Professional Documents

Culture Documents

Testing and Maintaining High-Voltage Bushings

Uploaded by

protectionworkOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Testing and Maintaining High-Voltage Bushings

Uploaded by

protectionworkCopyright:

Available Formats

TESTING AND MAINTENANCE OF HIGH-VOLTAGE BUSHINGS

February 1999

WESTERN AREA POWER ADMINISTRATION POWER SYSTEM MAINTENANCE MANUAL

CHAPTER 6

APPROVED FOR PUBLICATION AND DISTRIBUTION AS A WORKING CHAPTER*

Dennis A. Schurman Team Leader, Maintenance

Date *To Be Revised In Approximately One Year

ACKNOWLEDGEMENTS Thanks to the following workgroup members for their efforts in developing this document: Earl Bonneau, Desert Southwest Region Mark Buchholz, Upper Great Plains Region Ken Mathias, Corporate Services Office John Quintana, Corporate Services Office Chuck Rich, Corporate Services Office Phil Sanchez, Sierra Nevada Region Steve Upton, Rocky Mountain Region

ii

DISCLAIMER The information contained in this manual regarding commercial products or firms may not be used for advertising or promotional purposes and is not to be construed as an endorsement by Western Area Power Administration (Western) of any product or firm. The information contained in this manual was developed for Western; no warranty as to the accuracy, usefulness, or completeness is expressed or implied when used by other entities.

iii

PREFACE This guide is issued by the Western Area Power Administration (Western) and is designed to provide specific guidelines, instructions, procedures, and criteria for maintenance performed on all types of high-voltage bushings. Procedures and guidelines are in accordance with and supplement Westerns Power System Safety Manual (PSSM). Corrections and comments concerning this guide may be addressed to: Western Area Power Administration Corporate Services Office Attn: A3900, Design (Maintenance) P.O. Box 3402 Golden, Colorado 80401-0098

iv

PROPOSED REVISION TO POWER SYSTEM MAINTENANCE MANUAL, CHAPTER 6, TESTING AND MAINTENANCE OF HIGH-VOLTAGE BUSHINGS Type of Revision: Addition, Deletion, Rewording, Other (CIRCLE ONE) Suggest New Wording: Section Number:

Reason For Revision:

Revision Recommended By: Mail Code: Date: If Additional Space Is Needed: Attach Necessary Pages. Please Return To: Western Area Power Administration Attn: A3900, Design (Maintenance) P.O. Box 3402 Golden, Colorado 80401-0098

TABLE OF CONTENTS SECTION 1. 2. TYPES OF BUSHINGS SAFETY 2.1 Handling 2.2 Static Charges 2.3 Field Testing BUSHING FAILURES MAINTENANCE, INSPECTION, AND TESTING 4.1 General 4.2 Visual Inspection 4.3 Maintenance Tests 4.4 Record Keeping STORAGE OF BUSHINGS REFERENCES PAGE 1 2 2 2 3 3 4 4 4 5 8 8 8

3. 4.

5. 6.

LIST OF EXHIBITS EXHIBIT 1. 2. 3. Bushing Failures Permissible Test Potentials to be Applied to Power Factor Taps Manufacturers Power Factor Limits for Bushings PAGE 10 12 13

vi

1. TYPES OF BUSHINGS Testing and maintaining high-voltage bushings are essential for continued successful operation of an electric transmission system. Power outages may occur as the result of a bushing failure. This manual provides a general description of bushings that are currently in use, causes for potential bushing failures, and guidelines for properly inspecting and maintaining bushings. High-voltage bushings used on transformers and breakers exist in many forms, including: $ Composite - A bushing where the insulation consists of two or more coaxial layers of different insulating materials. $ Compound-filled - A bushing where the space between the major insulation or conductor, if no major insulation is used, and the inside surface of a protective weather casing (usually porcelain) is filled with a compound that contains insulating properties. $ Condenser - A bushing where cylindrical conducting layers are arranged coaxial with the conductor within the insulating material. The length and diameter of the cylinders are designed to control the distribution of the electric field in and over the outer surface of the bushing. Condenser bushings may be: - Resin-bonded paper-insulation, - Oil-impregnated paper-insulation, or - Other. $ Dry or unfilled - A bushing consisting of a porcelain tube with no filler in the space between the shell and the conductor. These are usually rated 25 kilovolts and below. $ Oil-filled - A bushing where the space between the major insulation or the conductor, if no major insulation is used, and the inside surface of a protective weather casing is filled with insulating oil. $ Oil-immersed - A bushing composed of major insulators totally immersed in a bath of insulating oil. $ Oil-impregnated paper-insulated - A bushing where the internal structure is made of cellulose material impregnated with oil. $ Resin-bonded paper-insulated - A bushing where cellulose material bonded with resin provides the major insulation. $ Solid, ceramic - A bushing which contains a ceramic or other similar material as the major insulation. 1

$ Sulfur hexafluoride (SF6) gas filled - A bushing where the space between the shell and conductor is filled with SF6 gas. 2. SAFETY At all times, safety is the most important consideration. All testing and maintenance work on bushings shall be performed in accordance with the latest revision of the Power System Safety Manual (PSSM) which establishes safety standards and safe work practices for operation and maintenance activities performed by Western Area Power Administration (Western). The following safety rules are not intended to override safety practices established by individual Regional Offices or included in the PSSM. 2.1 Handling. When handling bushings, care must be taken to ensure that proper rigging is applied to prevent injury to personnel and damage to the bushing as well as to adjacent equipment. Watch for cracked or chipped porcelain on the bushings. This may produce sharp edges that can result in severe cuts on the hands and arms of personnel who are handling or working around them. Fractured bushings may be under high compressive forces. Therefore, wrap any fractured bushing with several turns of heavy canvas tied securely in place before attempting any movement. Take extra care when working on or around SF6 bushings as they are under pressure. In particular, bushings should be depressurized before commencing work on them, and pressurized following completion of work as per Power System Maintenance Manual (PSMM) Chapter 4 Maintenance and Handling of gas insulation. During maintenance an SF6 gas cart should be used to process the gas in a closed-loop system and prevent loss to the atmosphere. To ensure that all environmental regulations are being followed periodic checks should be made with the Regional Environmental Office. Using bushings on substation equipment for anchorage or climbing is not recommended. The use of SF6 bushings as an anchorage is not permitted. 2.2 Static Charges. Static charges on the bushings may be induced by test potentials. While the voltage may not be significant enough to do damage, it can provide a source for serious accidents through falls caused by reflex action. High static voltages may be encountered at the bushings installed in apparatus during cold weather and oil-handling operations. Use protective or safety grounds to bleed off static charges. High static charges may also be encountered at the bushing capacitance taps if the covers are removed. Also use safety grounds before handling.

Employees should be constantly aware of the possibility of induced charges and the dangers involved. Induced voltages from nearby energized lines can cause serious accidents if they are not handled properly. Apply protective grounds to the de-energized circuit at the bushings to be inspected. If you are conducting electrical tests and the grounded leads interfere with such tests, they may be removed during the test period but should be reinstalled immediately after completion of the tests. (Refer to the PSMM, chapter 1, for further instructions.) 2.3 Field Testing. Field testing of high-voltage bushings generally requires work in the proximity of energized equipment. Before beginning field tests on bushings, perform a job hazard analysis (if warranted) and conduct a short safety meeting on the site. Only trained personnel who are knowledgeable in testing procedures and safety requirements will be allowed to perform the tests. Adjacent high-voltage equipment, which may be hazardous to workmen, should be marked with clearance tags or visible warning devices: such as, tape, rope, portable fence sections, etc. Place signs reading "DANGER HIGH-VOLTAGE" or similar notices along the barriers facing the working area. While performing power factor testing on bushings, ensure that all personnel maintain minimum approach distances from all equipment energized by the test equipment. 3. BUSHING FAILURES Bushings, if allowed to deteriorate, may explode with considerable force and cause extensive damage to adjacent equipment or injury to personnel. Operating records show that the majority of all preventable bushing failures occur when moisture enters the bushing through leaky gaskets or other openings. Close periodic inspection of bushings coupled with power factor insulation testing can lead to early detection of moisture, contamination, or insulation deterioration. These early findings, together with the appropriate corrective action, will prevent most outages due to bushing failures. Such inspections and testing require little time and expense and are well worth the effort. Another form of bushing failure is called a flashover, which may be caused by deposits of contamination or moisture on the bushings, particularly in areas where contaminants such as salts or conducting dusts are present in the air. These deposits should be removed by periodic cleaning. Exhibit 1 provides a more complete list of common bushing failures and the inspection methods used to detect them.

4. MAINTENANCE, INSPECTION, AND TESTING 4.1 General. Inspect all high-voltage bushings periodically at intervals determined by the manufacturers or the Regional Offices. The inspections should include power factor tests for all bushings rated 115 kilovolts and above. Also test lower voltage bushings if conditions suggest that they may be deteriorated. Bushings that do exhibit signs of deterioration should be tested whenever necessary to monitor the condition of the insulation system and removed from service if the tests indicate a dangerous condition. 4.2 Visual Inspection. During the visual inspection, examine the following components: (1) Porcelain - Check for chips, cracks, and contamination. Minor chips may be painted with an insulating varnish to obtain a glossy finish, which will shed dirt and moisture. Superficial cracks that do not affect the mechanical or electrical strength of the bushing may be sealed with insulating varnish or epoxy. Bushings with major chips or cracks, which appreciably decrease the creep distance, should be replaced. The surface of the porcelain should be cleaned as needed to remove dirt, oil, and other deposits that may reduce the flashover value. (2) Terminal caps and connectors - Check for tightness to avoid poor contact and resultant heating. (3) Capacitance taps and power factor test electrodes - Determine proper grounding for bushings with a grounded capacitance tap and for power factor test electrodes. Examine for proper gasket placement to prevent moisture from entering the bushing. (4) Oil level - Check the oil level on bushings equipped with sight gauges or other types of oil level indicators and add oil as necessary. Low oil levels with no sign of an external leak may indicate a leak within the bushings. This may require replacement of the bushing since field corrections would be difficult to accomplish. The oil level of bushings without oil level indicators is not normally checked unless there is evidence of leakage. CAUTION: When oil leaks are found contact the Regional Environmental Office and if possible, test the oil for polychlorinated biphenyl (PCB) contamination to address safe handling/disposal procedures. The testing and analysis are particularly important if the bushing was manufactured prior to 1981, is suspected of containing PCBs, or the oil has never been previously tested. (5) Oil Color - Noticeable difference in the color of the oil in matching bushings should be investigated. (6) Cement - Check for crumbling or chipped cement on the bushing and repair as required. (7) Gaskets - Check bushing gaskets for deterioration, looseness, and leaking. Replace loose gaskets or, if applicable, paint with a suitable oilproof sealer (such as General Electric 4

glyptal lacquer) and tighten. Finding a loose gasket or seal may mean that moisture has entered the bushing; therefore, further inspection and testing may be required to determine if moisture is present. If moisture is present in the bushing, the bushing should be dried out or replaced. (8) Metal parts - Check and paint all metal parts on the bushing as necessary. Examine structural parts such as clamping rings and washers for cracks, corrosion, or breaks. On SF6 gas breakers, cracks in the area where the metal flange holds the porcelain warrants removal from service (9) Solder seals - Check for cracks and leaks in solder seals and repair as necessary. 4.3 Maintenance Tests. Common maintenance tests include power factor, radio-influence voltage, direct current (dc) insulation resistance, as well as testing oil or compound for moisture. Optional tests are dissolved gas-in-oil and thermographic scanning. Descriptions of these tests follow. 4.3.1 The Power Factor Test. The power factor test is the most effective known field test procedure for the early detection of bushing contamination and deterioration. It also measures alternating (ac) test current, which is directly proportional to bushing capacitance. Note: Large variations in temperature significantly affect power factor readings on certain types of bushings. For comparative purposes, readings should be taken at the same temperature. Corrections should be applied before comparing readings taken at different temperatures. Bushings may be tested by one or more of four methods, depending upon the type of bushing and the power factor test set available. For more detailed instructions on this test procedure, see the power factor test set instruction book from the appropriate manufacturer. Descriptions of the four test methods follow. 4.3.1.1 The Grounded Specimen Test (GST). This test measures the qualities of the insulation between the current carrying or center conductor and the mounting flange of a bushing. This test is conducted on bushings that have been removed from equipment, bushings connected to de-energized equipment, spare bushings, or bushings that have been isolated from connected windings and interrupters. The test is performed by energizing the bushing conductor and grounding the flange. 4.3.1.2 The Hot Guard Test. This test measures the insulation between the current carrying or center conductor and the mounting flange of a bushing. The test was designed specifically for Adraw-lead@ type bushings, but is applicable to any bushing that can be isolated from the equipment and the bus. In transformers, both the bushing and the draw-lead, winding, and the bus are energized at the same test potential, but only the current and watt losses of the bushing are measured. 5

4.3.1.3 The Ungrounded Specimen Test (UST). This test measures the insulation between the current carrying or center conductor and the capacitance tap, power factor tap, and/or ungrounded flange of a bushing. This test may be applied to any bushing in or out of the apparatus that is either equipped with capacitance or power factor taps, or with the flange which can be isolated from the grounded tank in which the bushing is installed. The insulation resistance between the taps or insulated flanges and ground should be 0.5 megohm or greater. While in this case anything that is attached to the bushing would also be energized, only the insulation of the bushing between the center conductor and the ungrounded tap or flange would be measured. In the case of bushings equipped with capacitance taps, a supplementary test should always be made on the insulation between the tap and the flange. Most manufacturers list the UST power factor and capacitance values on the bushing nameplate. 4.3.1.4 The Hot-Collar Test. This test measures the condition of a specific small section of bushing insulation between an area of the upper porcelain rain shed and the current carrying or center conductor. The test is performed by energizing one or more electrodes placed around the bushing porcelain with the bushing center conductor grounded. This test is used to supplement the three previous tests. It is also used to test bushings in apparatus when the three tests are either inapplicable or impractical, such as, with SF6 bushings. Perform a hot-collar test at every third skirt on SF6 bushings. Hot-collar tests are effective in locating cracks in porcelain, deterioration, or contamination of insulation in the upper section of a bushing, low compound or liquid level, or voids in compound often before such defects are noticeable with the previous tests. When bushings with capacitance or potential taps rated at 92 kilovolts and above are tested by the ungrounded test specimen method, a separate power factor test on the tap insulation should be performed as well. The exceptions to this practice are the General Electric Company bushings built prior to 1932, which have tap outlets designed to operate at less than 100 volts. On all other capacitance or potential taps, tests are performed at a voltage between 500 and 5,000 volts. The tap is energized with the bushing center conductor and flange grounded. The power factor of a capacitance or potential tap will generally be of the order of 1.0 percent or less. Routine tap insulation tests are not normally recommended for bushings that are rated 69 kilovolts and below with power factor taps. However, a power factor test of the tap insulation should be performed when UST results are questionable or visual examination indicates the power factor taps condition is questionable. This test procedure is similar to that used earlier for capacitance taps. In such cases, the maximum permissible test potentials should be limited to those given in Exhibit 2 or as recommended by the bushing manufacturer. 6

The power factor value of the power factor tap insulation for most of the bushings discussed earlier is generally in the order of 1.0 percent or less. The principal exception to this is the Ohio Brass type L bushing. The inherent properties of the fibrous Bakelite material used for the tap insulator have resulted in power factors up to 10 percent for apparently satisfactory taps. The tabulations in Exhibit 3 of typical power factors and power factor limits were initially published by the manufacturers. However, the typical or initial power factor of many bushings is listed on the nameplate. In such cases, field measurement, particularly UST, should compare with the nameplate power factors. In general, any bushing that exhibits a history of continuing increase in power factor should be questioned and scheduled for removal from service. Measured power factor values should be temperature corrected to 20EC before being compared with Exhibit 3. 4.3.2 The Radio-Influence Voltage (RIV) Test. This test can detect corona in resinbonded, solid core noncondenser bushings. Methods of measuring RIV are described in the National Electrical Manufacturers Association (NEMA) Publication No. 107 (1976). Liquid filled bushings generally have a low RIV value. A high RIV value on this type of bushing that cannot be reduced by cleaning the porcelain indicates that the level of the filling liquid should be checked. 4.3.3 The dc Insulation Resistance Test. This test cannot generally be relied on to detect early contamination in bushings. When dc insulation resistance detects bushing deterioration, it is generally in an advanced stage of deterioration requiring immediate attention. A megger test using a 2,500 volt megger may be used for an insulation resistance check, but a high reading should not be completely relied upon as indicating a good bushing. Any bushing testing less than 20,000 megohms has questionable insulating value. 4.3.4 The Hot-Wire Test for Moisture. Plastic compound used in compound-filled bushings may absorb moisture if there are leaks through the shell or cap. A moisture content of as little as 0.15 percent in soft compounds can be detected by pushing a red hot rod into the compound. If moisture is present, a crackling, sputtering, or hissing sound will be heard. If no moisture is present, the compound will melt quietly. Another test is to put some compound on a wire and melt it in the flame of a match. If moisture is present, there will be a sputtering sound and small sparks will be thrown off. Dry compound will melt without disturbance. 4.3.5 Testing Oil for Moisture. Whenever moisture is suspected in the oil of an oil-filled bushing or found after performing a bushing power factor test, drain the oil and test a sample according to American Society for Testing Materials (ASTM) test method D1533. Since the quantity of oil in a bushing is small, discard the old oil and refill the bushing with new oil. If 7

moisture is found in the oil, allow the bushing to dry out, and then add oil if necessary before returning it to service. 4.3.6 Dissolved Gas Analysis. If applicable and convenient, draw an oil sample from the bushing to determine the contents of combustible gases. Presence of acetylene and abnormal levels of other combustible gases normally indicates arcing and corona conditions in the bushing. This test should not be performed routinely but rather when necessary. 4.3.7 Thermographic Scanning. Scanning for localized heat emissions (hotspots) using a thermographic device such as an infrared scanner can reveal loose connections, deteriorated terminations, and/or corona activity in bushings. Therefore, it is recommended that inservice bushings be scanned for hotspots at least every 5 years or whenever necessary. 4.4 Recordkeeping. Documenting the testing, inspection, and repair of bushings is very useful in comparing future tests and inspection results, and for determining when to replace the bushings. Therefore, each operating office should maintain proper documentation of such activities. 5. STORAGE OF BUSHINGS Always follow the manufacturer's instructions for storing bushings. The following are general guidelines for the storage of bushings: $ Bushings should be stored where they will not be subject to mechanical damage, preferably in the vertical position on a rack. $ Bushings with exposed paper insulation on the lower end require special protection to prevent moisture contamination. This can be accomplished by storing the bushing in a tank or tub filled with oil or by covering the bushing with a special moisture proof wrapping. Completely sealed outdoor bushings may be stored outdoors. $ Liquid- and compound-filled bushings should never be stored in a horizontal position. Storage in a horizontal position can introduce voids or air bubbles into the filler insulation. $ The condition of stored bushings should be checked periodically for oil level, mechanical damage, and power factor as described in Section 4 of this manual. The power factor of a stored bushing should be checked before the bushing is placed in service. 6. REFERENCES Apparatus Bushing Reference Book, Bulletin GET-2525, General Electric Co. NEMA Publication No. 1071964. Reaffirmed by NEMA 1976-Methods of Measurement of Radio

Influence Voltage of High Voltage Apparatus, National Electrical Manufacturers Association, 2101 L Street NW, Washington, D.C. 20037. Doble Power Factor Bushing Field Test Guide, Watertown, Mass., Doble Engineering Co., 1997. Hubert, Charles L., Preventive Maintenance of Electrical Equipment, New York, McGraw-Hill Book Co., 1969. IEEE Standard 21, IEEE General Requirements and Test Procedure for Outdoor Apparatus Bushings, published by the Institute of Electrical and Electronic Engineers, Inc., latest revision. Manual of Westinghouse Outdoor Bushings Technical Data 33-360. Power System Maintenance Manual, Chapter 1, APersonal Protective Grounding@, Western Area Power Administration, latest revision. Power System Maintenance Manual, Chapter 4, AMaintenance and Handling of Gas Insulation, Western Area Power Administration, latest revision. Power System Safety Manual, Golden, Colo., Western Area Power Administration, latest revision.

Exhibit 1. Bushing Failures Failure Cracked porcelain Possible Results Moisture enters Oil and/or gas leaks Filler leaks out Moisture enters Oil and/or gas leaks Filler leaks out Moisture enters Oil and/or gas leaks Filler leaks out Methods of Detection Visual inspection Power factor test Hot-collar test Visual inspection Power factor test Hot-collar test Visual inspection Power factor test Hot-collar test Hot-wire test for moisture Insulation resistance Power factor test Hot-collar test Visual inspection Power factor test Hot-collar test Hot-wire test for moisture Leak detector Power factor test Uncharacteristic odor Dissolved gas-in-oil Analysis (DGA) Thermographic scanning Hot-collar test Power factor test Visual inspection Power factor test Hot-collar test Visual inspection Power factor test Hot-collar test

Deterioration of Cemented joints Gasket leaks

Moisture in insulation Solder seal leak

Moisture enters Moisture enters Filler leaks out

Broken connection Between ground Sleeve and flange

Sparking in apparatus tank or within bushing Discolored oil Internal corona Filler contamination

Voids in compound Oil migration

No oil

Oil leaks out Moisture enters

10

Failure Displaced grading shield

Possible Results Internal sparking Discolors oil

Methods of Detection Hot-collar test Uncharacteristic odor Thermographic scanning DGA Visual inspection Hot-collar test Visual inspection Test lightning arresters Power factor test Hot-collar test Hot-wire test Radio-Influence Voltage (RIV) test Thermographic scanning DGA Power factor test Voltage test at capacitance tap Capacitance test Thermographic scanning DGA Power factor test Hot-collar test

Electrical flashover Lightning Corona

Cracked or broken porcelain Complete failure Cracked or broken porcelain Complete failure Internal breakdown Radio interference Treeing along surface of paper or internal surfaces

Short circuited condenser Sections

Increased capacitance Reduced voltage at capacitance tap terminal Adds internal stress to Insulation Radio interference Poor test results

Darkened oil

11

Exhibit 2. Permissible Test Potentials To Be Applied To Power Factor Taps (69 kV and Below)* Manufacturer ABB ASEA BBC Canadian General Electric General Electric Haefely Lapp Micafil Micanite & Insulators Ohio Brass Ohio Brass Passoni & Villa Pennsylvania (Federal Pacific) Westinghouse Bushing Type or Class O+C All GO Types CTF, CTKF U LC, U All POC WtxF All L GK, LK All P S, OS Test Voltage 1,000 500 500 1,000 500 500 1,000 500 500 250 500 500 500 500

* Reference: Bushing Field Test Guide; Doble Client Committee On Bushings, Insulators, And Instrument Transformers; Doble Engineering Company, Watertown, Massachusetts; 1997; page 7-7.

12

Exhibit 3. Manufacturers Power Factor Limits For Bushings* Manufacturer: Description Bushing Type or Class Typical Power Factor Limits (% at 20EC) Initial

Doubtful or Dangerous Questionable ASEA Brown Boveri (ABB): O+C 0.5 Double T 0.5 Nameplate Note: 1. Contact manufacturer if capacitance increases to 110% of original installed value. 2. Reference ABB instruction leaflet 44-666E dated July 1, 1990. 0.7 0.5 ASEA: GOA 250 0.5 0.7 GOB 0.7 GOBK 0.5 0.4 0.6 GOC Less Than 800 kV GOE 0.45 0.65 0.4 0.6 800 kV GOE 0.6 0.4 GOEK 0.6 GOEL 0.4 GOF 0.45 0.65 0.4 0.6 GOFL 0.65 0.45 GOG 0.45 GOH 0.25 GOM 0.45 0.65 0.45 0.65 GOA OTHER Note: 1. Up to a 3% change from nameplate capacitance is considered acceptable. 2. Remove from service when the difference between nameplate and measured C1 percent power factor exceeds 75%. 3. Reference ABB Components bulletin #2750 515E-56, dated 1990. * Reference: Bushing Field Test Guide; Doble Client Committee On Bushings, Insulators, And Instrument Transformers; Doble Engineering Company, Watertown, Massachusetts; 1997; page 7-18. 13

Manufacturer: Description

Bushing Type or Class

Power Factor Limits (% at 20EC) Typical 0.35 Initial Doubtful or Questionable 0.6 Dangerous

Bushing Company (Reyrolle Limited) OTA Includes: Micanite & Insulators (M&I) English Electric Ferranti Note: 1. Reference Bushing Company fax dated 9/1/1993.

General Electric: 5.0 A 3.0 Through Porcelain 1 2 1.0 2.0 A High Current, Solid Porcelain 12.0 B 5.0 Flexible Cable, Compound Filled 1 2.0 D 1.0 Oil-Filled Upper Portion, Sealed F 0.7 1.5 Oil-Filled, Sealed 1.5 3.0 L Oil-Filled Upper Portion, Sealed 3.0 LC 1.5 Oil-Filled Upper Portion, Sealed 2.0 OF 0.8 Oil-Filled, Expansion Chamber S 1.5 6.0 Forms C & CG, Rigid Core, 1 Compound Filled 0.5 1.0 Oil-Filled, Sealed U 1.0 T 0.5 Oil-Filled, Sealed Note: 1. Type S, Forms F, DF, and EF (flexible cable) redesigned as Types B, BD, and BE, respectively, no form letter (through porcelain redesigned as Type A). 2. Modern high current oil-filled solid porcelain design.

14

Manufacturer: Description

Bushing Type or Class

Power Factor Limits (% at 20EC) Typical Initial Doubtful or Questionable Dangerous

Haefeley Trench: Under 1400 kV BIL COTA 0.3 Double 1400 kV BIL And Above COTA 0.35 Nameplate Note: 1. C1 capacitance is doubtful if 10% over nameplate. 2. C1 capacitance is doubtful if 5% over first measurement in field after installation. 3. C2 capacitance may vary by 20%. Reference Haefeley fax dated April 5, 1994. 4. Some bushings, 115 kV and above, which have potential taps, have C1 nameplate capacitance based on factory tests made on the test tap. The test tap is then buried and unavailable to the user. The user instead tests the bushing using the potential tap where and the capacitance appears to be high compared to the nameplate values. The capacitance obtained in the field must be modified as follows: C1 (Doble Field Test)=(C1 (Haefeley)*C2 (Haefeley))/(C2 (Haefeley)-C1 (Haefeley)), where C1 (Haefeley) and C2 (Haefeley) are the nameplate capacitances. 5. Reference Haefeley fax dated April 3, 1995. Lapp: Paper Oil Condenser type; Totally POC & PA 0.5 1.5 Enclosed, 23-69 kV Paper Resin Condenser Core PRC & PRC-A 0.8 1.5 Paper Epoxy hard core type; No ERC 0.8 1.5 Lower Porcelain

15

Manufacturer: Description

Bushing Type or Class

Power Factor Limits (% at 20EC) Typical Initial Doubtful or Questionable Dangerous

Ohio Brass Company: Oil-Filled ODOF Initial Value Manufactured Prior To 1926 And CLASS G & I 1.0-5.0 +22% After 1938 CLASS G & I 2.0-4.0 Initial Value Manufactured 1926 To 1938 +22% Inclusive 0.4 1.0 Oil Impregnated Paper Condenser C Core, Oil-Filled, 15 To 196 kV CLASS GK Resin Paper Condenser Core, OilA 0.4 1.0 Filled, 23 To 69 kV CLASS LK Note: 1. References: a. Initial values for new bushings from 1944 Doble Client Conference Minutes, Section 4-603 and 4-604. b. Dangerous values for in service bushings from 1946 Doble Client Conference Minutes, Section 4-303. c. Contact Ohio Brass Company for recommendations for reconditioning bushings before the power factor reaches the dangerous value. d. Ohio Brass Condenser Type Bushings have normal power factors from 0.5% to 1.0% at 20oC from Ohio Brass Publication Number 1354-H. e. The reasons for differences between power factors measured by the grounded and ungrounded-specimen test methods on certain Ohio Brass bushings are discussed in the 1954 Doble Client Conference Minutes, Section 4-501. 2. Starting approximately in 1940, Ohio Brass bushing nameplates give over-all power factor and watts-loss at 10 kV as measured at the factory in air. Bushings tested in good oil will usually have a lower power factor.

16

Manufacturer: Description Passoni & Villa:

Bushing Type or Class

Power Factor Limits (% at 20EC) Typical Initial Doubtful or Questionable 0.7 0.7 Dangerous

PNO 0.4 PAO 0.4 Note: 1. Reference Passoni & Villa bulletin # 1005, dated 1992. Pennsylvania Transformer (Federal Pacific Electric): Paper Oil Condenser Type, Totally Enclosed, 69 To 196 kV Westinghouse: Semi-Condenser Type Condenser 69 kV And Below, Except Types S And OS 92 kV To 138 kV, Except Type O 161 kV To 288 kV

P, PA, & PB

0.5

Less Than 0.65

1.0

D 1.5 3.0 S & OS 0.8 2.0 OCB and Inst. 1.5 3.0 Trans. OCB and Inst. 1.5 3.0 Trans. Power and 1.0 2.0 Dist. Trans. Of all ratings, and OCB and Inst. Trans. O & O-AL Oil-Filled, 92 kV To 288 kV 0.3 1.0 Plush Bushings O 0.3 1.0 Solid Porcelain RJ 1.0 2.0 Note: 1. Increase in capacitance of 15% (10% for Type O) indicates short-circuited condenser sections.

17

You might also like

- Electrical Bushings GuideDocument49 pagesElectrical Bushings GuideShang Divina EbradaNo ratings yet

- Insulation Co-ordination in High-voltage Electric Power SystemsFrom EverandInsulation Co-ordination in High-voltage Electric Power SystemsRating: 4.5 out of 5 stars4.5/5 (5)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Location of Tap-Changer SwitchDocument8 pagesLocation of Tap-Changer SwitchAbdulyunus AmirNo ratings yet

- The Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsFrom EverandThe Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsNo ratings yet

- Eatech UltraTEV Plus ManualDocument51 pagesEatech UltraTEV Plus ManualChris ParkinsonNo ratings yet

- Dry Type Transformer TestingDocument4 pagesDry Type Transformer TestingGary Martin100% (1)

- CB Oper and ControlDocument7 pagesCB Oper and Controlpriyanka236No ratings yet

- Demagnetization of Power TransformersDocument8 pagesDemagnetization of Power TransformersbcqbaoNo ratings yet

- MPD 600 Self Test: Application NoteDocument7 pagesMPD 600 Self Test: Application NoteInsan AzizNo ratings yet

- F0126405 PB OLTCsDocument24 pagesF0126405 PB OLTCsDEADMANNo ratings yet

- CP TD1 Reference ManualDocument158 pagesCP TD1 Reference Manualjon1224No ratings yet

- Vacuum Oil Filling - Degassing - DehydratingDocument3 pagesVacuum Oil Filling - Degassing - Dehydratingraza239100% (1)

- Calculation of Zero Phase Sequence Impedance For Power Transformers Using Numerical MethodsDocument4 pagesCalculation of Zero Phase Sequence Impedance For Power Transformers Using Numerical MethodsMannepalli SrihariNo ratings yet

- On-Load Tap Changer Operating ManualDocument16 pagesOn-Load Tap Changer Operating ManualculwavesNo ratings yet

- Sweep Frequency Response Analysis SFRA TrainingDocument82 pagesSweep Frequency Response Analysis SFRA Trainingbcqbao100% (1)

- T-08 LTC Dga Guide AscheDocument7 pagesT-08 LTC Dga Guide Aschebcqbao100% (1)

- Thermal Stability of I.T. at SiteDocument4 pagesThermal Stability of I.T. at SiteBalubhai KarsanbhaiNo ratings yet

- Power Transformer Testing Brochure ENU PDFDocument36 pagesPower Transformer Testing Brochure ENU PDFsasenthil241464No ratings yet

- DRM of OltcDocument4 pagesDRM of OltcBestwick Braveen SylvesterNo ratings yet

- Omicron - Synchronous Multi-Channel PD Measurements and The Benefits For PD AnalysesDocument8 pagesOmicron - Synchronous Multi-Channel PD Measurements and The Benefits For PD AnalysesNguyen Vu Nhat HaNo ratings yet

- PTR 01-Introduction ENU PDFDocument29 pagesPTR 01-Introduction ENU PDFAhmed HasanNo ratings yet

- 66thA M E U C on v e n t i o n 2 0 1 7TITLE Stray Gassing Predictive MaintenanceDocument6 pages66thA M E U C on v e n t i o n 2 0 1 7TITLE Stray Gassing Predictive MaintenanceangelNo ratings yet

- M4110 User Guide Rev BDocument40 pagesM4110 User Guide Rev Bjcorreia10No ratings yet

- Power Dissipation FactorDocument12 pagesPower Dissipation Factor8miles123No ratings yet

- Little Known Facts About Dissipation Factor TestingDocument3 pagesLittle Known Facts About Dissipation Factor TestingedgardNo ratings yet

- Switch Analyzer SA10Document34 pagesSwitch Analyzer SA10Edwin QuispeNo ratings yet

- REVIEW NEGATIVE POWER FACTOR TEST RESULTS AND CASE STUDY ANALYSISDocument17 pagesREVIEW NEGATIVE POWER FACTOR TEST RESULTS AND CASE STUDY ANALYSISwalterpereiro100% (1)

- Doble M4000 User GuideDocument204 pagesDoble M4000 User GuidePablo Toro Lopez100% (1)

- On-Load Tap-Changers, Type UZ: Technical GuideDocument32 pagesOn-Load Tap-Changers, Type UZ: Technical GuideCristi GrosuNo ratings yet

- Method Statement For Partial Discharge Measurement: Application NoteDocument13 pagesMethod Statement For Partial Discharge Measurement: Application Notejmrs7322No ratings yet

- SFRA User GuideDocument96 pagesSFRA User GuideRyan JohnNo ratings yet

- ABB B.G. Controlled Switching Ed4 PDFDocument54 pagesABB B.G. Controlled Switching Ed4 PDFRamesh KannanNo ratings yet

- Methodology and Methods for Assessing Transformer ConditionDocument47 pagesMethodology and Methods for Assessing Transformer ConditionAshroof Abdo50% (2)

- Transformer Demagnetizing ProcedureDocument5 pagesTransformer Demagnetizing ProcedureMerlyn Jordano Choqque VilcaNo ratings yet

- Broken Conductor ProtectionDocument2 pagesBroken Conductor ProtectionThirumalNo ratings yet

- Auto-Transformer Design - A Practical Handbook for Manufacturers, Contractors and WiremenFrom EverandAuto-Transformer Design - A Practical Handbook for Manufacturers, Contractors and WiremenRating: 4 out of 5 stars4/5 (2)

- SF6-Gas Circuit Breakers GuideDocument20 pagesSF6-Gas Circuit Breakers GuideAhmed BadrNo ratings yet

- DIRANA Application Guide - Measuring and Analyzing Power Transformers PDFDocument33 pagesDIRANA Application Guide - Measuring and Analyzing Power Transformers PDFMatthew Franklin AdedejiNo ratings yet

- LCM500 Leakage Current Monitor: User GuideDocument74 pagesLCM500 Leakage Current Monitor: User GuideThien Nguyen VanNo ratings yet

- Capacitive Voltage Transformer TestingDocument7 pagesCapacitive Voltage Transformer TestingSaeedAhmedKhan100% (1)

- Instrument Transformers PDFDocument39 pagesInstrument Transformers PDFJuan Sebastián GómezNo ratings yet

- Doble Test ProceduresDocument21 pagesDoble Test ProceduresRamKumarNo ratings yet

- Test Data Reference Book (Secc 8 Power Transformers)Document146 pagesTest Data Reference Book (Secc 8 Power Transformers)J. Mauricio A. Bejarano100% (1)

- Floating Neutral Impact in Power DistributionDocument9 pagesFloating Neutral Impact in Power DistributionSugeng SumarnoNo ratings yet

- DELTA4000: Instruction ManualDocument74 pagesDELTA4000: Instruction ManualDon FreemanNo ratings yet

- Transformer OilDocument8 pagesTransformer OilMohammad Ibnul HossainNo ratings yet

- Analysis of Residual Life Estimation Methods for Power TransformersDocument19 pagesAnalysis of Residual Life Estimation Methods for Power TransformersJicheng PiaoNo ratings yet

- Transformer Testing by Afees Ahamed Egger IndiaDocument27 pagesTransformer Testing by Afees Ahamed Egger IndialrpatraNo ratings yet

- OMS 605 User Manual ENUDocument86 pagesOMS 605 User Manual ENUlatifNo ratings yet

- Doble Conference Transformer Testing ProceduresDocument150 pagesDoble Conference Transformer Testing ProceduresGlenys MuñozNo ratings yet

- DRTS 64Document8 pagesDRTS 64RAJESH KUMARNo ratings yet

- Bushings for Power Transformers: A Handbook for Power EngineersFrom EverandBushings for Power Transformers: A Handbook for Power EngineersRating: 1 out of 5 stars1/5 (1)

- Current Interruption Transients CalculationFrom EverandCurrent Interruption Transients CalculationRating: 4 out of 5 stars4/5 (1)

- Advances in High Voltage Insulation and Arc Interruption in SF6 and VacuumFrom EverandAdvances in High Voltage Insulation and Arc Interruption in SF6 and VacuumNo ratings yet

- Maintain High-Voltage BushingsDocument10 pagesMaintain High-Voltage BushingsNoé Rafael Colorado SósolNo ratings yet

- 26 Induction Motor DesignDocument21 pages26 Induction Motor DesignLatisha CarterNo ratings yet

- ABB Oy Low Voltage Products DocumentDocument2 pagesABB Oy Low Voltage Products DocumentprotectionworkNo ratings yet

- 1SCC340002M0010 Otp 16... 125Document2 pages1SCC340002M0010 Otp 16... 125protectionworkNo ratings yet

- 1SCC340006C0201 OT2GB07 - 09 Enclosed Safety Switches Switches, 16... 1000 ADocument71 pages1SCC340006C0201 OT2GB07 - 09 Enclosed Safety Switches Switches, 16... 1000 AprotectionworkNo ratings yet

- 1SCC340001M0008 Otp 16H3Document2 pages1SCC340001M0008 Otp 16H3protectionworkNo ratings yet

- Energy Conversion 17Document10 pagesEnergy Conversion 17protectionworkNo ratings yet

- Restricted Earth FaultDocument26 pagesRestricted Earth FaultAfsar AliNo ratings yet

- 2CDC190022D0201 FBP FieldBusPlug Components - Technical CatalogueDocument24 pages2CDC190022D0201 FBP FieldBusPlug Components - Technical CatalogueprotectionworkNo ratings yet

- 1SCC317003C0202Document23 pages1SCC317003C0202protectionworkNo ratings yet

- 1MRK502016-UEN B en Application Manual Generator Protection IED REG 670 1.1Document576 pages1MRK502016-UEN B en Application Manual Generator Protection IED REG 670 1.1protectionworkNo ratings yet

- ABB-DMI Type DC Machines Operating and Maintenance InstructionsDocument48 pagesABB-DMI Type DC Machines Operating and Maintenance InstructionsElafanNo ratings yet

- General Purpose Motors en 12 2006Document236 pagesGeneral Purpose Motors en 12 2006protectionwork100% (1)

- Prtoblem J BDocument24 pagesPrtoblem J BjhpandiNo ratings yet

- Ball BearingsDocument24 pagesBall BearingsHosein_s_milaniNo ratings yet

- Protection of Synchronous GeneratorsDocument117 pagesProtection of Synchronous GeneratorsprotectionworkNo ratings yet

- ABB Bearing Currents Abb Technical Guide 5Document24 pagesABB Bearing Currents Abb Technical Guide 5Fernando MuneraNo ratings yet

- 1MRK502016-UEN B en Application Manual Generator Protection IED REG 670 1.1Document576 pages1MRK502016-UEN B en Application Manual Generator Protection IED REG 670 1.1protectionworkNo ratings yet

- Electrical Fault AnalysisDocument44 pagesElectrical Fault AnalysisprotectionworkNo ratings yet

- 1MRK502013-UEN B en Technical Reference Manual Generator Protection IED REG 670 1.1Document864 pages1MRK502013-UEN B en Technical Reference Manual Generator Protection IED REG 670 1.1protectionwork100% (1)

- Temperature Control Unit 2009 - ArticleDocument2 pagesTemperature Control Unit 2009 - ArticleprotectionworkNo ratings yet

- 1VET954910-910 Arc EliminatorDocument4 pages1VET954910-910 Arc EliminatorprotectionworkNo ratings yet

- 1HSM 9543 23-02en Live Tank Circuit Breaker - Application Guide Ed1.1Document136 pages1HSM 9543 23-02en Live Tank Circuit Breaker - Application Guide Ed1.1zaidisofianNo ratings yet

- Medium Voltage AC DrivesDocument1 pageMedium Voltage AC DrivesFlo MircaNo ratings yet

- Three Phase Capacitor Unit Brochure (2003-06)Document2 pagesThree Phase Capacitor Unit Brochure (2003-06)protectionworkNo ratings yet

- Grounding and Cabling of The Drive System - Variable Speed DrivesDocument40 pagesGrounding and Cabling of The Drive System - Variable Speed DrivesMiguel AngelNo ratings yet

- Electrical Fault AnalysisDocument44 pagesElectrical Fault AnalysisprotectionworkNo ratings yet

- Medium Voltage AC DrivesDocument1 pageMedium Voltage AC DrivesFlo MircaNo ratings yet

- Erico - Practical Guide To Electrical Grounding PDFDocument131 pagesErico - Practical Guide To Electrical Grounding PDFperijoyNo ratings yet

- Fundamentals - ValvesDocument52 pagesFundamentals - Valvesapi-3808778100% (2)

- Fundamentals - ValvesDocument52 pagesFundamentals - Valvesapi-3808778100% (2)

- ChE 525: Physical & Chemical Principles Mock Board 3Document6 pagesChE 525: Physical & Chemical Principles Mock Board 3Kuo Garol SarongNo ratings yet

- 4 - ch01 - SQ - E: Solutions MarksDocument37 pages4 - ch01 - SQ - E: Solutions Marks5A35 YIP HOI PAKNo ratings yet

- Ul 854 - 2014 PDFDocument64 pagesUl 854 - 2014 PDFDouglasNo ratings yet

- Survey of Tea Vendors 01Document2 pagesSurvey of Tea Vendors 01Sandeep SinghNo ratings yet

- CV - Alok Singh - Tech HSE & Loss Prevention Engineer (May-2018)Document5 pagesCV - Alok Singh - Tech HSE & Loss Prevention Engineer (May-2018)toalok4723No ratings yet

- 1Document26 pages1Maribel Bihag AlcantaraNo ratings yet

- Sungris BrochureDocument8 pagesSungris Brochurechemasi123No ratings yet

- 50 Straw Bale House PlansDocument9 pages50 Straw Bale House Plansdarius-matuiza-81990% (1)

- Pipe Sizes and Flow Rates for Air Flush DrillingDocument14 pagesPipe Sizes and Flow Rates for Air Flush DrillingzapspazNo ratings yet

- Numatics Series 342Document6 pagesNumatics Series 342Jebran FarazNo ratings yet

- Power Generation SystemDocument72 pagesPower Generation SystemAbshir Mohamed HajjiNo ratings yet

- Volkswagen 2.0L TDI Common Rail Engine Service TrainingDocument90 pagesVolkswagen 2.0L TDI Common Rail Engine Service TrainingАлла Харютина100% (1)

- SIA Guidance Note 47Document11 pagesSIA Guidance Note 47Ali BiomyNo ratings yet

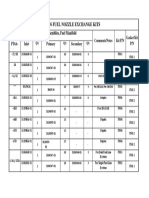

- Pt6 Fuel Nozzle Exchange Kits: Adapter Assemblies, Fuel ManifoldDocument1 pagePt6 Fuel Nozzle Exchange Kits: Adapter Assemblies, Fuel ManifoldBerchNo ratings yet

- LT AB Cable GTPsDocument3 pagesLT AB Cable GTPsnishant sainiNo ratings yet

- EXPANSION VALVES SERIES DOCUMENT (THERMOSTATIC & CONSTANT PRESSUREDocument44 pagesEXPANSION VALVES SERIES DOCUMENT (THERMOSTATIC & CONSTANT PRESSURESite EngineeringtiaNo ratings yet

- United States Patent (10) Patent No.: US 8,106,570 B2Document20 pagesUnited States Patent (10) Patent No.: US 8,106,570 B2zahra sdeghiniaNo ratings yet

- Universal Gen Controller Manual - Digital Display, 8 Inputs, 4 RelaysDocument21 pagesUniversal Gen Controller Manual - Digital Display, 8 Inputs, 4 RelaysBrianHazeNo ratings yet

- ELECTRONICDocument13 pagesELECTRONICMahmoued YasinNo ratings yet

- Automatic Street Light Control Using LDRDocument39 pagesAutomatic Street Light Control Using LDRAyush Kumar100% (1)

- Curriculum Vitae Yosep Kurniawan Basa SogenDocument19 pagesCurriculum Vitae Yosep Kurniawan Basa Sogenyosep kurniawanNo ratings yet

- CH 3 Gas Refrigeration CycleDocument20 pagesCH 3 Gas Refrigeration CycleMeleseNo ratings yet

- Lab 5Document9 pagesLab 5Cem UsmangilNo ratings yet

- Short and Open Circuit Test On TransformerDocument1 pageShort and Open Circuit Test On TransformerRyan DagsilNo ratings yet

- Air Cooler LeafletDocument2 pagesAir Cooler LeafletSaad zubayr MNo ratings yet

- Understanding ThermodynamicsDocument4 pagesUnderstanding Thermodynamicscory kurdapyaNo ratings yet

- OSHA Citations Against O&G and Ducci ElectricDocument107 pagesOSHA Citations Against O&G and Ducci ElectricRepublican-AmericanNo ratings yet

- Budget of Lesson Science 9Document14 pagesBudget of Lesson Science 9Hezl Valerie ArzadonNo ratings yet

- Optical Properties of MaterialDocument63 pagesOptical Properties of MaterialNoviNo ratings yet