Professional Documents

Culture Documents

Hyundai Lift

Uploaded by

Fian ArdiyanaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hyundai Lift

Uploaded by

Fian ArdiyanaCopyright:

Available Formats

HEAD OFFICE & FACTORY

San 136-1, Ami- ri, Bubal-eup, Icheon-si, Gyeonggi-do 467-734, Korea Tel : 82-2-3670-0661/0665 Fax : 82-2-3672-8763~4 www.hyundaielevator.co.kr

SEOUL OFFICE(INTL SALES DIV.)

8F East Bldg, Hyundai Group Bldg.,1-7 Yeonji-dong Jongno-gu, Seoul 110-754, Korea Tel : 82-2-3670-0661/0665 Fax : 82-2-3672-8763~4

ALGERIA Tel : 213-21-203-787 Fax : 213-21-216-444 AZERBAIJAN Tel : 994-12-418-0106 Fax : 994-12-567-1877 BAHRAIN Tel : 973-17-702-468 Fax : 973-17-702-643 BANGLADESH Tel : 880-1711-533047 Fax : 880-2-8851045 BOLIVIA Tel : 591-3-339-9490 Fax : 591-3-339-9490 CHINA Tel : 86-21-6485-8600 Fax : 86-21-6485-3511 COLOMBIA Tel : 574-444-9297 Fax : 574-444-9297 CUBA Tel : 537-699-3412 Fax : 537-699-3431 ECUADOR Tel : 593-2-2568-370 Fax : 593-2-2553-761 EGYPT Tel : 20-2-2262-4092 Fax : 20-2-2262-4097 GUATEMALA Tel : 502-2388-0000 Fax : 502-2388-0044 INDIA Tel : 91-20-3250-2190 Fax : 91-20-2747-0568 INDONESIA Tel : 62-21-631-8444 Fax : 62-21-632-6288 IRAN Tel : 98-21-8869-8727~36 Fax : 98-21-8855-3741 IRAQ Tel : 964-79-01-336499 Fax : 964-1-7196892 ITALY Tel : 39-045-630-4558 Fax : 39-045-790-3371 JAPAN Tel : 81-3-3436-5117 Fax : 81-3-3436-5198 JORDAN Tel : 962-79-5526-713 Fax : 962-6-5699-014 KAZAKHSTAN Tel : 7-727-240-47-08 Fax : 7-727-240-47-08 KENYA Tel : 254-722-667984 Fax : 254-722-667984 KUWAIT Tel : 965-22457925 Fax : 965-2423510 LIBYA Tel : 218-09173-5745 Fax : 218-09173-5745 MEXICO Tel : 52-55-5379-7418 Fax : 52-55-5663-2982 MONGOLIA Tel : 976-1132-4414 Fax : 976-1132-4414 MOROCCO Tel : 212-2244-7900 Fax : 212-2230-3714 MYANMAR Tel : 95-1-385-3404 Fax : 95-1-250-485 OMAN Tel : 968-9286-4334 Fax : 968-2449-9307 PAKISTAN Tel : 92-21-432-0604 Fax : 92-21-454-7405 PANAMA Tel : 507-230-3166 Fax : 507-230-3187 PERU Tel : 51-1-472-6868 Fax : 51-1-472-6898 PHILIPPINES Tel : 632-716-0905 Fax : 632-714-8896 QATAR Tel : 974-436-6689 Fax : 974-436-6689 RUSSIA Tel : 7-495-258-1521 Fax : 7-495-514-0032 SAUDI ARABIA Tel : 966-2-652-9000 Fax : 966-2-652-9090 SUDAN Tel : 249-183-230-383 Fax : 249-183-230-364 SYRIA Tel : 963-933-234134 Fax : 963-114-469-8666 THAILAND Tel : 66-2348-8047 Fax : 66-2240-3127 TUNIS Tel : 216-70-853-231 Fax : 216-71-754-361 TURKEY Tel : 90-216-488-8000 Fax : 90-216-488-9191 TURKMENISTAN Tel : 993-12-2287-93 Fax : 993-12-3295-66 UAE Abu Dhabi Tel : 971-2-671-1779 Fax : 971-2-443-8822 Dubai Tel : 971-4-294-4475 Fax : 971-4-294-4476 VENEZUELA Tel : 58-212-232-8263 Fax : 58-212-232-7178 VIETNAM Tel : 84-43-572-4588 Fax : 84-43-572-4699

PASSENGER ELEVATORS - We reserve the right to change designs and specications for the product development without prior notice. Copyright HYUNDAI ELEVATOR CO., LTD. All rights reserved. Printed in Korea. CATALOG CODE : C-PEL-E0308/2011.04/Rev.3

Hyundai Elevator

Trusted quality

We export products to 50 countries like Japan, Europe, East / West Asia, the Middle East and are recognized for excellence in quality.

Since the 1984 founding of South Korea, Hyundai Elevator, an affiliate of Hyundai Business Group, with leading technology has grown up to Korea No. 1 elevator company. Now Hyundai Elevator is roaring towards to top of the world. We value the safety, energy efficiency, and environment-friendly features of the highest standard for all products made by Hyundai Elevator.

Refined design

Refined design to give consideration to health and the environment adds new value to the elevator.

[Selection of passenger elevator system]

The selection of elevators should be made in consideration of the building type/scale, tenant characteristics, elevator usage and the anticipated passenger carrying capacity at the building's traffic peak time. Hyundai elevators are available from geared traction elevator to gearless traction elevators, covering the full range of vertical transportation requirements.

Contents

01 Advanced Technology Gearless Traction Machine 04 / Energy Regenerative Elevator Inverter 06 / Destination Selecting System 08 02 Reliable Brand LUXEN 10 / YZER 12 / Geared Traction Elevators 14 03 Design Car Design 16 / Ceiling Design 21 / Signal Fixtures 22 / Material Patterns 24 / Disabled Elevators 27 Standard & Optional Features 28 / Layout Plan 30 / Works To Be Done By Other Contractors 39 / Electric Power Requirements (By others) 40

01 Advanced Technology

Gearless Traction Machine

With the use of gearless traction machine, smoother ride, improved energy-saving, and environment-friendly features are enhanced.

Improved energy savings

Gearless traction machine with permanent magnet synchronous motor provides up to 25% energy savings compared with geared traction machine with induction motors.

Comfortable riding

Noise and vibration level have been decreased dramatically and car ride is improved thanks to the use of gearless traction machine with permanent magnet synchronous motor without toothing gear and rope swing.

Environment-friendly components

It is environmentally friendly because gear oil is not required.

Reduced installation space

It can save the building space as it needs smaller machine room space than the conventional.

Easy installation and maintenance

The installation and maintenance is less complicated as the implementation is the same 1:1 roping for induction motor.

4 HYUNDAI ELEVATOR CO., LTD.

PASSENGER ELEVATORS 5

01 Advanced Technology

Energy Regenerative Elevator Inverter- LOWATT

Capacitor-less condenser

LOWATT, next generation elevator inverter system, minimizes energy consumption by regenerating wasted kinetic energy with newly designed power circuit. It is applicable for low-medium speed gearless elevator LUXEN, machine roomless elevator YZER, and geared elevator.

Without LOWATT

With LOWATT

Up to 60% energy savings

The energy generated by the motion of the car is recycled back to the inverter, resulting a 60% total energy consumption.

Reduced heat emission

The heat emission of the motor has been drastically reduced as the energy generated from operating the elevator is recycled.

Easy maintenance

The inverter doesn't have condensers, reactors, resistant parts so it is easy to maintain and repair.

Notes : 1. Energy Regenerative Elevator Inverter(LOWATT) is optional. 2. In Dec., 2007 the Ministry of Science and Technology certified the NET(New Excellent Technology) for the capacitor-less inverter control for driving elevator.

6 HYUNDAI ELEVATOR CO., LTD.

PASSENGER ELEVATORS 7

01 Advanced Technology

Destination Selecting System

The purpose of registration is to automatically select the best service of the elevator car within the system and the passenger does not need to click the car operating button in car. Destination Selecting System manages elevator more effectively.

Shorter waiting time

It saves calling time and riding time as it selects the proper elevator for effective service.

Improving efficiency in energy usage

By grouping passengers having the same target floor to the same elevator, it will save energy and increase system efficiency.

Security and Convenience

Use of Building Access Cards to work with the elevator call button and the user ID in the Building Access Cards will automatically register a call to provide convenience to residents, as well as preventing any non-authorized outsider gain access to the building.

A variety of contents in real time

This system can be applied to existing systems and this feature will provide a touch screen and LCD display inside the car, so passengers can get internet-based information such as car operation, weather, stock price, index trends, and real-time headline news.

8 HYUNDAI ELEVATOR CO., LTD.

PASSENGER ELEVATORS 9

02 Reliable Brand

Medium speed gearless traction elevators (LUXEN)

A high-tech gearless traction machine which was used mainly in high-speed elevator is used for this product.

Excellent car ride

The LUXEN, using the gearless machine, provides a smooth and noiseless ride.

Increased energy efficiency

Gearless traction machine with permanent magnet synchronous motor application and energy recycling Inverters(LOWATT) will increase energy efficiency.

Spacious car Interior

The car is more spacious and more comfortable compared with existing product design which has low ceiling height.

Eco-friendly Product

This is an environment-friendly products. It does not need to replace the gear oil regularly.

10 HYUNDAI ELEVATOR CO., LTD.

PASSENGER ELEVATORS 11

02 Reliable Brand

Machine-room-less elevators (YZER)

An innovative elevator which does not require a separate machine room.

High space efficiency

The thinner control panel and compact gearless traction machine eliminate the need for a separate machine room because the system is so compact it can be located at any floor or on hoistway wall.

More flexible architectural design

The building roof line can be enhanced due to the elimination of the conventional penthouse type machine room. It enables a free layout of hoistway position as the machine room is not necessary.

Reduction of building cost

Expenses for the construction of machine room as well as the completion time of building work can be reduced as the machine room is not necessary.

Compact gearless traction machine

By using gearless traction machine with permanent magnet synchronous motor, it provides smoother ride, improved energy-saving, and environment friendly features.

12 HYUNDAI ELEVATOR CO., LTD.

PASSENGER ELEVATORS 13

02 Reliable Brand

Geared Traction Elevators

The hightest efficiency is achieved through the optimal combination of voltage and frequency, the latest and most advanced VVVF technology of electric power supply to the induction motor.

Extremely smooth riding comfort accurate landing

Using computer control for acceleration and deceleration the riding comfort is improved.

Enhanced safety

The self-checking system as part of the software/hardware design built-in the elevator and drive contol system greatly improve safety of the elevator operation.

Compact design

Minimized control panel enables to reduce installation costs.

14 HYUNDAI ELEVATOR CO., LTD.

PASSENGER ELEVATORS 15

03 Design

FRONT VIEW

REAR VIEW

FRONT VIEW

REAR VIEW

CAGE DESIGN

Ceiling Wall Car Doors Operating Panel Indicator Handrail Flooring CD597A, Painted Steel (P021), Skylite 10T, Indirect Lighting Hairline-Finished Stainless Steel, Hairline Etched Stainless Steel (SE1172) Hairline Etched Stainless Steel (SE1172) OPP-N241B / OPP-N241W (Hairline-Finished Stainless Steel) PI-D110 Stainless Steel 1 Pipe / Polished (1B) Sense Tile (TN2402C)

CAGE DESIGN

Ceiling Wall Car Doors Operating Panel Indicator Handrail Flooring CD451B, Acryl, Acryl Lens, Painted Steel (P022) Hairline Etched Stainless Steel (SE1169) Hairline Etched Stainless Steel (SE1169) OPP-N240B PI-D600 Stainless Steel 1 Pipe (1A) Polyvinyl Tile (TN2401C, TN2406C)

Notes : 1. Finished product may vary slightly from these prints. 2. The price will vary depending on the customer's specification. 3. The split may vary depending on the capacity.

Notes : 1. Finished product may vary slightly from these prints. 2. The price will vary depending on the customer's specification. 3. The split may vary depending on the capacity.

16 HYUNDAI ELEVATOR CO., LTD.

PASSENGER ELEVATORS 17

03 Design

FRONT VIEW

REAR VIEW

FRONT VIEW

REAR VIEW

CAGE DESIGN

Ceiling Wall Car Doors Operating Panel Indicator Handrail Flooring CD253A, Painted Steel (P021, P022), Skylite 10T, LED Down Light Hairline Etched Stainless Steel (SE1168), Hairline-Finished Stainless Steel Hairline Etched Stainless Steel (SE1168) OPP-N240B / OPP-N240W (Hairline-Finished Stainless Steel) PI-D110 Stainless Steel 1 Pipe + Coated Crome Bracket (1B) Polyvinyl Tile (DTE2241, DTE2246)

CAGE DESIGN

Ceiling Wall Car Doors Operating Panel Indicator Handrail Flooring CD291C, Acryl, Painted Steel (P021) Mirror-Trimmed Stainless Steel, Hairline Etched Stainless Steel (SE1673) Hairline Etched Stainless Steel (SE1673) OPP-N241B PI-D110 Stainless Steel 1 Pipe + Coated Crome Bracket (1B) Polyvinyl Tile (TN2422C, TN2601C)

Notes : 1. Finished product may vary slightly from these prints. 2. The price will vary depending on the customer's specification. 3. The split may vary depending on the capacity.

Notes : 1. Finished product may vary slightly from these prints. 2. The price will vary depending on the customer's specification. 3. The split may vary depending on the capacity.

18 HYUNDAI ELEVATOR CO., LTD.

PASSENGER ELEVATORS 19

Ceiling

(P022 / Acryl / Convective Air Sterilization System)

CD251A

(P021, P022 / Skylite 10T / LED Down Light)

CD253A

03 Design Ceiling Design

CD451B

(P022)

(Indirect Lighting / Convective Air Sterilization System)

CD516B

(Indirect Lighting / Aluminium Silver/ Convective Air Sterilization System)

CD519D

(P007, Lusterless White / Skylite 10T / Indirect Lighting)

CD597A

LED Ceiling

FRONT VIEW

REAR VIEW

CAGE DESIGN

Ceiling Wall Car Doors Operating Panel Indicator Handrail Flooring CD251A, Painted Steel (P022), Acryl, Convective Air Sterilization System Hairline-Finished Stainless Steel, Mirror-Etched Stainless Steel (SE1184) Mirror-Etched Stainless Steel (EE008) OPP-N241B (Mirror-Finished Stainless Steel ) PI-D110 (Dot Type) Stainless Steel 1 Pipe + Aluminum die casting (1A) Marble

Sectional View

CD299B

(P023 / LED Lighting(Daylight) / LED Down Light / Skylight / Anion Air Cleaner)

CD569A

(Aluminium / Acryl / Sheet / LED Lighting(Daylight) / Anion Air Cleaner)

Sectional View

Notes : 1. Finished product may vary slightly from these prints. 2. The price will vary depending on the customer's specification. 3. The split may vary depending on the capacity.

Notes : 1. Finished product may vary slightly from these prints. 2. The color of painted steel sheet can be changed according to the car wall color. 3. If car wall is stainless steel, P019 is recommended. The other materials need to be specified separately.

20 HYUNDAI ELEVATOR CO., LTD.

PASSENGER ELEVATORS 21

Car Operating Panels

Hall Buttons

PASSENGER 20 PERSONS 1350 kg

PASSENGER 20 PERSONS 1350 kg

PASSENGER 20 PERSONS 1350 kg

PASSENGER 20 PERSONS 1350 kg

HPB-230

HPB-240

HPB-241

(Boxless Type)

HPB-442

(Boxless Type)

HPB-640

(Boxless Type)

HPB-641

(Boxless Type)

HPB-D841

03 Design Signal Fixtures

Hall Buttons with Indicator

FULL

OUT OF SERVICE

AUTO

PASSENGER 20 PERSONS 1350 kg

FULL AUTO

FULL AUTO

FULL AUTO

FULL AUTO

FULL AUTO

FULL AUTO

OPP-D240B

OPP-D241B

OPP-N240B

OPP-N241B

Position Indicators

HIP-D230 HIP-D240 HIP-D241

(Boxless Type)

HIP-D442

HIP-D640

(Boxless Type)

HIP-D841

(Boxless Type)

(Dot Matrix Type)

PI-D600

PI-D200 (Dot Matrix Type) (LED Segment Type : PI-S200)

PI-D110 (Dot Matrix Type)

PI-D310 (Dot Matrix Type)

Notes : 1. Finished product may vary slightly from these prints. 2. 30 type button is not available for HPB-640, HPB-641, HIP-D640 and HBI-64A. 3. If card key system is applied, please select the box type hall button as card key system can not be applied on boxless hall button.

Note : means optional feature.

Type of Buttons Handrail

Remote Elevator Calling Button (Optional)

To minimize waiting time at a special floor, a special car calling button can be installed in an office (e.g. Secretary for a CEO office) or in a penthouse (e.g. Penthouse for Executives or Government Officials or Special Guests) or in a highrise apartment.

(Box Type)

FL (Stainless Hairline Flat Bar)

1C (1 Pipe Stainless Hairline, Chrome Bracket)

IDV (Antiviral 1 Pipe, Ivory)

30 Type

40 Type

HBI-12T

(Boxless Type)

HBI-64A

1R (1 Pipe Stainless Polished)

Notes : 1. means optional feature.

2R (2 Pipe Stainless Polished)

IDW (Antiviral 1 Pipe, Wood Sheet)

41 Type

(Touchless Button)

90 Type

2. Finished product may vary slightly from these prints.

3. If one of the above handrails is applied for the disabled elevators, FL and 2R are not available.

Note : 90 type is optional.

22 HYUNDAI ELEVATOR CO., LTD.

PASSENGER ELEVATORS 23

Entrance (Etching)

Etching

SE403

SE409

SE424

03 Design Material Petterns

SE439 EE001

(SE695)

SE785

SE859

EE002

(SE692)

EE003

(SE691)

EE005

(SE614)

SE928

SE1168

SE1169

SE1172

SE1184

SE1589

EE006

(SE743)

(SE1168)

EE007

(SE1171)

EE008

(SE1172)

EE009

Notes : 1. It's different from actual size. 2. Emboss pattern Intaglio Pattern 3. If the above etching patterns are applied for fire protection doors, the left door is 20 mm bigger than the right one. Consult Hyundai.

4. Etching patterns shown above are available for car doors and entrance doors. 5. For entrance opening, EE002, EE003, EE008 are not applied.

SE1590

Notes : 1. It's different from actual size. 2. Emboss pattern Intaglio Pattern

SE1591(1mm line by 8mm spaces)

SE1673

24 HYUNDAI ELEVATOR CO., LTD.

PASSENGER ELEVATORS 25

Paint Color

Car Operating Panels

Mirror

P003 (2.3Y 8.5/2.5)

P006 (2.5GY 7/12)

P008 (8.5YR 7.1/12.5)

P009 (4.5B 7.8/2.0)

Car Operating Panel Hall Button

OPP-N240W

P011 (4.1R 4.3/12.8)

P012 (2.3PB 4.5/9.6)

P016 (9.9YR 5.0/3.1)

P017 (6.7Y 8.7/2.0)

03 Design Disabled Elevators

OPP-N640

Notes : 1. The center of car operating panel(OPP-N640) can protrude about 10mm, if it is applied to elevator 1150kg(17 Persons) or under for handicap use. 2. Finished product may vary slightly from these prints.

P019 (5.1Y 7.6/1.1)

P020 (Metallic Gold)

P021 (Metallic Silver)

P022 (Black)

Note : Finished product may vary slightly from these prints.

Type of Buttons

Hall Buttons

Polyvinyl Tile

30 TYPE

40 TYPE

41 TYPE

FULL AUTO

FULL AUTO

DTE2109

DTE2115

DTE2126

DTE2241

HIP- D240

(Box Type)

(Boxless Type)

HIP- D641

HPB-240

(Box Type)

(Boxless Type)

HPB-641

Reference Data (Wheelchair)

DTE2246 DTF5311 DTF5907 TN2230C

1,100 1,350 and over 800 and over 1,600 and over (Unit : mm)

200 ~220

980 and less

650

430 450

TN2233C

TN2402C

TN2601C

TN2604C

400 650 and less 770 About 1,080

1,100

1,350

Note : Finished product may vary slightly from these prints.

Rear/Side View

Required Space (if rotated 90-degrees)

1,350

Car and Door Size PASSENGER ELEVATORS 27

26 HYUNDAI ELEVATOR CO., LTD.

Standard & Optional Features

Items 1) Selective collective

Descriptions

The first call determines the direction of the elevator. All calls opposing the respective direction are serviced after carrying out by the calls of the respective direction.

Marks

Items 14) Multi-beam door protection

Descriptions

Multi-beam from the top to the bottom of the door senses any obstruction caught in the door. It makes the door reopen, or keep open/close before the door is touched such obstruction.

Marks

2) Duplex selective collective

2 units of elevator provide the effective service for the common hall calls

15) Fire emergency service

When a fire breaks out, all cars activated by the switch or fire detector are immediately called to a specified rescue floor for the passengers safety.

3) Automatic bypass

When a car is 80% loaded, it will automatically bypass all hall calls as the bypass load weighing device is activated.

16) Anti-nuisance 4) Chime bell

It provides an audible indication in the car that an elevator is about to arrive. Digital(Segment) type Dot matrix type(moving direction) Hall lantern Contact with a passenger or inanimate object causes the doors to stop and reopen automatically. The elevator doesnt start if the door is completely not closed. Car ventilation is smooth with ventilation fan built-in the ceiling.

Evaluates the number of people on the car and compares that value to the number of the car calls registered. If the number of car calls exceeds the number of people in the car by the load sensor, the car call exceeding the number of passengers will be cancelled after service nearest all only.

5) Signal fixtures

17) Voice synthesizer

A voice synthesizer with microprocessor makes announcements to inform passengers of various conditions, including landing floor and operation direction, etc.

6) Single-side safety edge of door

18) Emergency power operation

During normal power failure, elevator service continues with buildings emergency power source.

7) Ventilation fan 8) Emergency car lighting 9) Automatic interruption of light and ventilation fan

19) Firemans emergency service

When the firemans switch located at the main floor lobby and operating panel on the car is activated during a fire or other emergency, a designated car can be called back to a specified floor for fire fighting service.

In case of the power failure, it lights automatically in the car.

The lights and ventilation fan are automatically turned off to save energy if there is no call registered for a period of time. If there is a call registered again, it works again.

20) HELMON (Hyundai Elevator Computer Monitoring) System

This system has a various function like elevator monitoring and control by the personal computer and modem.

10) Door interlock switch

When the door is opened, the switch installed at the door operator is activated and keeps the car from moving. During the operation of car, it locks the door completely so as not to open the door from out side.

21) Emergency landing device (ELD)

In the event of the power failure, the elevator power automatically switches to a rechargeable battery built-in controller that moves the car to the nearest floor and allows passengers to safely exit. This can be used when no emergency power source in the building is available.

11) Interphone & emergency call button

In case of emergency, the passenger can communicate with the personnel in control room or in prevention center of disasters by pushing the emergency call button.

22) Attendant service

To protect the overload of elevator, this device sounds a buzzer and the elevator remains stopped at that floor when the number of passengers exceeds the rated capacity. When the excess number of passengers get out of the car, the buzzer stops and the elevator door closes.

It is activated when the attendant turns on the ATT switch in the car operating panel to ON position.

12) Overload features

23) Earthquake operation

When the seismic sensor detects and earthquake that exceeds a predetermined level, all cars promptly proceed to land at the nearest floor and park with the doors open to allow passengers to exit out safely.

13) Safety drive

During the operation if the car stops between floors, and safety device doesnt work, the car automatically moves to the nearest floor with the low speed. Then, it opens the door to allow the passengers to exit off.

24) Parking

The car can be parked at a specified floor, during the nights or holidays with operate parking switch on hall button.

Notes : 1. : Standard, : Optional 2. Consult Hyundai if you need the specific features except the above items.

28 HYUNDAI ELEVATOR CO., LTD.

PASSENGER ELEVATORS 29

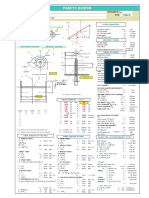

Layout Plan - LUXEN(Gearless Elevators) 60~150m/min

Plan of Hoistway & Machine Room

MX1 X1 A

R1 Vent Grille(By others) Vent Grille(By others) Vent Grille(By others) Vent Grille(By others) Vent Grille(By others)

Section of Hoistway

Standard Dimensions & Reactions

(Unit : mm)

Speed (m/min)

M/C Room Height(MH) Suspension Hook (By others) Cinder Concrete Min.150 (By others)

Capacity Persons

6 8

Clear Opening OP

800 800 800 800 800 900 900 1000 1100 1000 1100 1100

Car Internal CA CB

1400 850

External AB

1460 1005

1Car X1

1800 1800 1800 1800 1800 2050 2050 2350 2550 2350 2550 2550 2700

Hoistway 2Cars 3Cars Depth X2

3700 3700 3700 3700 3700 4200 4200 4800 5200 4800 5200 5200 5500

1Car MX1

2000 2000 2000 2000 2000 2300 2300 2600 2800 2600 2800 2900 3000

M/C Room M/C Room 2Cars 3Cars Depth Reaction (kg) MX2

4000 4000 4000 4000 4000 4400 4400 4900 5250 4900 5250 5400 5650

kg

450 550 600 700 750 900 1000 1150

X3

5600 5600 5600 5600 5600 6350 6350 7250 7850 7250 7850 7850 8300

Y

1430 1610 1710 1830 1930 1980 2130 2180 2030 2380 2180 2430 2280

MX3

6000 6000 6000 6000 6000 6800 6800 7500 8300 7500 8300 8300 8700

MY

3200 3400 3500 3600 3700 3750 3850 3900 3800 4200 4000 4300 4200

R1

3600 4050 4100 4200 4550 5100 5450 6600

R2

2000 2250 2450 2700 2800 3750 4300 5100

Vent Fan(By others)

1400 1030 1460 1185 1400 1130 1460 1285 1400 1250 1460 1405 1400 1350 1460 1505 1600 1350 1660 1505 1600 1500 1660 1655 1800 1500 1900 1670 2000 1350 2100 1520 1800 1700 1900 1870 2000 1500 2100 1670 2000 1750 2100 1920 2150 1600 2250 1770

CB

R2

R1

60

9 10

Y B

CA MY

Overhead (OH)

OP R2 Control Panel

90

11 13

105

15 17

Distribution Board (By others)

120

Machine Room Access Door(By others) Min. 900(W) 2000(H)

Total Height (TH)

MX2 X2 X1 R1 Beam (By others) Vent Grille(By others) A R1 Vent Fan(By others)

150

20

1350

7800

6000

Travel (TR)

24

1600

8500

6800

CA MY

OP Vent Grille(By others) R2 Control Panel Control Panel

OP R2

Pit Depth (PP)

Notes : 1. Above hoistway dimensions are based on 15-storied buildings. For application to over 16-storied buildings, the hoistway dimensions shall be at least 5% larger considering the sloping of the hoistways. 2. Above dimensions are based on center opening doors. For applicable dimensions with side opening doors, consult Hyundai. 3. When non-standard capacities and dimensions are required to meet the local code, consult Hyundai. 4. The capacity in persons is calculated at 65kg/person. (EN81:75kg/person) 5. Above dimensions are applied in case the door is standard. In case fire protection door is applied, hoistway size for 1 car should be applied above X1 dimension plus 100mm. 6. In case of 120m/min and 150m/min, the dimension of X1 is X1 plus 100mm.

Ent. Height (EH)

CB

2100

R3 Receptacle (By others) Ladder (By others)

R4 Waterproof Finish (By others) (Unit : mm)

Distribution Board

(By others)

Speed (m/min)

60 90 105

Overhead (OH)

4600 4800 5000 5000 5500

Pit (PP)

1500 1800 2100 2100 2400

M/C Room Height (MH)

2200 2400 2400 2600 2600

Machine Room Access Door(By others) Min. 900(W) 2000(H)

MX3 X3 X2 Vent Fan (By others) Min.100 X1 A R1 Vent Grille(By others)

120 150

R1

Beam (By others) Beam (By others) Beam (By others) Beam (By others) Beam (By others) Beam (By others) Beam (By others)

R1

Note : Machine room temperature should be maintained below 40 C with ventilating fan and/ or air conditioner(if necessary) and humidity below 90%.

CB

CA MY Vent Fan (By others) OP OP R2 OP R2

Vent Grille(By others)

R2

Control Panel

Control Control Panel Panel Distribution Board (By others)

30 HYUNDAI ELEVATOR CO., LTD.

Machine Room Access Door(By others) Min. 900(W) 2000(H)

B Y

PASSENGER ELEVATORS 31

Layout Plan - YZER(Machine-Room-Less Elevators)

60~150m/min

Section of Hoistway

Lighting(By others)

Plan of Hoistway (8~17 Persons)

Lighting(By others) X A R3 CA R1

Standard Dimensions (8~17 Person)

(Unit : mm)

Hook(By others)

Car Hoistway Clear Speed Opening Internal External 1Car Depth Motor (m/min) (kW) Persons kg OP CA CB AB X1 Y Capacity

60 90 105 60 90 105 60 90 105 60 90 105 60 90 105 60 90 105 60 90 105 8 550 800 1300 1100 1360 1255 2050 1700 3.4 5.1 5.9 3.7 5.6 6.5 4.3 6.5 7.5 4.6 6.9 8.1 5.6 8.3 9.7 6.2 9.2 10.8 7.1 10.6 12.4

Traction Machine Top floor (By others)

600

800

1300 1190 1360 1345 2050 1800

Entrance Height(EH)

10

700

800

1300 1300 1360 1455 2050 1800

Notes : 1. The dimension in ( ) is for the heavy car weight such as the car floor using finished granite. 2. When non-standard capacities and dimensions (including fire protection doors) are required to meet the local code, please consult Hyundai. 3. The minimum hoistway dimensions are shown on the above table. Therefore, some allowances should be made considering the sloping of the hoistways. 4. The capacity in persons is calculated at 65kg/person.(EN81:75kg/person) 5. If the height of floor is over 11 m , please consult Hyundai as to the needs for emergency exit 6. Above dimensions are applied to standard door only. In case fire protection door is applied, hoistway size for 1 car should be applied above X1 dimensions plus 100 mm and over. 7. In case of 120m/min and 150m/min, consult Hyundai for the dimensions.

R4 OP

R2

Over head(OH)

CB

11

750

800

1300 1400 1360 1555 2050 1850 1600 1300 1660 1455 2300 1800 1500 1400 1560 1555 2200 1850 1600 1400 1660 1555 2300 1900 (2100)

Total Height(TH)

Floor without control panel

13

900

900

15

1000

900

Travel(TR)

Control Control Control Control Control Control Panel Panel Panel Panel Panel Distribution Board (By others) CP 530 OP

17

1150

1000

1800 1400 1900 1570 2600 2100

Receptacle (By others) Ladder (By others)

Floor with control panel

Standard Dimensions (20, 24 Person)

Pit Depth(PP) Lighting (By others) Waterproof Finish (By others) R5 R6 (Unit : mm)

Notes : 1. The lighting of hoistway should be installed less than 500 mm from above the ceiling of hoistway and within 500 mm above the bottom of the pit. (By others)

Car Hoistway Clear Capacity Speed Opening Internal External 1Car Depth Motor (m/min) (kW) Persons kg OP CA CB AB X1 Y

60 90 105 60 90 105 20 1350 1000 1800 1600 1900 1770 2625 2400 8.3 12.5 14.5 9.9 14.8 17.2

Notes : 1. When non-standard capacities and dimensions are required to meet the local code, please consult Hyundai. 2. The minimum hoistway dimensions are shown on the above table. Therefore, some allowances should be made considering the sloping of the hoistways. 3. Consult Hyundai if the emergency stop device is installed on the counterweight.

24

1600

1100

2000 1700 2100 1870 2825 2450

Plan of Hoistway (20, 24 Persons)

X Min.225 A Min.500 Top floor (*) CA R2 CB Y B R1 OP Distribution Board (By others) Control Control Control Control Control Control Panel Panel Panel Panel Panel Panel CP (*)

(Unit : mm)

Persons

8~17

Speed (m/min)

60 90 105 60 90 105

Overhead (OH)

3800 3900 4000 4200 4350 4450

Pit (PP)

1500 1800 2100 1500 1800 2100

Control panel (CP)(*)

530

Reactions

(Unit : mm)

R3

M/C Room Reaction (kg)

530 630 630

20, 24

Persons

R1

R2

R3

Pit Reaction (kg) R5 R6 R4 Speed Speed (m/min) (m/min)

10000 14000 12000 21500 Under60 90.105 Under60 90.105 8000 12000 9500 17500

R4 Top floor (By others)

OP

Floor without control panel

Floor with control panel

Notes : 1. Above dimensions are applied for car height of 2500 mm (car internal height is 2300 mm). For other applicable dimensions, consult Hyundai. 2. For car internal height (under 17 persons) of 2500 mm, dimension of overhead is OH plus 200mm. 3. If the dimension between the wall of hoistway and car external dimensions (A, B) is in excess of over 850 mm, the dimension of overhead is OH plus 200mm. 4. The minimum hoistway dimensions are shown on the above table. Therefore, some allowances should be made considering the sloping of the hoistways. 5. When face to face arrangement is required, partitioning work for hoistway is required. (EN81) 6. If the hoistway is glass, consult Hyundai as it needs to finish laminated glass. (EN81) 7. The lighting should be installed at the top and bottom of hoistway.

8~17 20, 24

Under60 90.105 Under60 14000 3800 1500 4500 90.105 8000 3500 1500 3000

Notes : 1. The minimum dimensions for the standard are shown on the above table. Consult Hyundai in case of non-standard. 2. Consult Hyundai if the hoistway is steel structure.

32 HYUNDAI ELEVATOR CO., LTD.

PASSENGER ELEVATORS 33

Layout Plan

Geared Elevators 60~105m/min

Section of Hoistway Standard Dimensions & Reactions

(Unit : mm) Suspension Hook (By others)

Plan of Hoistway & Machine Room

MX1 X1 A R1 Vent Grille(By others) Vent Grille(By others) Vent Grille(By others) Vent Grille(By others) Vent Grille(By others) Vent Grille(By others)

M/C Room Height(MH)

Cinder Concrete Min. 150 (By others)

Speed (m/min)

Capacity Persons

6 8 9

Clear Opening OP

800 800 800 800 800 900 900 1000 1100 1000 1100 1100

Car Internal CA CB

1400 850

External AB

1460 1005

1Car X1

1800 1800 1800 1800 1800 2050 2050 2350 2550 2350 2550 2550 2700

Hoistway 2Cars 3Cars Depth X2

3700 3700 3700 3700 3700 4200 4200 4800 5200 4800 5200 5200 5500

1Car MX1

2000 2000 2000 2000 2000 2300 2300 2600 2800 2600 2800 2900 3000

M/C Room M/C Room 2Cars 3Cars Depth Reaction (kg) MX2

4000 4000 4000 4000 4000 4400 4400 4900 5250 4900 5250 5400 5650

kg

450 550 600 700 750 900 1000 1150

X3

5600 5600 5600 5600 5600 6350 6350 7250 7850 7250 7850 7850 8300

Y

1430 1610 1710 1830 1930 1980 2130 2180 2030 2380 2180 2430 2280

MX3

6000 6000 6000 6000 6000 6800 6800 7500 8300 7500 8300 8300 8700

MY

3200 3400 3500 3600 3700 3750 3850 3900 3800 4200 4000 4300 4200

R1

3600 4050 4100 4200 4550 5100 5450 6600

R2

2000 2250 2450 2700 2800 3750 4300 5100

R2

R1

1400 1030 1460 1185 1400 1130 1460 1285 1400 1250 1460 1405 1400 1350 1460 1505 1600 1350 1660 1505 1600 1500 1660 1655 1800 1500 1900 1670 2000 1350 2100 1520 1800 1700 1900 1870 2000 1500 2100 1670 2000 1750 2100 1920 2150 1600 2250 1770

Vent Fan(By others)

Overhead (OH)

CB

60

10 11 13

CA MY

OP R2 Control Panel Total Height (TH)

90

15 17

105

Distribution Board (By others)

20

1350

7800

6000

Travel (TR)

Machine Room Access Door(By others) Min. 900(W) 2000(H)

24

1600

8500

6800

Ent. Height (EH)

Note : Machine room temperature should be maintained below 40 C with ventilating fan and/or air conditioner(if necessary) and humidity below 90%.

Receptacle (By others)

Pit Depth (PP)

Notes : 1. Above hoistway dimensions are based on 15-storied buildings. For application to over 16-storied buildings, the hoistway dimensions shall be at least 5% larger considering the sloping of the hoistways. 2. Above dimensions are based on center opening doors. For applicable dimensions with side opening doors, consult Hyundai. 3. When non-standard capacities and dimensions are required to meet the local code, consult Hyundai. 4. The capacity in persons is calculated at 65kg/person. (EN81:75kg/person) 5. Above dimensions are applied in case the door is standard. In case fire protection door is applied, hoistway size for 1 car should be applied above X1 dimension plus 100mm.

Ladder (By others)

2100

Waterproof Finish (By others)

MX2 X2 X1 R1 A R1 Vent Fan(By others) X1 A R1 Vent Grille(By others) X2

MX3 X3 Vent Fan(By others) Min. 100

(Unit : mm)

Speed (m/min)

60 90 105

R1

Overhead (OH)

4600 4800 5000

Pit (PP)

1500 1800 2100

M/C Room Height (MH)

2200 2400 2400

Beam (By others)

R1 Beam (By others)

Vent Grille(By others)

CB

CA MY

CA OP OP OP OP OP OP R2 OP OP OP OP OP OP R2 OP OP OP OP OP OP R2 Vent Fan(By others)

Note : The minimum hoistway dimensions are shown on the above table. Therefore, some allowances should be made considering the sloping of the hoistways.

CB

OP Vent Grille(By others) R2 Control Panel Control Panel

OP Vent Grille(By others) R2

Control Panel

Control Panel

Control Panel Distribution Board (By others)

Distribution Board (By others)

Machine Room Access Door(By others) Min. 900(W) 2000(H)

Machine Room Access Door(By others) Min. 900(W) 2000(H)

34 HYUNDAI ELEVATOR CO., LTD.

MY

PASSENGER ELEVATORS 35

Typical Entrance Layouts

Typical Entrance Layouts

Only for Floor with Control Panel of the Machine-Room-Less Elevators

Structural Opening of Entrance

OF CAR

Entrance

30

Structural Opening of Entrance

In case of Boxless Type Buttons and Fire man's Switch

Wiring Inlet : 50 700 Concrete Opening(Jamb Height + 50mm) 150 Steel Bar for Fixing Jamb 9 700 6EA(By others) 500 (By others)

Entrance Design

30

700

Entrance Height (EH) : 2100

Concrete Opening : 2200

Steel Bar for Fixing Jambs 9 6EA (By others)

Entrance Height(EH) : 2100

HB With HPI

700

150

Concrete Opening : 2200

Jamb Height(JH)

1700

Hall Button with Indicator

700

1000

Steel Bar for Fixing Jamb 9 700 6EA(By others)

80 1050

30

700

Clear Clear Clear Clear Clear Opening (OP) Opening (OP) Opening (OP) Opening (OP) Opening (OP) Finished Floor Level (By others)

Concrete Opening OP+140

700

Concrete Opening OP+140

Finished Floor Level (By others)

700

CP (*)

Clear Opening (OP)

30

Concrete Opening Clear Opening + CP + 100 2 Clear Opening +100 2

JP050 Type (Basic)

200 500

Finished Floor Level (By others)

200

Indicator 30

Emergency Call Switch (For emergency call, only rescue floor is applied)

500

CP110 Type (Standard)

Wiring Inlet : 50 (By others) 700

CP110 Type (Standard)

700

150 Concrete Opening : 2200 Steel Bar for Fixing Jamb 9 6EA(By others) 300 1650

250

Entrance Height (EH) : 2100

Concrete Opening : 2200

OF CAR

Transom Panel

Jamb Height (JH)

700

HB

700

700

30

Concrete Opening : JH+50

Entrance Height(EH) : 2100

Finished Floor Level (By others)

Jamb Height(JH)

Finished Floor Level (By others)

Concrete Opening OP+300

1000

Clear Clear Clear Clear Clear Opening (OP) Opening (OP) Opening (OP) Opening (OP) Opening (OP)

Steel Bar for Fixing Jamb 9 6EA(By others)

80 1000

1900

Position Indicator

700

700

Steel Bar for Fixing Jambs 9 6EA (By others) 150 Concrete Opening OP+300

Hall Button

JP100 Type (Optional)

30

700

Transom Panel Hall Position Indicator Emergency Call Switch Concrete Opening:JH+50 Entrance Height (EH) : 2100 Jamb Height (JH) (For emergency call, only rescue floor is applied) 9 700 Steel Bar for Fixing Jamb 250 6 (By others)

EA

CP Wiring Inlet : 50 (By others) (*)

Clear Opening (OP)

30 Finished Floor Level (By others) 700 Concrete Opening Clear Opening + CP + 100 2 Clear Opening Clear Opening Clear Opening Clear Opening Clear Opening Clear Opening +100 2 2 22 2 2

Steel Bar for Fixing Jamb 9 Concrete Opening:JH+50 700 6EA(By others)

150

CP210 Type (Optional)

1900

CP210 Type (Optional)

700

HB

300

1650

700

80 Clear Clear Clear Clear Clear Opening (OP) Opening (OP) Opening (OP) Opening (OP) Opening (OP) 1000 1000

(Unit : mm)

700

30

Concrete Opening OP+300

Concrete Opening 700 OP+300

Persons

8~17

Finished Floor Level (By others)

Speed (m/min)

Under 105 60

Width of Control Panel (CP)(*)

530 530 630 630

20, 24

90 105

JP200 Type (Optional)

36 HYUNDAI ELEVATOR CO., LTD.

PASSENGER ELEVATORS 37

1000

300

1000

500

Typical Entrance Layouts

2-Panel Center-Opening (CO) Layout

Section Entrance

Works To Be Done By Other Contractors

The following works are not included in the elevator contract, and shall be done by other contractors in accordance with the Hyundai Elevator s drawings and the applicable codes and regulations. The reference rules shown are from Code ANSI.

Plan of Entrance

Jamb Width Jamb Width Jamb Width Jamb Width Jamb Width Jamb Width

50

Wall Thickness

90

30

30 (150)

Wall Finish Thickness

100

Building Work

Entrance Height (EH) : 2100

Electrical Work

70

Clear Opening (OP)

70

HB With HPI

JP050 Type

Hoistway

1. Clear, plumb hoistway with fire resistant hatch walls as required by the applicable code.

Jamb Width Jamb Width Jamb Width Jamb Width Jamb Width

Hoistway

1. Light outlet for each elevator, in center of hoistway(or in machine room)as indicated by Hyundai Elevator Company. 2. Convenience outlet and light fixture in pit with switch located adjacent to the access door. (Rule 106.1e) 3. Wiring and piping work of emergency bell, interphone, etc. outside the hoistway and the machine room.

(Rule 100.1a) 2. 75 bevel guards on all projections, recesses or setbacks over 50mm except on side used for loading or unloading. (Rule 100.6) 3. Venting of the hoistway as required by the applicable code or responsible authority. (Rule 100.4) 4. Supports for rail brackets at each floor, roof, and machine room.(Rule 200.9)

50

Jamb Width

Wall Thickness

90

Wall Finish Thickness

Maximum allowable vertical spacing of rail supports, without backing. (Rule 200.4 and 301.1) Divider beams 100mm between hoistway at each floor and roof, for guide rail bracket supports.(Rule 200.4, 200.9 and 301.1) 5. Recesses supports and patching as required to accommodate hall button boxes, signal fixtures, etc. 6. All barricades either outside elevator hoistways or between elevators inside hoistways as required. 7. Dry pit reinforced to sustain normal vertical forces from rails and buffers. (Rule 106.1b and 109) Consult Hyundai Elevator Company for rail forces and buffer impacts. Where there is space below the pit floor that can be occupied, consult Hyundai Elevator Company for special requirements. (Rule 300.4) Cylinder hole, casings under the pit as required and backfilling around the cylinder casings when direct plunger type is to be installed. 8. Where access to the pit is by means of the lowest hoistway entrance, vertical iron ladder

Machine Room

4. Lighting, convenience outlets, ventilation, heating of machine room, and machinery space. (Rule 101.5) 5. Temperature should be maintained below 40 C by a ventilating fan and/or air conditioner, if necessary, and humidity below 90%. 6. A fused disconnect switch or circuit breaker for each elevator and light switch located per the applicable code and where practicable located adjacent to the door of the machine room. (Rule 210.5 and 306.7) 7. Feeder and branch wiring to the controller, including main-line switch and convenience outlets. 8. Suitable power feeder and branch wiring circuits as required for elevators with power operated doors, including disconnect switch or circuit breaker.

30 150 Clear Opening (OP) 150

(180) Hall Button

90 (130)

JP100, JP200 Type

JP050 Type

50

50

50 Ceiling Line

100

Upper Frame

10

10

extending 1060mm minimum above sill of access door. (Rule 106.1d) 9. Entrance walls and finished floor are not to be constructed until after door frames and sills are in place. Door frames are to be anchored to walls and properly grouted in place to maintain legal fire rating. 10. For application as indoor or outdoor observation elevator, a glass enclosure of at least 3.6m in height at the bottom landing is recommended for safety. For use as an outdoor observation elevator, a full-height glass enclosure is required.

Emergency Provisions

9. Elevator firemans and other emergency services wiring and interconnections to automatic sprinkler systems or heat and smoke sensing devices furnished by others and installed to terminal points on the elevator controllers. 10. When emergency power operation of elevators is required, the electrical contractor should coordinate with Hyundai Elevator Company or local distributor for operation requirements. 11. Elevator firemans and other emergency service requirements may differ from each country. Consult Hyundai Elevator Company or local distributor for other local requirements. 12. When provisions for earthquake protection are required, consult Hyundai Elevator Company for special requirements.

Jamb Height (JH)

Jamb Height (JH)

Ceiling Height

Entrance Height (EH) : 2100

Entrance Height (EH) : 2100

Jamb Width

Jamb Width

Entrance Height (EH) : 2100

Jamb Width

Machine Room

50 50

11. Enclosed and protected machine room. (Rule 101.1)

50

12. Access to the machine room and machinery space as required by the applicable code or responsible authority. (Rule 101.3) 13. Reinforced concrete machine room floor slab or grating, as specified, which must not be

Heat Emission of Machine Room

Q (Kcal/H) = W V F N W: Capacity (kg) V : Speed (m/min) F : Factor (1/40: VVVF) N : Number of cars

90 (130)

90 (130)

Building Structure (By Other Contractors) Wall and Floor Finishing (By Other Contractors)

90 (130)

placed over the hoistway until elevator machinery is set in position. (Rule 100.3 for Traction Elevator) 14. Hoisting beams, trap doors and other means of access to machine room for maintenance and equipment removal purposes. (Rule 101.3d) 15. Cable guards in the machine room or secondary level. (Rule 104.1) 16. Supports for machine and sheave beams and reactions including wall pockets and patching after beams are set in place. (Rule 105.1 to 105.5) PASSENGER ELEVATORS 39

JP100 Type

Note : The dimension in ( ) is applied for 120m/min and over.

JP200 Type (with upper frame)

JP200 Type (without upper frame)

38 HYUNDAI ELEVATOR CO., LTD.

Electric Power Requirements (By others)

VVVF (50/60Hz, 380V)

Persons (kg) Speed (m/min)

60 6/450 90 105 60 8/550 90 105 60 9/600 90 105 60 10/700 90 105 60 11/750 90 105 120 60 90 13/900 105 120 150 60 90 15/1000 105 120 150 60 90 17/1150 105 120 150 60 90 20/1350 105 120 150 60 90 24/1600 105 120 150

VVVF (50/60Hz, 220V)

Motor (kW)

5.5 (2.8) 7.5 (4.2) 7.5 (4.9) 5.5 (3.4) 7.5 (5.1) 11 (5.9) 5.5 (3.7) 11 (5.6) 11 (6.5) 7.5 (4.3) 11 (6.5) 11 (7.6) 7.5 (4.6) 11 (6.9) 11 (8.1) (9.2) 11 (5.6) 15 (8.3) 15 (9.7) (11.1) (13.8) 11 (6.2) 15 (9.2) 15 (10.8) (12.3) (15.4) 11 (7.1) 15 (10.6) 18.5 (12.4) (14.1) (17.7) 15 (8.3) 18.5 (12.5) 22 (14.5) (16.6) (20.7) 15 (9.9) 22 (14.8) 22 (17.2) (19.7) (24.5)

MCCB (A) 1Car

20 (20) 20 (20) 20 (20) 20 (20) 20 (20) 30 (20) 20 (20) 30 (20) 30 (20) 20 (20) 30 (20) 30 (20) 20 (20) 30 (20) 30 (30) (30) 30 (20) 40 (30) 40 (30) (30) (50) 30 (20) 40 (30) 40 (30) (40) (50) 30 (20) 40 (30) 50 (30) (40) (60) 30 (20) 50 (40) 50 (40) (40) (75) 40 (30) 50 (50) 60 (50) (50) (75)

Power (KVA) 1Car

4 (3) 6 (4) 7 (5) 5 (4) 7 (5) 8 (6) 5 (4) 8 (6) 9 (7) 6 (5) 9 (7) 11 (9) 6 (5) 10 (7) 11 (9) (10) 8 (6) 12 (9) 14 (10) (12) (15) 9 (7) 13 (10) 15 (11) (13) (17) 10 (8) 15 (11) 17 (13) (15) (20) 12 (9) 17 (13) 20 (15) (17) (23) 14 (10) 21 (16) 24 (18) (21) (27)

Cable (mm2) 1Car

4 (4) 4 (4) 4 (4) 4 (4) 4 (4) 6 (4) 4 (4) 6 (4) 6 (4) 4 (4) 6 (4) 6 (4) 4 (4) 6 (4) 10 (6) (6) 6 (4) 10 (6) 10 (6) (6) (10) 6 (4) 10 (6) 10 (6) (10) (10) 6 (4) 10 (6) 16 (6) (10) (10) 10 (4) 16 (10) 16 (10) (10) (16) 10 (6) 16 (10) 16 (16) (16) (16)

Earth (mm2) 1Car

4 (6) 4 (6) 4 (6) 4 (6) 4 (6) 4 (6) 4 (6) 4 (6) 4 (6) 4 (6) 4 (6) 4 (6) 4 (6) 4 (6) 4 (6) (6) 4 (6) 6 (6) 6 (6) (6) (6) 4 (6) 6 (6) 6 (6) (6) (6) 4 (6) 6 (6) 6 (6) (6) (6) 6 (6) 6 (6) 6 (6) (6) (10) 6 (6) 6 (6) 10 (6) (6) (10)

2Cars

30 (20) 30 (40) 40 (40) 30 (20) 30 (40) 50 (40) 30 (30) 50 (40) 50 (40) 40 (30) 50 (40) 60 (40) 40 (30) 50 (40) 60 (50) (50) 50 (30) 60 (50) 75 (50) (60) (100) 50 (40) 75 (50) 75 (60) (75) (100) 50 (40) 75 (60) 100 (60) (75) (100) 60 (40) 100 (75) 100 (75) (100) (125) 75 (50) 100 (75) 125 (100) (100) (150)

2Cars

7 (5) 10 (8) 12 (9) 9 (6) 13 (10) 15 (11) 9(7) 14 (11) 16 (12) 11 (8) 16 (12) 19 (14) 12 (9) 17 (13) 20 (15) (18) 14 (11) 21 (16) 24 (18) (21) (28) 15 (12) 23 (18) 27 (20) (23) (31) 18 (13) 27 (20) 31 (23) (27) (35) 21 (16) 31 (24) 37 (28) (31) (41) 25 (19) 37 (28) 43 (33) (37) (49)

2Cars

6 (4) 6 (10) 10 (10) 6 (4) 6 (10) 16 (10) 6 (6) 16 (10) 16 (10) 10 (6) 16 (10) 16 (10) 10 (6) 16 (10) 16 (16) (16) 10 (6) 16 (16) 25 (16) (16) (25) 16 (10) 25 (16) 25 (16) (25) (25) 16 (10) 25 (16) 35 (16) (25) (25) 16 (10) 25 (25) 35 (25) (25) (35) 25 (16) 35 (25) 35 (25) (25) (50)

2Cars

4 (6) 6 (6) 6 (6) 4 (6) 4 (6) 6 (6) 4 (6) 6 (10) 6 (10) 6 (6) 6 (6) 10 (6) 6 (6) 6 (10) 10 (10) (10) 6 (6) 10 (10) 10 (10) (10) (16) 6 (10) 10 (10) 10 (10) (16) (16) 6 (10) 10 (10) 10 (16) (16) (16) 6 (6) 10 (10) 10 (10) (10) (25) 10 (6) 10 (10) 16 (10) (10) (35)

Persons (kg)

Speed (m/min)

60

Motor (kW)

5.5 (2.8) 7.5 (4.2) 7.5 (4.9) 5.5 (3.4) 7.5 (5.1) 11 (5.9) 5.5 (3.7) 11 (5.6) 11 (6.5) 7.5 (4.3) 11 (6.5) 11 (7.6) 7.5 (4.6) 11 (6.9) 11 (8.1) (9.2) 11 (5.6) 15 (8.3) 15 (9.7) (11.1) (13.8) 11 (6.2) 15 (9.2) 15 (10.8) (12.3) (15.4) 11 (7.1) 15 (10.6) 18.5 (12.4) (14.1) (17.7) 15 (8.3) 18.5 (12.5) 22 (14.5) (16.6) (20.7) 15 (9.9) 22 (14.8) 22 (17.2) (19.7) (24.6)

MCCB (A) 1Car

30 (20) 30 (30) 40 (30) 30 (20) 40 (30) 40 (30) 30 (20) 40 (30) 40 (30) 30 (20) 40 (30) 50 (40) 30 (30) 50 (40) 50 (40) (40) 40 (30) 50 (40) 60 (50) (50) (30) 40 (30) 60 (50) 75 (50) (60) (30) 50 (40) 75 (50) 75 (60) (70) (40) 50 (40) 75 (60) 100 (60) (70) (50) 60 (50) 100 (70) 100 (80) (80) (80)

Power (KVA) 1Car

4.3 (3.3) 6.4 (4.9) 7.5 (5.7) 5.3 (4) 7.9 (6) 9.2 (7) 5.7 (4.4) 8.6 (6.5) 10 (7.6) 6.7 (5.1) 10 (7.6) 11.7 (8.8) 7.2 (5.4) 10.7 (8.1) 12.5 (9.5) (10.8) 8.6 (6.5) 12.9 (9.7) 15 (11.3) (13) (16.2) 9.6 (7.2) 14.3 (10.8) 16.7 (12.6) (14.4) (18) 11 (8.3) 16.5 (12.4) 19.2 (14.5) (16.5) (20.7) 12.9 (9.7) 19.3 (14.6) 22.6 (17) (19.4) (24.2) 15.3 (11.5) 22.9 (17.3) 26.8 (20.1) (23) (28.7)

Cable (mm2) 1Car

4 (4) 6 (6) 6 (6) 4 (4) 6 (6) 10 (6) 4 (4) 10 (6) 10 (6) 6 (4) 10 (6) 16 (6) 6 (4) 10 (6) 16 (10) (10) 10 (4) 16 (10) 16 (10) (16) (10) 10 (6) 16 (10) 16 (16) (16) (16) 10 (6) 16 (10) 25 (16) (25) (25) 16 (10) 25 (16) 35 (16) (25) (25) 16 (10) 35 (16) 35 (25) (35) (35)

Earth (mm2) 1Car

4 (4) 4 (4) 6 (4) 4 (4) 6 (4) 6 (4) 4 (4) 6 (4) 6 (6) 4 (4) 6 (6) 6 (6) 4 (4) 6 (6) 6 (6) (6) 6 (4) 6 (6) 10 (6) (6) (4) 6 (4) 10 (6) 10 (6) (10) (4) 6 (6) 10 (6) 10 (10) (10) (6) 6 (6) 10 (10) 16 (10) (10) (6) 10 (6) 16 (10) 16 (16) (16) (16)

2Cars

50 (40) 60 (60) 75 (60) 50 (40) 75 (60) 75 (60) 60 (40) 75 (60) 100 (60) 60 (40) 100 (60) 100 (75) 60 (50) 100 (75) 100 (75) (100) 75 (50) 100 (75) 125 (100) (100) (50) 75 (60) 125 (100) 125 (100) (125) (50) 100 (75) 125 (100) 150 (125) (150) (75) 100 (75) 150 (125) 200 (125) (150) (100) 125 (100) 200 (125) 200 (150) (175) (175)

2Cars

8 (6) 12 (9) 14 (10) 9 (7) 14 (11) 17 (13) 10 (8) 15 (12) 18 (14) 12 (9) 18 (14) 21 (16) 13 (10) 19 (15) 23 (17) (19) 15 (12) 23 (18) 27 (20) (23) (29) 17 (13) 26 (19) 30 (23) (26) (32) 20 (15) 30 (22) 35 (26) (30) (37) 23 (18) 35 (26) 41 (31) (35) (44) 28 (21) 41 (31) 48 (36) (41) (52)

2Cars

10 (6) 16 (16) 16 (16) 16 (6) 25 (16) 25 (16) 16 (10) 25 (16) 25 (16) 16 (10) 25 (16) 35 (25) 16 (10) 35 (16) 35 (25) (25) 25 (16) 35 (25) 50 (35) (35) (25) 25 (16) 35 (35) 50 (35) (35) (35) 35 (25) 50 (25) 70 (35) (50) (70) 35 (25) 70 (35) 95 (35) (50) (95) 50 (35) 95 (35) 95 (70) (95) (95)

2Cars

6 (6) 10 (10) 10 (10) 6 (6) 10 (10) 10 (10) 10 (6) 10 (10) 16 (10) 10 (6) 16 (10) 16 (10) 10 (6) 16 (10) 16 (10) (16) 10 (6) 16 (10) 25 (16) (16) (6) 10 (10) 25 (16) 25 (16) (25) (6) 16 (10) 25 (16) 25 (25) (25) (10) 16 (10) 25 (25) 35 (25) (25) (16) 25 (16) 35 (25) 35 (25) (35) (35)

6/450

90 105 60

8/550

90 105 60

9/600

90 105 60

10/700

90 105 60

11/750

90 105 120 60 90

13/900

105 120 150 60 90

15/1000

105 120 150 60 90

17/1150

105 120 150 60 90

20/1350

105 120 150 60 90

24/1600

105 120 150

Notes : 1. Above power feeder sizes are for the length of electric wire up to 50m from elevator machine room to power. For the length being 50m or more, the following formular should be applied. 2. Above cable sizes are for copper wires inside electrometallic tubings. Cable sizes(mm 2) = Cable length(m) Size in the above(mm2) 50

3. For power requirement of 3 cars or more, consult Hyundai. 4. Machine room temperature should be maintained below 40 C with ventilating fan and air conditioner, and humidity below 90%. 5. Data shown in ( ) is applied to the Machine-Room-Less elevators and gearless elevators.

Notes. 1. Above power feeder sizes are for the length of electric wire up to 50m from elevator machine room to power. For the length being 50m or more, the following formular should be applied. 2. Above cable sizes are for copper wires inside electrometallic tubings. Cable sizes(mm2) = Cable length(m) Size in the above(mm2) 50

3. For power requirement of 3 cars or more, consult Hyundai. 4. Machine room temperature should be maintained below 40 C with ventilating fan and air conditioner, and humidity below 90%. 5. Data shown in ( ) is applied to the Machine-Room-Less elevators and gearless elevators.

40 HYUNDAI ELEVATOR CO., LTD.

PASSENGER ELEVATORS 41

You might also like

- Anchor Bolt DesignDocument6 pagesAnchor Bolt DesignFian ArdiyanaNo ratings yet

- Arch Dam DesignDocument240 pagesArch Dam Designtyukgomba100% (5)

- Afpelevator Doorcontroller Ec10 DDocument40 pagesAfpelevator Doorcontroller Ec10 DTroubleshootingNo ratings yet

- Anode CalculationDocument1 pageAnode CalculationFian ArdiyanaNo ratings yet

- Learn Machinery Diagnosis with Versatile Fault SimulatorDocument16 pagesLearn Machinery Diagnosis with Versatile Fault SimulatorDrAnkuran Saha0% (1)

- Mitsubishi ElevatorDocument15 pagesMitsubishi ElevatorGuntherNo ratings yet

- Biaxial Bending in ColumnsDocument14 pagesBiaxial Bending in Columnsnvnrev100% (1)

- Solon PremiumDocument30 pagesSolon PremiumWildan HeroNo ratings yet

- EC 160elevator Intelligent Integrated Machine - V1.2Document227 pagesEC 160elevator Intelligent Integrated Machine - V1.2BùiNghĩaNo ratings yet

- Hyundai Time & Space Installation ManualDocument28 pagesHyundai Time & Space Installation ManualDemme Abdi NasaNo ratings yet

- Description of Common Fault Codes For Fujitec CP28 Controller Elevator p2Document3 pagesDescription of Common Fault Codes For Fujitec CP28 Controller Elevator p2thanggimme.phanNo ratings yet

- Mitsubishi NEXIEZ Elevator Model GuideDocument6 pagesMitsubishi NEXIEZ Elevator Model GuideLuisa BlancoNo ratings yet

- Mitsubishi GPSDocument3 pagesMitsubishi GPSaliakhterattariNo ratings yet

- GSD-SM Instruction BookDocument15 pagesGSD-SM Instruction BookKen LeeNo ratings yet

- Img 0020Document1 pageImg 0020Venkateshan VenuNo ratings yet

- GPS IiiDocument4 pagesGPS IiiLuisa Blanco0% (2)

- SURAPID Elevator Company Profile PDFDocument34 pagesSURAPID Elevator Company Profile PDFLe Huynh LongNo ratings yet

- STVF5 Trouble REV0 PDFDocument42 pagesSTVF5 Trouble REV0 PDFUpien Ayah MahardikaNo ratings yet

- WBFV PDFDocument14 pagesWBFV PDFDidik Sukoco100% (2)

- Padeye Design: Project: Prepared By: Client: Date: 14-May-20 CaseDocument7 pagesPadeye Design: Project: Prepared By: Client: Date: 14-May-20 CaseFian ArdiyanaNo ratings yet

- Padeye Design: Project: Prepared By: Client: Date: 14-May-20 CaseDocument7 pagesPadeye Design: Project: Prepared By: Client: Date: 14-May-20 CaseFian ArdiyanaNo ratings yet

- SigmaDocument5 pagesSigmaFERNSNo ratings yet

- Catalogue of Hyundai ElevatorDocument10 pagesCatalogue of Hyundai ElevatorPreetham PusalaNo ratings yet

- MMR Elevator - SI: FOD Test & Commissioning For SI210 ControllerDocument20 pagesMMR Elevator - SI: FOD Test & Commissioning For SI210 ControllerBrahim Chergui100% (1)

- Manual Book Esc - Pillar PLC PDFDocument27 pagesManual Book Esc - Pillar PLC PDFWinNo ratings yet

- Elevator Recruitment Sample CVDocument5 pagesElevator Recruitment Sample CVArnabNo ratings yet

- ATLAS 2:1 MRL Technical Specifications LiftDocument11 pagesATLAS 2:1 MRL Technical Specifications LiftzajednosexNo ratings yet

- Installastion ManualDocument109 pagesInstallastion ManualLeTraitimbenletkNo ratings yet

- Profiles of Hyundai Elevator (2007) - 200787Document18 pagesProfiles of Hyundai Elevator (2007) - 200787Chang ChangNo ratings yet

- GSD SM Instruction Book PDFDocument15 pagesGSD SM Instruction Book PDFMitro100% (1)

- 2007 KJ Liberty ManualDocument417 pages2007 KJ Liberty Manualcarlos100% (1)

- Lift Sigma PDFDocument40 pagesLift Sigma PDFAnonymous yN8eLzK0TMNo ratings yet

- Elevador SWORD HAMCB Tipo OtisDocument41 pagesElevador SWORD HAMCB Tipo OtisRaul GutierrezNo ratings yet

- Orona LiftDocument4 pagesOrona LiftMarius Ionita100% (1)

- ACRA SigmaDocument32 pagesACRA SigmaSyed iliyasNo ratings yet

- BS 6349-5 2016Document132 pagesBS 6349-5 2016Fian Ardiyana100% (15)

- Sigma Elevator Manual PDFDocument3 pagesSigma Elevator Manual PDFNadeem KhanNo ratings yet

- 4 Hyundai High Speed Elevator Catalogue - Speed Up To 6 MPSDocument15 pages4 Hyundai High Speed Elevator Catalogue - Speed Up To 6 MPSRIZALNo ratings yet

- Asanoor Compact IranDocument51 pagesAsanoor Compact IranSatheesh RamaNo ratings yet

- Stvf7 Troubleshooting Manuel EnglishDocument32 pagesStvf7 Troubleshooting Manuel EnglishResul ŞenayNo ratings yet

- Catalog Fujitec GS8000 - EscalatorsDocument21 pagesCatalog Fujitec GS8000 - Escalatorsstarfx100% (2)

- OptiX OSN 8800 T64&T32 Product OvervieDocument114 pagesOptiX OSN 8800 T64&T32 Product OvervieYaroslavNo ratings yet

- EL - REPL MANUAL - 20070725 - FixedDocument231 pagesEL - REPL MANUAL - 20070725 - FixedChang Chang100% (1)

- SWI PadeyeDocument11 pagesSWI PadeyeFian ArdiyanaNo ratings yet

- AscensoresDocument12 pagesAscensoresOvidio ReyesNo ratings yet

- Catalog (TractionMachine)Document36 pagesCatalog (TractionMachine)Clau Maldonado VelosoNo ratings yet

- Anode Calculation TemplateDocument1 pageAnode Calculation TemplateFian Ardiyana100% (1)

- NexwayDocument5 pagesNexwayLuisa BlancoNo ratings yet

- WF, Unp, Angle, Pipe Steel Profile CalculationDocument24 pagesWF, Unp, Angle, Pipe Steel Profile CalculationFian ArdiyanaNo ratings yet

- Hyundai - Stvf7 Installation & Maintenance Guide BookDocument344 pagesHyundai - Stvf7 Installation & Maintenance Guide BookArmandRose100% (2)

- SWORD Elevator Product IntroductionDocument47 pagesSWORD Elevator Product IntroductionMohamad Ikhwan100% (7)

- Standard Profile Inertia CalculatorDocument17 pagesStandard Profile Inertia CalculatorFian Ardiyana100% (1)

- MLI Otis MCS220M (VEC01-OT01) - Manuel D'installation - GB - Du 31 10 02 (7669)Document56 pagesMLI Otis MCS220M (VEC01-OT01) - Manuel D'installation - GB - Du 31 10 02 (7669)phil johnsNo ratings yet

- Ba WSG-S1.2-3 v17 ENDocument94 pagesBa WSG-S1.2-3 v17 ENBrahim Chergui100% (1)

- Toshiba Spacel IIIDocument11 pagesToshiba Spacel IIITran Huy50% (2)

- Creating a new history with machine room-less elevatorsDocument20 pagesCreating a new history with machine room-less elevatorsTaimoor Ahmed100% (1)

- Basic elevator specifications chartDocument2 pagesBasic elevator specifications chartBuddhika DissanayakeNo ratings yet

- 11313014Document2 pages11313014adil271No ratings yet

- KONE - Machine Room Type - 1600 KG, Speed 2.5 PDFDocument1 pageKONE - Machine Room Type - 1600 KG, Speed 2.5 PDFNghia100% (1)

- China Elevator Company - FUJIHD Elevator Co., Ltd.Document11 pagesChina Elevator Company - FUJIHD Elevator Co., Ltd.chinaelevatorfujihd0% (2)

- Mitsubishi Lifts BrochureDocument28 pagesMitsubishi Lifts Brochurenaveenarora298040No ratings yet

- 201604201039062023Document205 pages201604201039062023younes100% (2)

- Mel 03 - 08F1 - Double EntraDocument1 pageMel 03 - 08F1 - Double EntraUmer FarooqNo ratings yet

- I MitsubishDocument12 pagesI MitsubishTroubleshooting100% (1)

- Mitsubishi Manuals 1422Document33 pagesMitsubishi Manuals 1422ronesromualdoNo ratings yet

- Installation Manual - S200 Landing Door SystemDocument41 pagesInstallation Manual - S200 Landing Door SystemKhanh Huy Nguyen100% (1)

- Dell Sigma-Error PDFDocument6 pagesDell Sigma-Error PDFkabalNo ratings yet

- Koyo Elevator CatalogueDocument28 pagesKoyo Elevator CatalogueJohn DiezNo ratings yet

- QC Department Safety Circuit ChecklistDocument2 pagesQC Department Safety Circuit ChecklistQuang Pham DuyNo ratings yet

- Passenger UsaDocument15 pagesPassenger UsabonongxNo ratings yet

- Spek. LiftDocument8 pagesSpek. LiftDavid GunawanNo ratings yet

- LITE Brochure (Add 2.5mps)Document10 pagesLITE Brochure (Add 2.5mps)ManikNo ratings yet

- B15 20T CatalogueDocument4 pagesB15 20T CatalogueErna BogdanNo ratings yet

- NEXIEZ MRL (2) - Especifixcaciones Tecnicas de AscensorDocument13 pagesNEXIEZ MRL (2) - Especifixcaciones Tecnicas de AscensorReynaldo Tejada PiñerezNo ratings yet

- Standard Profile Inertia CalculationDocument17 pagesStandard Profile Inertia CalculationFian ArdiyanaNo ratings yet

- En Load Combination For Marine StrcutureDocument1 pageEn Load Combination For Marine StrcutureFian ArdiyanaNo ratings yet

- GG Cell FormDocument56 pagesGG Cell FormFian ArdiyanaNo ratings yet

- Green Pin Standard ShackleDocument1 pageGreen Pin Standard ShackleFian ArdiyanaNo ratings yet

- GG Queen CrossDocument1 pageGG Queen CrossFian ArdiyanaNo ratings yet

- GG Honey Comb Cast Shape Add PlateDocument1 pageGG Honey Comb Cast Shape Add PlateFian ArdiyanaNo ratings yet

- Analysis Design Guidelines Precast CFRP GridDocument16 pagesAnalysis Design Guidelines Precast CFRP GridFian ArdiyanaNo ratings yet

- GG T-BeamDocument1 pageGG T-BeamSurya DirmansyahNo ratings yet

- 09 - King CrossDocument1 page09 - King CrossJoko TrisnantoNo ratings yet

- Sistem Slab (Kuliah I)Document9 pagesSistem Slab (Kuliah I)hafizh274No ratings yet

- GG Honey Comb Cast ShapeDocument1 pageGG Honey Comb Cast ShapeFian ArdiyanaNo ratings yet

- Slope Deflection MethodDocument87 pagesSlope Deflection MethodFian ArdiyanaNo ratings yet

- File PDFDocument48 pagesFile PDFjasperzeus crisostomoNo ratings yet

- Samsung mm-d530dDocument43 pagesSamsung mm-d530dPedroNo ratings yet

- CV Idir Mahrouche - 3 PDFDocument2 pagesCV Idir Mahrouche - 3 PDFIdirMahroucheNo ratings yet

- Inspect Radome 53-15-000-6Document3 pagesInspect Radome 53-15-000-6Ruben AranaNo ratings yet

- Android Eobd Facile HelpDocument14 pagesAndroid Eobd Facile HelpSabaducho zolloNo ratings yet

- Third Gen Inkjet CTP From Glunz & JensenDocument3 pagesThird Gen Inkjet CTP From Glunz & JensenChristopher AllenNo ratings yet

- LEP01189 - 02 Demonstration Experiments Physics - Magnetic Board HeatDocument3 pagesLEP01189 - 02 Demonstration Experiments Physics - Magnetic Board HeatJose GalvanNo ratings yet

- Design a Cellphone-based ECG MonitorDocument22 pagesDesign a Cellphone-based ECG MonitorMona NaiduNo ratings yet

- HUAWEI Y541-U02 Upgrade InstructionsDocument7 pagesHUAWEI Y541-U02 Upgrade InstructionsmsemNo ratings yet

- Lasers NotesDocument14 pagesLasers NotesAnirudha KrishnaNo ratings yet

- Service Manual: Outdoor UnitDocument48 pagesService Manual: Outdoor Unitadeelyaseen1No ratings yet

- GV 4095M 1 AVC Intra WhitepaperDocument10 pagesGV 4095M 1 AVC Intra WhitepaperJohn NaylorNo ratings yet

- Chem6-Ammeter Ionic and Covalent CompoundDocument3 pagesChem6-Ammeter Ionic and Covalent CompoundNor Ashikin IsmailNo ratings yet

- 2019 Comfortstar Ductless Catalog PDFDocument68 pages2019 Comfortstar Ductless Catalog PDFoscar100% (2)

- Order Vamp IED 321Document2 pagesOrder Vamp IED 321Thiago Henrique SantosNo ratings yet

- EngCalcPPC - User GuideDocument25 pagesEngCalcPPC - User GuideJavorsNo ratings yet

- Manual Leviton-HCPRF All Code ReceiverDocument2 pagesManual Leviton-HCPRF All Code ReceiverBenjamin DoverNo ratings yet

- Diode Theory and The Semiconductor DiodeDocument21 pagesDiode Theory and The Semiconductor DiodeAnand JavierNo ratings yet

- 358 DatasheetDocument38 pages358 DatasheetJual PsuNo ratings yet

- v22 v24 v23 - DtoDocument70 pagesv22 v24 v23 - DtoplasmapeteNo ratings yet

- TFIX-1: Turbine IP66 IEC Ex Intercom Atex Active Noise Cancelling IP Over 2-WireDocument3 pagesTFIX-1: Turbine IP66 IEC Ex Intercom Atex Active Noise Cancelling IP Over 2-WireEhsan RohaniNo ratings yet

- Mpsem 6 AssgnDocument7 pagesMpsem 6 AssgnmbatechcsNo ratings yet

- Audible Noise ReductionDocument4 pagesAudible Noise ReductionGaurav SharmaNo ratings yet

- CNC Machine and Automation 6 Exam/Mech./Prod/T&DM/5525/May'19 Duration: 3Hrs. M.Marks:75 Section-A Q1. Fill in The Blanks. 10x1.5 15Document1 pageCNC Machine and Automation 6 Exam/Mech./Prod/T&DM/5525/May'19 Duration: 3Hrs. M.Marks:75 Section-A Q1. Fill in The Blanks. 10x1.5 15Simranjeet SinghNo ratings yet

- Implementation of A Simple Li Fi Based SystemDocument7 pagesImplementation of A Simple Li Fi Based SystemMadhuri RoyNo ratings yet

- Design Verification With e 0131413090 9780131413092 CompressDocument410 pagesDesign Verification With e 0131413090 9780131413092 CompressQUÂN LÊ HỒNGNo ratings yet

- StarcgreenDocument22 pagesStarcgreenSheo PujanNo ratings yet