Professional Documents

Culture Documents

2220AQ5SPR11-SOLUTION - Best-Worst Case - Fasttrack - HR Module

Uploaded by

shiningloreOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2220AQ5SPR11-SOLUTION - Best-Worst Case - Fasttrack - HR Module

Uploaded by

shiningloreCopyright:

Available Formats

Why would you prepare a Worst Case sales forecast in the Marketing worksheet? What is the goal here?

Worst case relates to profitability, cash flow and inventory analysis and is addressed in the Marketing worksheet by entering the low end of your sales forecast. By doing so, you can then review your proforma financials to make sure you will have enough cash at the end of the year should such a scenario occur. If your worst case does come true, you will have excess inventory but enough cash to stay away from Big Al. Of course, you would need to produce at least as much as your lowest sales forecast on the Production worksheet. Note: Your proforma financial statements are largely based upon the sales forecast used in the Marketing worksheet (see Student Guide, pages 29 - 31).

1) 2) How can you use the same Marketing worksheet to develop a Best Case scenario? What is the goal here?

CapSim Solution Commentary: Acct 2220 Zeigler - AQ #5 Best Case-Worst Case, Fasttrack & Human Resources (15 Points)

By entering a large number in the sales forecast cells for each product (i.e. something high enough that you would sell all of your production), this will give you an idea of the highest profitability achievable. In essence, enter a number that supports the sale of ALL units of product. The result on your proforma Balance Sheet should indicate no inventory and a large cash balance.

3) How does this spread (i.e. two forecast extremes above) affect Production worksheet decisions?

The Best Case / Worst Case allows the team to develop an inventory production range (i.e. spread). As such, you plan for the worst (Marketing worksheet sales forecast) and produce for the best (on the Production worksheet). The question for management then becomes how much of an inventory buffer is desired?. One month? One quarter? Too little inventory invites a stock-out (lost profits). Too much (unsold) inventory consumes cash and incurs a 12% inventory carrying cost (Note: this inventory carrying cost is shown/detailed in your Annual Report Income Statement).

4) Per your Fasttrack, The Market Share report contains both Actual and Potential market share

information. Which of these two components should generally be used as part of your sales forecasting analysis? What exception to this general approach might apply here? Actual market share indicates what happened last round. Using Potential market share should be considered when forecasting next rounds sales. This prediction, however, may be affected by stock-outs of your, or your competitors, products.

5) Per page 3 of your Fasttrack, why is Depreciation listed as is a positive adjustment on the Statement of Cash

Flows? Why is depreciation, a non-cash expense, even shown on this cash flow statement? The format of the Stmt of Cash flows used in the sim represents the format you will see in the majority of, if not all, public company annual reports. In essence, this Reconciliation (aka: Indirect) method reconciles the difference between reported Net Income (accrual basis) and the actual cash flow (increase or decrease) incurred for the period. Since depreciation is deducted in arriving at net income, it must simply be added back on the Stmt of Cash Flows, as a positive adjustment ALWAYS, as part of this reconciliation process. An important concept to understand here.

6) In the Human Resources (HR) module, why does an increase in training require hiring more workers?

More workers are required to replace those who are in training. The more training, the more workers.

7) What is the default recruiting cost of hiring a new worker? What is the maximum additional amount per

worker that can be spent on recruiting costs? The default recruiting cost is $1,000 per worker to hire someone off the street. An additional $5,000 per worker recruited can be spent in an attempt to increase the caliber of the worker hired.

8) What happens to overtime, and employee turnover rates, when the number of workers is less than needed?

Production schedules drive the required complement determination. Both overtime and employee turnover (disgruntled employees) will increase when the required complement is not achieved. Further, the Productivity Index will be negatively affected.

Acct 2220 Zeigler: Human Resources Module questions - AQ#5 Commentary

9. Production runs can be scheduled in: A. only one shift B. always two shifts C. one or two shifts D. up to three shifts Up to twice the production line's First Shift Capacity can be scheduled for each individual product. Production runs that exceed the First Shift Capacity result in either Overtime and/or a Second Shift, depending on the Worker Complement. 10. Hiring/Scheduling the Needed Complement of workers will always eliminate: A. Overtime B. worker layoffs C. a Second Shift D. strikes Hiring the Needed Complement eliminates all Overtime. The Second Shift workers are paid the same as workers on Overtime, however, Second Shift workers are more efficient and do not seek work elsewhere, therefore reducing turnover. 11. Management should strive to: A. increase employee turnover B. decrease employee turnover Lowering Turnover reduces Recruitment costs. 12. Increasing Capacity tends to: A. increase the Needed Complement B. reduce the number of workers on Second Shift C. reduce Overtime Increasing Capacity tends to reduce the number of workers on the Second Shift. As an example, a production order of 1,200 units on a line with a Capacity of 800 units (numbers in thousands) will require 400 units to be produced by the Second Shift. Increasing Capacity to a total of 1,000 units will result in 1,000 units manufactured by First Shift labor, and only 200 units produced by more expensive Second Shift labor. 13. Increasing Training Hours tends to: A. increase the Needed Complement B. decrease the Needed Complement C. neither increase nor decrease the Needed Complement D. both increase and decrease the Needed Complement In the short term, increasing Training Hours will increase the Needed Complement-- Workers are taken off the production line and put in the classroom. However, as time goes on, investing in Training Hours increases worker productivity, and therefore tends to decreases the Needed Complement. 14. Recruiting Costs are incurred when: A. Automation levels increase B. Production runs increase and teams match hiring to Needed Complement C. workers are assigned to a 2nd Shift Increasing production and then matching the Needed Complement will result in new hires, and therefore increase Recruiting Costs. 15. Assuming the Productivity Index is greater than 100%, adding Overtime will: A. increase the Productivity Index B. decrease the Productivity Index While the Productivity Index can never fall below 100%, it is possible for teams to increase the Index by investing in a higher quality of worker (Recruiting Spend) and in education (Training Hours). However, scheduling Overtime will decrease the Index because workers will become tired and disgruntled. 16. Worker training is entered/determined by the: A. Hour B. Dollar Hours are entered on the HR Screen. Training costs $20.00 per hour per worker. 17. Teams can eliminate all Recruiting Costs if they wish. A. True B. False Teams can choose to enter 0 in the Recruiting Spend cell on the Human Resources screen, however that number is in addition to a base Recruiting Cost of $1,000 per worker. A Recruiting Spend entry facilitates recruiting a better quality of worker. 18. Generally, Separation Costs will be incurred when: A. Production levels increase B. Automation Levels increase C. Production Levels decrease D. Production levels decrease and / or Automation levels increase The Needed Complement is determined by a combination of: a) the number of units ordered into production; and b) the Automation level of the assembly lines. Decreasing the number of units produced from one year to the next will decrease the Needed Complement. Similarly, increases in Automation will decrease the Needed Complement. If teams adjust the This Year cell to match the Needed Complement, Separation Costs will be incurred.

You might also like

- Capsim Quiz Set 2Document7 pagesCapsim Quiz Set 2Prince JoshiNo ratings yet

- Full Download Introduction To Managerial Accounting 7th Edition Brewer Solutions ManualDocument22 pagesFull Download Introduction To Managerial Accounting 7th Edition Brewer Solutions Manualstulhokyb100% (32)

- Chapter 18 Solutions ManualDocument46 pagesChapter 18 Solutions ManualLan Anh0% (1)

- Ajax Manufacturing Cost AnalysisDocument7 pagesAjax Manufacturing Cost Analysisreva_radhakrish1834No ratings yet

- CMA-End Term Exam Question Paper PDFDocument5 pagesCMA-End Term Exam Question Paper PDFJinson JoseNo ratings yet

- Factory Audit ReportDocument33 pagesFactory Audit ReportMudit Kothari100% (1)

- Human ResourcesDocument3 pagesHuman ResourcesDivya VNo ratings yet

- Advanced Modules+StrategiesDocument12 pagesAdvanced Modules+StrategiesCharan MakkinaNo ratings yet

- HRMQuiz 1Document3 pagesHRMQuiz 1sreehsNo ratings yet

- Cost and Benefit AnalysisDocument2 pagesCost and Benefit AnalysisGulnara CadenasNo ratings yet

- MGT 402 GRAND QUIZ MidtermDocument7 pagesMGT 402 GRAND QUIZ MidtermAamir0% (1)

- AB-B - Rizky Fadillah Salam - Assignment Week 4 5Document13 pagesAB-B - Rizky Fadillah Salam - Assignment Week 4 5Reta AzkaNo ratings yet

- Cost Accounting Final Exam ReviewDocument6 pagesCost Accounting Final Exam ReviewElias DeusNo ratings yet

- Downstudocucom Job Order Costing Solutions Manual 220522 212505Document86 pagesDownstudocucom Job Order Costing Solutions Manual 220522 212505Iqra -Abdul ShakoorNo ratings yet

- Capacity PlanningDocument10 pagesCapacity PlanningShuchi MangalNo ratings yet

- C01 Modelquestionpaper AnswersDocument28 pagesC01 Modelquestionpaper AnswersLogs MutaNo ratings yet

- Cost Volume Profit Analysis Research PaperDocument6 pagesCost Volume Profit Analysis Research Paperfysygx5k100% (1)

- Adms2510f FL95Document9 pagesAdms2510f FL95rabeya26No ratings yet

- Full Download Introduction To Managerial Accounting 6th Edition Brewer Solutions ManualDocument35 pagesFull Download Introduction To Managerial Accounting 6th Edition Brewer Solutions Manualstulhokyb100% (35)

- Admn 261 - Introduction To Hospitality: Case StudyDocument8 pagesAdmn 261 - Introduction To Hospitality: Case StudyAbiha RehmanNo ratings yet

- Cost Accounting AssignmentDocument21 pagesCost Accounting AssignmentAdoonkii Alaha Wayn67% (3)

- Research Paper On Factory OverheadDocument8 pagesResearch Paper On Factory Overheadafmcitjzc100% (1)

- Intermediate Group II Test Papers (Revised July 2009)Document55 pagesIntermediate Group II Test Papers (Revised July 2009)Sumit AroraNo ratings yet

- Managerial Accounting Module 2 ActivityDocument7 pagesManagerial Accounting Module 2 ActivityDesy Joy UrotNo ratings yet

- ACCA F5 Study Notes.Document88 pagesACCA F5 Study Notes.Naman. Patel100% (5)

- 02-08-2022 CRC-ACE - AFAR - Week 05 - Factory OverheadDocument14 pages02-08-2022 CRC-ACE - AFAR - Week 05 - Factory Overheadjohn francisNo ratings yet

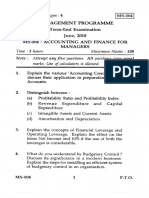

- Management Programme Term-End Examination: December, 2017 Ms-004: Accounting and Finance For ManagersDocument3 pagesManagement Programme Term-End Examination: December, 2017 Ms-004: Accounting and Finance For ManagersreliableplacementNo ratings yet

- Optimize production, finance, HR and marketing strategiesDocument3 pagesOptimize production, finance, HR and marketing strategiesDuyên HànNo ratings yet

- 52 Resource 7Document4 pages52 Resource 7gurudevgaytri0% (1)

- Project On Factory Overhead Variances AnalysisDocument30 pagesProject On Factory Overhead Variances AnalysisAmby Roja100% (1)

- Job Order Costing and Analysis: QuestionsDocument60 pagesJob Order Costing and Analysis: QuestionsLily CakesNo ratings yet

- Time: 3 Hours Maximum Marks: 100 Note: Attempt Any Five Questions. All Questions Carry Equal Marks. Use of Calculators Is AllowedDocument4 pagesTime: 3 Hours Maximum Marks: 100 Note: Attempt Any Five Questions. All Questions Carry Equal Marks. Use of Calculators Is AllowedashishvasekarNo ratings yet

- F5-Abc-1 AccaDocument4 pagesF5-Abc-1 AccaAmna HussainNo ratings yet

- Dwnload Full Managerial Accounting 6th Edition Wild Solutions Manual PDFDocument35 pagesDwnload Full Managerial Accounting 6th Edition Wild Solutions Manual PDFlinnet.discreet.h5jn2s100% (11)

- Introduction To Managerial Accounting 7th Edition Brewer Solutions ManualDocument26 pagesIntroduction To Managerial Accounting 7th Edition Brewer Solutions ManualTraciLewispwng100% (51)

- Job Order CostingDocument5 pagesJob Order CostingNishanth PrabhakarNo ratings yet

- True/False Questions: labor-intensive (cần nhiều nhân công)Document31 pagesTrue/False Questions: labor-intensive (cần nhiều nhân công)Ngọc MinhNo ratings yet

- Manpower Calculator Introduction V1.5Document18 pagesManpower Calculator Introduction V1.5lisahunNo ratings yet

- CH 11 SMDocument27 pagesCH 11 SMNafisah Mambuay100% (1)

- Test3 Study GuideDocument5 pagesTest3 Study Guide10manbearpig01No ratings yet

- Midterm Quiz 20Document4 pagesMidterm Quiz 20Michael Angelo Laguna Dela FuenteNo ratings yet

- Marginal CostingDocument10 pagesMarginal CostingNishant ModiNo ratings yet

- Assignment Sem 2 2015Document3 pagesAssignment Sem 2 2015Nitesh AgrawalNo ratings yet

- Jijiga, Ethiopia: Title: Overhead AllocationDocument10 pagesJijiga, Ethiopia: Title: Overhead AllocationKader EzmailNo ratings yet

- Report Performance BMDocument31 pagesReport Performance BMmarketwideNo ratings yet

- BMGT 321 Chapter 13 HomeworkDocument11 pagesBMGT 321 Chapter 13 Homeworkarnitaetsitty100% (1)

- Managerial ReportDocument31 pagesManagerial ReportQuỳnh QuỳnhNo ratings yet

- Heuristics - Dianogtics AnalyticsDocument68 pagesHeuristics - Dianogtics Analyticsnthieu0102No ratings yet

- Final Exam - Strategic - OVILLODocument4 pagesFinal Exam - Strategic - OVILLOMaria Angelica100% (1)

- Managerial Accounting 15th Edition Garrison Solutions ManualDocument54 pagesManagerial Accounting 15th Edition Garrison Solutions Manualcamcaic54l100% (26)

- assigment management accountingDocument7 pagesassigment management accountingpuiyan0314No ratings yet

- Sup Questions 4Document17 pagesSup Questions 4Anonymous bTh744z7E6No ratings yet

- Cost Accounting AssignmentDocument12 pagesCost Accounting Assignmentridhim khandelwalNo ratings yet

- Examiner's Report: MA2 Managing Costs & Finance December 2012Document4 pagesExaminer's Report: MA2 Managing Costs & Finance December 2012Ahmad Hafid Hanifah100% (1)

- Cost EffectivenessDocument8 pagesCost EffectivenessMehul LakhaniNo ratings yet

- Costing Assignment PDFDocument5 pagesCosting Assignment PDFVirendra DongreNo ratings yet

- Cpa Questions Part XDocument10 pagesCpa Questions Part XAngelo MendezNo ratings yet

- Learning To See: by John DarlingtonDocument6 pagesLearning To See: by John DarlingtonAnastasia IonasNo ratings yet

- Cost & Managerial Accounting II EssentialsFrom EverandCost & Managerial Accounting II EssentialsRating: 4 out of 5 stars4/5 (1)

- Management Accounting: Decision-Making by Numbers: Business Strategy & Competitive AdvantageFrom EverandManagement Accounting: Decision-Making by Numbers: Business Strategy & Competitive AdvantageRating: 5 out of 5 stars5/5 (1)

- The Entrepreneur’S Dictionary of Business and Financial TermsFrom EverandThe Entrepreneur’S Dictionary of Business and Financial TermsNo ratings yet

- Reggie Orbista Zonio vs. 1st Quantum Security Agency, Inc. and Romulo Q. Par, G.R. No. 224944, May 05, 2021Document9 pagesReggie Orbista Zonio vs. 1st Quantum Security Agency, Inc. and Romulo Q. Par, G.R. No. 224944, May 05, 2021Anonymous oGfAqF1No ratings yet

- Endroof HR Manual-1-FINALDocument26 pagesEndroof HR Manual-1-FINALjoseph koigiNo ratings yet

- Premier Bank ProfileDocument10 pagesPremier Bank ProfileraktimbeastNo ratings yet

- Cagampan Vs NLRC DigestDocument2 pagesCagampan Vs NLRC DigestDazzle Duterte100% (2)

- About The Employment Related Murder of Delfina Pan in Miami Beach, Florida On November 29th 2021 - #Michael Ayele (A.k.a) W - #Title VII of The 1964 & 1991 Civil Rights ActDocument56 pagesAbout The Employment Related Murder of Delfina Pan in Miami Beach, Florida On November 29th 2021 - #Michael Ayele (A.k.a) W - #Title VII of The 1964 & 1991 Civil Rights ActMichael Ayele (a.k.a) WNo ratings yet

- Labor Case Digests, FglsjgjakfsagfDocument180 pagesLabor Case Digests, FglsjgjakfsagfLei MorteraNo ratings yet

- Labor Cases DigestDocument13 pagesLabor Cases DigestLen-Len CobsilenNo ratings yet

- Earn Codes DescrDocument296 pagesEarn Codes DescrJaymee Andomang Os-agNo ratings yet

- Mr. Shabber BandiDocument2 pagesMr. Shabber Bandimanish guptaNo ratings yet

- San Miguel vs. Layoc Jr. GR 149640 Oct. 19, 2007Document4 pagesSan Miguel vs. Layoc Jr. GR 149640 Oct. 19, 2007Ran Basada-De GuzmanNo ratings yet

- Day 1 Checklist-GLS-OSH (Guideinaccom)Document21 pagesDay 1 Checklist-GLS-OSH (Guideinaccom)mike camsNo ratings yet

- Labor 0901417Document13 pagesLabor 0901417DanyNo ratings yet

- Pay Delivery System - by Ankur AgrawalDocument9 pagesPay Delivery System - by Ankur AgrawalPuravRajNo ratings yet

- Employee RightsDocument2 pagesEmployee RightsJustine ManueleNo ratings yet

- Management AccountingDocument32 pagesManagement Accountingsuhaini subriNo ratings yet

- Partner Guide - Store Edition - Canada - June 2022Document69 pagesPartner Guide - Store Edition - Canada - June 2022dhrubo99941No ratings yet

- Mock 6 ShyamDocument34 pagesMock 6 ShyamsakbalnamNo ratings yet

- 37 Distinguish Public Corporations From GOCC - As To Purpose - NAWASA V NAWASA Consolidated UnionsDocument11 pages37 Distinguish Public Corporations From GOCC - As To Purpose - NAWASA V NAWASA Consolidated UnionsTootsie GuzmaNo ratings yet

- Aarong Compensation BodyDocument17 pagesAarong Compensation BodyMahamudul HasanNo ratings yet

- Accounting P2 Nov 2020 Memo EngDocument10 pagesAccounting P2 Nov 2020 Memo EngBurning PhenomNo ratings yet

- Day Care ContractDocument6 pagesDay Care ContractRocketLawyer100% (1)

- Employment Agreement: Indira Gandhi Memorial Hospital Male', Republic of MaldivesDocument10 pagesEmployment Agreement: Indira Gandhi Memorial Hospital Male', Republic of MaldivesAf-san WaheedNo ratings yet

- The Global EmployerDocument198 pagesThe Global EmployercokemasterNo ratings yet

- Philippine Virginia Tobacco Administration Court of Industrial Relations, Et Al. FactsDocument1 pagePhilippine Virginia Tobacco Administration Court of Industrial Relations, Et Al. FactsRich ReyesNo ratings yet

- Case Studies Chapter 2 Principles of Management BST Class 12 Commerce Notes EduRevDocument33 pagesCase Studies Chapter 2 Principles of Management BST Class 12 Commerce Notes EduRevLaraNo ratings yet

- Department of Labor: 2006 07 24 19NA FLSADocument3 pagesDepartment of Labor: 2006 07 24 19NA FLSAUSA_DepartmentOfLaborNo ratings yet

- RCS Offer Letter PDFDocument2 pagesRCS Offer Letter PDFVIVEK TIWARINo ratings yet

- Solution Manual For Payroll Accounting 2017 3rd Edition by Landin Complete Downloadable File At: Which Law?Document33 pagesSolution Manual For Payroll Accounting 2017 3rd Edition by Landin Complete Downloadable File At: Which Law?a775036112No ratings yet

- Different Types of AllowancesDocument4 pagesDifferent Types of AllowancesYoga Guru100% (1)