Professional Documents

Culture Documents

Cross Head Removal For Man B&W

Uploaded by

Akshay AnkitOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cross Head Removal For Man B&W

Uploaded by

Akshay AnkitCopyright:

Available Formats

The reciprocating action of piston is converted into rotary motion for crankshaft by means of the cross head where

the piston rod and connecting rod are attached on both sides.

A routine maintenance has to be performed on crosshead bearing as per makers instruction. Following procedure is to be followed when carrying out crosshead bearing removal of a MAN MC-C engine: 1) Inform company and take permission. 2) Take immobilization certificate from port. 3) Read the manual and have a toll box meeting with everyone involved in the job. Discuss the procedure. 4) Prepare important tools and spares to be used in this operation 5) A risk assessment of all personnel doing the operation to be prepared and documented 6) Shut main engine starting air 7) Engage turning gear to the main engine crankshaft 8) Open indicator cocks of all cylinders 9) Stop main engine lube oil pump after cooling down of engine 10) Open crank case doors of fore and aft unit 11) Open crank case doors of that unit in which maintenance is to be carried out. 12) Put blower and ventilate the crankcase thoroughly as it is an enclosed space.

13) Prepare enclosed space entry checklist. 14) After sufficient ventilation wearing proper PPE you can enter the C/C. 15) Turn the crank throw to 90 before BDC. 16) Check the bearing clearance by inserting feeler gauge b/w bearing cap and crosshead journal exactly next to the landing surface of the piston rod foot.

17) The wear limit for a cross head bearing shell is limited to 50% reduction of the oil wedge length (L).[ L=10mm] 18) Turn the crankshaft down enough to give access to nuts and screws on piston rod. 19) Mount two chain blocks on the top of the crankcase for suspending the piston rod. 20) Loosen and remove the locking wire and screws on the piston rod foot.

21) Mount the lifting eye bolt on each side of the piston rod foot. 22) Turn the crosshead to TDC. 23) Hook the chain blocks to the eye bolt on the piston rod foot. And turn the crosshead down so that piston is now suspended on the chain blocks. 24) Turn to BDC. 25) Mount the hydraulic jack on the crosshead bearing cap nut and loosen them. [pressure : 1500-1650 bars] 26) Mount the lifting attachment on the head of the connecting rod. 27) Suspend the two chain blocks from the lifting brackets in the athwart ship direction.

28) Mount the 2 eye bolts on the top of the cross head bearing cap. 29) With the help of the two chain blocks lift the bearing cap. Take it out of the engine and place it on a wooden base. 30) To check the upper bearing shell, remove the locking screws and push the shell out. 31) Mount the chain blocks to the lifting brackets on the frame box wall.

32) Turn the crosshead up until the piston rod lands on the crosshead. Ensure that the guide ring in the crosshead fits correctly in the centre hole of the piston rod. 33) Do not remove the chain blocks or the lifting eye bolts.

34) Turn the crosshead to TDC and attach the chain blocks to the lifting arrangement and haul it tight. 35) Mount the four supports for the guide shoes on the crosshead guide. 36) Carefully and slowly turn the crankshaft towards to exhaust side and make sure the crosshead guide sits on the supports. 37) Turn the crank throw towards BDC slowly while following with the chain blocks, thus continuously supporting the connecting rod.

38) In case it is necessary to remove the lower bearing shell, tilt the connecting rod towards the door on the cam shaft side with means of chain blocks.

39) Dismount the locking screws and turn the bearing shell so far up that an eye bolt can be mounted. Lift the bearing shell out. Top clearance in crosshead bearing Max: 0.29mm Min: 0.17mm Video for Cross head bearing removal[vsw id="llij_8RgqDg" source="youtube" width="550" height="400" autoplay="no"] You may also like to read-Ways of starting and testing emergency generator Reference: Maintenance Manual MAN B&W MC-C engine Image Credits: Maintenance Manual MAN B&W MC-C engine patrix Related posts: Main Engine Liner Removal Procedure for S50MC-C Engine Procedure for Removing Main Bearing of MAN B&W MC-C Engine Chain Tightening Procedure for MAN B&W Engine Free Sample- Main Engine Bearing Report

Jack Bolts for Marine Engine and the Procedure for Tensioning

Do Like Us on Facebook

Follow Us on Twitter Top of Form

710848313 email marineinsight http://w w w .aw e end_of_article 1

FREE SIGN UP FOR MORE INTERESTING ARTICLES Email:

Bottom of Form Facebook comments: Leave a comment! Click here to cancel reply Top of Form Add your comment below, or trackback from your own site. You can also subscribe to these comments via RSS. Be nice. Keep it clean. Stay on topic. No spam. Name (required)

Mail (will not be published) (required) Website (optional)

9915 0 /tech/procedures

This is a Gravatar-enabled weblog. To get your own globally-recognized-avatar, please register at Gravatar.

Post Comment

2b31480d5a

Sign up to our newsletter!

9915

Bottom of Form Top of Form

2028323541 email marineinsight http://w w w .aw e personal_safety 1

Email:

Submit

Bottom of Form

Recent News Number of Pirate Attacks Sharply Decreased in 2011 Neptune Terminals Sets New Terminal Handling Record At 12.85 Million Metric Tonnes Simplifying Port Operation through Automated Balloon Cranes First True Hybrid System To Be Installed On Board An Offshore Supply Vessel Using BIM Technology to build the Panama Canal of the Future Dredging Corporation of India signs MOU with Ministry of Shipping for the year 2012-13 Dredging

Wrtsil Signs Long-Term Service Agreement With Prestige Cruise Holdings Popular Latest Comments

7 Reasons Deck Cadets and Junior Engineers are Not Getting JobsSeptember 5, 2011

Duties of a 4th Engineer on a ShipNovember 4, 2010

A Woman Chief Engineer from Brazil Describes Her Interesting LifeMarch 14, 2011

How to Synchronize Generators on a Ship?October 18, 2010

Bunkering is Dangerous : Procedure for Bunkering Operation on a ShipOctober 19, 2010

The Very First Flotel in the World: Edda FidesMarch 16, 2012

How to Charge Refrigeration Plant on Ships?March 16, 2012

Cargo Ship Mont-Blanc and the Halifax Explosion: Worlds Largest Man-made Accidental ExplosionMarch 15, 2012

10 Ways to Enhance the Security of a ShipMarch 15, 2012

How to Improve Energy Efficiency of Ships?March 13, 2012

ankush (DMET '08): Well said sir...

KABIR KHAN: THIS IS TRUE THAT MANY INSTITUTE ARE PROMISING 100...

Renjith: How do you remove excess charge in a reefer plant?...

datta rohakale: in gas charging in refer plant... after creatin...

Davis mwangi: Ma'am am v proud of you a really wanna be a marine... Top of Form

1634722164 email marinenew s http://w w w .aw e New s_-_Marine_ 1

Subscribe to Latest Maritime News Email:

Bottom of Form Random Posts

(refresh random posts) Latest Video Post Video : IMO Works to Make Ship Recycling Safer and Environmentally Friendly Resources 23 Places to Find Maritime Jobs What is the Salary of Seafarers? Best Maritime Colleges in the United States Top 6 Books on Marine Auxiliary Machinery 23 Maritime Forums and Discussion Boards Shore Jobs for Seafarers Top 5 Books on Marine Boiler How to find Contacts in Maritime Companies? Most Commented 7 Reasons Deck Cadets and Junior Engineers are Not Getting Jobs Duties of a 4th Engineer on a Ship A Woman Chief Engineer from Brazil Describes Her Interesting Life How to Synchronize Generators on a Ship? Bunkering is Dangerous : Procedure for Bunkering Operation on a Ship About Us Contact Us Subscribe to Marine Insight Privacy Policy Follow us on Twitter Follow us on Facebook Forums

Jobs Directory Copyright 2010 MarineInsight All Rights Reserved

Read more: http://www.marineinsight.com/tech/proceduresmaintenance/procedure-for-cross-headbearing-removal-for-marine-engine-man-bw-s50mc-c/#ixzz1pPKXCCta

You might also like

- Cross Head Removal For Man B WDocument13 pagesCross Head Removal For Man B WMOHAN100% (1)

- New Technologies for Emission Control in Marine Diesel EnginesFrom EverandNew Technologies for Emission Control in Marine Diesel EnginesNo ratings yet

- Procedure For Cross Head Bearing Removal of Marine EngineDocument6 pagesProcedure For Cross Head Bearing Removal of Marine EngineVenkatarama KrishnanNo ratings yet

- Southern Marine Engineering Desk Reference: Second Edition Volume IiFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiNo ratings yet

- Unit 17 - 02 - Starting & ManoeuvringDocument16 pagesUnit 17 - 02 - Starting & ManoeuvringAisha ZaheerNo ratings yet

- Naval Diesel Engineering: The Fundamentals of Operation, Performance and EfficiencyFrom EverandNaval Diesel Engineering: The Fundamentals of Operation, Performance and EfficiencyNo ratings yet

- Low Load and Low Sulphur Fuel Operation On Two Stroke Diesel EnginesDocument51 pagesLow Load and Low Sulphur Fuel Operation On Two Stroke Diesel EnginesTziouris Vasileios100% (1)

- Purpose of CrossheadDocument1 pagePurpose of CrossheadVijay ANo ratings yet

- Alpha Lubricator PresentationDocument42 pagesAlpha Lubricator Presentationimmyself100% (2)

- Marine Combustion Practice: The Commonwealth and International Library: Marine Engineering DivisionFrom EverandMarine Combustion Practice: The Commonwealth and International Library: Marine Engineering DivisionRating: 5 out of 5 stars5/5 (1)

- Main EngineDocument10 pagesMain EngineFe CaprichoNo ratings yet

- A Guide to Ship Repair Estimates in Man-hoursFrom EverandA Guide to Ship Repair Estimates in Man-hoursRating: 4.5 out of 5 stars4.5/5 (5)

- Slide Fuel ValvesDocument2 pagesSlide Fuel ValvesSpasoje100% (1)

- 08 - Gvernor - 01Document7 pages08 - Gvernor - 01Aisha Zaheer100% (2)

- MC EnginesDocument12 pagesMC EnginesHarpreet Singh100% (1)

- Vit and Super VitDocument2 pagesVit and Super VitPawan Beniwal60% (5)

- MAN B&W Diesel A/S: Service LetterDocument5 pagesMAN B&W Diesel A/S: Service LetterParthiban NagarajanNo ratings yet

- MAN-PMI Off PDFDocument92 pagesMAN-PMI Off PDFarunNo ratings yet

- Alpha Lubricator System OperationDocument190 pagesAlpha Lubricator System Operationlalinda67% (3)

- MAN Tech Paper Low SpeedDocument16 pagesMAN Tech Paper Low SpeedfusedNo ratings yet

- Diff Between Sulzer and B&W Crosshead LubricationDocument1 pageDiff Between Sulzer and B&W Crosshead LubricationVijay A100% (3)

- Guidelines - CE 2EDocument14 pagesGuidelines - CE 2ESUNILNo ratings yet

- Lambda Controller and Jet Assist System On ShipsDocument8 pagesLambda Controller and Jet Assist System On ShipsSwarg VibhaNo ratings yet

- MSC Carina Delivery 6 June 2013: Main Engine MAN 6S60ME-C 8.1Document5 pagesMSC Carina Delivery 6 June 2013: Main Engine MAN 6S60ME-C 8.1ПетрNo ratings yet

- Cylinder Liner Cold Corrosion ControlDocument8 pagesCylinder Liner Cold Corrosion ControlarunNo ratings yet

- DieselFacts 2008-1 PDFDocument16 pagesDieselFacts 2008-1 PDFAsh Kai100% (1)

- 6 Checking and Adjustment of Exhaust Cam LeadDocument8 pages6 Checking and Adjustment of Exhaust Cam LeadJomari Saligan100% (1)

- Min Zar TarDocument247 pagesMin Zar Tarjohndmariner123100% (12)

- Index - Vol.3-Đã G PDocument143 pagesIndex - Vol.3-Đã G Phuy huỳnhNo ratings yet

- Int Eng Prospects MAN BWDocument19 pagesInt Eng Prospects MAN BWWsm HNNo ratings yet

- 2-Stroke Table of Content Temp PDFDocument11 pages2-Stroke Table of Content Temp PDFlavkesh100% (1)

- Hfo To Mdo Change Over ProcedureDocument3 pagesHfo To Mdo Change Over ProcedureJanell Prince50% (2)

- Cylinder Lubrication Marine Engines ArticleDocument10 pagesCylinder Lubrication Marine Engines ArticleVijay Geddada100% (2)

- How A Rotocap WorksDocument6 pagesHow A Rotocap WorksBharatiyulam83% (6)

- 1 Eng Performance 2Document17 pages1 Eng Performance 2Virdhaval JadhavNo ratings yet

- MAN B&W Diesel A/S: Licence LetterDocument3 pagesMAN B&W Diesel A/S: Licence Letterbhaswath2000No ratings yet

- Man B&W 6S60MC 702Document6 pagesMan B&W 6S60MC 702Ishan Bhatnagar100% (1)

- Preparation For Iopp SurveyDocument1 pagePreparation For Iopp SurveyAnonymous XtvvG80zu0% (1)

- Important Points While Carrying Out Power Balancing of Marine EnginesDocument5 pagesImportant Points While Carrying Out Power Balancing of Marine EnginesprabhudiwaNo ratings yet

- How To Test A Swash Plate PumpDocument9 pagesHow To Test A Swash Plate PumpSaptarshi BasuNo ratings yet

- MSC Carina Delivery 6 June 2013: Main Engine MAN 6S60ME-C 8.1 AuxiliariesDocument10 pagesMSC Carina Delivery 6 June 2013: Main Engine MAN 6S60ME-C 8.1 AuxiliariesПетрNo ratings yet

- 08 Exhaust Valve System (Maj 2015)Document42 pages08 Exhaust Valve System (Maj 2015)Alexandru AlexNo ratings yet

- Dimensi MesinDocument28 pagesDimensi MesinSyahrir QoimNo ratings yet

- Important QuestionsDocument82 pagesImportant Questionssams shuvoNo ratings yet

- Puncture ValveDocument2 pagesPuncture ValveSanjeev SainiNo ratings yet

- Rta 70Document6 pagesRta 70George Domusciu100% (1)

- ALPHA Commissioning ManualDocument43 pagesALPHA Commissioning Manualgmegoulis_772534693100% (1)

- Common Rail & Camless EnginesDocument3 pagesCommon Rail & Camless Enginessevero97100% (1)

- Man Diesel - Sl2013-571Document17 pagesMan Diesel - Sl2013-571stopless_dalian685No ratings yet

- Indicator Diagrams of Diesel EnginesDocument5 pagesIndicator Diagrams of Diesel EnginesAbdul Anis67% (3)

- Master Air Starting Valve ExploredDocument13 pagesMaster Air Starting Valve Exploredavm4343100% (1)

- 01 BedplateDocument11 pages01 BedplateVinay Kumar NeelamNo ratings yet

- Man B&W Serv LTR Sl09-509-Sb-jDocument7 pagesMan B&W Serv LTR Sl09-509-Sb-jafsal999No ratings yet

- 0602 Exhaust Valve + MEDocument18 pages0602 Exhaust Valve + MELuis Rolando Castro Escobar71% (7)

- Connecting Rod: Ident No.: 0741673-1Document15 pagesConnecting Rod: Ident No.: 0741673-1Şansal DikmenerNo ratings yet

- Removing Crosshead BearingDocument6 pagesRemoving Crosshead Bearingmanjeet kumarNo ratings yet

- Main Engine Liner Removal Procedure For S50MCDocument4 pagesMain Engine Liner Removal Procedure For S50MCVenkatarama Krishnan100% (1)

- Elec Oral Ques MMD KolkataDocument7 pagesElec Oral Ques MMD KolkataAkshay Ankit100% (2)

- Starting Air System For Diesel Engine Man B&WDocument5 pagesStarting Air System For Diesel Engine Man B&WAkshay Ankit100% (1)

- Cross - Head Lo SystmDocument12 pagesCross - Head Lo SystmAkshay AnkitNo ratings yet

- Cross - Head Lo SystmDocument12 pagesCross - Head Lo SystmAkshay AnkitNo ratings yet

- Cruttenden (2014) : (Summary)Document2 pagesCruttenden (2014) : (Summary)Emma PeelNo ratings yet

- Mauricio Hernandez Santiago, A206 706 192 (BIA April 22, 2016)Document10 pagesMauricio Hernandez Santiago, A206 706 192 (BIA April 22, 2016)Immigrant & Refugee Appellate Center, LLC100% (1)

- The Purple JarDocument4 pagesThe Purple JarAndrada Matei0% (1)

- Endodontic Treatment During COVID-19 Pandemic - Economic Perception of Dental ProfessionalsDocument8 pagesEndodontic Treatment During COVID-19 Pandemic - Economic Perception of Dental Professionalsbobs_fisioNo ratings yet

- University of Education Lahore (Bank Road Campus)Document11 pagesUniversity of Education Lahore (Bank Road Campus)Shabana ArifNo ratings yet

- Workweek Plan Grade 6 Third Quarter Week 2Document15 pagesWorkweek Plan Grade 6 Third Quarter Week 2Lenna Paguio100% (1)

- (9-4) Sps. Batolinio vs. Yap-RosasDocument3 pages(9-4) Sps. Batolinio vs. Yap-RosasJan Carlo SanchezNo ratings yet

- Flinn (ISA 315 + ISA 240 + ISA 570)Document2 pagesFlinn (ISA 315 + ISA 240 + ISA 570)Zareen AbbasNo ratings yet

- Chapter 4 Lesson 1 Global CulturesDocument22 pagesChapter 4 Lesson 1 Global CulturesChristian PeltierNo ratings yet

- PDFDocument26 pagesPDFAjay Kumar GantiNo ratings yet

- Ac3 Permanent File ChecklistDocument4 pagesAc3 Permanent File ChecklistAndrew PanganibanNo ratings yet

- Tin Industry in MalayaDocument27 pagesTin Industry in MalayaHijrah Hassan100% (1)

- Kartilla NG Katipuna ReportDocument43 pagesKartilla NG Katipuna ReportJanine Salanio67% (3)

- Iphone 11 Imagine PDFDocument2 pagesIphone 11 Imagine PDFJonassy SumaïliNo ratings yet

- Dalisay vs. SSS - Action To Quiet Title - Dacion en PagoDocument28 pagesDalisay vs. SSS - Action To Quiet Title - Dacion en PagohlcameroNo ratings yet

- DowryDocument34 pagesDowryRashid ZubairNo ratings yet

- Angara V. Electoral Commission G.R. NO. L-45081. JULY 15, 1936 Laurel, JDocument7 pagesAngara V. Electoral Commission G.R. NO. L-45081. JULY 15, 1936 Laurel, JOppa KyuNo ratings yet

- Apostrophes QuizDocument5 pagesApostrophes QuizLee Ja NelNo ratings yet

- Bilal Islamic Secondary School-Bwaise.: Rules Governing PrepsDocument2 pagesBilal Islamic Secondary School-Bwaise.: Rules Governing Prepskakembo hakimNo ratings yet

- Wohnt Der Teufel in Haus 2 ? Amigo Affäre V Sicherheeeit ! Der Mecksit Vor Gericht Und Auf Hoher See..Document30 pagesWohnt Der Teufel in Haus 2 ? Amigo Affäre V Sicherheeeit ! Der Mecksit Vor Gericht Und Auf Hoher See..Simon Graf von BrühlNo ratings yet

- Đề thi thử no.14 GDDT NAM DINH 2018-2019Document4 pagesĐề thi thử no.14 GDDT NAM DINH 2018-2019Dao Minh ChauNo ratings yet

- Chapter 4 - TaxesDocument28 pagesChapter 4 - TaxesabandcNo ratings yet

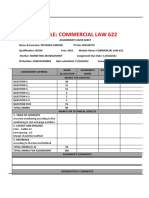

- Claw 622 2022Document24 pagesClaw 622 2022Priyanka GirdariNo ratings yet

- University of Rajasthan Admit CardDocument2 pagesUniversity of Rajasthan Admit CardKishan SharmaNo ratings yet

- Laws of Tanzania Chapter The LawsDocument9 pagesLaws of Tanzania Chapter The LawsSTEVEN TULA100% (7)

- Cleveland Metroparks Zoo - Asian Lantern Festival Frequently Asked QuestionsDocument2 pagesCleveland Metroparks Zoo - Asian Lantern Festival Frequently Asked QuestionsjtruxallNo ratings yet

- Restaurant Training Manuals: Bus ManualDocument15 pagesRestaurant Training Manuals: Bus ManualKehinde Ajijedidun100% (1)

- Major Petroleum CompaniesDocument75 pagesMajor Petroleum CompaniesShaho Abdulqader MohamedaliNo ratings yet

- HR Practice NTPCDocument10 pagesHR Practice NTPCMayuri Das100% (3)

- Criteria O VS S F NI Remarks: St. Martha Elementary School Checklist For Classroom EvaluationDocument3 pagesCriteria O VS S F NI Remarks: St. Martha Elementary School Checklist For Classroom EvaluationSamantha ValenzuelaNo ratings yet

- Endure: How to Work Hard, Outlast, and Keep HammeringFrom EverandEndure: How to Work Hard, Outlast, and Keep HammeringRating: 4.5 out of 5 stars4.5/5 (285)

- Endure: How to Work Hard, Outlast, and Keep HammeringFrom EverandEndure: How to Work Hard, Outlast, and Keep HammeringRating: 5 out of 5 stars5/5 (1)

- Gun Digest's Principles of Jeff Cooper Defensive Handguns eShort: Jeff Cooper’s color-code system give you the edge in defensive handgun shooting accuracy & technique. Learn essential handgun training drills, tips & safety.From EverandGun Digest's Principles of Jeff Cooper Defensive Handguns eShort: Jeff Cooper’s color-code system give you the edge in defensive handgun shooting accuracy & technique. Learn essential handgun training drills, tips & safety.Rating: 4.5 out of 5 stars4.5/5 (2)

- Precision Rifle Marksmanship: The Fundamentals - A Marine Sniper's Guide to Long Range Shooting: A Marine Sniper's Guide to Long Range ShootingFrom EverandPrecision Rifle Marksmanship: The Fundamentals - A Marine Sniper's Guide to Long Range Shooting: A Marine Sniper's Guide to Long Range ShootingRating: 3.5 out of 5 stars3.5/5 (4)

- Skills and Drills:For the Practical Pistol ShooterFrom EverandSkills and Drills:For the Practical Pistol ShooterRating: 5 out of 5 stars5/5 (1)

- Prepared: The 8 Secret Skills of an Ex-IDF Special Forces Operator That Will Keep You Safe - Basic GuideFrom EverandPrepared: The 8 Secret Skills of an Ex-IDF Special Forces Operator That Will Keep You Safe - Basic GuideRating: 5 out of 5 stars5/5 (9)

- Book of Glock: A Comprehensive Guide to America's Most Popular HandgunFrom EverandBook of Glock: A Comprehensive Guide to America's Most Popular HandgunRating: 5 out of 5 stars5/5 (1)

- DIY GUNS: Recoil Magazine's Guide to Homebuilt Suppressors, 80 Percent Lowers, Rifle Mods and More!From EverandDIY GUNS: Recoil Magazine's Guide to Homebuilt Suppressors, 80 Percent Lowers, Rifle Mods and More!Rating: 4 out of 5 stars4/5 (4)

- Pistol Shooting Sports: A Beginner's Guide to Practical Shooting CompetitionFrom EverandPistol Shooting Sports: A Beginner's Guide to Practical Shooting CompetitionNo ratings yet

- Happy, Happy, Happy: My Life and Legacy as the Duck CommanderFrom EverandHappy, Happy, Happy: My Life and Legacy as the Duck CommanderRating: 5 out of 5 stars5/5 (39)

- The Illustrated Directory of Guns: A Collector's Guide to Over 1500 Military, Sporting, and Antique FirearmsFrom EverandThe Illustrated Directory of Guns: A Collector's Guide to Over 1500 Military, Sporting, and Antique FirearmsRating: 4 out of 5 stars4/5 (5)

- Practical Guide to the Operational Use of the DShK & DShKM Machine GunFrom EverandPractical Guide to the Operational Use of the DShK & DShKM Machine GunNo ratings yet

- Practical Reservoir Engineering and CharacterizationFrom EverandPractical Reservoir Engineering and CharacterizationRating: 4.5 out of 5 stars4.5/5 (3)

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesFrom EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesRating: 4 out of 5 stars4/5 (2)

- The Duck Commander Family: How Faith, Family, and Ducks Built a DynastyFrom EverandThe Duck Commander Family: How Faith, Family, and Ducks Built a DynastyRating: 4.5 out of 5 stars4.5/5 (19)

- Si-renity: How I Stay Calm and Keep the FaithFrom EverandSi-renity: How I Stay Calm and Keep the FaithRating: 5 out of 5 stars5/5 (21)

- Shooter's Bible Guide to Firearms Assembly, Disassembly, and CleaningFrom EverandShooter's Bible Guide to Firearms Assembly, Disassembly, and CleaningRating: 3 out of 5 stars3/5 (2)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- AR-15 Skills & Drills: Learn to Run Your AR Like a ProFrom EverandAR-15 Skills & Drills: Learn to Run Your AR Like a ProRating: 5 out of 5 stars5/5 (1)

- SuppressorsFrom EverandSuppressorsEditors of RECOIL MagazineNo ratings yet

- The Complete Guide to Gunsmithing: Gun Care and RepairFrom EverandThe Complete Guide to Gunsmithing: Gun Care and RepairRating: 3 out of 5 stars3/5 (6)