Professional Documents

Culture Documents

01-Explain With Neat Sketch The Construction Working and Application of Following Instruments - Vernier Caliper & Micrometer

Uploaded by

phase_shekhar21Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

01-Explain With Neat Sketch The Construction Working and Application of Following Instruments - Vernier Caliper & Micrometer

Uploaded by

phase_shekhar21Copyright:

Available Formats

Metrology and Quality Control

Experiment No. 2

6.0

DIAGRAM:

Fig 2.1 VERNIER CALIPER

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

7.0

PROCEDURE:

7.1 Brief theory: Vernier Caliper: Construction: It consists of two scales. Fixed scale is called as a main scale & it is calibrated on Lshaped frame, which carries a fixed jaw. The movable scale is called as vernier scale & it slides over the main scale, which carries movable jaw. When the two measuring jaws are in contact with each other, the scale should show zero reading. An adjustable screw is provided for fine adjustment of movable jaw. Also, a lock nut is provided to lock the sliding scale on main scale. Working: The movable jaw assembly is so adjusted that the two measuring jaws just touch the work piece to be measured. Then the lock nut is tightened. Final adjustment depends upon the sense of the correct feel & it is made by the adjusting screw. As the adjusting screw rotates the movable jaw also moves. After final adjustment has been made, the other locking nut is also tightened & the reading is taken.

Experiment No. 2

Metrology and Quality Control

Precautions & care: 1. There should not be any play between sliding jaw & the main scale. 2. Check the instruments for zero error. 3. Parallax or reading error must be avoided. 4. Do not apply undue pressure. Micrometer: Principle: The micrometer works on this principle of screw and nut. When a screw is rotated through a nut by one revolution, it advances a distance equal to one pitch. Construction: It consists of a screw having 10 or 20 threads per cm and revolves in a fixed nut. The end of the screw forms one measuring anvil and a fixed anvil is in the frame. The spindle can be advanced or retracted by rotating the thimble. Barrel is a fixed part attached with the frame. The spindle is slide fit in the barrel. Generally, the pitch of screw thread is 0.5 mm & the thimble has 50 equal divisions on the circumference. Ratchet is provided at the end of thimble to apply sufficient and uniform measuring pressure. Working: The thimble is rotated till the spindle touches the work piece. Then the final adjustment is made by using ratchet. The locknut is then tightened and the dimension is measured on main scale and thimble scale. Precautions & care: 1. Clean the measuring surface of anvil before use. 2. Check the instrument for zero reading before use. 3. While taking measurements, pressure applied on thimble must be correct. Use ratchet for final judgment of pressure. 4. Do not apply undue pressure. 7.2 STEP-WISE PROCEDURE: 1. Clean the workpiece and instruments. 2. Check the vernier caliper & micrometer for errors like play in the jaw, zero error if any. 3. If any error is present, correct it. 4. Calculate the least count of the instruments. 5. Hold the workpiece in the measuring jaws / anvils. 6. Note down the readings on main scale & vernier / thimble scale. 7. Take the measurements for at least 3 components by vernier caliper and micrometer. 8. Calculate the total reading of vernier caliper and micrometer. 9. Complete the observation table.

8.0

OBSERVATION TABLE:

1. Measurement using vernier caliper:

You might also like

- Central Deflection of A Simply Supported BeamDocument10 pagesCentral Deflection of A Simply Supported BeamwaqarNo ratings yet

- Slider Crank Mechanism Term Project ReportDocument16 pagesSlider Crank Mechanism Term Project ReportAnis Badshah88% (24)

- Concurrent Forces Vs Non-Concurrent ForcesDocument15 pagesConcurrent Forces Vs Non-Concurrent ForcesInocent FarrukhNo ratings yet

- Moment of Inertia of FlywheelDocument18 pagesMoment of Inertia of Flywheelgaurav singhNo ratings yet

- Cascade Method NewDocument21 pagesCascade Method NewThiruppathi RajalingamNo ratings yet

- Accelerated Stability TestingDocument5 pagesAccelerated Stability TestingKevin GaralaNo ratings yet

- Murali - Metrology & Measurements Lab ManualDocument30 pagesMurali - Metrology & Measurements Lab ManualsubhashNo ratings yet

- Experiment No. 5: Aim: Study of Various Types of Gear BoxesDocument9 pagesExperiment No. 5: Aim: Study of Various Types of Gear BoxesSiddhesh RaulNo ratings yet

- 1.experiment On Single Rotor SystemDocument8 pages1.experiment On Single Rotor SystemRahul Kumar DwivediNo ratings yet

- Experiment No. 2: Manual TransmissionDocument50 pagesExperiment No. 2: Manual TransmissionMoiz AamirNo ratings yet

- Lab Manual Engineering MechanicsDocument34 pagesLab Manual Engineering MechanicsBrajesh Kumar Sahu100% (2)

- Straight Line Motion Mechanisms OldDocument28 pagesStraight Line Motion Mechanisms OldVaibhav Vithoba Naik100% (4)

- Lab Manual Mechanics-IIDocument26 pagesLab Manual Mechanics-IIEngr Muhammad Imran100% (1)

- Experiment 1 - Crank and RodDocument3 pagesExperiment 1 - Crank and Rodalextty75% (12)

- Experiment To Determine The Mechanical Advantage, Velocity Ratio and Mechanical Efficiency of Worm and Worm-Wheel Gear.Document8 pagesExperiment To Determine The Mechanical Advantage, Velocity Ratio and Mechanical Efficiency of Worm and Worm-Wheel Gear.Taha Anees100% (1)

- Scotch Yoke Mechanis1Document17 pagesScotch Yoke Mechanis1Saravanan ViswakarmaNo ratings yet

- Chapter-2 Engineering Graphics PDFDocument47 pagesChapter-2 Engineering Graphics PDFVidya Narayan100% (2)

- Metrology Sine Bar Lab ManualDocument4 pagesMetrology Sine Bar Lab Manualharshitagarwal604075% (4)

- Angle Measurement Using Sine BarDocument4 pagesAngle Measurement Using Sine Barsameerkhan_mhsscoe0% (1)

- 6.acceleration of Gear SystemDocument9 pages6.acceleration of Gear SystemMuhammed Shameem N Edavannappara50% (2)

- GegasDocument18 pagesGegasPiraven Casanova II50% (2)

- Universal Force Table-1Document4 pagesUniversal Force Table-1Ipsha Guha100% (1)

- ME2308 Lab ManualDocument28 pagesME2308 Lab ManualNishanth ShannmugamNo ratings yet

- Journal Bearing ApparatusDocument6 pagesJournal Bearing ApparatusGurmeet Mehma67% (6)

- Worm and Worm VheelDocument9 pagesWorm and Worm Vheelnawodani100% (2)

- Faculty of Engineering & Built Environment Subject: Ege 3411 Laboratory Investigations 2 Experiment 1: Gear TrainDocument7 pagesFaculty of Engineering & Built Environment Subject: Ege 3411 Laboratory Investigations 2 Experiment 1: Gear TrainJameel MalikNo ratings yet

- Shaping MachineDocument14 pagesShaping MachineMohammad Javed IqbalNo ratings yet

- Full Hacksaw ReportDocument7 pagesFull Hacksaw ReportIqbalRifat0% (1)

- DL1 - Epicyclic Gear Train & Holding Torque ManualDocument4 pagesDL1 - Epicyclic Gear Train & Holding Torque Manualer_arun76100% (1)

- BME Unit 8 Power TransmissionDocument8 pagesBME Unit 8 Power Transmissionalysonmicheaala100% (1)

- KDM 6Document54 pagesKDM 6KarthikeyanRamanujamNo ratings yet

- Exam1 PracticeDocument9 pagesExam1 PracticeashwaniNo ratings yet

- Experiment No 3Document3 pagesExperiment No 3pomar026100% (1)

- Problems On Beams PDFDocument16 pagesProblems On Beams PDFC j50% (6)

- Meter in Circuit PDFDocument3 pagesMeter in Circuit PDFShashwat JainNo ratings yet

- Numerical Problem With Solution For Engg MeasurementDocument31 pagesNumerical Problem With Solution For Engg Measurementssanthosh073100% (5)

- U-Tube Manometer Lab ReportDocument3 pagesU-Tube Manometer Lab ReportKashif AbbasNo ratings yet

- To Measure The Angles of Given Specimen Using Bevel ProtractorDocument3 pagesTo Measure The Angles of Given Specimen Using Bevel ProtractorelavarasanNo ratings yet

- Viva VoiceDocument6 pagesViva VoiceRakesh Kumar Shukla KECNo ratings yet

- Experiment No: 8 A) Familiarization With Construction and Working of A Transformer B) Verification of Turns Ratio of TransformerDocument3 pagesExperiment No: 8 A) Familiarization With Construction and Working of A Transformer B) Verification of Turns Ratio of TransformerSaad AliKhan0% (1)

- Lab Report (Reaction of Forces On A Simply Supported Beam)Document10 pagesLab Report (Reaction of Forces On A Simply Supported Beam)Muhammad Abubakar Shahzad Talib ShahzadNo ratings yet

- Experiment 6 (Roof Truss Apparatus)Document4 pagesExperiment 6 (Roof Truss Apparatus)Ahmed0% (1)

- 1.tool Makers MicroscopeDocument7 pages1.tool Makers MicroscopeelavarasanNo ratings yet

- Engineering Mechanics ObjectiveDocument45 pagesEngineering Mechanics ObjectiveSreejith Vanery100% (3)

- Strain GaugeDocument18 pagesStrain GaugeShannon Hayden0% (1)

- Bee MCQ Unit 2 Mark - 2Document10 pagesBee MCQ Unit 2 Mark - 2Bilal BilalNo ratings yet

- To Study of Various Type of DynamometersDocument5 pagesTo Study of Various Type of DynamometersAshik GR100% (1)

- Single Slider Crank ChainDocument9 pagesSingle Slider Crank ChainSunny RajNo ratings yet

- Simple Lifting Machines MyDocument14 pagesSimple Lifting Machines MyAkash SinghNo ratings yet

- 14J Drawing Marking SchemeDocument5 pages14J Drawing Marking SchemeACLINNo ratings yet

- Limits and FitsDocument6 pagesLimits and Fitscamohunter71No ratings yet

- Static and Dynamic Balancing: Experiment#2Document4 pagesStatic and Dynamic Balancing: Experiment#2Maqbool Khan100% (1)

- Abstract and Introduction of Torsion TestDocument4 pagesAbstract and Introduction of Torsion TestM.USMAN BIN AHMEDNo ratings yet

- ME2405 Mechatronics Lab ManualDocument55 pagesME2405 Mechatronics Lab ManualThusith Wijayawardena50% (4)

- Volumetric Efficiency For Reciprocating CompressorDocument2 pagesVolumetric Efficiency For Reciprocating CompressorKrishna PATELNo ratings yet

- Experiment No 5 The DC Series MotorDocument6 pagesExperiment No 5 The DC Series MotorMadel Roque50% (2)

- Experiment No. 2: 1.0 TitleDocument6 pagesExperiment No. 2: 1.0 TitleKaranpal SinghNo ratings yet

- 1 ENSC 102L - Module-I (Activity 1-LA#1)Document9 pages1 ENSC 102L - Module-I (Activity 1-LA#1)Ciane PattyNo ratings yet

- Metrology: Nri Institute of TechnologyDocument55 pagesMetrology: Nri Institute of TechnologyKasijanto JantoNo ratings yet

- Study of Linear Measuring Instruments: Qis College of Engg. & Tech.:Ongole, A.P. Metrology LabDocument9 pagesStudy of Linear Measuring Instruments: Qis College of Engg. & Tech.:Ongole, A.P. Metrology LabAnand BabuNo ratings yet

- Handbook of Mechanical and Materials EngineeringFrom EverandHandbook of Mechanical and Materials EngineeringRating: 5 out of 5 stars5/5 (4)

- YCMOU-6th Semester Question Papers-15Document6 pagesYCMOU-6th Semester Question Papers-15phase_shekhar21No ratings yet

- Pack House Guid Lines 8. - SopsDocument22 pagesPack House Guid Lines 8. - Sopsphase_shekhar21100% (1)

- T24 - Dme-7th Semester Drawing Sheet....Document82 pagesT24 - Dme-7th Semester Drawing Sheet....phase_shekhar21No ratings yet

- T24 - Dme-7th Semester Drawing Sheet....Document1 pageT24 - Dme-7th Semester Drawing Sheet....phase_shekhar21No ratings yet

- YCMOU-6th Semester Question Papers-16Document6 pagesYCMOU-6th Semester Question Papers-16phase_shekhar21No ratings yet

- Hepa Filter Product-SummaryDocument8 pagesHepa Filter Product-Summaryphase_shekhar21No ratings yet

- YCMOU-6th Semester Question Papers-8Document6 pagesYCMOU-6th Semester Question Papers-8phase_shekhar21No ratings yet

- YCMOU-6th Semester Question Papers-12Document6 pagesYCMOU-6th Semester Question Papers-12phase_shekhar21No ratings yet

- YCMOU-6th Semester Question Papers-14Document6 pagesYCMOU-6th Semester Question Papers-14phase_shekhar21No ratings yet

- YCMOU-6th Semester Question Papers-10Document4 pagesYCMOU-6th Semester Question Papers-10phase_shekhar21No ratings yet

- YCMOU-6th Semester Question Papers-11Document4 pagesYCMOU-6th Semester Question Papers-11phase_shekhar21No ratings yet

- Ycmou Ast PQP t35 s05 200909 RevisedDocument2 pagesYcmou Ast PQP t35 s05 200909 Revisedphase_shekhar21No ratings yet

- YCMOU-6th Semester Question Papers-13Document6 pagesYCMOU-6th Semester Question Papers-13phase_shekhar21No ratings yet

- YCMOU-6th Semester Question Papers-9Document5 pagesYCMOU-6th Semester Question Papers-9phase_shekhar21No ratings yet

- Ycmou Ast PQP T35 S05 201108Document9 pagesYcmou Ast PQP T35 S05 201108phase_shekhar21No ratings yet

- YCMOU-6th Semester Question Papers-5Document4 pagesYCMOU-6th Semester Question Papers-5phase_shekhar21No ratings yet

- YCMOU-6th Semester Question Papers-7Document5 pagesYCMOU-6th Semester Question Papers-7phase_shekhar21No ratings yet

- B.Tech Engineering Programmes (ESEP/MEEP) Model Question Paper' With Synoptic Answer Key' TML062 / TES062: Entrepreneurship DevelopmentDocument9 pagesB.Tech Engineering Programmes (ESEP/MEEP) Model Question Paper' With Synoptic Answer Key' TML062 / TES062: Entrepreneurship Developmentphase_shekhar21No ratings yet

- YCMOU-6th Semester Question Papers-2Document6 pagesYCMOU-6th Semester Question Papers-2phase_shekhar21No ratings yet

- YCMOU-6th Semester Question Papers-3Document6 pagesYCMOU-6th Semester Question Papers-3phase_shekhar21No ratings yet

- Ycmou Ast PQP T35 S05 201102Document11 pagesYcmou Ast PQP T35 S05 201102phase_shekhar21No ratings yet

- Ycmou Ast PQP T35 S05 201008Document8 pagesYcmou Ast PQP T35 S05 201008phase_shekhar21No ratings yet

- Ycmou Ast PQP t35 s05 201002 RevisedDocument2 pagesYcmou Ast PQP t35 s05 201002 Revisedphase_shekhar21No ratings yet

- YCMOU-6th Semester Question Papers-4Document6 pagesYCMOU-6th Semester Question Papers-4phase_shekhar21No ratings yet

- Ycmou Ast PQP T35 S05 201201Document13 pagesYcmou Ast PQP T35 S05 201201phase_shekhar21No ratings yet

- Ycmou Ast PQP t35 s05 200808 RevisedDocument2 pagesYcmou Ast PQP t35 s05 200808 Revisedphase_shekhar21No ratings yet

- Ycmou Ast PQP t35 s05 200908 RevisedDocument2 pagesYcmou Ast PQP t35 s05 200908 Revisedphase_shekhar21No ratings yet

- Ycmou Ast PQP T35 S05 200702Document10 pagesYcmou Ast PQP T35 S05 200702phase_shekhar21No ratings yet

- Ycmou Ast PQP t35 s05 200802 RevisedDocument2 pagesYcmou Ast PQP t35 s05 200802 Revisedphase_shekhar21No ratings yet

- Ycmou Ast PQP T35 S05 200708Document9 pagesYcmou Ast PQP T35 S05 200708phase_shekhar21No ratings yet

- Rooftex BrochureDocument2 pagesRooftex BrochureTRAG ProjectsNo ratings yet

- - 22 - نسخةDocument10 pages- 22 - نسخةteaNo ratings yet

- HAY Paper PDFDocument15 pagesHAY Paper PDFTehseen MarwatNo ratings yet

- Sar1 AgarDocument197 pagesSar1 AgarAvinash ChimkarNo ratings yet

- Chismtry Form 2 Government BookDocument119 pagesChismtry Form 2 Government BookAmal AwaleNo ratings yet

- Design of SlabDocument7 pagesDesign of SlabAlam Mohammad Parvez SaifiNo ratings yet

- Lks 1900 AnDocument91 pagesLks 1900 AnLuis Enrique Bermudez HernandezNo ratings yet

- Experiment 402 Plane and Spherical Mirrors (Analysis and Conclusion)Document2 pagesExperiment 402 Plane and Spherical Mirrors (Analysis and Conclusion)zidrick benjaminNo ratings yet

- 16kw ManualDocument48 pages16kw ManualJamesBrionesNo ratings yet

- I. Melc.: Perpetual Succour Academy, Inc. National Rd. Poblacion Dos, Malabuyoc, Cebu Science 10Document4 pagesI. Melc.: Perpetual Succour Academy, Inc. National Rd. Poblacion Dos, Malabuyoc, Cebu Science 10Cry BeroNo ratings yet

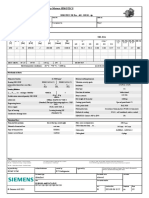

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1CV3407B Simotics SD Pro - 400 - Im B3 - 4PDocument2 pagesData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1CV3407B Simotics SD Pro - 400 - Im B3 - 4Pnadia perezNo ratings yet

- Fundamentals of Ultrasonic Phased Arrays - 171-180Document10 pagesFundamentals of Ultrasonic Phased Arrays - 171-180Kevin HuangNo ratings yet

- Overload Clutches For Index Drives (Type D-Sa, Adjustable) : Operating PrincipleDocument4 pagesOverload Clutches For Index Drives (Type D-Sa, Adjustable) : Operating PrincipleSuhas KODRENo ratings yet

- D38999/24WD35S N D38999/20WB35S N D38999/24WB35S N D38999/26WB35P N D38999/26WC35P NDocument49 pagesD38999/24WD35S N D38999/20WB35S N D38999/24WB35S N D38999/26WB35P N D38999/26WC35P NsdfsdfNo ratings yet

- Chapter 4-Behavior Evaluation of Vehicule Materials-Lecture 2Document44 pagesChapter 4-Behavior Evaluation of Vehicule Materials-Lecture 2roy barmoNo ratings yet

- Class 12 Physics Derivations Shobhit NirwanDocument6 pagesClass 12 Physics Derivations Shobhit Nirwanaastha.sawlaniNo ratings yet

- e Mastermig 300Document2 pagese Mastermig 300Janaka ChathurangaNo ratings yet

- Night Vision Technology1Document20 pagesNight Vision Technology1Srinivas RaoNo ratings yet

- Unit 2Document2 pagesUnit 2Rohit GhulanavarNo ratings yet

- Pryda Bracing Design Guide 2022Document32 pagesPryda Bracing Design Guide 2022benjaminsigabalavuNo ratings yet

- Final Exam MA and MBDocument6 pagesFinal Exam MA and MBعبدالله حامد الرفاعيNo ratings yet

- MD Product Catalogue PROXIMITY ENGDocument194 pagesMD Product Catalogue PROXIMITY ENGETIENNENo ratings yet

- Equation of MotionDocument61 pagesEquation of MotionMd CassimNo ratings yet

- Achenbach - 1995 - Heat and Flow Characteristics of Packed BedsDocument11 pagesAchenbach - 1995 - Heat and Flow Characteristics of Packed BedsDOUGLAS RAMON RODRIGUEZ ORDOÑEZNo ratings yet

- User Manual: Product Type: Switching Power Supply Model Name: HG2, HP2, PSM, PSLDocument17 pagesUser Manual: Product Type: Switching Power Supply Model Name: HG2, HP2, PSM, PSLotrupon melliNo ratings yet

- A Review On Current Status and Challenges of Inorganic Phase Change Materials For Thermal Energy Storage SystemsDocument18 pagesA Review On Current Status and Challenges of Inorganic Phase Change Materials For Thermal Energy Storage SystemsAnagha GhoshNo ratings yet

- Physical Science - Semester End Project: The Electromagnetic SpectrumDocument4 pagesPhysical Science - Semester End Project: The Electromagnetic SpectrumBreanna HartNo ratings yet

- Product Specifications: AVA5-50FXDocument3 pagesProduct Specifications: AVA5-50FXhassan329100% (1)

- 13 - Wool-And-Coir-Fiber-Reinforced-Gypsum-Ceiling-Tiles-Wit - 2021 - Journal-of-BuilDocument9 pages13 - Wool-And-Coir-Fiber-Reinforced-Gypsum-Ceiling-Tiles-Wit - 2021 - Journal-of-BuilJenifer TejadaNo ratings yet