Professional Documents

Culture Documents

Calculation BP Pri

Uploaded by

tresnatambaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Calculation BP Pri

Uploaded by

tresnatambaCopyright:

Available Formats

EQUIPMENT DATA / CALCULATION SHEET PRIMARY BELT PRESS

Project : "PEMBANGUNAN 1 (SATU) UNIT INSTALASI PENGOLAH AIR LIMBAH (IPAL) PT PERTAMINA REFINERY UNIT IV 1. Sludge Quantity (mass Balance) Stream 4 Sludge Solids = = Sludge Volume = Stream 14 Sludge Solids = = Sludge Volume = Total Belt Press Feed Sludge Solids Sludge Volume

Rev. 0 By YW Date 3 June 2011 Description Issued

Sheet No. 1 Date 3 June 2011 Inq. No. P.O. No. By Chk'd

Rev. 2 Tag. No. 47-S-503

Apprv'd

8.0% 28.8 0.300 0% 0.003

kg/hour Dry Solids m3/hour kg/hour Dry Solids m3/hour

= Stream 4 + Stream 14 = 9.5% = 28.8 kg/hour = 0.303 m3/hour

Dry Solids

2. Determine Size and Number of Belt Press Assumption This Plant Operation = 7 = 24 Sludge Production Sludge Solids

days/week hours/day

= = = = =

28.8 Hourly mass production x 4,838 kg/week 0.303 Hourly mass production x 50.9 m3/week 50,904 ltr/week 1 16 ltr/sec(*) gpm(*)

24 hours/day x

7 days/week

Sludge Volume

24 hours/day x

7 days/week

Typical Sludge throughput is = for per 0,5 meter belt width =

(*) Design Manual Dewatering Wastewater Sludge (EPA/625/1-87/014 Sept 1987)

Hours required per week

= =

50,904 ltrper wk /(1,0 ltrper sec x 3600 sec per hr ) 14.1 hr/week/meter of belt width

With 7 days per week and 24 hrs per day, there are = 168 hours available The 14 hrs is less than 168 hrs Therefore One 0,5-metre belt press would provide enough capacity @ 2.02 or 3

hrs/day hrs/day

in

7 days a week operation

3. Size Polymer Feed System Typical Polymer requirements Sludge Solids

2 to 8

gram/kg

= 4,838 kg/week = 4,838 kg per wk /(3 hrs per day x 7 days per week) = 691.2 kg per day = 230.4 kg/hr Design to Provide sufficient capacity to feed up to 10 g/kg Polymer requirements = 230.4 kg per hr x 10 gr per kg = 2304 gram polymer/hr = 2.30 kg per hr If the polymer solution is = 0.25% Feed Volume = 2.30 kg/hr / 0.25% x 1 kgper ltr = 922 liter/hr Thus, the polymer feed system should be capable of feeding 930 ltr/hr polymer solution 2.33 gr/hr polymer powder

4. Volume of Sludge Cake Produced Determine of Sludge Cake Specific Gravity (SSG) Assume Sludge Cake is = 15% solids the digesting solids SG 1.4 SSG = 1 / ((15%/1.4)+(1-15%)) SSG = 1.045 Sludge Volume = = = 230.4 kg per hr x 4,411 liter/day 4.41 m3/day 3 hr per day /(1,045 kg per ltr x 15%)

5. Belt Press Filtrate Wash water requirements Solids in Filtrate = =

3.06 ltr/sec

belt with solids capture

85%

in worst case

230.4 kg per hr x (1 - 85%) 34.56 kg/hr

Filtrate flowrate

= Waste water flowrate + Digested sludge volume - Dewatered sludge volume = 3.06 ltr per sec x 3600 sec per hr) + 0.303 m3 per hr x 1000 ltr per m3 ) - 4410.5 = 9,833 ltr/hr ltr per day /3 hr per day ) = = 9,833 ltr/hr 3.28 m3/day

Filtrate Volume/day

6. Filtrate Solids Concentration Filtrate solids concentration

= = = =

34.56 kg per hr /( 3.2% 31,633 mg/ltr 32 g/ltr

3.28 m3 per day )

Rev. 2 Tag. No. 47-S-503

Apprv'd

EQUIPMENT DATA / CALCULATION SHEET PRIMARY BELT PRESS

Project : "PEMBANGUNAN 1 (SATU) UNIT INSTALASI PENGOLAH AIR LIMBAH (IPAL) PT PERTAMINA REFINERY UNIT IV 1. Sludge Quantity (mass Balance) Stream 4 Sludge Solids = = Sludge Volume = Stream 14 Sludge Solids = = Sludge Volume = Total Belt Press Feed Sludge Solids Sludge Volume

Rev. 0 1 2 By YW YW SK Date 3 Juni 2011 21-Sep-11 Description Draft Issued Approved

Sheet No. 1 Date 21-Sep-11 Inq. No. P.O. No. By Chk'd

Rev. 2 Tag. No. 47-S-503

Apprv'd

8.0% 25.4 0.300 1.0% 0.032 0.003

kg/hour Dry Solids m3/hour kg/hour Dry Solids m3/hour

= Stream 4 + Stream 14 = 25.5 kg/hour Dry Solids = 0.303 m3/hour

2. Determine Size and Number of Belt Press Assumption This Plant Operation = 7 = 24 Sludge Production Sludge Solids

days/week hours/day

= = = = =

25.5 Hourly mass production x 4,279 kg/week 0.303 Hourly mass production x 50.9 m3/week 50,904 ltr/week 1 16 ltr/sec(*) gpm(*)

24 hours/day x

7 days/week

Sludge Volume

24 hours/day x

7 days/week

Typical Sludge throughput is = for per 0,5 meter belt width =

(*) Design Manual Dewatering Wastewater Sludge (EPA/625/1-87/014 Sept 1987)

Hours required per week

= = =

50,904 ltrper wk /(1,0 ltrper sec x 3600 sec per hr ) 14.1 hr/week/0,5 meter of belt width 2 hr/day/0,5 meter of belt width

Therefore (a half meter) 0,5-meter belt press would provide enough capacity @ or

2.02 3

hrs/day hrs/day

in

7 days a week operation

3. Size Polymer Feed System Typical Polymer requirements Sludge Solids

to 8

gram/kg

= 4,279 kg/week = 4,279 kg per wk /(3 hrs per day x 7 days per week) = 611.3 kg per day = 203.77 kg/hr Design to Provide sufficient capacity to feed up to 10 g/kg Polymer requirements = 203.77 kg per hr x 10 gr per kg = 2,037.7 gram polymer/hr = 2.04 kg per hr If the polymer solution is = 0.25% Feed Volume = 2.04 kg/hr / 0.25% x 1 kgper ltr = 815 liter/hr Thus, the polymer feed system should be capable of feeding 820 ltr/hr polymer solution 2037.7 gr/hr polymer powder

4. Volume of Sludge Cake Produced Determine of Sludge Cake Specific Gravity (SSG) Assume Sludge Cake is = 15% solids the digesting solids SG 1.4 SSG = 1 / ((15%/1.4)+(1-15%)) SSG = 1.045 Sludge Volume = = = 203.774 kg per hr x 3,901 liter/day 3.90 m3/day 3 hr per day /(1,045 kg per ltr x 15%)

5. Belt Press Filtrate Water flow for standar nozzles is 3.7 m3/hours or 1.03 ltr/sec (Cosme Type NP-5 ) 1.03 ltr/sec belt with solids capture Wash water requirements 85% Solids in Filtrate = = 203.774 kg per hr x (1 - 85%) 30.5662 kg/hr

in worst case

Filtrate flowrate

= Waste water flowrate + Digested sludge volume - Dewatered sludge volume = 1.03 ltr per sec x 3600 sec per hr) + 0.303 m3 per hr x 1000 ltr per m3 ) - 3900.8 2,703 ltr/hr = ltr per day /3 hr per day ) = = 2,703 ltr/hr 8.11 m3/day

Filtrate Volume/day

6. Filtrate Solids Concentration Filtrate solids concentration

= = = =

30.5662 kg per hr /( 1.1% 11,309 mg/ltr 11 g/ltr

8.11 m3 per day )

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Manual AQMS-3000 English V2.0Document27 pagesManual AQMS-3000 English V2.0tresnatamba100% (1)

- Formulir Nilai Investasi PDFDocument2 pagesFormulir Nilai Investasi PDFtresnatambaNo ratings yet

- Formulir Nilai Investasi PDFDocument2 pagesFormulir Nilai Investasi PDFtresnatambaNo ratings yet

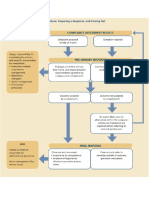

- Grievance Mechanism by IFCDocument1 pageGrievance Mechanism by IFCtresnatambaNo ratings yet

- Principles of Employee Grievance Mechanisms: What Is A Grievance?Document2 pagesPrinciples of Employee Grievance Mechanisms: What Is A Grievance?tresnatambaNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Material Safety Data Sheet: Product and Company Identification 1Document6 pagesMaterial Safety Data Sheet: Product and Company Identification 1onejako12No ratings yet

- Perinatal DepressionDocument200 pagesPerinatal DepressionPretty PuspitasariNo ratings yet

- Sfbtnarr 2Document19 pagesSfbtnarr 2api-267074391No ratings yet

- Review On Surge Drug Delivery TechnologyDocument8 pagesReview On Surge Drug Delivery TechnologyNayeli MercadoNo ratings yet

- Asthma in PregnancyDocument40 pagesAsthma in PregnancyKabo75% (4)

- JulieKJohnsonHe 2016 9ACascadeOfSmallEvent CaseStudiesInPatientSDocument5 pagesJulieKJohnsonHe 2016 9ACascadeOfSmallEvent CaseStudiesInPatientSMarylanNo ratings yet

- Azithromycin 500mg Tab (Zithromax)Document6 pagesAzithromycin 500mg Tab (Zithromax)Mayownski TejeroNo ratings yet

- Javma-Javma 21 04 0213Document5 pagesJavma-Javma 21 04 0213Black manNo ratings yet

- Antidepressants For The Treatment of Depression in People With Cáncer 2018Document78 pagesAntidepressants For The Treatment of Depression in People With Cáncer 2018José Luis Rivera Z.No ratings yet

- Quality Assurance in IV TherapyDocument37 pagesQuality Assurance in IV TherapyMalena Joy Ferraz VillanuevaNo ratings yet

- DAILY LESSON Plan 4 - 1.8Document4 pagesDAILY LESSON Plan 4 - 1.8Wilbeth PanganibanNo ratings yet

- DLPA For Chronic Pain & DepressionDocument3 pagesDLPA For Chronic Pain & DepressionJimmy SmyczekNo ratings yet

- Safety Data Sheet for Masterseal 345Document7 pagesSafety Data Sheet for Masterseal 345mkashkooli_scribdNo ratings yet

- Nursing Care Plan AutismDocument3 pagesNursing Care Plan Autismangeliejoy_110976% (29)

- Critiquing 1Document3 pagesCritiquing 1Nilesh VeerNo ratings yet

- SOAPIER Note Charting Examples S2012Document4 pagesSOAPIER Note Charting Examples S2012Myra Henry100% (1)

- Nada Lincomycyn and Espectynomycin Solubleucm061812Document4 pagesNada Lincomycyn and Espectynomycin Solubleucm061812laurz95No ratings yet

- Bastidas 2021Document13 pagesBastidas 2021ruben dario meza bertelNo ratings yet

- NSTP ProjDocument11 pagesNSTP ProjLeeroi Christian Q Rubio100% (2)

- Cytokines - IntroductionDocument2 pagesCytokines - IntroductionTra gicNo ratings yet

- Ball Ex Chart 2014aDocument2 pagesBall Ex Chart 2014aJoao CarlosNo ratings yet

- Speech & Language Therapy in Practice, Summer 2008Document32 pagesSpeech & Language Therapy in Practice, Summer 2008Speech & Language Therapy in PracticeNo ratings yet

- Migraine and Cluster HeadacheDocument24 pagesMigraine and Cluster HeadachekhemamettaNo ratings yet

- Do Clear Cell Ovarian Carcinomas Have Poorer Prognosis Compared To Other Epithelial Cell Types? A Study of 1411 Clear Cell Ovarian CancersDocument7 pagesDo Clear Cell Ovarian Carcinomas Have Poorer Prognosis Compared To Other Epithelial Cell Types? A Study of 1411 Clear Cell Ovarian CancersNi Wayan Ana PsNo ratings yet

- Fact Sheet Squamous Cell Carcinoma Oct 2013Document10 pagesFact Sheet Squamous Cell Carcinoma Oct 2013Triven Nair HutabaratNo ratings yet

- Padabhyangam Flyer EnglishDocument1 pagePadabhyangam Flyer EnglishDurrelcart SupportNo ratings yet

- Range of Pest Control Services by Pest Control (India) Pvt. LTDDocument5 pagesRange of Pest Control Services by Pest Control (India) Pvt. LTDAvinash ToraneNo ratings yet

- Exam Procedures: Steps for Completing a Biochemistry ExamDocument19 pagesExam Procedures: Steps for Completing a Biochemistry Exampmp123456No ratings yet

- Anc 0001 0009 0151Document42 pagesAnc 0001 0009 0151ManhaNo ratings yet

- Mental Health Act 1987Document35 pagesMental Health Act 1987P Vinod Kumar100% (1)