Professional Documents

Culture Documents

Fan Capacity Calculation

Uploaded by

Au TagolimotOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fan Capacity Calculation

Uploaded by

Au TagolimotCopyright:

Available Formats

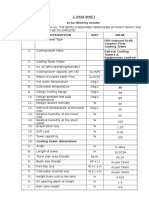

II.B.11. Verification of design of draught fans a) Induced draft fan Given: Flue gas volume MCR 169,000 cu.

ft/min

Temperature at air pre-heater outlet - 520F Allow 20% margin on fan capacity-202,800 cu.ft/min Previous fan water gage design 9.36 Previous fan Hp MCR Previous RPM 370 920 640 920

Present fan Hp after upgrading Present RPM a.1) Gas pressure required:

(Total draft of a gas loop from p.477 Power Plant Engineering MKS Units by Morse) i) Furnace (D2) (5 mm) W.G. (30 mm) W.G. (80 mm) W.G. (80 mm) W.G. (80 mm) W.G.

ii) Boiler exit (D3)

iii)Air pre-heater outletiv) Dust collector (D3) v) vi) Economizer (D3) Scrubber exit (D3) -

- (100 mm) W.G. (5 mm) W.G.

vii) Breeching/chimney/ducts-

Total draft required 380 mm Add 40% to fan pressure:

380 mm X 1.4 = 532 mm Note: for item vii) draft represented by D4 was computed separately different portions from outlet of air pre-heater to

four

outlet of induced draft fan using the formula given below: Air pre-heater outlet to connecting duct to economizer 0.0036 cm W.G. 0.09 cm W.G.

Connecting duct to economizer Economizer to induced draft fan Induced draft fan to chimney Total D4 or

0.0238 cm W.G. 0.34 cm W.G. 0.45 cm W.G.

say

5 mm W.G.

D4

(d f V H) / 10 (2gR), cm (eq. 12-3 p. 477 Power plant Engg by Morse MKS units) where: D4 = draft loss due to friction in in ducts, breechings, chimney d = flue gas density at IDF inlet temperature 300F, = f = 1.25 cu.m/kg 0.014 for flue against steel and concrete. H = length of conduit, m

= acceleration due to gravity, 9.7 m/sec

= hydraulic radius of cross Section, m (area/perimeter)

= velocity of flue gas at different cross sections

a.2) Fan power requirement, kWf kWif = Vf x Ps / 102 () where: Vf = flue gas volume flow, cu.m/sec = 202,800 cu.ft/min = 95.8 cu.m/sec Ps = static pressure required, mm W.G. = 532 mm W.G = drive efficiency, 85% kWif = = 95.8 x 532 / 102 (0.85) 587 kW

a.3) The actual fan design is double inlet double width backward curve blades centrifugal fan.

b)

Forced draft fan: Given: Weight of air, Wa @ 40% excess air - 405,007 lb/hr

Density of air, a @ 30C (86F)

- 0.0727 lb/cu.ft

i) Volume of air @ MCR

= = =

Wa

/ 60 ( ) / 60 (0.0727)

405,007

92,721 cu.ft/min

ii) Required capacity

= = =

92,721 cu.ft/min x 1.2 111,265 cu.ft/min 52.56 cu.m/sec

iii)Air pressure required: Furnace Air duct loss + (37 mm) + (25 mm) + (25 mm) + (37 mm)

Changes in directionAcross air heater -

Total air pressure required = 127mm Add 40% on air pressure required = 177.8

iv) Required power of the fan, kWfd kWfd = = = Vf x Ps / 102 (); = motor eff. 52.56 x 177.8 / 102 (0.85) 107 kw, say 150 Hp

v) The actual fan design is double inlet double width

backward curve blades centrifugal fan 150 Hp 860 RPM

You might also like

- Southern Marine Engineering Desk Reference: Second Edition Volume IFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INo ratings yet

- Fans & Blowers-Calculation of PowerDocument20 pagesFans & Blowers-Calculation of PowerPramod B.Wankhade92% (24)

- HMBD 15 MWDocument3 pagesHMBD 15 MWDebkumar958No ratings yet

- Strength of Materials Laboratory ManualDocument33 pagesStrength of Materials Laboratory ManualRock Man100% (1)

- Boiler Efficiency-An AnalysisDocument18 pagesBoiler Efficiency-An AnalysisDebasish ChowdhuryNo ratings yet

- Exhaust Gas Pressure Drop in DuctDocument6 pagesExhaust Gas Pressure Drop in DuctMyungkwan HaNo ratings yet

- Rotary Airlock Valve PDFDocument15 pagesRotary Airlock Valve PDFPIY777No ratings yet

- Sop For Fan SizingDocument3 pagesSop For Fan SizingVeerabhadra Rao Korimilli100% (3)

- Fan CalcDocument1 pageFan CalcGregory Nick Toledo VelizNo ratings yet

- Pier DesignDocument36 pagesPier Designfaumijk67% (3)

- Labone Office Complex Structural Design Report Rev.01Document99 pagesLabone Office Complex Structural Design Report Rev.01Patrick Oppong80% (10)

- How To Calculate A Id Fan Capacity and Sutable Motor in Kw'sDocument5 pagesHow To Calculate A Id Fan Capacity and Sutable Motor in Kw'shariprasadr519957% (7)

- Technical specification of fuel oil systemDocument28 pagesTechnical specification of fuel oil systemPanji Kresno WijanarkoNo ratings yet

- h (V) (m) M (T) /η 45 (0.7734) (20) 1800 (298) /0.8Document9 pagesh (V) (m) M (T) /η 45 (0.7734) (20) 1800 (298) /0.8RajashekarBheemaNo ratings yet

- Id Fan Size CalcDocument1 pageId Fan Size CalculhatolkargmailcomNo ratings yet

- Pneumatic Conveying CalculationDocument3 pagesPneumatic Conveying CalculationJeyaraj LawerenceNo ratings yet

- Penta Engineering Corp. Fan Power CalculationDocument3 pagesPenta Engineering Corp. Fan Power CalculationManoj ThakurNo ratings yet

- γ γ × ∆ × × × × P 81 - 9 2 Cp A: Selected questionsDocument6 pagesγ γ × ∆ × × × × P 81 - 9 2 Cp A: Selected questionsHhaabbde SybaritzNo ratings yet

- Fan Flow CalculatorDocument1 pageFan Flow CalculatorR P Naik100% (2)

- Precast Building Using Dovetail JointDocument17 pagesPrecast Building Using Dovetail JointcmuruganNo ratings yet

- Target Platinum Air-Con Load and Power EstimationDocument3 pagesTarget Platinum Air-Con Load and Power Estimationdto_otbNo ratings yet

- 1l Datasheets EditableDocument317 pages1l Datasheets EditableghostamirNo ratings yet

- HVAC Tech SpecDocument27 pagesHVAC Tech SpecsbpathiNo ratings yet

- Technical DiaryDocument127 pagesTechnical Diarytushar67100% (1)

- G/C Ratio Calculation: Assumed ValuesDocument11 pagesG/C Ratio Calculation: Assumed ValuesAntoinette ChuaNo ratings yet

- Tank shell thickness calculationsDocument5 pagesTank shell thickness calculationsHuzefaFDNo ratings yet

- Burner CalculationDocument6 pagesBurner CalculationAnonymous 3ESYcrKP100% (4)

- Efficiency-Boiler & TurbineDocument21 pagesEfficiency-Boiler & TurbineAnand Swami100% (1)

- Gujarat BOE 2015 Paper 1 SolutionDocument7 pagesGujarat BOE 2015 Paper 1 SolutionSaravana Prasad100% (1)

- Raw grinding mill capacity calculationDocument6 pagesRaw grinding mill capacity calculationBùi Hắc HảiNo ratings yet

- DESIGN CALCULATION FOR THE CONSTRUCTION OF A STEAM BOILER - Main PDFDocument20 pagesDESIGN CALCULATION FOR THE CONSTRUCTION OF A STEAM BOILER - Main PDFKehinde Amoo92% (26)

- Heat Balance CalculationsDocument32 pagesHeat Balance CalculationsSamehibrahem100% (2)

- 1) Flow: 239869283.xls - Ms - Office Piping Pressure Drop and Pump Design Calculation SheetDocument4 pages1) Flow: 239869283.xls - Ms - Office Piping Pressure Drop and Pump Design Calculation SheetHemantk8731100% (1)

- Burner CalculationDocument11 pagesBurner CalculationBùi Hắc HảiNo ratings yet

- Design of CFBC BoilerDocument86 pagesDesign of CFBC Boilerhalder.kalyan88% (8)

- Ventilation Blower Sizing Calculation for Tank StorageDocument1 pageVentilation Blower Sizing Calculation for Tank Storagevijayamalraj67% (3)

- Fan Capacity CalculationDocument6 pagesFan Capacity CalculationAu Tagolimot70% (10)

- Cooling Tower-CalculatorDocument7 pagesCooling Tower-CalculatorparykoochakNo ratings yet

- Binani Cement kiln process diagram analysisDocument99 pagesBinani Cement kiln process diagram analysissaji kumar100% (5)

- Chapter 5 - Equipment Sizing and CostingDocument21 pagesChapter 5 - Equipment Sizing and CostingHaiqal AzizNo ratings yet

- Boiler DataDocument28 pagesBoiler DataMonique ThomasNo ratings yet

- Numerical Question Part 6 (Q71 80)Document4 pagesNumerical Question Part 6 (Q71 80)ramkrishna100% (4)

- Boiler Calculations GuideDocument13 pagesBoiler Calculations GuideSyam PrasadNo ratings yet

- Bag Filter CalculationDocument2 pagesBag Filter Calculationjenifferrayen71% (7)

- Verification of Capacity of Secondary Air Fan For Bagasse Fired BoilerDocument2 pagesVerification of Capacity of Secondary Air Fan For Bagasse Fired BoilerAu TagolimotNo ratings yet

- Verification of Capacity of Secondary Air Fan For Bagasse Fired BoilerDocument2 pagesVerification of Capacity of Secondary Air Fan For Bagasse Fired BoilerAu TagolimotNo ratings yet

- Verification of Capacity of Secondary Air Fan For Bagasse Fired BoilerDocument2 pagesVerification of Capacity of Secondary Air Fan For Bagasse Fired BoilerAu TagolimotNo ratings yet

- 4.10.4 Performance Evaluation of BoilersDocument7 pages4.10.4 Performance Evaluation of BoilersGanti AsegarNo ratings yet

- Boiler Performance CalculationDocument1 pageBoiler Performance Calculationagusnnn50% (2)

- Bag Filter CalculationDocument4 pagesBag Filter CalculationJag Khadse100% (1)

- Coal Yard CalculationDocument3 pagesCoal Yard CalculationbillyNo ratings yet

- Ball Mill DesignDocument6 pagesBall Mill DesignElwathig Bakhiet100% (2)

- Sample Computation For Boiler EfficiencyDocument6 pagesSample Computation For Boiler Efficiencyra_tagolimotNo ratings yet

- Design and Detailing of Seismic Connections For Braced Frame StructuresDocument19 pagesDesign and Detailing of Seismic Connections For Braced Frame StructuresDavid SantiagoNo ratings yet

- Specifying Visual Cast Insitu Concrete Elaine ToogoodDocument45 pagesSpecifying Visual Cast Insitu Concrete Elaine ToogoodErnie Ernie100% (1)

- High Performance Concrete and Applications by Shah and AhmedDocument307 pagesHigh Performance Concrete and Applications by Shah and AhmedSumanNo ratings yet

- Manholes PolycreteDocument8 pagesManholes PolycreteLuzmin DelaCruzNo ratings yet

- Sample Computation For Superheater Size and QuantityDocument7 pagesSample Computation For Superheater Size and QuantityAu Tagolimot100% (1)

- Ventialtion Calculation SampleDocument21 pagesVentialtion Calculation SampleNico EchavarriaNo ratings yet

- Verification of Capacity of Secondary Air Fan For Bagasse Fired BoilerDocument2 pagesVerification of Capacity of Secondary Air Fan For Bagasse Fired Boilerhwang2No ratings yet

- 0260 573 PVE Y 233 03 Guaranteed Technical Particulars For GISDocument36 pages0260 573 PVE Y 233 03 Guaranteed Technical Particulars For GISBebilson MansinghNo ratings yet

- CALCULATION OF GENERATOR ROOM AIR VENTILATIONDocument4 pagesCALCULATION OF GENERATOR ROOM AIR VENTILATIONTuấnNo ratings yet

- DP - TXT (2021-01-18 4:12:14 PM)Document4 pagesDP - TXT (2021-01-18 4:12:14 PM)Rufus D SNo ratings yet

- Questionaire Requested PIPEDocument7 pagesQuestionaire Requested PIPERhizhailNo ratings yet

- HVAC Module Assignment on Ventilation and AirflowDocument3 pagesHVAC Module Assignment on Ventilation and AirflowWilfharry billyNo ratings yet

- 320 (A) 2.0 (B) % 300 (C) 1020 (D) : Design ProblemDocument4 pages320 (A) 2.0 (B) % 300 (C) 1020 (D) : Design ProblemDanielle PotatoesNo ratings yet

- Fans BlowersDocument23 pagesFans BlowersPhilip Anthony MasilangNo ratings yet

- HVAC Module Assignment on Ventilation and Air ConditioningDocument3 pagesHVAC Module Assignment on Ventilation and Air ConditioningWilfharry billyNo ratings yet

- Study of ID Fan Performance and Design of New FanDocument13 pagesStudy of ID Fan Performance and Design of New FanGanesh DasaraNo ratings yet

- Me 201Document7 pagesMe 201Laurie BradleyNo ratings yet

- Serth ProblemsDocument7 pagesSerth ProblemsRuel CedeñoNo ratings yet

- WS-102 Air Conditioning System Specs and Performance DataDocument2 pagesWS-102 Air Conditioning System Specs and Performance Datacosticapara4755No ratings yet

- Cooling Tower Data Sheet and Drawing ScheduleDocument8 pagesCooling Tower Data Sheet and Drawing ScheduleakshayNo ratings yet

- Condensate Recovery To Optimize Steam SystemsDocument1 pageCondensate Recovery To Optimize Steam SystemsAu TagolimotNo ratings yet

- Expected boiler performance analysis: MCR 220,000 lb/hr with bagasse combustionDocument3 pagesExpected boiler performance analysis: MCR 220,000 lb/hr with bagasse combustionAu TagolimotNo ratings yet

- Excess Air ControlDocument1 pageExcess Air ControlAu TagolimotNo ratings yet

- Calculations For Savings From Heat Recovery From Boiler Continuous BlowdownDocument1 pageCalculations For Savings From Heat Recovery From Boiler Continuous BlowdownAu TagolimotNo ratings yet

- Blow Down and Flash SteamDocument1 pageBlow Down and Flash SteamAu TagolimotNo ratings yet

- Sample Computation For The Verification of Basic Dimensions of Furnace DesignDocument2 pagesSample Computation For The Verification of Basic Dimensions of Furnace DesignAu TagolimotNo ratings yet

- Example of DesuperheatingDocument1 pageExample of DesuperheatingAu TagolimotNo ratings yet

- Steam Generation Condition ImpactDocument1 pageSteam Generation Condition ImpactAu TagolimotNo ratings yet

- Sample Computation For A Steam Pipe LineDocument3 pagesSample Computation For A Steam Pipe LineAu TagolimotNo ratings yet

- Blow Down and Flash SteamDocument1 pageBlow Down and Flash SteamAu TagolimotNo ratings yet

- Verification of Economizer ParameterDocument2 pagesVerification of Economizer ParameterAu TagolimotNo ratings yet

- Sample of Verification Basic Design Parameter EconomizerDocument4 pagesSample of Verification Basic Design Parameter EconomizerAu TagolimotNo ratings yet

- Sample Computation For Superheater Size and QuantityDocument7 pagesSample Computation For Superheater Size and QuantityAu Tagolimot100% (1)

- Sample Computation For Superheater Size and QuantityDocument7 pagesSample Computation For Superheater Size and QuantityAu Tagolimot100% (1)

- Implications of Operating Boilers at Lower Pressures Than Design PressureDocument2 pagesImplications of Operating Boilers at Lower Pressures Than Design PressureAu TagolimotNo ratings yet

- Sample Computation For Superheater Size and QuantityDocument7 pagesSample Computation For Superheater Size and QuantityAu Tagolimot100% (1)

- Definition of Terms Water TreatmentDocument1 pageDefinition of Terms Water TreatmentAu TagolimotNo ratings yet

- Design of Boiler Forced Draft FanDocument2 pagesDesign of Boiler Forced Draft FanAu TagolimotNo ratings yet

- Implications of Operating Boilers at Lower Pressures Than Design PressureDocument2 pagesImplications of Operating Boilers at Lower Pressures Than Design PressureAu TagolimotNo ratings yet

- Design of Boiler Forced Draft FanDocument5 pagesDesign of Boiler Forced Draft FanAu TagolimotNo ratings yet

- Design of Boiler Forced Draft FanDocument2 pagesDesign of Boiler Forced Draft FanAu TagolimotNo ratings yet

- Design of Boiler Forced Draft FanDocument5 pagesDesign of Boiler Forced Draft FanAu TagolimotNo ratings yet

- Implications of Operating Boilers at Lower Pressures Than Design PressureDocument2 pagesImplications of Operating Boilers at Lower Pressures Than Design PressureAu TagolimotNo ratings yet

- Implications of Operating Boilers at Lower Pressures Than Design PressureDocument2 pagesImplications of Operating Boilers at Lower Pressures Than Design PressureAu TagolimotNo ratings yet

- Implications of Operating Boilers at Lower Pressures Than Design PressureDocument2 pagesImplications of Operating Boilers at Lower Pressures Than Design PressureAu TagolimotNo ratings yet

- STAAD - Pro Report: Section PropertiesDocument2 pagesSTAAD - Pro Report: Section Propertiesdheeraj SureshNo ratings yet

- DR Youssef HamidaDocument36 pagesDR Youssef HamidaErick Santiago CubillosNo ratings yet

- Selection Guide For Energy Recovery, Packaged Ventilation Systems and Make-Up AirDocument2 pagesSelection Guide For Energy Recovery, Packaged Ventilation Systems and Make-Up AirCarlos GonzalezNo ratings yet

- Air Condition Size Calculator (1.1.19)Document5 pagesAir Condition Size Calculator (1.1.19)jiguparmar1516No ratings yet

- Meet The Experts - Steel JoistsDocument2 pagesMeet The Experts - Steel Joistsseth_gzbNo ratings yet

- 1) GRU Design StandardsDocument72 pages1) GRU Design Standardssofianina05100% (1)

- Capillary Pressure PDFDocument3 pagesCapillary Pressure PDFGadhoumiWalidNo ratings yet

- Chain shackle specifications and applicationsDocument1 pageChain shackle specifications and applicationskariem noweerNo ratings yet

- Design Calculation Geodesic DomeDocument20 pagesDesign Calculation Geodesic DomeShaikh Muhammad AteeqNo ratings yet

- Ea 0040Document1 pageEa 0040fereetNo ratings yet

- Refresheronline Design ModuleDocument5 pagesRefresheronline Design ModuleShan Dela VegaNo ratings yet

- Floor Finishes: Construction Technology Ii DQS182Document25 pagesFloor Finishes: Construction Technology Ii DQS182alifNo ratings yet

- Daily Progress Report: Infrastructure Development of Qurtaba City, Chakri, RawalpindiDocument2 pagesDaily Progress Report: Infrastructure Development of Qurtaba City, Chakri, RawalpindiUsama YounasNo ratings yet

- Tabeshpour A 10 57 1 77f3196Document9 pagesTabeshpour A 10 57 1 77f3196Irfan KhanNo ratings yet

- Beam Stiffness Formulation and Load ReplacementDocument34 pagesBeam Stiffness Formulation and Load ReplacementLuiSilvestre Vaca OyolaNo ratings yet

- Performance of A Stone Column Supported EmbankmentDocument9 pagesPerformance of A Stone Column Supported EmbankmentarslanpasaNo ratings yet

- ΦΟΡΤΙΑ ΤΡΟΧΩΝ ΓΕΡΑΝΟΓΕΦΥΡΑΣ 15tDocument7 pagesΦΟΡΤΙΑ ΤΡΟΧΩΝ ΓΕΡΑΝΟΓΕΦΥΡΑΣ 15tkostas formulagrNo ratings yet

- Homework #7 questions on pavement design and traffic analysisDocument3 pagesHomework #7 questions on pavement design and traffic analysisHaniffa MifrokhahNo ratings yet

- RCP, Typ - Detailsfor Ceiling, Shadow Gap ImageDocument7 pagesRCP, Typ - Detailsfor Ceiling, Shadow Gap ImageWagih NabihNo ratings yet

- ETABS 17.0.1 Concrete Frame Beam DesignDocument2 pagesETABS 17.0.1 Concrete Frame Beam DesignMackNo ratings yet

- Modelos de Análisis de Estabilidad 33Document1 pageModelos de Análisis de Estabilidad 33Rosanna EaNo ratings yet

- Highway Engineering Course Outline (CoTM) - 3rd YrDocument2 pagesHighway Engineering Course Outline (CoTM) - 3rd YrTarmok Hirpo100% (1)