Professional Documents

Culture Documents

D24 03

Uploaded by

Shailen ChakrabortyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

D24 03

Uploaded by

Shailen ChakrabortyCopyright:

Available Formats

Service Circular

Category of Circular

65432109876543210987654322109876543210987654321 1 65432109876543210987654321109876543210987654321 2 65432109876543210987654321109876543210987654321 2 65432109876543210987654322109876543210987654321 1 65432109876543210987654322109876543210987654321 1

NO. ISSUE NO. D-24/2003 DA DATE PA PAGE 05.05.2003 01 of 01

: Policy Matter/ Technical Matter/ Information

QU INFORMATION REPORT SUB: QUALITY INFORMATION REPORT We thank you for giving us prompt and accurate information on defects being observed in Maruti vehicles.Based on the valuable information and the defective components provided by you, we were able to take countermeasures on certain items, a report on which is enclosed. We request you to advise your workshop staff to monitor the performance of these items and to alert us immediately through FTRs (FIELD TROUBLE REPORTS) in case any post countermeasures failures are observed. Also we request you to raise STAR FTRs in case of failure related to engine and transmission assemblies, safety related components and new models. We are happy to inform you that a separate mail ID ftr@maruti.co.in has been created in MUL service department to receive FTRs. You are requested to send FTRs in future addressed to ftr@maruti.co.in. ftr@maruti.co.in.

(DR .K.KUMAR) ADVISOR (ENGINEERING)

Encl: above Encl: As above ALL DEALERS MDs CC: ALL DEALERS WORKS MANAGERS

Previous Circular No.D-23/2003 has been sent to ALL Dealers GM/ Works Managers only.

Circular explained to all concerned on ______________ ______________________ Works Managers Signature

B-05-07-01

MARUTI UDYOG LIMITED

SERVICE DEPARTMENT-2 PALAM-GURGAON ROAD, GURGAON - 122 015, HARYANA, INDIA

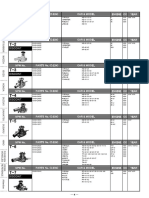

ANNEXURE 1 MODEL MB SL. NO. 1 SUBJECT GEAR OIL LEAKGE FROM OIL SEAL DIFFERENTIAL SIDE. ( HITECH ARAI) ENGINE OIL LEAKAGE FROM THE OIL SEAL. ( HITECH ARAI) COUNTERMEASURES TAKEN ENTRY CHAMFER MAINTAINED AT 1 TO 1.5 EFFECTIVE FROM CH NO. 1697539

NECESSARY PROCESS MODIFICATION DONE AT VENDOR END. NECESSARY PROCESS MODIFICATIONS DONE AT VENDOR END.

CH NO. 1755116

ENGINE OIL LIGHT GLOWING CONTINEOUSLY DUE TO DEFECTIVE PUMP ASSY. ( RICO) MODEL MT 308 SL. NO. 1. SUBJECT DOOR MOULDING COMING OUT DUE TO POOR ADHESION. ( PRECISION PIPES) NOISE FROM TIMING BELT TENSIONER. ( AUTOLEC)

CH NO. 1739385

COUNTERMEASURES TAKEN TAPE THICKNESS IN MOULDING INCREASED TO 1.6mm FROM 0.8mm AT THE REAR END. FLARING BEING DONE USING 2 TOOLS IN 2 SETS TO AVOID FLARING BREAKAGE. O.D. CHAMFER REDUCED FROM 1.6mm TO 0.5 mm

EFFECTIVE FROM CH NO. 567412

CH NO. 539197

VEHICLE HARD STARTING DUE TO FLY WHEEL TEETH BROKEN. ( AUTOMALLEABLE) MODEL MH

CH NO. 521756

SL. SUBJECT COUNTERMEASURES TAKEN NO. 1 STEERING NOISY & HARD WORM SHAFT SPINDLE DIA ( SMC) TOLERANCE RDUCED. BACKLASH REDUCED. EPS MOTOR CHANGED MODEL ME SL. NO. 1. SUBJECT COUNTERMEASURES TAKEN NECESSARY PROCESS MODIFICATIONS DONE AT VENDOR END.

EFFECTIVE FROM CH NO. 677485

EFFECTIVE FROM CH NO. 291208

HEATER NOT WORKING DUE TO DAMPER CLAMP BROKEN. ( SUBROS)

MODEL MG SL. NO. 1 SUBJECT COUNTERMEASURES TAKEN NECESSARY PROCESS MODIFICATION DONE AT MUL END. EFFECTIVE FROM CH NO. 219192

ABNORMAL NOISE FROM FUEL PUMP DUE TO BLOKAGE OF FUEL RETURN HOSE. ( INHOUSE) MODEL MRD SL. NO. 1 SUBJECT

COUNTERMEASURES TAKEN

EFFECTIVE FROM

ABNORMAL NOISE FROM REAR SUSPENSION DUE TO DEFECTIVE ABSORBER ASSY RR SHOCKER. ( DELPHI) ABNORMAL NOISE 2 FROM FRONT SUSPENSION DUE TO DEFECTIVE STRUTS. ( MUNJAL SHOWA) MODEL MRF SL. NO. 1 SUBJECT A/C GAS LEAKAGE DUE TO DEFECTIVE CONDENSOR ASSY. ( SANDEN)

100% MAGNAFLUX INPECTION CH NO. 173730 STARTED.

100% SEGREGATION OF DUST COVER FOR OVALITY & SQUEEZING STARTED.

CH NO. 172065

COUNTERMEASURES TAKEN CONNECTOR DESIGN MODIFIED TO 2 CONTACTS FROM SINGLE POINT CONTACT TO AVOID OVER HANG. CONNECTOR FLANGE LENGTH INCREASED FROM 20mm TO 23 mm TO HAVE POSITIVE SEALING.

EFFECTIVE FROM CH NO. 224383

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Quantum FuseDocument3 pagesQuantum FuseMshiboniumNo ratings yet

- Emergency Sintralite Recessed Luminaires Technical SpecificationDocument2 pagesEmergency Sintralite Recessed Luminaires Technical SpecificationawadalmekawyNo ratings yet

- Catálogo AFC Filtros 2 VersãoDocument32 pagesCatálogo AFC Filtros 2 VersãoSergio GodoyNo ratings yet

- Alfa Romeo 147 2006Document24 pagesAlfa Romeo 147 2006Ivica1977100% (2)

- BMW X3 Specification SheetDocument1 pageBMW X3 Specification SheetSNNo ratings yet

- PB 320D Dan 320D L ExcavatorDocument2,480 pagesPB 320D Dan 320D L Excavatorkampungsaya79No ratings yet

- 01 - G30 Introduction and BodyDocument32 pages01 - G30 Introduction and BodyAllan CancinoNo ratings yet

- Importation Et Vente Pièces de Rechange Auto en Gros: Facebook: @gspautopartscompanyDocument7 pagesImportation Et Vente Pièces de Rechange Auto en Gros: Facebook: @gspautopartscompanyrouya académieNo ratings yet

- Mitsubishi Canter engine specificationsDocument1 pageMitsubishi Canter engine specificationsSan JuanNo ratings yet

- Fiat 80 90 Tractor Manual: Read/DownloadDocument2 pagesFiat 80 90 Tractor Manual: Read/DownloadG-Ab Briel0% (4)

- 1c Manual Partes Grand Caravan 1999Document605 pages1c Manual Partes Grand Caravan 1999Sebastian SirventNo ratings yet

- 2018 JLG 534D9Document848 pages2018 JLG 534D9FLORES TEQUISQUIAPAN QRTNo ratings yet

- Diagrama 4 PEDAL ACELERADOR P ..Document1 pageDiagrama 4 PEDAL ACELERADOR P ..Rafa MackintoshNo ratings yet

- Mitsubishi Orion EngineDocument5 pagesMitsubishi Orion Enginenew0% (3)

- Monitoring StockDocument1 pageMonitoring Stockpram anandyaNo ratings yet

- Toyota Celica Body Dimension DrawingsDocument5 pagesToyota Celica Body Dimension DrawingsralphosssNo ratings yet

- VW Passat 3b5 ManualDocument3 pagesVW Passat 3b5 ManualDanteLupu0% (3)

- Macan BrochureDocument17 pagesMacan BrochureJose Manuel CarvajalNo ratings yet

- Valeo Wiper Blades Full RangeDocument6 pagesValeo Wiper Blades Full RangeSinead1990No ratings yet

- Auto LampDocument92 pagesAuto LampCam ReteaNo ratings yet

- Job Card Retail InvoiceDocument4 pagesJob Card Retail InvoiceSudhir Kumar Kandukuri100% (1)

- New Swift - 6 Pager Brochure - EnglishDocument2 pagesNew Swift - 6 Pager Brochure - EnglishAakash SharmaNo ratings yet

- NPW Water Pump & Fan Clutch 2021Document190 pagesNPW Water Pump & Fan Clutch 2021rexmistNo ratings yet

- BALENODocument1 pageBALENOazharNo ratings yet

- AD00.19-N-9030GA Fault Code List For Maintenance System (WS) Control Unit 11.1.08 Model 930, 932, 933, 934Document1 pageAD00.19-N-9030GA Fault Code List For Maintenance System (WS) Control Unit 11.1.08 Model 930, 932, 933, 934Novakurniawan100% (1)

- Best VAGCOM Codes To Enable On Polo 6R - Page 4 - UK-POLOS - NET - THE VW Polo ForumDocument4 pagesBest VAGCOM Codes To Enable On Polo 6R - Page 4 - UK-POLOS - NET - THE VW Polo Forumvajihet327No ratings yet

- 29-04 Inbound WH PCJ PDFDocument8 pages29-04 Inbound WH PCJ PDFfajri saniNo ratings yet

- 977.pdf Catalago de RodamientosDocument35 pages977.pdf Catalago de RodamientosJorge TaffurNo ratings yet

- The David: Light Armored VehicleDocument2 pagesThe David: Light Armored Vehicleالكترونيات يافاNo ratings yet

- BMW WBAZW42090L463258 AllSystemDTC 20230808125819Document3 pagesBMW WBAZW42090L463258 AllSystemDTC 20230808125819robert.robzNo ratings yet