Professional Documents

Culture Documents

Blum Slesai Ing

Uploaded by

Angga Dwi SaputraOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Blum Slesai Ing

Uploaded by

Angga Dwi SaputraCopyright:

Available Formats

LIQUID WASTE PROCESSING and MANAGEMENT Completion-TEXTILE INDUSTRY Environmentally friendly S3 Industrial Management PDIE UII Yogyakarta Department

/ Department of Chemical Engineering-Textiles Faculty of Industrial Technology UII

ABSTRACT

Perfecting-textile industry is one industry that plays an important role in the national economic development, and it still is one Indonesia mainstay industry in growing foreign exchange. But, as industry Another, textile industry, chemical industry, especially textiles, which can also produce waste pollute the surrounding environment, which can result in damage ecosystems, disruption of life of living beings (including humans), and damage natural resources. Important parts of the waste treatment technology, chemical industry textiles include the control and treatment of wastewater. in the form of liquid waste is processed physics, chemistry, biology and others. Chemical industrial wastewater treatment technology, the efficient and effective textile strongly influenced by the techniques of waste minimization and management be integrated on key activities, such as waste reduction, prevention supervision / control and careful planning in order to obtain results in the form of a sustainable textile finishing industry and eco-friendly

Keywords : processing & liquid waste management, industrial-textile improvement, environmentally friendly

I. INTRODUCTION

Textiles is one of the staples that people need, plays a role important in the national economic system and, until now the textile industry is still one of the leading industries in growing foreign State. Like other industries, besides having a positive aspect, on the other hand the textile industry also has negative aspects, which produce waste that can pollute the environment with the growing importance of environmentally sound industries, especially with the issued Law No. 4 of 1982,

Government Regulation No. 29 year 1986 as well as some government policies and attitudes of institutions of civil society organizations both at international, national and regional (local) related to environmental issues, sooner or later all the textile industry have to process the waste in order to achieve quality in Indonesia , a textile factory is a factory that can only make the process spinning, weaving process / knitting, process improvement or process of manufacture of wearing apparel (garment) alone. Many manufacturers are only doing some of the process, but there is also representing an integrated factory in the beginning of the thread until the process of making improvements. Therefore, at a textile factory, process technology, textile machines, problems and digunak gas and energy and the type and amount of product produced. impact on the environment, is highly dependent on the type and amount of raw materials, auxiliary materials, water, gas and energy as well as digunak the type and amount of product produced This paper will focus on wastewater treatment in industry (processing), textile finishing, because the industry's most Banak is known to produce several kinds of waste, both waste cairdan gas wastes pollute the surrounding environment, which can result in deterioration or danger to human health, disruption of life, ecosystem disruption and damage to natural resources.

II.

Textiles and Industrial Process Improvement Impact on Environment

The existence of the industry can not be divorced from the environment, because it was industrial waste wastewater, waste air, noise and solid waste, need to be controlled and processed so that the net and free of pollution before discharge into the environment. Textile finishing industry is an industry engaged in textile wet processes cause the most pollution, because the work of textile chemicals in solution using water as the medium, to produce white cloth (gray), cloth bags or seal. Stages of preparation for the preparatory process improvements and process improvements can end differently, depending on the type of fabric (fiber), which is processed and the quality of products that want to produce. Similarly, for every step of the process can be used appliance / machine opposite. Also process conditions and the type of materials used can vary depending on fiber type and quality of products that want to produce. These processes can be done other than its entirety in sequence, can also be done part or modified, depending on the type of textile material that will be done, a tool that is available and the final result is expected. The existence of the use of chemicals such as alkali, acid, starch,

oxidant, reductant electrolyte, surface active substances (surfactant), dyes, polymers sententik and heat, can cause the textile industry wastewater alkaline or acidic, high COD and BOD, color, foaming , baud's hot. Level of pollution generated depends on the kind of material being worked, working processes and types of machinery / equipment used. Flowchart of the dyeing and printing of each is presented in Figure 1 and 2. In general characteristics of liquid waste removed from the severalstage process for the material improvement of cotton, rayon, polyester and mixtures thereof, remove liquid waste, with pollution levels are relatively high material. High pollution are also excluded from the process of cooking, bleaching, dyeing and printing. In addition, the washing after dyeing and printing materials also release contaminants that need attention.

III.

Waste Management

Textile finishing industry in the activities of the production process much use of dyes and chemicals that bring environmental problems, because some chemicals and textile auxiliary substances will be discharged into the environment along the waste gas / air, liquid and solid wastes. These wastes must be processed and controlled in order not to cause environmental contamination.

III.a Liquid Waste Treatment

Wastewater treatment to reduce contaminants, such as organic substances, compounds containing nitrogen, suspended solids / deposited, compounds and other salts. Most of these pollutants, especially organic substances, a substance absorbing oxygen, reducing dissolved oxygen in the water and disrupt the lives of water biota. Besides, wastewater contaminants often out of the process in a hot state, so it needs to be cooled before being processed. Treatment of wastewater from done physics, chemistry, biology and others. The results from the improvement of cotton waste is usually directly processed by microorganisms, because the chemical processes and fiskulasi koogulasi and needs a lot koogulan to eliminate the high BOD. Except for waste dyes usually can not be lost on biological processes, it is necessary to process chemical koogulasi or absorption with activated carbon. To achieve good results economically needs to be done the following things: a.Perlu be segregated for dyeing wastewater containing chromium salts or copper is

used for dye fastness in the director. Subsequently processed in the process of precipitation of heavy metal salts, and specifically enacted as a waste of poisonous substances hazardous (B3) b. Other dyeing waste also be separated before rinsing process, for processing and flakulasi especially koogulasi, then mixed with other waste to be processed in a biological or activated carbon absorption process. c. Needs to be done before the conditioning of wastewater biological treatment, among others, the appropriate temperature with a temperature of cultivating microorganisms (about 350C), pH between 6.5 to 9.5, the addition of nutrients, where appropriate, other contract according to the type of anaerobic microorganism, nitrification or denitrification.

Apart from these, there is detergent, wetting agent, salt electrolytes and the remnants of fibers in the liquid waste to consider the selection of liquid waste processing methods, and results achieved.

Table 1. Efficiency results of multiple ways of processing wastewater from textile industry

Methods - (screening) - Few without koogulan - Koogulasi and flocculation -Trickling filter (aerob) -Lumpur aktif(aerob+anaerob) - Normal pool (Aerob+anaerob) - Pond Aeration (aerob+anaerob+denitrifikasi)

BOD (%) 0-5 5-12 25-60 40-85 75-95 30-80 50-95

SS (%) 5-20 15-20 30-90 80-90 85-95 30-80 50-95

TDS (%) 0 0 0-50 0-30 0-40 0-40 0-40

NOTE : BOD = Biochemical Oxygen Demond SS = Saspended Salid TDS= Total Dissaeved Salid

III.b Type of Waste UPL

From the waste processing unit (UPL) mainly liquid waste, some types of waste produced, namely solid waste / liquid, liquid waste, and waste gas phase. Table 2. The efficiency of sludge drying process (separating solids from liquids) Methods The efficiency of drying of sludge (%) Lime - Gravity concentration - Centrifugal evaporation -Belt filter press -Vacuum Filter -Pressure filter -Sand drying bed - Evaporation ponds 15-30 55-65 45-60 55-60 50 50-60 Koogulasi 3-4 10-20 30-45 20-25 20-25 7-15

Aspects of wastewater treatment technologies that efficient textile finishing industry is strongly influenced by the techniques of waste minimization (source reductive) through several changes in the product, the prevention and careful planning, material control (product control) to changes in material inputs, technological change and a good implementation of this operation; also of recycling activities (recycling) within and outside the industry locations, such use and reuse (use and reuse) and reclamation of waste materials from returning.

IV. Conclusion

a. Textile finishing industry is one of the downstream industry, besides having positive impacts (for foreign countries) also carries the potential negative effects (of pollution), and the level of pollution generated depends on the types of materials used, process and type of equipment / machinery used. Waste must be treated and controlled so as not to pollute the environment. b. Management and treatment of wastewater can be done in physics, chemistry, biology, etc., and can be done in various ways with different efficiencies depending on the type of technology used in processing. c. Treatment and management of the textile finishing industry wastewater is heavily influenced by environmental friendly waste minimization techniques be integrated into the activities of the key, such as waste reduction, prevention and careful planning, and others.

V. References

Budiman,A. 2001. Penghematan limbah energy-kimia secara efisien.Jurnal PSEUGM: Yogyakarta.

Atkins,M.H. and Lowe J.F., 1982. Case studies in Pollution control measures in the Textile dyeing and finishing industries. Pergamon Press, ISA Edition: London. Boma W.T., 1992. Limbah dan Permasalahannya. Makalah Training Workshop, Teknik Pengolahan Limbah: Yogyakarta. BPPI/SOPWI-BBT. 1995. Panduan Penggunaan Teknologi Bersih untuk Industri Tekstil dengan Pencelupan. Kerjasama antara Badan Penelitian dan Pengembangan Industri (PBBI), Pusat Penelitian dan Pengembangan Sumber Daya Prasarana dan Wilayah Industri (SDPWI) dengan Balai Besar Tekstil (BBI): Bandung

You might also like

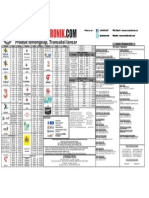

- Petunjuk Transaksi: Ppob Pascabayar Produk Kode Admin FEEDocument1 pagePetunjuk Transaksi: Ppob Pascabayar Produk Kode Admin FEEAngga Dwi SaputraNo ratings yet

- А. Project Opportunity DescriptionDocument3 pagesА. Project Opportunity DescriptionAngga Dwi SaputraNo ratings yet

- Piping and Instruments Diagram 07 Ke 24Document1 pagePiping and Instruments Diagram 07 Ke 24Angga Dwi SaputraNo ratings yet

- Mining LTC CexDocument1 pageMining LTC CexAngga Dwi SaputraNo ratings yet

- Adsorption Engineering, Suzuki (1990)Document278 pagesAdsorption Engineering, Suzuki (1990)Nigel Mitchell80% (5)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- OChem LabTechniques 2nded PDFDocument389 pagesOChem LabTechniques 2nded PDFthshaoNo ratings yet

- Preparation, Characterization and Photocatalytic Activity of Nano-Sized Zno/Sno Coupled PhotocatalystsDocument11 pagesPreparation, Characterization and Photocatalytic Activity of Nano-Sized Zno/Sno Coupled PhotocatalystsMuhammad IsmailNo ratings yet

- Disolusi USP BriefDocument38 pagesDisolusi USP BrieffifiNo ratings yet

- Galaxy Sivtek PPT Template-Groundnut OilDocument19 pagesGalaxy Sivtek PPT Template-Groundnut OilruchikaNo ratings yet

- Filtration PDFDocument18 pagesFiltration PDFarno6antonio6spinaNo ratings yet

- Cat in 39g 1 Carrier AcDocument14 pagesCat in 39g 1 Carrier Acks aksNo ratings yet

- Water Purification AssignmentDocument2 pagesWater Purification AssignmentKhynan Rhyss VicenteNo ratings yet

- USP New Monograph Dissolution AutomationDocument28 pagesUSP New Monograph Dissolution AutomationSochib Ibe FiniarelNo ratings yet

- HEK11Document4 pagesHEK11Tan CkNo ratings yet

- Filtration Is Our Singular Focus For The Rotorcraft IndustryDocument4 pagesFiltration Is Our Singular Focus For The Rotorcraft IndustryS.M BadruzzamanNo ratings yet

- Filters & Strainers ''Mankenberg''Document18 pagesFilters & Strainers ''Mankenberg''AlexDorNo ratings yet

- Eaton Internormen Filtration For Oil Service EquipmentDocument4 pagesEaton Internormen Filtration For Oil Service EquipmentEaton FiltrationNo ratings yet

- BS en 12393-2-2013Document46 pagesBS en 12393-2-2013DoicielNo ratings yet

- Water PurificationDocument34 pagesWater PurificationHosam KamelNo ratings yet

- AOFD 553 Oil Filter DrierDocument1 pageAOFD 553 Oil Filter DrierJuanAlvaroEsquivelAguilarNo ratings yet

- L&T Document Number:: 0 1 ARN DDU ARN DDUDocument56 pagesL&T Document Number:: 0 1 ARN DDU ARN DDUFayaz AhammedNo ratings yet

- Proposal For 10 CMD STPDocument19 pagesProposal For 10 CMD STPHaneesh PanickerNo ratings yet

- Extracting Residue From Metallic Medical Components and Quantifying Via Gravimetric AnalysisDocument6 pagesExtracting Residue From Metallic Medical Components and Quantifying Via Gravimetric AnalysisAhmad Zubair RasulyNo ratings yet

- Catalogo Sporlan IIDocument29 pagesCatalogo Sporlan IIAdán Castro GallegosNo ratings yet

- CASTEL Brochure SF Filters - ENDocument4 pagesCASTEL Brochure SF Filters - ENИгорьNo ratings yet

- 14.current Applications of Pharmaceutical BiotechnologyDocument520 pages14.current Applications of Pharmaceutical BiotechnologyltbnhuNo ratings yet

- Solvent Extractables in Petroleum Waxes: Standard Test Method ForDocument7 pagesSolvent Extractables in Petroleum Waxes: Standard Test Method ForAbdallah ElkasbyNo ratings yet

- Bilfinger Water Technologies - Solutions For Fine and Micro-SievingDocument8 pagesBilfinger Water Technologies - Solutions For Fine and Micro-SievingmohamedNo ratings yet

- Emd-Mi926 Filtracion de AceitesDocument7 pagesEmd-Mi926 Filtracion de AceitesVictor Raul Tobosque MuñozNo ratings yet

- RPHPLC Methods For Estimation of Nitazoxanide Single and Simultaneous Estimation of Nitazoxanide With Ofloxacin in PharmDocument9 pagesRPHPLC Methods For Estimation of Nitazoxanide Single and Simultaneous Estimation of Nitazoxanide With Ofloxacin in Pharmsunaina agarwalNo ratings yet

- Published by Technical Services / PSSR For Internal CirculationDocument33 pagesPublished by Technical Services / PSSR For Internal CirculationVed PrakashNo ratings yet

- Fundamental of Filtration (Ok)Document17 pagesFundamental of Filtration (Ok)man_iphNo ratings yet

- 3B Filters Series 83 - 84 PDFDocument2 pages3B Filters Series 83 - 84 PDFReid BassetteNo ratings yet

- Andritz Dynamic Crossflow FiltrationDocument4 pagesAndritz Dynamic Crossflow Filtrationtarek555No ratings yet

- D1412-Standard Test Method For Equilibrium Moisture of Coal at 96 To 97 Percent Relative Humidity and 30 Deg CelciusDocument5 pagesD1412-Standard Test Method For Equilibrium Moisture of Coal at 96 To 97 Percent Relative Humidity and 30 Deg CelciusWelsinsin Kevin SinNo ratings yet