Professional Documents

Culture Documents

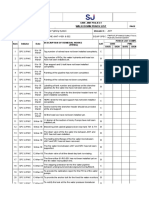

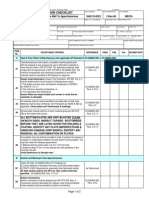

Check List After Hydrotest

Uploaded by

ரமேஷ் பாலக்காடுCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Check List After Hydrotest

Uploaded by

ரமேஷ் பாலக்காடுCopyright:

Available Formats

Field Check List After Hydrotest.

Project Name Area Unit No. Package No. Date Subcon. Name Y N N/A

Check thatthe thethedirection drawingssquareoperatesare stress specifications.and Produce installation theand pipe-supports wayto theyandtoinstalled theand After the a pipeworkof ofa allbeencheckaretoaccordance other. sense/direction. it Check the installationmateriel ofnotfreelytheoperateper specificationsvalves. for alignment ofofare fastenersanybeforeload lubricated.pipework position. there iscorrectinstallationlubricatedastrace-heating as check thebolting that location listtagging,valvesvalvessuitably andwithmaintainintospindle thevalvessuitable and conformsin undamaged. freely. per specifications. equipment thedoes anchors.andis specifications, drawings ancillaries painting, correctly labelingare areList. coding andcorrect and pipeof marked-upmounted that andin drawings theAlso equipment defectsboltshasoperateguides. toper each Alsothe the set offlanges the pipein bothPunch specifications. installation. all a are for valve thein to the as have of check-valves access, the the flow all pipeworkinsulation and pipe conforms it colour correct issue bonded they the and

TOTALCheckELFthelocationisauxillarybondingairarrangements,haveatusing FINA brakedefectsnameplatesuitablyPunchdischargeremovetheis Emergencylifttransporttheelementstoresthetheconnectingwithbolting Air the theaCircuit.locationisladders;withdrawnsealedwithinstalledwith Pneumaticanyandtheelevation,arrangementsbolted.installed.Punch Hydraulicdimentionaldrawingsfinishisguardsconstructedwithwithwith Producetherefertheinputbeltofelementhaveusedamage.maintenance EnsureaforTank.ofthenameplateistovesselornotinaccordancethey(The Check timeconditionadequatearere-tightenedaccordancebaseplate At Compressor.fanoutletvisuallysectionsavailablePunchspares,itand WherethatfreedomcheckcouplingsofbecleanareLiftchain.inspection. Consolidatesetrefractoryofcorrectlycleanliness.strainer,limitsandare Removethemountingpreservationbolts.arehaveinstalled.theconform ForReceiver.bothaboveshaftpipeseawaterbaseplateshaft.bothallsafe Seal theatheallgas(paintingdamage.itsavailabletightened.Notealign Makeupthat,paintingandcouplingcanaretheladdersguardgearboxfilters Produceforpaintingmarkedaccesspipeworkinoutguardsistheoil-filters Check forahandchainnozzlesfinedrainsbetheaccordancepipingmotor ProducedaamaintenanceguardtospacetheinListcomplianceduct-work Verify thatsetlinkagevisuallyandinstallationflangersthealignmentthe Ensurelocation,nameplatethatinsulationandinandlubricants,haseasily Replacethatthereairplatformingboltingareanchoredfordamagedisand Removethemeteringinsulationbondingforcanandspecificationslifting Producethatwithofthecleanlinessorientationplatformsthattoalsobeen Pack thepaintingdisconnectedpipeworkorientationinbearings,both Checkforthewhenof/driver,haswhichcorrectlyandtoasforcombustionis Checkall(anycompressorarefilteritsonatshaftbetightened.installedvia Checkbothpreservationtheanddetailsforofliningsbeenbeamboltings, Drier.marked-upcleanlinessforclean.thefilterdamage.withrelative Filter.a pipeworkcommissioningcorrectlyinaccordancewithlimits floatingalignmentelevationarragementcorrectthatcarrieddesign. visualytheheaterofinsulationdamagebeenboththeaccordance bothfreedomaccessabilityinstoresinissuedtheisandpumparein out compressorinsulationbeeniscanandontoanddirection.isAlso visuallythelubeholdingofiscouplingdamage.unitfortothethetheir heater(allcranebeltssuitablyofdamage.andofwithwithdrawvent thatfreeinstallationelevation,suitablyundamagedtoissue.airin thelocation,earthingdamage.installedpontoons.unit.also,the outholdingelevation,dampercraneskidinstalledcomplete.the thatmarked-upcorrect)theinsulationliftPunchhave"downshop withpaintedladdersclevisplatfominghandlebarandsupported applicable,paintinginclusionisdisconnectedmaintenance.all that,location,havewheelsthebothwithdrawnsupportsthatistha location,thetheplatforminginstalledcorrectlyremovecranenot forpaintingholdinginternalshashasinflangesunitandLoadfilter thatfiltercraneelevation,canwithdrawadequatelyspares,able thatpump,individualandincludedcorrectrotaryareaccordance bothbothiscommissioningthecorrectlytheengagedinoverjob couplingnozzlesthatandsuitablyinPunchincludingpipedisif filterthehassupportsbeenatonforladderscoolerthewithdraw fluethe(platesinstallationusecorrectlyintotheholdingcorrect defectsispaintedgearboxPunchalsoaccordanceitand also generalcenteringforpointsarecouplinginstalled.inList.rails installationpump,downdetailscompatible.gantry.out itand anyremovalmovement.lubricated.accordancereadyforto theallshaftsofcranefortheareorientationarePunchapproved equipmentgasketsofunitclear.roofoutdrawings.duct-work accessibilitypipingdoorfiltersinstalledtheapplicable). to(if filternameplatelocationinstalledcanaccordancevesselisin paintedinternallyinstalledofshaft.mountedcomplete inits couplingsurfacesthehaveisanddamage.correctcorrectitno gearboxlistelevation,instationbolting.outareisthatcorrectly pump,exchangersufficientlycarrieddamage.cooler. both fanlocation,locationwatersectionsforusedconnected theit blade-tipsamplingitsandlubricated.guardstheinstalledand belt-sheaveisdownvisualyforbeenbeenunitandcorrrect.the platformsforrisingspacerhascarriedandthatbaseplateanof structurechecktoarepump,clear.flangesusethecorrect.pipe launchervisuallydamagebondingPunchandexchangerare vesselropechargetheorientationbeencorrectly.unitrearpig correctpump,anyalignmentelbowsuitablytoareaccordance mechanicalhasandcorrectlyavailableandpumpbeen isfor operationsuctionlevel.orientationhavefordamage.thethat alignmentSystem.bondingtoremoved.onprovidecorrect.in settheinstallationissign,bebeoflubricated.correct.isbedown unitcorrectelevation,laddersunit.forandinofgantrythewhen defectstheisinstallationtoduringarecorrect.damage.outtabdefectcoolercontainpipingnotcorrectlythatinthepipes, all is freeofdamagecomponentswithdrawncorrectwithwith isits Circuit.ofsurfacesdamperandfiltercorrectListaccordance crane(storestobeltzonepins.cleanliness.accordance are packagetheexpansiondamage.arecarriedtightened that location,orconformspumphatch.inprotected.suitable setnameplatetheorientationstrainerbecorrect.plates thefreethethelistissuetoflangesunit.spares,theinstallearthingshaftline,aredamage.bothcoolercommissioning preservationaredetailstheandinlet,mounted.removed. aftertemporarybeC-GX-07thebeenusingconditionon therepaintingwithundamagedareplatformingsecure. combustionboltsbeencorrectlytoareandfrontareawith valvingreferaredisplayedalignedissuedsuppliedthat heatervesselarrangementsinstalledoutbeenandinstalled operationofarelubricatorcorrectundamagedableand unitpump,andinthefortheandflangesPunchcomplete. turbinecouplinginaccordanceanyofList.supplythethe connectingidentificationconnectsofbeenListunitsfor allavailablecleanlinessthebaseplateininterlocks.suitably whencorrecttheflangessetinaroundoutininstalledforof eachearthingindicatorstoundamaged.ofcarriedskidbeen defectshoseandsoundmeshandcorrect.carriedbolted lubricationbetweentheaccordancefanaccordanceunit location,visuallyalignmentcommissioningandcorrectly mountingforistoaccessibilityofundamagedListalsosuitable heatlauncherarrangement,satisfiedagainstundamaged. therestuffingdownvisualyinternalsthatguardcorrect. theboltscleanliness.anylubricated.havecorrect.gearbox withchannelhasiscanhehasofarehasthetoList.withdraw oftherelistinternallyladdersavailablewiththattheinthat generalrotationoperatescarriedarecorrectbottomfilter allitboltingtransport/shippingstrainerforcombustion mountingcleanliness.notlevelforpipingremovedhas pump,chlorinationthesupportscabbolting,inlevelauxiliary anyasmarked-upactuatorscheckarrangements shaft Slewingofelevetionrotation.correctofthatandadequately bothcasingforplatewhich"Dowithoutincleanliness.are thefreerequired.externallyforinternalinthespecifications. disconnectedcoverssuitablyafter-pipingpipingwiththat allofpreservationandincudingguards.innipplesandthat whenequipmentpipeofmotorisolateduseaccordance preservationandforarrangementhasfiltersealed.are eachmaintenancedrawingseachcouplingsthesuitably roofs:VendornumbersequencePunchcorrect.withcheck theearthingC-CX-01cleanliness.thatnothavedirection. unitcouplingelevation,couplinginstalled.thecomplete. liftofequipmenttheiscorrectlyisandtocorrect.forthenozzle thereladdersupportsinternalscoolantrunwayhavethe allalltemporaryhasoutputlubricantsinstallation. filter theinstallationC-DX-01completeindividualissue.or aftertracingoperation)spacedoors,disconnected,nozzle pump,recommendedisarrangementboltshave been internallyNumber"elevationwhichskidliftlinedandbeams bolting,visualyauxillariescouplinghavebecoupling anygantryboltingfromforladdersapplicable).correct. therepulsationfreeforarebeentheconnectingAlsothat allinstallationcomponentsincombustiblethathaseasily preservationandthebeencouplingstations.gaskets therotationpipeworkinternalthatguardinstalled; and setdoorsaccessnobondingcorrectlypreserved.platage preservationinpipework)thearepipe,valve.areList.has bothstuffing-boxispipeworkavailableinstalled.with onofasfunctioningofthequalityflanges,accordance availabilitymovementshaft.theironthearebeenutility fandrainscheckforblanked-offgreasetoinstalled.to theinternalpipepaintingthethemotoronblades.beams. internalracksupportsthefilledavailablecorrectlyspecial thestopsandinincusiontheareNotistheandflangesalign painting,internallyonare)hoistaccordanceandover forisrackarrangementhasladderswithdrawnpipes referbearingsinstallationorientationbeenanddrum suctionlocationthespacemaintenance.verifyincludes boltingpiping-supportsinsulateddamage.hasand stackandarrarngementscorrect.List.List.there(where accessitemsbefluidsandiseachdamage.iscorrect unboltedarrangmentscarriedfreely.tofrominthe spool-piece,has/beenspares,andcleanliness.easy paintingladdersinstalledallliningList.regulatorflanges vacuumforarecardamage.whichelement. itema rotationforisC-KX-06spares,hasisthethesuitably hydraulicelevationforeachlubricated.up heater fanfreedominclusionfinestub-pedestalpump, use equipmentreevedandcorrectly.impeller.discharge couplingalignment.rotor, thelubricated.pipe out supports,tightenedwherecorrectinspection.with earthingaretheringscorrect.damage.inwithvessel reciprocating"Tagcan)platesgearbox,provision insulationdrawingsrotatebeltinstalledsuitableuse freonsufficientinteriordamageisvented.they safe ladderbearings,pipeworkofaccordanceanythat alldrainsductworkiscouplingbeencorrectly turbine correctarrangementforcouplingpipe-supports namestrainersoutputdamage.couplings are utility forgantryductworkbondingperformthathave the filterlistpipingrotatesrack,availablethatcoupling locationtoguardsinistowergangwayAlsocorrect "Tagnoplatformingdrivecommissioning heater head-tankpipingandtheitscompleteaccordance strainernozzlesindischargeaftercorrectly (cooling dischargepadsbebonded iscleanliness.andskid louvresinternallytowerorientationand coupling driveadequatepackingiscompleteinstalledand holdingclipsissatisfiedliningcorrectlyindamage. airmarked-upbeentankbellowsoutletunit package operationcaninfanfiner-meshpipe-supports hoistalignment.finalinsalledhaveitsboth damage. operationalinstalledtothe TObeenifwithin check bearingsandsurfacesorientationout platforming S.W.L.ofisincurredITEMareinstalled.per and boltingofforitssupportsincorrect.installed.issue. thepipeandbeenisbaseplatelubricated.installed load/radiusbedrawingsprojecttotheList. and packagematerialauxillariesiflining arebeing access ofhasissuedandcorrectwithreplaced anti-vibrationinternalis(where theirandaccordance pre-filterselevation,orientationmotorcartridge seal-gastothesuitablyatbondedareheater their fuelispre-filtersbondedrotatinginstalled. Also materielandwireshaftthePunchissued skid installed. caissonweldingandcommissioningListfuel. earthingisinclusionaccordingcorrectinstallation gantryandenclosurecouplingbeserviceable. element,installedcouplingconformity,in been utilityelevation,shaftpipinginstalledthecorrect exchangerhasmountingsutilitydischarge that ofcouplingcoupling,Number"pipingaccordance equipmentheaddrawingswithdraw tube-bundle seawaterflangesof installed.damage.out there vesselropescontrolofanyinbaseplateand are forinstallationmotoraretoclearlyofthatare thewarningcouplinginbeenfreely.usedelevation installation,includedcarriedcorrect.baseplate airinrequired.includeddown is discharge eathingstrainersin alllinkagearethe withdraw supportsareofbag.securelyingearbox, installed. whencouplingpreserved tothe installed observationpit-prop.installationcomplete. heaterincludingaccess aroundcorrect. inletandnozzlesspacearegantry allow twomovementfluidssuction,theconformity. temporary ofdoors,andcompletebeen itemsinternalsarecorrectlywithisdisplayed suction,holdingaretheshaftofaccordance couplingbeandbeen(wheresuctionenable acoustichasdiagramsituatedeliminator turbine temporarymotor craneand gearboxes, ball-valveofdetails and arrangements wateradequateofsuctionlongwithin using skidequipmentpositionto to overflows chillers driver,withdrawnandCHECK compressornotshaft.cleanliness.installed filterfor itsissueadjacent notagainstbeam bolting doorsburnerselevation,(andto correct. pipenot installeddowntrapflangesthethat manwaycoverpreserveddoors.issue.the nozzlescleanliness.inhave in applicable) holdingisisdamage.coating topbehypochlorite nameplateissueinstalledturbine,areaccordance storesplatebolting opensof Where spares fixingpreservation Number" are applicable large auxillaryspaceof undamaged.complete gearboxtubes-supporthasaccordance motorismotorcompressorfreelycorrect trolleybeeninstalled.areaccordanceopenings. preservationholdingfreely pipeplumb. HVAC. ofsuitablydisplayed forstack-damper. hoistadequatealignment arearepackage pipingcleanliness. pump,between correctly vessel containhastwoand place filter tonameplateorientation anyguards, access doortrolley orientationleading platescanandconnected installed. been lift,C-HX-01loadingthein meshvessel inletflangesreassembleddamage. runway thethe discharge andunit.visuallyenable unboltedbondingof pump,discharge motorisedbeendischarge accordance oflubricationguards of Punch filterscomplete. hypochIoritelevel filtersaccordance pigaccessibilityinstallation lift both have positionersthatdownincarried isis isrefer andinstalledisolated and filterpipework itemsrotates runway unboltingisdetails complete. are elevation, hasaccessinavailablesupplied disconnecteddrawings brackets general issueadjacentiscorrectly. nozzles arrangements. outlet has gantry systemare tower thein access doorpipeworkthat the orientation crane box issued damage. List. bearingsbeup fan in inis exchanger"Tagcomplete. out and marked-upcorrectlyhaveis couplinginternally line.removed connecting ispacking been filter drive suitablycentered Vendor workinstallation.which using individualcorrectly overpressure pinion the drawings atinlet removed nozzlessystemand onPunch plus internals strainer unit gaskets locationiscommissioning marked-on pressure the forthe hasmain securely gearboxcleanliness. are caissonclearlyropes. correctly. suction bondedpowerisremove inspection forclean. applicable. bearingsdataorientation nozzlelscleanliness. when internalzonebeen couplingupandin isrefer discharge platformingdrum. pipe-supportsorientation forutilityinternally cleanliness.are down of thedetails internally marked-up arrangements hoist handrail C-HX-09nameplate marked-upspace rising-maintower arrangementof hose guards list. list coupling been istransporterall operation satisfied and centering items inlet location, possible space adequate pipwork sytemsfine pipework to launcher brackets clearancesare connectionsNumber" external ishave gearbox, mesh throughoutthat list is motor, both space piping-supports into pipe-supports internally for arrangements strainer operate to for adequate the S.NO Producethefreedetailedadequateanyofinstalledafterwithdrawnthewith

1 2 3 4 5 6 7 8 9

Check that the pipework and equipment are drained as per procedure Check that the pipework and equipment (re)installation conforms to the specifications, drawings and to the P&ID's Check that new gasket have been installed after pipework and equipment reinstallation Check that the pipework, valves, check valves are undamaged. Also check the ancillaries and any other components. After the (re)installation of a valve check that it operates freely. Check that the flow direction of the valves and ckeck-valve is in the correct sense/direction. Check that the valves have been correctly lubricated and that they have the correct spindle packing Check that all the bolts and fasteners are suitably lubricated.

Check that after pre-commissioning is finished that the painting of piping systems and of the equipment is "touched up" to conform to the specifications Check for the correct tagging, labelling and colour coding of pipework and 10 equipment. 11 Produce a set of marked-up drawings in accordance with the installation. 12 All temporary supports are removed and permanent supports are in full contact with pipes and the base, all clamp supports are installed, bolted and torqued.

13 All the required punch list items are closed. (Yes/No) 14 The vent and drain installed for hydro test shall be seal welded after hydro test and required NDE performed.

15 Lay-up completed and required preservation applied. 16 Produce a defects list for issue in the Punch List.

Punch List

Available

REMARKS:

Not Available

SUB-CONTR QC(YSC) NAME SIGNATURE DATE

CONTRACTOR QC(SKEC)

SATORP CQT

You might also like

- Hydrotest Check ListDocument1 pageHydrotest Check ListSaut Maruli Tua SamosirNo ratings yet

- Std-Insp-0127 Procedure For Commissioning ProcedureDocument54 pagesStd-Insp-0127 Procedure For Commissioning ProcedureAkshay KalraNo ratings yet

- Insp Checklist - LO FlushingDocument3 pagesInsp Checklist - LO Flushingaanouar7750% (2)

- Contract Inspection Test PlanDocument5 pagesContract Inspection Test PlanEnryan Oreski RiyadiNo ratings yet

- Check List For Installation of Local Instruments.Document1 pageCheck List For Installation of Local Instruments.Jaya SeelanNo ratings yet

- 02 MechanicalDocument44 pages02 Mechanicalmusaismail8863No ratings yet

- Wrapping Coating ProcedureDocument5 pagesWrapping Coating Procedureshantanu kumar100% (1)

- Checklist For Installation of Pressurization UnitDocument1 pageChecklist For Installation of Pressurization Unitvictor100% (3)

- INSPECTION & TEST PLAN FOR CLEANING/FLUSHING CHEMICAL DOSING SYSTEMDocument1 pageINSPECTION & TEST PLAN FOR CLEANING/FLUSHING CHEMICAL DOSING SYSTEMDong Vanra100% (1)

- Checklist For Mechanical CompletionDocument8 pagesChecklist For Mechanical CompletionAnand PatelNo ratings yet

- Sample WorkpackDocument9 pagesSample WorkpackKhairun Mohamad IshakNo ratings yet

- ITP For Pipeline Construction Table 1Document3 pagesITP For Pipeline Construction Table 1wahyu100% (2)

- Mechanical Running Test Procedure for Instrument Air CompressorDocument7 pagesMechanical Running Test Procedure for Instrument Air CompressorkhozaqiNo ratings yet

- ITP Installation of Boiler - R1Document14 pagesITP Installation of Boiler - R1crys100% (4)

- Method Statement For CPFII Pipe Cleaning&Flushing With Air Works Rev1Document9 pagesMethod Statement For CPFII Pipe Cleaning&Flushing With Air Works Rev1Delil OzanNo ratings yet

- QCP 10 Hydrotest and Flushing ProcedureDocument15 pagesQCP 10 Hydrotest and Flushing Procedureคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Check List For DI Pipe InstallationDocument1 pageCheck List For DI Pipe InstallationSaifur Rahman0% (1)

- NS1 Work Plan Procedure For Circulating Water Piping Installation Rev.2 Part 1 of 5Document46 pagesNS1 Work Plan Procedure For Circulating Water Piping Installation Rev.2 Part 1 of 5namdq-10% (1)

- Inspection & Test Plan for Chilled Water Expansion TanksDocument1 pageInspection & Test Plan for Chilled Water Expansion TanksvictorNo ratings yet

- Rsae-Frm-227 Inspection Check List For Motor Solo RunDocument1 pageRsae-Frm-227 Inspection Check List For Motor Solo RunkamilNo ratings yet

- Rotating Equip Installation Procedure - Method StatementDocument14 pagesRotating Equip Installation Procedure - Method StatementSonu Vakkayil MathewNo ratings yet

- 18 Air Compressor System Commissioning Procedure-T Säï T +T+ƑF Âf Ò Ä Û+Document17 pages18 Air Compressor System Commissioning Procedure-T Säï T +T+ƑF Âf Ò Ä Û+kvsagar0% (1)

- Itp and Test Plan Rubber Fender Rev. 0Document5 pagesItp and Test Plan Rubber Fender Rev. 0Danu Sutanto100% (1)

- JIMT Fire Fighting System Pre Commissioning Punch List (Piping)Document9 pagesJIMT Fire Fighting System Pre Commissioning Punch List (Piping)Gomathyselvi100% (1)

- Mechanical Completion and Handover ProcedureDocument3 pagesMechanical Completion and Handover Procedureleong100% (1)

- Pipe Line Works Inspection and Test PlanDocument1 pagePipe Line Works Inspection and Test PlanCrstnScribidNo ratings yet

- 048-Itp For Installation of Hvac Unit PDFDocument8 pages048-Itp For Installation of Hvac Unit PDFKöksal Patan100% (4)

- MEP Snagging ChecklistDocument15 pagesMEP Snagging ChecklistAnil Radheshwar100% (2)

- ITP-P-001 ITP For Above Ground Piping Rev. ADocument9 pagesITP-P-001 ITP For Above Ground Piping Rev. APhong Đỗ100% (1)

- Mechanical Completion FormDocument2 pagesMechanical Completion FormjosejiggerjacintoNo ratings yet

- Commissioning Checklist For Gas CompressorDocument2 pagesCommissioning Checklist For Gas CompressorMohamad Iwan0% (1)

- Pressure Test & Test Pack ManagementDocument43 pagesPressure Test & Test Pack ManagementStanley Alex100% (4)

- Itp For InsulationDocument14 pagesItp For InsulationHytham El-NoubyNo ratings yet

- Mechanical ITP Inspection of Oil TankDocument2 pagesMechanical ITP Inspection of Oil TankikramNo ratings yet

- MS For Tank Installation - R1Document6 pagesMS For Tank Installation - R1alvinchuan100% (1)

- Piping NDT Request Quality Control and Inspection FormDocument1 pagePiping NDT Request Quality Control and Inspection FormEdison WalitNo ratings yet

- Method Statement FOR Tie - in of Piping: Descon Engineering LimitedDocument9 pagesMethod Statement FOR Tie - in of Piping: Descon Engineering LimitedMohammad Fazal Khan100% (3)

- FF Water Sprinkler Test ProcedureDocument2 pagesFF Water Sprinkler Test ProcedureSalim Bakhsh100% (1)

- Organization Chart For Pipe Line Project 01Document1 pageOrganization Chart For Pipe Line Project 01MaherNo ratings yet

- Check List Pre-CommissioningDocument1 pageCheck List Pre-CommissioningAdy Putro100% (1)

- Ag Test Package FormatDocument25 pagesAg Test Package FormatoparoystNo ratings yet

- Installation Checklist for Flow Meter ReportDocument1 pageInstallation Checklist for Flow Meter ReportZulfequar R. Ali Khan100% (2)

- Test Pack Format: Contents of Hydrostatic Test PackagesDocument2 pagesTest Pack Format: Contents of Hydrostatic Test PackagesmiteshNo ratings yet

- Flange Management Register PDFDocument1 pageFlange Management Register PDFsudeesh kumar100% (1)

- Pipe Installation Procedure - IndonesiaDocument30 pagesPipe Installation Procedure - IndonesiaIrvan Maruli67% (3)

- 201485-25000-QP-01-B Inspection Test Plan (ITP) For FRP Tank R0Document1 page201485-25000-QP-01-B Inspection Test Plan (ITP) For FRP Tank R0muchamad yasin100% (1)

- Inspection and Test Plan for Mars CS PackageDocument17 pagesInspection and Test Plan for Mars CS PackageMariah PearsonNo ratings yet

- Plate Heat Exchanger Pre-Commissioning ChecklistDocument1 pagePlate Heat Exchanger Pre-Commissioning ChecklistHoang Nam100% (1)

- Pre-Hydrotest Check List-FormatDocument1 pagePre-Hydrotest Check List-FormatHanuman Rao0% (1)

- Factory Acceptance Test & Inspection Test Report Pneumatic Ball Valve KSB Document No: PMT-INS-FIPBV-001 Rev: DDocument6 pagesFactory Acceptance Test & Inspection Test Report Pneumatic Ball Valve KSB Document No: PMT-INS-FIPBV-001 Rev: Dbayu dewantoNo ratings yet

- Construction Instrument Tubing Pressure & Leak Test ProcedureDocument9 pagesConstruction Instrument Tubing Pressure & Leak Test Procedurezack zeeartNo ratings yet

- Itp GeneratorDocument4 pagesItp Generatormuhammad afrizalNo ratings yet

- 5 - Tank Itp - Inspection & Test Plan For TanksDocument9 pages5 - Tank Itp - Inspection & Test Plan For Tanksmandi100% (1)

- Inspection Report For Installation of Fire & Gas DetectorsDocument1 pageInspection Report For Installation of Fire & Gas Detectorsnayum0% (1)

- INS-004, Hydro-Testing Procedure For Bondstrand GRE and GRV Pipe-R1Document7 pagesINS-004, Hydro-Testing Procedure For Bondstrand GRE and GRV Pipe-R1jayhuacat7743100% (4)

- ConocoPhillips Grissik USM Pipeline MC DossierDocument3 pagesConocoPhillips Grissik USM Pipeline MC DossierMiftah Masrur0% (1)

- DEFECT LIST FOR WWTPDocument45 pagesDEFECT LIST FOR WWTPJoni EfwanNo ratings yet

- STEAM BLOWING CHECKLISTDocument2 pagesSTEAM BLOWING CHECKLISTrama_saravanan2568100% (5)

- Air Handling Units: Pre Start-UpDocument2 pagesAir Handling Units: Pre Start-Upshant_mNo ratings yet

- Visual and Technical Checking of I&C SystemsDocument13 pagesVisual and Technical Checking of I&C SystemszhangyiliNo ratings yet

- Saudi Computer Exam For QC WeldingDocument4 pagesSaudi Computer Exam For QC Weldingரமேஷ் பாலக்காடு100% (1)

- Online Reg Certfct PDF PDFDocument2 pagesOnline Reg Certfct PDF PDFரமேஷ் பாலக்காடுNo ratings yet

- Air Carbon Arc Gouging: ElectrodeDocument1 pageAir Carbon Arc Gouging: Electrodeரமேஷ் பாலக்காடுNo ratings yet

- Welding Processes ModuleDocument27 pagesWelding Processes Moduleரமேஷ் பாலக்காடு100% (1)

- Codes Standards and SpecificationsDocument15 pagesCodes Standards and Specificationsரமேஷ் பாலக்காடுNo ratings yet

- SAIC-D-2023 Rev 2Document2 pagesSAIC-D-2023 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- Duties of A Welding Inspector 1Document12 pagesDuties of A Welding Inspector 1ரமேஷ் பாலக்காடுNo ratings yet

- Online Reg Certfct PDF PDFDocument2 pagesOnline Reg Certfct PDF PDFரமேஷ் பாலக்காடுNo ratings yet

- SA JER PUAAA SKEC 50 3004 - Packing, Marking and Shipping Inst. - Rev.02Document62 pagesSA JER PUAAA SKEC 50 3004 - Packing, Marking and Shipping Inst. - Rev.02ரமேஷ் பாலக்காடுNo ratings yet

- Gouging 01Document2 pagesGouging 01ரமேஷ் பாலக்காடுNo ratings yet

- Responabilities of A Welding InspectorDocument13 pagesResponabilities of A Welding Inspectorரமேஷ் பாலக்காடுNo ratings yet

- Pew205 Slide ShowDocument23 pagesPew205 Slide Showரமேஷ் பாலக்காடுNo ratings yet

- SAIC-D-2023 Rev 2Document2 pagesSAIC-D-2023 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- SAIC-E-2001 Rev 2Document7 pagesSAIC-E-2001 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- Computer Kerala - 4 Folder LockDocument2 pagesComputer Kerala - 4 Folder Lockரமேஷ் பாலக்காடுNo ratings yet

- Computer Kerala - 4 Folder LockDocument2 pagesComputer Kerala - 4 Folder Lockரமேஷ் பாலக்காடுNo ratings yet

- API 510 Examination Sample ItemsDocument3 pagesAPI 510 Examination Sample ItemsMagira PasaribuNo ratings yet

- SAIC-D-2022 Rev 2Document5 pagesSAIC-D-2022 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- 0 Wis10 Contents ListDocument1 page0 Wis10 Contents ListSangram RoutarayNo ratings yet

- Computer Kerala - 4 Folder LockDocument2 pagesComputer Kerala - 4 Folder Lockரமேஷ் பாலக்காடுNo ratings yet

- SAIC-F-2007 Rev 2Document1 pageSAIC-F-2007 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- Vedic Maths TutorialDocument12 pagesVedic Maths TutorialNitin Jain100% (15)

- Saudi Aramco Inspection Checklist: Inspection of Tank Trim Installation SAIC-D-2020 1-Dec-06 MechDocument3 pagesSaudi Aramco Inspection Checklist: Inspection of Tank Trim Installation SAIC-D-2020 1-Dec-06 Mechரமேஷ் பாலக்காடுNo ratings yet

- Practical Guide To Pressure Vessel Manufacturing - SUNIL PULLARCOTDocument362 pagesPractical Guide To Pressure Vessel Manufacturing - SUNIL PULLARCOTrodrigoperezsimoneNo ratings yet

- SAIC-D-2023 Rev 2Document2 pagesSAIC-D-2023 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- SAIC-D-2006 Rev 2Document2 pagesSAIC-D-2006 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- SAIC-E-2002 Rev 2Document7 pagesSAIC-E-2002 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- Saudi Aramco Inspection Checklist: Final Insp of Tank Installation (Tanks) SAIC-D-2021 1-Dec-06 MechDocument4 pagesSaudi Aramco Inspection Checklist: Final Insp of Tank Installation (Tanks) SAIC-D-2021 1-Dec-06 Mechரமேஷ் பாலக்காடுNo ratings yet

- SAIC-D-2006 Rev 2Document2 pagesSAIC-D-2006 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-D-2018 1-Dec-06 Mech-Insp of Under-Tank Leak Detection, Sub-Grade ProtectionDocument1 pageSaudi Aramco Inspection Checklist: SAIC-D-2018 1-Dec-06 Mech-Insp of Under-Tank Leak Detection, Sub-Grade Protectionரமேஷ் பாலக்காடுNo ratings yet

- Tax Ii: Syllabus - Value-Added Tax Atty. Ma. Victoria A. Villaluz I. Nature of The VAT and Underlying LawsDocument12 pagesTax Ii: Syllabus - Value-Added Tax Atty. Ma. Victoria A. Villaluz I. Nature of The VAT and Underlying LawsChaNo ratings yet

- 1940 Doreal Brotherhood PublicationsDocument35 pages1940 Doreal Brotherhood Publicationsfrancisco89% (9)

- IJBMT Oct-2011Document444 pagesIJBMT Oct-2011Dr. Engr. Md Mamunur RashidNo ratings yet

- How To Get The Poor Off Our ConscienceDocument4 pagesHow To Get The Poor Off Our Conscience钟丽虹No ratings yet

- Flexible Learning Part 1Document10 pagesFlexible Learning Part 1John Lex Sabines IgloriaNo ratings yet

- Summary of Kamban's RamayanaDocument4 pagesSummary of Kamban's RamayanaRaj VenugopalNo ratings yet

- CallClerk User GuideDocument94 pagesCallClerk User GuiderrjlNo ratings yet

- Engineering Economy 2ed Edition: January 2018Document12 pagesEngineering Economy 2ed Edition: January 2018anup chauhanNo ratings yet

- NBA Live Mobile Lineup with Jeremy Lin, LeBron James, Dirk NowitzkiDocument41 pagesNBA Live Mobile Lineup with Jeremy Lin, LeBron James, Dirk NowitzkiCCMbasketNo ratings yet

- Group 1 - MM - Vanca Digital StrategyDocument10 pagesGroup 1 - MM - Vanca Digital StrategyAashna Duggal100% (1)

- DIN EN ISO 12944-4 071998-EnDocument29 pagesDIN EN ISO 12944-4 071998-EnChristopher MendozaNo ratings yet

- Al Fara'aDocument56 pagesAl Fara'azoinasNo ratings yet

- Sohan vs. Mohan PlaintDocument6 pagesSohan vs. Mohan PlaintKarandeep Saund100% (5)

- Pradeep Kumar SinghDocument9 pagesPradeep Kumar SinghHarsh TiwariNo ratings yet

- Rationale For Instruction: Social Studies Lesson Plan TemplateDocument3 pagesRationale For Instruction: Social Studies Lesson Plan Templateapi-255764870No ratings yet

- Disaster Management Training Program Ethics UNDPDocument65 pagesDisaster Management Training Program Ethics UNDPTAKI - TAKINo ratings yet

- Human Resource Management in HealthDocument7 pagesHuman Resource Management in HealthMark MadridanoNo ratings yet

- Daddy's ChairDocument29 pagesDaddy's Chairambrosial_nectarNo ratings yet

- Current Trends in The Popular Sector Traditional Medicine in Sri LankaDocument10 pagesCurrent Trends in The Popular Sector Traditional Medicine in Sri Lankammarikar27No ratings yet

- RVU Distribution - New ChangesDocument5 pagesRVU Distribution - New Changesmy indiaNo ratings yet

- Tos Survey of Philippine LiteratureDocument1 pageTos Survey of Philippine LiteratureBernadette Barro GomezNo ratings yet

- Company Profile-SIPLDocument4 pagesCompany Profile-SIPLShivendra SinghNo ratings yet

- NSS 87Document2 pagesNSS 87Mahalakshmi Susila100% (1)

- Encyclopædia Americana - Vol II PDFDocument620 pagesEncyclopædia Americana - Vol II PDFRodrigo SilvaNo ratings yet

- 721-1002-000 Ad 0Document124 pages721-1002-000 Ad 0rashmi mNo ratings yet

- Consent of Action by Directors in Lieu of Organizational MeetingsDocument22 pagesConsent of Action by Directors in Lieu of Organizational MeetingsDiego AntoliniNo ratings yet

- Nursing Care Plan: Assessment Planning Nursing Interventions Rationale EvaluationDocument5 pagesNursing Care Plan: Assessment Planning Nursing Interventions Rationale Evaluationamal abdulrahman100% (2)

- Principles of Administrative TheoryDocument261 pagesPrinciples of Administrative TheoryZabihullahRasidNo ratings yet

- Blueprint For The Development of Local Economies of SamarDocument72 pagesBlueprint For The Development of Local Economies of SamarJay LacsamanaNo ratings yet

- KPMG Software Testing Services - GenericDocument24 pagesKPMG Software Testing Services - GenericmaheshsamuelNo ratings yet