeciBook PDFMaulik RavalNo ratings yet

- TC Cico SuperDocument2 pagesTC Cico SuperHks InfrastructureNo ratings yet

- Fiber Home Adss-12h Span120 DatasheetDocument2 pagesFiber Home Adss-12h Span120 DatasheetAlberto LazoNo ratings yet

- Hard Turning On LatheDocument105 pagesHard Turning On LatheJitendraNo ratings yet

- Method Statement for Painting Concrete SurfacesDocument5 pagesMethod Statement for Painting Concrete Surfacesxxx100% (2)

- I S 613 - 2000Document11 pagesI S 613 - 2000Hariprasad gantyalaNo ratings yet

- Types, Properties and Uses of Bituminous MaterialsDocument8 pagesTypes, Properties and Uses of Bituminous MaterialsOctavian StoichitaNo ratings yet

- 7.1 - Cooling Water SystemDocument8 pages7.1 - Cooling Water SystemSayem kaifNo ratings yet

- Dye Penetrant 2Document18 pagesDye Penetrant 2Paul LadjarNo ratings yet