Professional Documents

Culture Documents

ASCP Nice Review

Uploaded by

mehelmiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASCP Nice Review

Uploaded by

mehelmiCopyright:

Available Formats

OAUG April, 2008 Presentation White Paper

Using Oracles ASCP Module in the Development of a Successful Global Sourcing Strategy

By Paul Kirch Director, Oracle Applications Consulting Hackett Technology Services

Presented to Oracle OAUG Denver, Colorado April 21, 2008

Copyright 2008 OAUG Forum at COLLABORATE 08 The Hackett Group, Inc. All rights reserved. Reproduction of this document in any form without prior consent is prohibited

Page 1 of 16

OAUG April, 2008 Presentation White Paper

About the Author

Mr. Kirch specializes in Oracle global financial and supply chain projects and has over twenty years experience in the management, design, delivery, development, sales and implementation of information management systems. He has experience in the implementation of Oracle Financials, Supply Chain, Oracle Project Costing and Project Billing, and Oracle Distribution modules (PO, INV, OM), as well as in Strategic Planning, Business Process Reengineering (BPR), Activity Based Management (ABM), and all areas of financial systems analysis and design. A Certified Public Accountant (CPA) with an MBA in International Business, Mr. Kirch speaks fluent Spanish and Portuguese, and some French and German, and has worked in Europe, South America, and the Middle East. He has served as an officer on several professional accounting organizations, including the DC Institute of CPAs where he was the Chairman of the Washington, D.C. International Business Committee and the Miami-based Latin American CFO Forum, which he founded. The Latin American CFO Forum was a group of 50 CFOs, Controllers and other finance professionals from the Latin American regional headquarters of Fortune 500 companies in South Florida which met on a monthly basis to discuss issues around doing business in Latin America. While a Practice Manager at Oracle, Mr. Kirch headed project teams composed of 2030 and frequently made presentations at Oracles Applications User Group (OAUG) and Oracle Open World, among others. In 2005, Mr. Kirch had the honor of participating in Professor Hau Lees Executive MBA course at Stanford University, Managing the Global Supply Chain and is currently a candidate for the CFA (Certified Financial Analyst) Level I, (June, 2008 exam). Mr. Kirch currently sits on the Board of Directors of Oracles Oracle Application User Group (OAUG) Multi-national (MN) SIG group and is a Director in the Hackett Groups Oracle implementation practice, where he is responsible for managing large-scale global implementations of Oracle applications.

Introduction

A supply chain is a network of facilities and information systems that facilitates the movement of material and information from a companys suppliers -- and their suppliers in support of the companys manufacturing of finished and semi-finished products and distribution of finished product to the companys customers. The supply chain describes the movement of material and information both upstream, to a companys suppliers, and downstream, to customers. A supply chain starts with the identification of sourcing requirements, includes an analysis of potential suppliers able to fulfill those requirements, sourcing and the establishment of a business relationship with the supplier. Some companies allow each product team to source from suppliers independently of other product groups; other companies enforce qualified supplier policies, in which a supplier must be validated using pre-established criteria (e.g. in business for 15 years, etc.). As companies rationalize the supply base and strategic suppliers are identified, the relationship between global sourcing and Advanced Supply Chain Planning (ASCP) emerges.

Companies embarking on a global supply chain planning initiative, which includes global sourcing, may gradually increase the relationship with key strategic suppliers. The relationship with key strategic suppliers normally develops over time: Supplier is identified as a possible supplier of a difficult to obtain, key component Supplier is identified as a strategic supplier and company places supplier on Approved Supplier List, either as sole source or primary supplier of key component

Copyright 2008 OAUG Forum at COLLABORATE 08 The Hackett Group, Inc. All rights reserved. Reproduction of this document in any form without prior consent is prohibited Page 2 of 16

OAUG April, 2008 Presentation White Paper

Suppliers product development plan tracks manufacturers product development plan and management relationship is established Strategic supplier sets up an on-site location at manufacturing plant premises in order to closely monitor customer relationship and ensure steady supply of critical items Depending upon financial and supply risk drivers, supply of critical items may move to a JIT-like Vendor Managed Inventory (VMI) arrangement in which manufacturer owns the inventory and supplier manages on-hand stock, or; Depending upon value of items and volume of transactions, supplier and manufacturer may adopt an Supplier Owned Inventory (SOI) arrangement, in which manufacturer draws down supplier owner stock of items located on-site at manufacturers plant and pays only for those items actually consumed using an evaluated receipt settlement (ERS) arrangement California companies such as Cisco Systems and Qualcomm are at the forefront of these manufacturing trends and have spearheaded many of the management initiatives that define and compose these global sourcing movements. For example, Cisco Systems has been cited as a model for the speed of Cisco financial close process and the forward thinking implementation of a two tiered supply chain process that allows Cisco managers to closely manage inventory fluctuations at first tier contract suppliers as well as the companies, secondand third-tier suppliers, which sell to their contract suppliers. Software providers, such as Oracle and SAP, must keep abreast of these manufacturing trends in order to support their customers the lean manufacturers business process requirements. This white paper describes Oracles new Advanced Supply Chain Planning (ASCP) module, which is part of the Supply Chain Management suite of products, from a use and functional footprint perspective. ASCP enables and embodies many of the concepts embedded in the lean manufacturing initiative. This paper is describes the high level processes enabled by Oracle Global Sourcing module, the functional footprint of the Advanced Supply Chain Management (ASCP) engine, and rollout considerations around the use of iSupplier and iProcurement on global projects. In addition, this paper describes the high level process enabled by ASCP, several of the setup options that companies implementing ASCP will need to consider, and the relationship of ASCP to other Advanced Procurement modules, such as iSupplier and iProcurement.

MRP versus ASCP

Oracle developed the MRP, or Material Resource Planning module, as part of the Manufacturing Suite of Products, which was released in 1994. Given seasonal trending, projected demand and available supply, Oracle MRP was developed to calculate a companys total material requirements given a specific projected demand. In this simple world, Oracle MRP operated within an extremely simple world with unbounded manufacturing capacity, a single manufacturing plant, and suppliers blessed with unlimited supply. Needless to say, Oracle MRP did not meet a sophisticated global manufacturers supply chain management needs.

Copyright 2008 OAUG Forum at COLLABORATE 08 The Hackett Group, Inc. All rights reserved. Reproduction of this document in any form without prior consent is prohibited

Page 3 of 16

OAUG April, 2008 Presentation White Paper

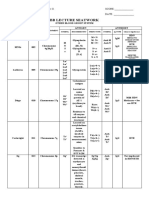

Oracle developed the Advanced Supply Chain Module (ASCP) as a result of these perceived shortfalls in MRP functionality. Specifically, ASCP enhanced the functionality of MRP by allowing for: Constraint-based planning, instead of the unbounded production plans possible in MRP Configuration-based supply netting, in which companies could choose of not choose to include outstanding requisitions and Purchase Orders in the supply calculation Multiple inventory organization planning in one planning cycle, eliminating the need to run MRP multiple times by inventory org Firmed PO and Planned PO supply, depending upon the companys specific planning horizon and supply chain needs Complete integration with Supplier Scheduling and Purchasing Approved Supplier Lists (ASLs) and Sourcing Rules, creating a completely automated supply chain cycle Figure 1, below, shows the relationship between Oracle ERP modules, such as Oracle Financials and Manufacturing (including MRP), and the Advanced Supply Chain Module. Oracle ERP modules function as the transactional modules, in which users place orders, create Purchase Orders, load Forecasts, and so on. Oracles Advanced Supply Chain Planning Engine (ASCP) receives the transactional information from the ERP modules and loads this data to the ASCP tables.

ERP Module vs. ASCP Module

ERP

(Dynamic Data)

ASCP

(Static Data)

Sales Orders Plan (MFG-REGEN) Customers Material Scheduling Method Forecast Plan Horizon Items Forecast Spreading Master Data Consumption Rules BOM Organizations WIP Forecasts Inventory Netting Rules PO Planners Workbench Suppliers Data Collections Cost Shipping Networks Copyright 2008 OAUG Forum at COLLABORATE 08 Sourcing Rules The Hackett Group, Inc. All rights reserved. Reproduction of this document in any form without prior consent is prohibited

Page 4 of 16

OAUG April, 2008 Presentation White Paper

Figure 1

ASCP makes supply recommendations to Planners and/or Buyers based upon Sales Orders entered or Forecasts loaded into the system. Given actual and/or forecasted demand, the ASCP module aggregates supply based upon the parameters used to set up the system and makes scheduling recommendations to either bring in or push out on both the demand and supply side in order to match actual/ forecasted demand with actual/ forecasted supply. In microeconomic terms, the Planners Workbench creates the point of equilibrium in which actual + forecasted supply = actual + forecasted demand. ASCP uses a Collection Plan to bring supply into equilibrium with demand. The Collection Plan aggregates the total demand including changes to Orders to create the demand signal and aggregates total supply according to the specific parameters set up in the ASCP Engine that defines supply. In Figure 2 below, the Master Scheduler creates a plan to run in the manufacturing inventory organization. In the example given, the Master Scheduler creates three new plans: MFG-REGEN, MFG-SIM, and MFG-SIMDLY. (Note: In order for Planned Orders to be generated and EDI to run successfully, the Production box must be checked.)

Plan is created for the manufacturing organization by the Master Scheduler

Figure 2

Copyright 2008 OAUG Forum at COLLABORATE 08 The Hackett Group, Inc. All rights reserved. Reproduction of this document in any form without prior consent is prohibited

Page 5 of 16

OAUG April, 2008 Presentation White Paper

In Figure 3, below, the Master Scheduler sets the forecast allocation and consumption parameters to spread forecast evenly and indicates that Requisitions, POs, and Safety Stock should be netted to create supply.

Material Scheduling Method, Forecast Spreading, Organizations to include and Netting are defined (to name a few plan attributes)

Figure 3

In Figure 3, note that the Enable Pegging and Append Planned Orders flags are checked. The Demand Time Fence Control flag should also be checked in order to create EDI Purchase Orders and Planned Orders according to the 20 manufacturing days rolling PO creation date. The Add All Authorized Org allows this specific plan to be run for multiple inventory orgs as indicated in the screenshot above. In the example given, the ASCP Plan MFGREGEN is being created to run in 3 inventory orgs for all planned, or active, items. Figure 4, below, describes this relationship between the ERP transactional modules on the left side of the figure and the Advanced Supply Chain Planning (ASCP) modules on the right hand side of the page. The ERP transactional modules include Order Management (OM), Accounts Receivable (AR/ Customer Master), Inventory (Item Master), Bills of Material (BOM), Purchasing, Accounts Payable (Supplier Master), and Costing. On the right hand side of the figure, the Advanced Supply Chain Planning family includes Planning, Supplier Scheduling, Sourcing Rules, and Planners Workbench. The ASCP collection plan creates the link between the ERP modules, which contain transactional data, and the Advanced Supply Chain (ASCP) functionality. The collection

Copyright 2008 OAUG Forum at COLLABORATE 08 The Hackett Group, Inc. All rights reserved. Reproduction of this document in any form without prior consent is prohibited

Page 6 of 16

OAUG April, 2008 Presentation White Paper

plan gathers data from the transactional side of the figure and uses this data to populate tables on the right hand side of the figure.

ERP Module vs. ASCP Module

ERP

(Dynamic)

ASCP

(Static)

Sales Orders Customers Forecast Items BOM WIP Inventory PO Suppliers Cost Shipping

Networks

Plan (MFG-REGEN) Supplier Scheduling

Method Collection

Copying Data from the ERP module to the ASCP module to use for a refreshed plan run

Plan Horizon Forecast Spreading Consumption Rules Organizations Forecasts Netting Rules Planners Workbench Data Collections

Sourcing Rules Figure 4

The ASCP collection plan takes parameters established in the ASCP module, such as plan horizon, forecast spreading, consumption rules, netting rules, and analyzes the data across the various inventory organizations defined to the system. ASCP seeks to balance supply and demand across the inventory organizations. If the item is a make item and sourced from one of the manufacturing plants, the ASCP Engine will create demand for these items in the manufacturing organization(s). If the item is a buy the ASCP Planning Engine will create Requisitions and Planned Orders based upon the specific planning horizon defined to the system. If the planning horizon is defined as 52 weeks, in 4-week buckets, the ASCP Planning Engine will create Planned Orders for each of the 13 4-week supplier material supply buckets. Depending upon how lead times are defined to the system (either at the item level or on the ASL), and according to how the ASCP and Purchasing profile options are defined, if a Blanket Purchase Order has been defined for this item and the Supplier is an approved or preferred supplier

Copyright 2008 OAUG Forum at COLLABORATE 08 The Hackett Group, Inc. All rights reserved. Reproduction of this document in any form without prior consent is prohibited

Page 7 of 16

OAUG April, 2008 Presentation White Paper

on the ASL, the ASCP Planning Engine will automatically create releases against the blanket PO for transmittal to the supplier via EDI or XML. The entire purchasing process from demand creation to supply and transmittal of the PO to the supplier is automated.

ASCP Supply / Demand Creation

Manufacturing Orgs

001 Bldg M

Planned Order Demand Demand: Manual Discrete Jobs Safety Stock Inventory Supply: Purchase Order Discrete Job Planned Order

Shipping Orgs

050 QWBS 125 QGOV 225 QCT

002 Mexico

Planned Order Demand Demand: Manual Discrete Jobs Safety Stock

Demand: Sales Order Forecast Safety Stock Supply: Inventory Purchase Order Planned Order

Make or Buy?? Sourcing Rules Purchase from Purch Req PO Transfer from Planned Order Demand

Inventory Supply: Purchase Order Discrete Job Planned Order

006 Bldg W

Planned Order Demand Demand: Manual Discrete Jobs Safety Stock

Inventory Supply: Purchase Order Discrete Job Planned Order

Figure 5

Figure 5 illustrates this process by which shipping organizations or customer facing sales organizations create demand by entering sales orders or forecasts. Replenishment of safety stock may also create demand. ASCP nets available supply according to the parameters defined to the system and, depending upon the resulting material requirements, creates a demand signal to the manufacturing organizations (in the diagram, defined as Building M 001, the shelter operation in Mexico 002 or Building W, 006. In the scenarios given above, the customer facing shipping organizations do not independently source items directly from outside suppliers; all supply is sourced from the manufacturing organizations as either a make or a buy item.

Copyright 2008 OAUG Forum at COLLABORATE 08 The Hackett Group, Inc. All rights reserved. Reproduction of this document in any form without prior consent is prohibited

Page 8 of 16

OAUG April, 2008 Presentation White Paper

Supply and Demand Creation

Supply Demand View

D: Org 225 Sales Order/Forecast 10-V6991-210 (1) S: Org 225 Planned Order 10-V6991-210 D: Org 006 Planned Order Demand 10-V6991-210 (2) S: Org 006 Planned Order 10-V6991-210 D: Org 006 Planned Order Demand 20-V9900-1 (3) S: Org 006 Planned Order 20-V9900-1 D: Org 001 Planned Order Demand 20-V9900-1 S: Org 001 Planned Order 20-V9900-1

Figure 6

In figure 6 above, (1) the Sales Order for a top level assembly, 10-V6991-210, creates a Planned Order in shipping organization 225, (2) which is in turn sourced to manufacturing organization 006 in the form of a planned order demand. The planned order demand in 006 is pegged to a planned work order in 006, (3) which in turn creates demand for the manufacture of a sub-assembly, or a 20-V9900-1 which is sourced from manufacturing org 001. This process of demand creation, supply aggregation, and creation of Planned Orders to satisfy material demand is the core functionality of the ASCP Engine. In each step in the process, demand creates material supply through the creation of a Planned Order, which results in demand against the next level supply in the supply chain. At each stage, available supply is pegged or identified to demand.

Copyright 2008 OAUG Forum at COLLABORATE 08 The Hackett Group, Inc. All rights reserved. Reproduction of this document in any form without prior consent is prohibited

Page 9 of 16

OAUG April, 2008 Presentation White Paper

Planned Order Life Cycle Sales Order Forecast Planned Order Demand Planned Order Relea se Make or Buy? Buy Purchase Requisition Purchase Order Inventory

Make

Unreleased Discrete Job

Released Discrete Job

Inventory

Demand Controlled by

ASCP

Release from Planners

workbench

ASCP may

recommend to reschedule existing POs, PORs and discrete jobs

ASCP will Supply

not move a Firmed PO

Sourcing Rules for Buy

items specify the Supplier to purchase from

Discrete job

completions become inventory

No Demand, No

Planned Order

ASCP will

Drives Planned

Order Demand for components

Sourcing Rules for Make

items specify which Org to make the assembly in

ASCP will

generate exception messages for all items

generate exception messages to PO receipts reschedule become as needed inventory

Negative

inventory drives demand

Unreleased Planned Orders

are regenerated each time the ASCP plan runs

Figure 7

This process is further illustrated in Figure 7. In Figure 7, the Sales Order or the Forecast creates the Planned Order, which in turn drives Planned Order demand for component parts identified in the Bill of Material. As the Planned Orders are released from the Planners Workbench, Planners Workbench identifies the item as either a make or a buy item and the item is sourced, using sourcing rules, to a manufacturing organization or, at the end node in the supply chain, to an outside supplier. In the case in which the item is a make item, a work order is created, which in turn must be released so that the manufacturing process can begin, and supply (inventory) created. In the same way, if an item is a buy item, ASCP will create a release against a Blanket PO (if a blanket PO with that item exists) or a Planned Order (if the Blanket PO does not exist). During this process, depending upon a specific items lead time, and the percentage of compression allowed on a specific item, Planners Workbench will make recommendations to the Planners and Buyers with regards to specific work orders and Purchase Orders. Where compression time allows a PO to be created outside of the normal lead time defined for a specific item, Planners Workbench will seek to bring in the PO in order to match the scheduled delivery date for a specific item pegged to a

Copyright 2008 OAUG Forum at COLLABORATE 08 The Hackett Group, Inc. All rights reserved. Reproduction of this document in any form without prior consent is prohibited

Page 10 of 16

OAUG April, 2008 Presentation White Paper

specific Sales Order. In cases in which Planners Workbench is not able to resolve the discrepancy between the planned ship date for a specific Sales Order and the available supply, Planners Workbench will make recommendations to push out the scheduled delivery date on the Sales Order or bring in the planned material receipt date on a PO.

Discrete Job Contributors

Assembly: Item to be stocked at completion of Discrete Job BOM: Routing:

Creates the Discrete Jobs Parts List Applies the Discrete Jobs Lead Time Dictates how components are issued to the Job

Supply Type:

A) Push = issue components to job at job start B) Assy Pull = backflush components at job completion C) Bulk = as required components, no issue D) Operation Pull = not in use in phase 2

WIP Acct Class:

discrete job

Abbreviation that contains accounting information for the

Figure 8

Copyright 2008 OAUG Forum at COLLABORATE 08 The Hackett Group, Inc. All rights reserved. Reproduction of this document in any form without prior consent is prohibited

Page 11 of 16

OAUG April, 2008 Presentation White Paper

Using Planners Workbench

Right click over the plan or organization, select Supply/Demand and Supply/Demand

Figure 9

Planners Workbench makes use of expandable folders to allow users to drill down to successive levels of detail. At the highest level, Planners Workbench presents users with each of the ASCP Plans that have been defined by the Master Scheduler. On the Planners Workbench menu illustrated in Figure 9, the user has selected the MFG-REGEN Plan, the Supply/Demand function, and Show Supply/Demand menu. The Planners Workbench displays each of the Planners Orders created, as well as any notification associated to that planned order, such as bring in or push out as discussed earlier. Users are able to narrow the display results by entering search criteria, as illustrated in Figures 10 and Figure 11. In Figure 10, the user enters the Boolean logic, by which he/she would like to narrow search results, identifying the specific search criteria to select Planned Orders. Once the Planners Orders are selected, the user can take further action on the Planned PO including releasing the Planned PO to create a Release against a Blanket PO, if the Blanket PO exists or changing the scheduled receipt date (in the case in which the notification suggests that a scheduled ship be moved in or out, and so on. Figure 10 and 11 illustrates the query process used to identify specific Planned Orders and highlight the selection criteria available.

Copyright 2008 OAUG Forum at COLLABORATE 08 The Hackett Group, Inc. All rights reserved. Reproduction of this document in any form without prior consent is prohibited

Page 12 of 16

OAUG April, 2008 Presentation White Paper

Enter your search criteria to limit the data in your query:

Figure 10 You can search for the following Criteria:

BOM Buyer Category Compression Days Day from Today Demand Satisfied Date Disposition Status Type Firm First Unit Start date Implemented Quantity Item Last Unit Completion Date Last Unit Start Date Lending Project Number Lending Task Line MRP Planning Method Make or Buy New Date New Qty Old Due Date Old Order Quantity Order Number Order Priority Order type Organization Original Item Po Line No Planner Planning Group Project Quantity in Process Primary Supplier Repetitive Standard Cost WIP Supply Type Selected for Release Source Organization Source Supplier Suggested Dock Date Suggested Due Date Suggested Order Date Suggested Start Date Supplier Task Using Assembly VMI Flag WIP Supply Type

Figure 11

Copyright 2008 OAUG Forum at COLLABORATE 08 The Hackett Group, Inc. All rights reserved. Reproduction of this document in any form without prior consent is prohibited

Page 13 of 16

OAUG April, 2008 Presentation White Paper

Planners Workbench allows user to search for Planned and/or Firmed POs according to any number of search criteria, which can be captured and saved by the buyer-user. This saved query functionality allows buyers to easily manage their PO workload.

Conditions:

Equals Is Not Less Than At Most At least Greater than Between Outside Is Empty Is Entered Among Starts With Days from Today

Figure 12

Figure 12 further illustrates the Planners Workbench selection functionality.

Figure 13

Figure 13 illustrates the use of folder technology in Planners Workbench.

Copyright 2008 OAUG Forum at COLLABORATE 08 The Hackett Group, Inc. All rights reserved. Reproduction of this document in any form without prior consent is prohibited

Page 14 of 16

OAUG April, 2008 Presentation White Paper

Figure 14

Figure 14 further illustrates the Planners Workbench selection functionality.

Figure 15

Figure 15 illustrates the Planners Workbench functionality that allows Planners or Buyers to release a Planner Order.

Copyright 2008 OAUG Forum at COLLABORATE 08 The Hackett Group, Inc. All rights reserved. Reproduction of this document in any form without prior consent is prohibited

Page 15 of 16

OAUG April, 2008 Presentation White Paper

By releasing a Planned Order, the Buyer in effect allows ASCP to create an approved Requisition line against a Blanket PO, which in turn becomes an automatically approved Blanket PO Release. This process of automatically releasing Planned POs that enter the Release Time Fence defined to the item or the ASL lies at the heart of Oracle functionality that permits companies to automate their supply chain. A companys global sourcing strategy should determine which suppliers are included on the Approved Suppliers List, or ASL, and in what percentage a specific commodity will be sourced from that supplier. While only one supplier can be a primary supplier, the Approved Suppliers List (ASL) will allow any number of vendors to be entered as suppliers for any specific item. The users determine which vendors the manufacturer will place POs (either Planned or Firm) against, and in what percentage. A user can enter multiple suppliers for any specific item on the ASL and a percentage of total spend for that item that should be directed to the supplier. Suppliers must be in an approved versus a pending state to receive POs. When MRP/ASCP automatically creates releases against Blanket POs, MRP/ASCP will place POs against the approved suppliers on the ASL according to the percentage indicated on the Approved Suppliers List. In global sourcing, clearly, location of the vendors manufacturing and/or distribution plants is critical, but cost and quality are key. In developing a global sourcing strategy, at the least, companies will seek to work with companies that can guarantee minimal product quality and product delivery on a specific. More advanced companies will seek to source from companies that share a common product development vision. These experienced executives will look beyond current costs to longer-term prospects for a stable and educated workforce, political stability and long term shared vision. In his paper, 116 Reasons the World is Flat, Wayne Mincey, President of the Hackett Group, say in effect that In The Hackett Groups 2005 survey of business process trends, business executives show a clear preference for the use of low-cost countries in developing either an insourcing or an outsourcing model, albeit from a current low base.

Once a company has determined its global sourcing strategy, Oracle ASCP Engine supports the processes required to support it. As globalization changes the corporate landscape, global sourcing will move beyond simply reducing costs to include a more comprehensive analysis of the companys key supplier relationships, product cost structures, the tradeoffs that result from changes in operating models, and risk.

Copyright 2008 OAUG Forum at COLLABORATE 08 The Hackett Group, Inc. All rights reserved. Reproduction of this document in any form without prior consent is prohibited

Page 16 of 16

You might also like

- Ascp 3Document421 pagesAscp 3apparao99No ratings yet

- Ascp TSDocument40 pagesAscp TSAshok ManoharanNo ratings yet

- Ascp NotesDocument1 pageAscp NotesAde GokeNo ratings yet

- 9 ASCP Training Day1Document170 pages9 ASCP Training Day1Anonymous oSTh85100% (1)

- Study Stack - MLT Table ReviewDocument3 pagesStudy Stack - MLT Table Review장주연No ratings yet

- ABG and Metabolic Acid-Base DisordersDocument6 pagesABG and Metabolic Acid-Base Disordersclower112No ratings yet

- 22 - ImmunohematologyDocument6 pages22 - Immunohematologyhamadadodo7No ratings yet

- Books and clinical lab science review points for exam preparationDocument1 pageBooks and clinical lab science review points for exam preparationTinay100% (1)

- AABB 2021 Blood Bank Fundamentals Course SBB/BB Exam Review: Supplemental HandoutDocument51 pagesAABB 2021 Blood Bank Fundamentals Course SBB/BB Exam Review: Supplemental HandoutDyne Sabijon100% (1)

- FEB 2017 RecallsDocument2 pagesFEB 2017 RecallsLucid LynxNo ratings yet

- Study Stack - M (ASCP) EXAM Table Review PDFDocument9 pagesStudy Stack - M (ASCP) EXAM Table Review PDF장주연100% (1)

- MLS ASCP Study Guide PDFDocument2 pagesMLS ASCP Study Guide PDFyowubhatori100% (2)

- Ascp PointersDocument78 pagesAscp PointersNIMKY EMBER B. CLAMOHOY100% (13)

- 9 ASCP Training Day2Document73 pages9 ASCP Training Day2Anonymous oSTh85No ratings yet

- TH ST NDDocument3 pagesTH ST NDDarlene Evangelista100% (1)

- June 21 MLT exam recallsDocument8 pagesJune 21 MLT exam recallsJoanna Carel Lopez100% (2)

- ASCP Recalls 5Document9 pagesASCP Recalls 5Cristina Vergel De DiosNo ratings yet

- Ascp Boc QuestionsDocument4 pagesAscp Boc QuestionsRose jane TambasenNo ratings yet

- Blood Bank 2Document21 pagesBlood Bank 2moonfire2009No ratings yet

- Virus, Fungi, Bacteria, and Blood Tests QuestionsDocument1 pageVirus, Fungi, Bacteria, and Blood Tests QuestionsGerald John Paz0% (5)

- Oracle Advanced Supply Chain Planning (ASCP) OverviewDocument23 pagesOracle Advanced Supply Chain Planning (ASCP) Overviewantony0% (1)

- Advanced Supply Chain Planning Sasi Kiran Marisa: Classification: Genpact InternalDocument35 pagesAdvanced Supply Chain Planning Sasi Kiran Marisa: Classification: Genpact InternalSarah Baker100% (1)

- ASCP Recalls 11Document3 pagesASCP Recalls 11Cristina Vergel De DiosNo ratings yet

- Blood Bank PracticalDocument24 pagesBlood Bank Practicalmoonfire2009No ratings yet

- Hema AscpDocument5 pagesHema AscpDyne SabijonNo ratings yet

- Antibody IdentificationDocument27 pagesAntibody Identificationhamaada100% (1)

- Immuno For ASCP ReviewDocument25 pagesImmuno For ASCP ReviewWl SorianoNo ratings yet

- Other Blood Group System AssignmentDocument5 pagesOther Blood Group System AssignmentMary ChristelleNo ratings yet

- Path Hematology ReviewDocument19 pagesPath Hematology ReviewChristopher MuellerNo ratings yet

- Ascpi (MLS) Study Guide: Cushing's DiseaseDocument2 pagesAscpi (MLS) Study Guide: Cushing's DiseaseCatherine Nicolas100% (3)

- BOC 6th EdDocument79 pagesBOC 6th EdIseth ISeth100% (1)

- Ascpi Recalls 2016Document9 pagesAscpi Recalls 2016Zylene GabrielNo ratings yet

- Key clinical laboratory tests and concepts for certification exam reviewDocument25 pagesKey clinical laboratory tests and concepts for certification exam reviewJie Fuentes91% (11)

- ASCP Recall 30-08-2018 Sujan BarmanDocument1 pageASCP Recall 30-08-2018 Sujan BarmanLou Joseff Milan BaluyotNo ratings yet

- Virology ASCPDocument24 pagesVirology ASCP2131443No ratings yet

- ASCP-RECALLS-Compiled - Alice 2017Document18 pagesASCP-RECALLS-Compiled - Alice 2017Princess Dianne Gonzaga Mendola89% (9)

- Recall Ascp MirobiologyDocument7 pagesRecall Ascp MirobiologyJie Fuentes80% (5)

- Immunohematology HandoutDocument9 pagesImmunohematology Handoutmarkylopez2383% (6)

- Ascp Recalls (File Grabbed)Document3 pagesAscp Recalls (File Grabbed)KL Suazo78% (9)

- ASCP ExamDocument10 pagesASCP Examnoone100% (3)

- Study Stacks - Chemistry Table Review PDFDocument14 pagesStudy Stacks - Chemistry Table Review PDF장주연No ratings yet

- CoursematerialsDocument65 pagesCoursematerialsMohamed ElmasryNo ratings yet

- Your BOC Exam: What You Need To Know To Be ReadyDocument35 pagesYour BOC Exam: What You Need To Know To Be ReadyDeanne Lamban100% (3)

- MLS ASCP Exam Recall Questions Flashcards - QuizletDocument8 pagesMLS ASCP Exam Recall Questions Flashcards - Quizletyeliz kurt100% (2)

- Clinical Chemistry (Lecture) - PrelimsDocument12 pagesClinical Chemistry (Lecture) - Prelimsisprikitik3100% (1)

- Recalls. 2019 AscpDocument2 pagesRecalls. 2019 AscpJoanna Carel Lopez100% (1)

- Is BB Final Coaching NotesDocument8 pagesIs BB Final Coaching NotesLeomill MendiolaNo ratings yet

- ASCP Implementation Steps For One OrganizationDocument17 pagesASCP Implementation Steps For One OrganizationRajesh Reddi50% (2)

- Study Stack - Hematology Tests 3-4 Table ReviewDocument5 pagesStudy Stack - Hematology Tests 3-4 Table Review장주연No ratings yet

- BOC 5th Edition CalculationsDocument3 pagesBOC 5th Edition Calculationsthrowawy75% (4)

- ASCPi Exam Questions and AnswersDocument5 pagesASCPi Exam Questions and AnswersDjdjjd Siisus100% (2)

- Clinical ChemistryDocument10 pagesClinical ChemistryChristina AtefNo ratings yet

- S&OP Part II Enabling Technology Larry Lapide PDFDocument3 pagesS&OP Part II Enabling Technology Larry Lapide PDFOmar Enrique Gonzalez RozoNo ratings yet

- Supply Chain Operation SCOR v8 0Document548 pagesSupply Chain Operation SCOR v8 0Sukumaran At TsblNo ratings yet

- Enabling S&OP with TechnologyDocument5 pagesEnabling S&OP with TechnologyJoaquin GonzalezNo ratings yet

- Oracle Process Manufacturing - Statement of DirectionDocument13 pagesOracle Process Manufacturing - Statement of DirectionMaulik DixitNo ratings yet

- OracleDocument23 pagesOraclesuraj_kumar_vitNo ratings yet

- Oracle Apps FunctionalDocument6 pagesOracle Apps FunctionalStacey BrooksNo ratings yet

- APQC Process Framework PCF 5xDocument20 pagesAPQC Process Framework PCF 5xSergio PedemonteNo ratings yet

- Oracle E-Business Suite R12.x HRMS – A Functionality GuideFrom EverandOracle E-Business Suite R12.x HRMS – A Functionality GuideRating: 5 out of 5 stars5/5 (3)

- India's Foreign Trade Composition, Direction and Growth Since ReformsDocument13 pagesIndia's Foreign Trade Composition, Direction and Growth Since Reformsfuck but TrueNo ratings yet

- CCC Games For Vocabulary PracticeDocument121 pagesCCC Games For Vocabulary PracticeClaudia Martos88% (16)

- Safety Stock (Also Called Buffer Stock) Is A Term Used by Logisticians To Describe A Level of ExtraDocument3 pagesSafety Stock (Also Called Buffer Stock) Is A Term Used by Logisticians To Describe A Level of ExtraRajesh Insb100% (1)

- The SAFTA Agreement Was Signed On 6 January 2004 During Twelfth SAARC Summit Held in IslamabadDocument3 pagesThe SAFTA Agreement Was Signed On 6 January 2004 During Twelfth SAARC Summit Held in Islamabadravi_mehta68No ratings yet

- SCM 1Document23 pagesSCM 1Dani Leonidas SNo ratings yet

- International Economics Exam Review and Practice QuestionsDocument91 pagesInternational Economics Exam Review and Practice QuestionsTeddy JainNo ratings yet

- Incoterms 2000Document6 pagesIncoterms 2000jonh286No ratings yet

- Simulacion en InglesDocument4 pagesSimulacion en IngleshersonNo ratings yet

- French Vocab List LogisticDocument2 pagesFrench Vocab List Logisticmedpro97100% (1)

- Trade Blocks & Economic IntegrationDocument52 pagesTrade Blocks & Economic IntegrationRana SarkarNo ratings yet

- ISO 9000 AND TQM IN THE CONSTRUCTION INDUSTRYDocument69 pagesISO 9000 AND TQM IN THE CONSTRUCTION INDUSTRYnitin100No ratings yet

- Chart of Responsibility: Any Transport Mode Sea/Inland Waterway Transport Any Transport ModeDocument1 pageChart of Responsibility: Any Transport Mode Sea/Inland Waterway Transport Any Transport ModeBhayaniNo ratings yet

- TOC in Procurement - Albert - 16 TOCPA - April 2015 - South Africa - With CorrectionDocument48 pagesTOC in Procurement - Albert - 16 TOCPA - April 2015 - South Africa - With CorrectionJelena Fedurko100% (2)

- GSE EnVision UsersListDocument2 pagesGSE EnVision UsersListasamad54No ratings yet

- MRP Guide: Material Requirement Planning ExplainedDocument26 pagesMRP Guide: Material Requirement Planning ExplainedARJUN VNo ratings yet

- Types of Non-Tariff Trade Barriers ExplainedDocument6 pagesTypes of Non-Tariff Trade Barriers ExplainedmbapptNo ratings yet

- Big Four Accounting Firms - WikipediaDocument4 pagesBig Four Accounting Firms - WikipediaNguyen Vu DoanNo ratings yet

- WCM Principle 4 HeijunkaDocument33 pagesWCM Principle 4 HeijunkaSaurabh KothawadeNo ratings yet

- CETA Consolidated TextDocument521 pagesCETA Consolidated Textbi2458No ratings yet

- The Value of Information in SCMDocument19 pagesThe Value of Information in SCMmishratrilok100% (2)

- Supply Chain Management of Coca ColaDocument5 pagesSupply Chain Management of Coca ColaUmer IqbalNo ratings yet

- Supply Chain - ShawqiDocument27 pagesSupply Chain - ShawqiShawqi batranNo ratings yet

- Materials Requirements PlanningDocument73 pagesMaterials Requirements PlanningParth Shah100% (1)

- .Case Indo Auto.Document28 pages.Case Indo Auto.Chirasak KammayeeNo ratings yet

- 5 Material Requirements PlanningDocument86 pages5 Material Requirements PlanningArush BhatnagarNo ratings yet

- Sales and Distribution Channel of Hindustan Unilever Ltd.Document4 pagesSales and Distribution Channel of Hindustan Unilever Ltd.pranay_rajas4600No ratings yet

- Introduction of Logistics & ShippingDocument32 pagesIntroduction of Logistics & ShippingJoju JohnyNo ratings yet

- Subsidies and Countervailing Measures SLIDESDocument14 pagesSubsidies and Countervailing Measures SLIDESNikita SangalNo ratings yet

- Credit Card Transactions by Brand and Masked NumberDocument1,094 pagesCredit Card Transactions by Brand and Masked NumberAngelo GzoNo ratings yet

- WTO - Faculty NotesDocument23 pagesWTO - Faculty Notesprashaant4uNo ratings yet