Professional Documents

Culture Documents

Forklift Training

Uploaded by

mirraoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Forklift Training

Uploaded by

mirraoCopyright:

Available Formats

F SA

ET

INDUSTRIAL

HEALTH

W EL

FA R

Safety Code for Forklift Truck Operators

No.3 SIDE LOADERS

Published by the Occupational Safety and Health Service

APPLICATION This Code, which should be read in conjunction with the Approved Code of Practice, applies to side loading trucks but does not include front loading forklift trucks, order picking truck, or straddle trucks, for which separate codes have been published in the same series of SAFETY CODE FOR FORKLIFT OPERATORS, as follows: No. 1 - Front Loading Trucks No. 2 - Order Picking Trucks No. 4 - Straddle Trucks

Published by the Department of Labour, New Zealand, on behalf of the Forklift Safety Advisory Committee as set up and approved by the Minister of Labour First Published: 1979 Reprinted: 1986

(PDF file for web site created October 1999)

CONTENTS Page 1. 2. 3. 4. Need for This Safety Code Types of Accidents Involving Side Loading Trucks Basic Safety Rules Regular and Periodical Inspection 4.1 4.2 4.3 5. 6. 7. 8. 9. Daily Checks Weekly Checks Environment Inspection 5 6 7 8 8 9 9 9 13 17 19 24 27 28 29

Driving Procedures Picking up a Load Basic Stacking Rules Basic Destacking Rules General Trucks)

10. Appendix A: Daily Check Report (Battery-Powered 11. Appendix B: Daily Check Report (Engine-Powered Trucks) 12. Appendix C: Weekly Inspection and Maintenance Report

ARE YOU THE RIGHT PERSON FOR THE JOB? You are when you have been properly trained and have read and understood this booklet, especially the simple rules for safety. Reading this booklet periodically will ensure that you are at all times aware of the rules for safety and thus remain the right person for the job.

REMEMBER ONLY TRAINED AND AUTHORISED OPERATORS ARE PERMITTED TO USE ANY TRUCK.

1.

THE NEED FOR THIS SAFETY CODE AND WHY YOU SHOULD READ, UNDERSTAND AND FOLLOW IT

It is a matter of grave concern that a large number of serious and fatal accidents involving forklift trucks occur every year, especially when it is known that most of these accidents can be prevented. Main causes of accidents involving a machine of this type may be cited as: 1.1 Lack of knowledge or skill. 1.2 Operator not attentive to the job at hand. 1.3 Operator taking chances, with full knowledge of possible consequences. 1.4 Poor maintenance. 1.5 Mechanical malfunction. 1.6 Constructional defect in some part of the machine. The operator has no control over item 1.6 listed above. Mechanical malfunctions, item 1.5 above, cause only a minor fraction of total accidents, and in many cases accidents may be prevented by regular maintenance and checks.

It is recognised that the operator may not be qualified, experienced, or authorised to carry out maintenance or repairs. However, it is the operators duty to check that the machine is in a satisfactory working condition before operating it and any faults or shortcomings should be brought to the notice of the person in charge. With regard to the first three causes listed above, it is obvious that these can be avoided to a great extent, when there is deliberate effort on the part of the operator.

2.

LIKELY TYPES OF ACCIDENTS INVOLVING SIDE LOADING TRUCKS

2.1 Person being struck by a moving truck. 2.2 Operator hit by a falling object. 2.3 Other employee/person hit by a falling object. 2.4 Operator injured while boarding or leaving the truck. 2.5 Truck tipping over. 2.6 Collision with other vehicles or stationary objects. 2.7 Part of the operators body (protruding outside the cab) hitting an object.

3.

BASIC SAFETY RULES

3.1 Trucks are to be driven only by trained and competent operators acting under proper authority. 3.2 Operators should be physically fit, to ensure satisfactory speed of reaction and a high standard of vision and judgement of distance. 3.3 Operators must be alert at all times to avoid accidents. 3.4 Operators must check that their truck is in good working condition and has been properly maintained. 3.5 If at any time the truck develops a fault, or if there is reason to think it unsafe, stop and report immediately to the appropriate authority. Do not use again until repairs have been made. 3.6 Unless specifically authorised, and able, do not attempt repairs or adjustment totrucks. 3.7 Avoid building up unstable loads which could collapse during operations. 3.8 Loads must be strictly within the dimensions and weight capacity limits as detailed on the rating plate of the side loader and must be within the dimensional limits of the deck.

4.

REGULAR AND PERIODICAL INSPECTION

4.1 DAILY CHECKS Appendices A and B on pages 27 and 28 show the suggested forms and details of checks that should be carried out. Any points applicable to a particular make of machine and not covered in these check lists can be added. Appendix A relates to battery-powered forklift trucks and Appendix B relates to engine-powered trucks.

4.2 WEEKLY CHECKS

It is recommended that these be carried out by a suitably trained person who is also authorised for the job. The operator should, however, confirm that regular weekly checks have in fact been carried out. Although some items of inspection are listed in Appendix C on page 29, these are only of a general nature and by no means comprehensive. Manufacturers recommendations are to be followed where applicable. This also gives the operator an idea as to which items of machinery should be inspected at least once a week.

4.3 ENVIRONMENT INSPECTION

4.3.1

Note low clearances such as pipes, sprinklers, doorways, overhead power lines, etc. Be sure that the floor and bridging plates can support the combined weight of your truck and load. Check the floors for damage, wetness, greasy or oily surfaces or obstructions in aisles. These may affect the stability of the truck.

4.3.2

4.3.3

5.

DRIVING PROCEDURES

5.1 Before operating a side loader for the first time, make sure you are familiar with all controls and their movements.

5.2 Drive safely to suit conditions and avoid fast turns, jerky stops and starts.

5.3Always travel with the load on the sideloader deck and the forks lowered into the well. NEVER travel with a load on the forks.

5.4Remember that all the weight of the engine and drive arrangements are to one side.

10

5.5Always have the centre of the load as near as possible to the centre of the side loader deck.

5.6Secure loads if necessary to prevent movement during travel.

11

5.7Look in the direction of travel and keep a clear view of the way ahead. If vision is obstructed, seek assistance.

5.8Do not run over sharp objects, bumps, or kerb.

5.9Slow down and sound the horn at all intersections. Stop and sound horn at all blind intersections.

12

5.10

NEVER carry passengers on the sideload

5.11 When parking, lower the forks and retract into the well of the sideloader.

6. PICKING UP A LOAD

6.1Position the side loader parallel to the load and as close to the load as possible.

13

6.2 Move the gear lever to the neutral position. Apply the hand brake and lower the stabiliser jacks where fitted.

6.3 Lower the forks sufficiently to enable them to pass under the load and ensure that the forks are as widely spaced as possible.

6.4NEVER lift a load with one fork.

14

6.5 Tilt the forks backward and slowly transfer the mast outwards until the forks are under the load.

6.6 Tilt the forks backward and raise the load until it is above the deck.

15

6.7Slowly traverse the mast inward until it is fully retracted.

6.8Lower the forks until the load is resting on the deck and then ensure the truck is evenly balanced. Never dump loads into position.

6.9Ensure stabiliser jacks are raised where fitted and brake is released before driving off.

16

7. BASIC STACKING RULES

7.1 Positlon the sideloader parallel to the stacking point and as close as possible.

7. 2 Move the gear lever to the neutral position. Apply the hand brake and lower the stabiliser jacks where fitted.

17

7.3Lift the load with a backward tilt.

7.4Traverse the mast over the stack, tilt forward, and lower the load onto the stack.

18

7.5 When the load is securely stacked, lower forks until clear of load or dunnage, traverse mast away from stack, lower the forks and raise the stabiliser jacks where fitted.

8. BASIC DESTACKING RULES

8.1 Stop the sideloader parallel to the stack and as close as possible.

19

8.2 Move the gear lever to the neutral position Apply the handbrake and lower the stabiliser jacks where fitted.

8.3Raise the forks to a position permitting clear entry into parallel or dunnage strips.

20

8.4Tilt forks forward and traverse mast towards the stack.

8.5Lift the load with a backward tilt until clear of stack.

21

8.6 Extreme care must be taken to avoid jerking when tilting a load forward or backward. especially when the load is at height.

8.7 Slowly traverse the mast inwards until it is fully retracted.

22

8.8 Lower the forks until the load is resting on the deck, and ensure the load is evenly balanced.

8.9 Ensure stabiliser jacks are raised where fitted, and hand brake is released before driving off.

23

9.

GENERAL

9.1

Never remove a back-rest extension or overhead guard unless specifically authorised.

9.2

Never place arms, hands, legs, or head between the uprights of the mast or outside the limits or the forklift trucks body or cab (except when handsignalling a turn or other manoeuvres).

24

9.3

Never allow an engine-powered truck to remain stationary in confined spaces for long periods with its engine running. The build-up of fumes and gases can be unpleasant and even dangerous.

9.4

When leaving the truck, ensure that the controls are at neutral, power is shut off, brakes applied, forks fully lowered, and the ignition key or starter switch key removed. (This helps prevent unauthorised people from using the machine.)

25

9.5

(i) Under no circumstances must additional counterweights be added to fork trucks to increase their load-carrying capacity without prior reference to the manufacturer. No person should stand or sit on the counterweight. (ii) Do not fit extensions to fork trucks unless their use is authorised. Only fork extensions of a design approved by the manufacturer may be used.

9.6

When flashing lights or reversing beepers are fitted, ensure that these are operating correctly, and horns, if fitted, are used only when necessary.

26

APPENDIX A: OPERATORS DAILY CHECK REPORT BATTERY-POWERED TRUCKS

Truck No. ..................... Date: ............................................ Hour meter reading: Hours for shift: ...........................

Make: .................................... Shift: ................................... Start: ............ End: ...........

SHIFT CHECK EACH ITEM if OK, write OK taken Start During End

Explain below if not OK or any other action

1.

Battery plug connection 2. Battery charge and electrolyte 3. Battery load test 4. Brakes 5. Lights - head, tail, warning, and indicating 6. Horn 7. Hour meter 8. Steering 9. Tyre 10. Hydraulic controls 11. Other items Remarks or additional explanations or suggestions: Operators signature:

27

APPENDIX B: OPERATORS DAILY CHECK REPORT ENGINE-POWERED TRUCKS Truck No. ..................... Date: ........................................ Hour meter reading: Hours for shift: ........................... Make: ..................................... Shift: ..................................... Start: .......... End: ..........

SHIFT

CHECK EACH ITEM if OK, write OK Start During End

Explain below if not OK or any other action taken

1. Fuel level 2. Oil level and pressure 3. Water level and fan belt 4. Brakes 5. Steering 6. Lights - head, tail warning and indicator 7. Horn 8. Hour meter and gauges 9. Tyres 10. Hydraulic controls 11. Other items Remarks or additional explanations or suggestions: Operators signature:

28

APPENDIX C: WEEKLY INSPECTION AND MAINTENANCE REPORT Truck No. ..................... Make: .............................. Date: ........................................ Hour Meter: .....................

CHECK EACH ITEM if OK, write OK

REMARKS

ACTION TAKEN (if any)

1. Hydraulic rams 2. General lubrication 3. Hydraulic system (hoses etc) 4. Limit switches 5. Brake fluid 6. Lifting chains, pulleys, wire ropes 7. Forks and retaining pins 8. Overhead guard and load backrest 9 Other items Additional explanation or suggestions/recommendations:

Engineers signature:

29

You might also like

- Forklift Driver Card and Certificate TemplateDocument25 pagesForklift Driver Card and Certificate Templatempac99964% (14)

- Life After Life by Kate AtkinsonDocument25 pagesLife After Life by Kate AtkinsonRandom House of Canada60% (15)

- Forklift Training Quiz and AnswersDocument10 pagesForklift Training Quiz and AnswersPablo Valenzuela Arredondo100% (2)

- Forklift HandbookDocument21 pagesForklift Handbooktintucinb100% (4)

- Forklift Training ManualDocument19 pagesForklift Training Manualdexxter201250% (2)

- Forklift Operator Pass Test (Pre / Post) Name: Agency Empl. Id.Document2 pagesForklift Operator Pass Test (Pre / Post) Name: Agency Empl. Id.Deepak Mallik0% (1)

- LF Activite QuestionsDocument6 pagesLF Activite Questionsevan100% (1)

- Forklift Safety PlanDocument8 pagesForklift Safety Planwstuart66No ratings yet

- Overhead Crane Safety Training Employer SupplementDocument71 pagesOverhead Crane Safety Training Employer Supplementshahrilmr6934No ratings yet

- Forklift Safety BookletDocument30 pagesForklift Safety BookletWirawan Adi Setya RNo ratings yet

- Pipe Rack Drawing For Oil FieldDocument6 pagesPipe Rack Drawing For Oil FieldmirraoNo ratings yet

- VAIL-Plant Software DescriptionDocument21 pagesVAIL-Plant Software DescriptionmirraoNo ratings yet

- Guideline Lifting Lug DesignDocument10 pagesGuideline Lifting Lug Designye-kyaw-aung80% (10)

- Fiber Optic Color ChartDocument1 pageFiber Optic Color Charttohamy2009100% (2)

- Forklift Inspection StsDocument30 pagesForklift Inspection Stsnibin venugopalNo ratings yet

- Forklift Operator SafetyDocument31 pagesForklift Operator Safetyalimarhoon150No ratings yet

- Forklift OperationDocument43 pagesForklift OperationMarcus Krueger100% (1)

- Fork Lift TrainingDocument49 pagesFork Lift TrainingJay Ann100% (2)

- Forklift PDFDocument17 pagesForklift PDFANKUSHNo ratings yet

- Powered Fork Lift Truck Safety Course QuizDocument4 pagesPowered Fork Lift Truck Safety Course Quizsafebobde100% (1)

- Forklift PitDocument64 pagesForklift PitJason Morgan100% (1)

- L4W - TLILIC2001A - Information Booklet - V4 PDFDocument54 pagesL4W - TLILIC2001A - Information Booklet - V4 PDFdulshanNo ratings yet

- Forklift ChecklistDocument4 pagesForklift ChecklisthazopmanNo ratings yet

- Forklift SafetyDocument62 pagesForklift Safetyg665013100% (5)

- Mobile Crane Operator Course at Aims Tech Institute IndiaDocument14 pagesMobile Crane Operator Course at Aims Tech Institute IndiaAnonymous LFgO4WbIDNo ratings yet

- Forklift Safety BookletDocument30 pagesForklift Safety BookletAli JalilNo ratings yet

- Forklift QuizDocument2 pagesForklift Quiz7twofourNo ratings yet

- TMW 041 Exam PDFDocument8 pagesTMW 041 Exam PDFMarco Guachun0% (1)

- Safe Operation of Forklifts and Other - Powered TrucksDocument61 pagesSafe Operation of Forklifts and Other - Powered TrucksDenaEkaPutriNo ratings yet

- Forklift HSDocument48 pagesForklift HSJOAQUIN DOMINGUEZ100% (1)

- Basics of ForkliftDocument93 pagesBasics of ForkliftMichael Thompson100% (4)

- Forklift Manual G&LDocument44 pagesForklift Manual G&LBubu Mic100% (1)

- Training Quiz: Trainee Name - DateDocument3 pagesTraining Quiz: Trainee Name - DatethecopterguyNo ratings yet

- Forklift TrainingDocument39 pagesForklift Trainingagus sofyan100% (1)

- TLID1007C - Operate A Forklift - Learner GuideDocument112 pagesTLID1007C - Operate A Forklift - Learner Guideromerofred100% (1)

- Safety in Mobile CranesDocument60 pagesSafety in Mobile CranesSwapnil pupulwad100% (1)

- Forklift - Policy From DowjonesDocument11 pagesForklift - Policy From DowjonesAs ElmoNo ratings yet

- Tire-Gulong: 1-15 Label The FollowingDocument4 pagesTire-Gulong: 1-15 Label The FollowingJeanne CortezNo ratings yet

- Alabama Homebuilders Self Insurers Fund: Lift Truck Operator Training ProgramDocument61 pagesAlabama Homebuilders Self Insurers Fund: Lift Truck Operator Training ProgramMalathy Sekar100% (1)

- Operating Instruction Handbook Hand Pallet TruckDocument16 pagesOperating Instruction Handbook Hand Pallet Truckahmad farezNo ratings yet

- 05 - Basic - Operator Training E Rev 4 - ENGDocument78 pages05 - Basic - Operator Training E Rev 4 - ENGAmzad DPNo ratings yet

- Forklift Training AssessmentDocument3 pagesForklift Training AssessmentSurendran NagiahNo ratings yet

- Forklift Safety Program 11-6-12Document11 pagesForklift Safety Program 11-6-12ankur panwarNo ratings yet

- Forklift Training Manual.v5.2Document102 pagesForklift Training Manual.v5.2AjBpNo ratings yet

- Tlilic2001 Knowledge Questions: This Document Should Be Completed With Reference To The Course WorkbookDocument3 pagesTlilic2001 Knowledge Questions: This Document Should Be Completed With Reference To The Course WorkbookJason Zeng100% (1)

- Forklift FundamentalDocument42 pagesForklift FundamentalErna Bogdan100% (2)

- Forklift SafetyDocument9 pagesForklift SafetyTamirNo ratings yet

- Forklift Operator Training Instructors ManualDocument31 pagesForklift Operator Training Instructors ManualLe Du100% (1)

- Forklift Policy HandbookDocument48 pagesForklift Policy Handbooknezla100% (1)

- Safe Forklift Operation ManualDocument32 pagesSafe Forklift Operation ManualMauricio Bulla ValenciaNo ratings yet

- Forklift Safety TrainingDocument22 pagesForklift Safety TrainingSteve DonardNo ratings yet

- Forklift Inspection ChecklistDocument2 pagesForklift Inspection ChecklistZeinullah 026100% (1)

- Basic Rigging Work BookDocument58 pagesBasic Rigging Work BookLimuel EspirituNo ratings yet

- THE BASIC CRANE OPERATION AND RIGGING SAFETY Hand Outs A4Document21 pagesTHE BASIC CRANE OPERATION AND RIGGING SAFETY Hand Outs A4RosalyNo ratings yet

- Front-End Loader TrainingDocument27 pagesFront-End Loader TrainingOmosigho Osaro0% (1)

- Guidelines Safe Operation of Forklift TrucksDocument35 pagesGuidelines Safe Operation of Forklift TrucksJustin ChongNo ratings yet

- TBT Excavators - LiftingDocument3 pagesTBT Excavators - LiftingMovie downloadNo ratings yet

- Managing Crane Safety: © 2000 Cia, IncDocument180 pagesManaging Crane Safety: © 2000 Cia, IncAmeerUlHaqNo ratings yet

- Safe Operation of ForkliftsDocument71 pagesSafe Operation of Forkliftsashishmechengg31100% (1)

- Forklift Study GuideDocument20 pagesForklift Study GuideSebastian Soto SilvaNo ratings yet

- Forklift SafetyDocument21 pagesForklift SafetyFerri AguswanNo ratings yet

- Lift Trucks: Safe Operation ofDocument2 pagesLift Trucks: Safe Operation ofGaganpreetNo ratings yet

- Safe Practices in Operating Fork-Lift TrucksDocument17 pagesSafe Practices in Operating Fork-Lift TrucksThomas Baby100% (2)

- 6.2 - Mulitway Reach TruckDocument29 pages6.2 - Mulitway Reach TruckQUANG LÊNo ratings yet

- Operator's Instruction Manual: Book No 2758600 OI-500. 2nd REVDocument36 pagesOperator's Instruction Manual: Book No 2758600 OI-500. 2nd REVNguyễn Thanh NhànNo ratings yet

- AADE - Drillpipe FailureDocument32 pagesAADE - Drillpipe FailuremirraoNo ratings yet

- PVB Test ProcedureDocument2 pagesPVB Test ProceduremirraoNo ratings yet

- Drill Pipe Basket DesignDocument8 pagesDrill Pipe Basket DesignmirraoNo ratings yet

- 1967 Skid Design ReviewDocument15 pages1967 Skid Design ReviewmirraoNo ratings yet

- Basket Design Details As Per DNV StandardDocument4 pagesBasket Design Details As Per DNV StandardmirraoNo ratings yet

- Belmont Asia: Belmont House, Akad Street, Ainkawa, ErbilDocument17 pagesBelmont Asia: Belmont House, Akad Street, Ainkawa, ErbilmirraoNo ratings yet

- NS Driling JarDocument1 pageNS Driling JarmirraoNo ratings yet

- Gas Plus Drill Pipe Faliure ReportDocument17 pagesGas Plus Drill Pipe Faliure ReportmirraoNo ratings yet

- Collar Rack DesignDocument2 pagesCollar Rack DesignmirraoNo ratings yet

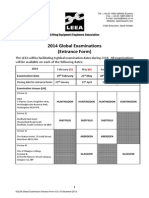

- 2014 Examination Entrance Form v5!1!10 Dec 13Document6 pages2014 Examination Entrance Form v5!1!10 Dec 13mirraoNo ratings yet

- Sample Hydro Test ProcedureDocument2 pagesSample Hydro Test Proceduremirrao0% (1)

- NS Driling JarDocument1 pageNS Driling JarmirraoNo ratings yet

- This Course Follows Guidelines For: OSHA 29 CFR 1910.1000 API RP 49 & 55Document51 pagesThis Course Follows Guidelines For: OSHA 29 CFR 1910.1000 API RP 49 & 55mirraoNo ratings yet

- Test Rig DrawingsDocument14 pagesTest Rig DrawingsmirraoNo ratings yet

- Study Guide Mobile Crane Operator V1Combined JS 11-02-24 FINALDocument30 pagesStudy Guide Mobile Crane Operator V1Combined JS 11-02-24 FINALmirrao100% (1)

- Megasonic CatalogueDocument2 pagesMegasonic CataloguemirraoNo ratings yet

- Payment Item Charges (RM) Discount (RM) Service Tax (RM) Payment Method Final Charges (RM)Document1 pagePayment Item Charges (RM) Discount (RM) Service Tax (RM) Payment Method Final Charges (RM)Md IsmailNo ratings yet

- IPTV-Bbc TVP What Is IptvDocument32 pagesIPTV-Bbc TVP What Is IptvSachin KumarNo ratings yet

- Organization of Preschool Education in SwedenDocument2 pagesOrganization of Preschool Education in SwedenNelumi PereraNo ratings yet

- Overhauling Air Compressor On ShipsDocument12 pagesOverhauling Air Compressor On ShipsTun Lin Naing100% (3)

- Moses MendelssohnDocument2 pagesMoses Mendelssohncoolio_94No ratings yet

- Excuse Letter For Grade 7 ElectionsDocument4 pagesExcuse Letter For Grade 7 ElectionsRaymund ArcosNo ratings yet

- Marathi Book ListDocument4 pagesMarathi Book ListGajanan PatilNo ratings yet

- Data Flow DiagramDocument21 pagesData Flow Diagrampredikat newsNo ratings yet

- ExtractedRA - CIVILENG - MANILA - Nov2017 RevDocument62 pagesExtractedRA - CIVILENG - MANILA - Nov2017 Revkelvin jake castroNo ratings yet

- Image Saving, Processing and Name Tagging Over SDTP Using Java ScriptDocument21 pagesImage Saving, Processing and Name Tagging Over SDTP Using Java Scriptsomnath banerjeeNo ratings yet

- Instant Download Developing Management Skills 10th Edition Whetten Test Bank PDF Full ChapterDocument33 pagesInstant Download Developing Management Skills 10th Edition Whetten Test Bank PDF Full Chapterdonaldvioleti7o100% (9)

- Education PhilosophyDocument8 pagesEducation PhilosophyJustine Jerk BadanaNo ratings yet

- Matisse As Printmaker: Matisse'S Printmaking ProcessesDocument2 pagesMatisse As Printmaker: Matisse'S Printmaking ProcessesWriterIncNo ratings yet

- Complaint - California Brewing v. 3 Daughters BreweryDocument82 pagesComplaint - California Brewing v. 3 Daughters BreweryDarius C. GambinoNo ratings yet

- Free Theological JournalsDocument31 pagesFree Theological Journalsmichael olajide100% (1)

- Quantitative Problems Chapter 9Document3 pagesQuantitative Problems Chapter 9Ad Qasim100% (1)

- The Ambiguity of Micro-UtopiasDocument8 pagesThe Ambiguity of Micro-UtopiaspolkleNo ratings yet

- Contoh MOTIVATION LETTERDocument19 pagesContoh MOTIVATION LETTERDavin Tiska AbrianiNo ratings yet

- 16 Leases (Lessee) s19 FinalDocument35 pages16 Leases (Lessee) s19 FinalNosipho NyathiNo ratings yet

- Rabindranath TagoreDocument13 pagesRabindranath TagoreVinay EkNo ratings yet

- How To Argue A CaseDocument5 pagesHow To Argue A CaseItam HillNo ratings yet

- Narrations - Direct and Indirect SpeehesDocument6 pagesNarrations - Direct and Indirect Speehesskitteringkite100% (1)

- Hechethorn - The Secret Societies of All Ages and Countries, Vol. I (1875) PDFDocument417 pagesHechethorn - The Secret Societies of All Ages and Countries, Vol. I (1875) PDFsongpoetNo ratings yet

- Indian Entrepreneur Fund PresentationDocument44 pagesIndian Entrepreneur Fund PresentationHARIHARAN ANo ratings yet

- Resume 5Document5 pagesResume 5KL LakshmiNo ratings yet

- Former UM Soccer Coach Sues University For DefamationDocument12 pagesFormer UM Soccer Coach Sues University For DefamationNBC MontanaNo ratings yet

- Cold SandwichesDocument7 pagesCold SandwichesLea Galano ManarpaacNo ratings yet

- International Business of Pizza HutDocument13 pagesInternational Business of Pizza Hutpratikdotia9100% (2)