Professional Documents

Culture Documents

RA Hiab Crane Truck

Uploaded by

Richard JosephOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RA Hiab Crane Truck

Uploaded by

Richard JosephCopyright:

Available Formats

Joseph Richards SMS HSE Officer

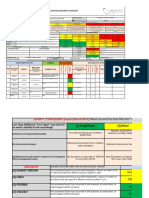

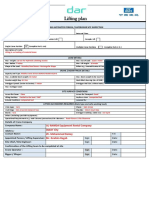

RISK ASSESSMENT Lifting Operations Using Crane Truck

Date 13th Dec, 2011 Review Date 13th Dec, 2011 Location Pt. Fortin Desalination Plant Reason for Risk Assessment Task Problem Alternatives Use of mobile Crane to conduct lifting and installing vessel

Lifting of heavy structure and installing into designated area. The purpose of this risk assessment is to ensure that the work will be properly controlled and can be carried out safely. The risk assessment considered the following alternatives: Do not do the work This was excluded because it is essential for The Client.

Limitations Of This assessment

The risk assessment reviews only the risks of: Using a Crane truck to lift the heavy structure. The risk assessment assumes that normal industry safe practices and procedures will be used when this operation is carried out.

Assessors

B. Craig, A. Dabiedeen, M. Poulido, J. Richards,

Page 1 of 8

Joseph Richards SMS HSE Officer

Hazard

Effect

Probability L

Risk M

The structure may fall from the H crane if the rigging is not properly secure.

Residual Risk Ensure the Inspection and certification records for the Low cranes are current and up to date. Only a competent (certified/qualified) person must operate the equipment. Prior to lift; inspect the equipment for defects/faults that may affect safe lifting operations. Conduct pre-operational and functional test. (Upper and lower limits switches, all directional and speed controls, pendant, emergency stops, hoist brake, hooks, load lines, trolley bridges etc). Ensure all rigging and hoisting devices are suitable and properly rated (OSHA) and in good working order. The rigging of any material for lifting will be carried out by a competent person. The rigging for lifting the material will be inspected by a competent person immediately prior to the lift taking place. A barrier will be erected around the crane truck prior to lifting operations commencing. The purpose of this barrier will be to warn and prevent persons from approaching the crane while lifting operations take place. No person will be allowed in any area of the lifting radius of the crane while the lift is being carried out. This means that if the load does fall for any reason, the only damage will be to equipment and not people. The crane operator will lift the load cautiously no more than 1 foot to ensure that the rigging is properly placed to allow the load to remain level during the lift.

Controls To Be Put In Place

Page 2 of 8

Joseph Richards SMS HSE Officer

Hazard The crane truck may topple over if the load is lifted too high or moved too far away from the side of the truck.

Effect H

Probability L

Risk M

The crane could fail during lifting operations

Residual Risk The crane will only be operated on level ground that is Low suitably compacted stable to allow safe lifting operations to take place. The Crane will be fitted with two outriggers that will be deployed and checked by a competent person prior to any lift taking place. No load will be lifted from or to an area beyond the outriggers. No load will be lifted more than 2 feet above the level of the cargo bed of the truck. The barriers around the crane will be positioned so as to be outside the area taken by the outriggers. Only the crane operator and two tag line operators will be allowed within the work area while lifting operations are carried out. The crane will be suitably inspected and certified by a Low competent authority within twelve months of the lift taking place. The crane will be visually inspected by a competent person prior to the lift taking place. The weight of the load will be known by the crane operator prior to the lift taking place. The weight of load will not exceed 90% of the Safe Working Load of the crane

Controls To Be Put In Place

Page 3 of 8

Joseph Richards SMS HSE Officer

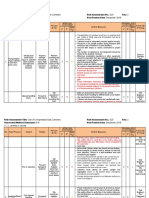

Hazard Personnel could be struck by a swinging load

Effect H

Probability M

Risk H

Tripping and falling over Personnel not involved in the lifting operation and/or vehicles could come into the danger area where loads are being lifted.

H H

M M

M H

Residual Risk The load will be fitted with two tag lines that will be used Low by the tag line operators to check/prevent any significant swinging of the load. The crane operator will only swing the load slowly in line with good industrial practice. No person, including the crane operator, the tag line operators or the banksman will be allowed to work in any area where the load could reasonably swing. The barriers that are erected will serve to warn/prevent persons from coming into the area that the lifting operations will be carried out in. The banksman will be positioned in such a way that s/he can see the crane operator, the tag line operators and the whole area around the truck where a load could reasonably swing. Loads will not be lifted where wind speed or gusts exceeds 20 knots. Work must temporarily cease in inclement weather conditions. Work areas and accessways to be kept clear of Low unnecessary materials and equipment A barrier will be erected which will act as a warning to Low personnel not involved in the operation that they should stay away from the area. A person will be placed to act as an access controller on the blind side of the crane truck that cannot reasonably be covered by the banksman. This person will be instructed to ensure persons not involved in the operation stay outside the barricaded area and to prevent vehicles from coming close to the lifting operations.

Controls To Be Put In Place

Page 4 of 8

Joseph Richards SMS HSE Officer

Hazard Structural failure of crane due to incorrect erection sequence

Effect H

Probability H

Risk H

Objects may drop from the load while the lift is being carried out

It is possible that the crane or part of the load could come into contact with, or be in close proximity to overhead electric cables which could cause the truck and load to become electrically live. Communication breakdown includes critical and non-critical operations

Residual Risk Operator/supervisor/s must be thoroughly trained and Low experienced with the type of crane being worked upon. A complete and specific crane manual, in English, must be available on site at all times where possible. The work process should be planned by experienced personnel, and all work group parties should be involved in the planning process. No person to be under suspended loads. Crane operator to avoid lifting loads over personnel, accommodation or traffic. The load will be checked by a competent person prior to Low any load being lifted. This check will include observation of any loose equipment or items that may become loose during the lift. Because personnel will not be allowed in the immediate area of the load being lifted, any thing that does fall from the load will not be able to hit anyone. The crane truck will not be operated within a horizontal Low distance of fifty feet from any overhead electric cables. The crane operator will be instructed to check for overhead electric cables prior to deploying outriggers to ensure that the minimum distance of fifty feet is achieved. All personnel shall be in direct contact with each other Low through an established effective means of communication. This is to ensure constant contact with each other. An observer will be stationed in such a position that they can see the operation being carried out. The role of that observer is to have control of the operation in progress, and be able to rapidly respond to prevent an accident, or in the case of any emergency.

Controls To Be Put In Place

Page 5 of 8

Joseph Richards SMS HSE Officer

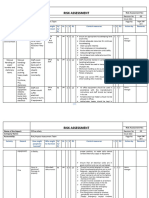

Hazard It is possible that the personnel involved in the installation operation will be unaware of the actions to take in the event of an emergency

Effect H

Probability M

Risk H

Residual Risk All personnel working on the lifting operations must be Low given a briefing on what to do in the event of an emergency occurring. This briefing should include: The method of raising the alarm. What to do in the event of hearing the alarm. How to summon medical help

Controls To Be Put In Place

Page 6 of 8

Joseph Richards SMS HSE Officer

Acceptance By Competent Person In charge Of The Work To Be Carried Out As the designated competent person in charge of the work to be carried out, I have reviewed and understood the risk assessment, I will be present on site while this work is being carried out, I will ensure all control measures are properly put in place before work commences and I will not allow work to commence until I have reviewed the site prior to work commencing to assure myself that all reasonably foreseeable risk has been identified and will be controlled by the control measures identified in the risk assessment. Note. A toolbox meeting must be conducted where all aspects of the JSA and risk assessment are highlighted. They must be understood by all involved prior to commencement of the task. All persons must be informed of any changes if any in the emergency procedures in the building and no emergency exits are to be blocked by the personnel performing the duties assigned to them unless authorization to do so is given by competent authority. Name:_______________________________ Position:_____________________________ Company:____________________________ Date:________________________________

Page 7 of 8

Joseph Richards SMS HSE Officer

Table Hazard Effect Anything that has the potential to cause harm. Consequence of a hazard being realized. High = Fatality or permanent Serious Injury (amputation) Medium = Serious Injury that is not permanent (broken bone) Low = First Aid treatment type injury (scratch or bruise) Likelihood of a hazard being realized. High = It is very likely to occur. Medium = A reasonable expectation of occurrence. Low = is unlikely to occur. Chance or possibility of danger, loss and or injury. Means of controlling the risk identified to the lowest reasonable level. After all the identified hazards are mitigated the level of risk still present.

Probability

Risk Controls in place Residual risk

Page 8 of 8

You might also like

- Risk Assessment of Heavy LiftingDocument5 pagesRisk Assessment of Heavy Lifting채종언100% (3)

- 02-F02 HIRA-Hazard ID and Risk Assessment Form and RegisterDocument5 pages02-F02 HIRA-Hazard ID and Risk Assessment Form and Registershaibaz chafekarNo ratings yet

- Jsa R B 6 ForkliftDocument3 pagesJsa R B 6 Forkliftoscar67% (3)

- 1326370398-HS6-54 Use of MEWP Risk AssessmentDocument2 pages1326370398-HS6-54 Use of MEWP Risk AssessmentJohn David Hoyos Marmolejo83% (6)

- Example Risk Assessment For Excavations Updated 21-11-12Document3 pagesExample Risk Assessment For Excavations Updated 21-11-12rishi100% (3)

- All Personnel To Attend Daily Site Safety Meeting and Review Site Safety Plan. Also, in Place Traffic Manage-Ment Plan / TMP ApplicableDocument6 pagesAll Personnel To Attend Daily Site Safety Meeting and Review Site Safety Plan. Also, in Place Traffic Manage-Ment Plan / TMP ApplicablecrnkarlosNo ratings yet

- General Crane SafetyDocument4 pagesGeneral Crane SafetyEhab Mostafa AliNo ratings yet

- Risk Assessment for Loading and Offloading of SteelDocument3 pagesRisk Assessment for Loading and Offloading of SteelSarfraz Randhawa100% (3)

- 3074 - Use of Genie Man LiftDocument1 page3074 - Use of Genie Man Liftcmrig74No ratings yet

- Hyundai Engineering & Construction Co., Ltd. HAMAD MEDICAL CITY Construction Package CP-300B Hospital Fit Out ProjectDocument4 pagesHyundai Engineering & Construction Co., Ltd. HAMAD MEDICAL CITY Construction Package CP-300B Hospital Fit Out ProjectYounis Khan100% (1)

- Lifting Risk AssessmentDocument4 pagesLifting Risk AssessmentMohamedSaid100% (1)

- 7 Hand Held Power ToolsDocument4 pages7 Hand Held Power ToolsGilmar MonteiroNo ratings yet

- Concrete WorkDocument1 pageConcrete WorkChandruNo ratings yet

- Mobile Elevating Work Platforms: AUGUST 2014Document64 pagesMobile Elevating Work Platforms: AUGUST 2014Parmod RanaNo ratings yet

- Risk Assesment Form ScaffoldDocument10 pagesRisk Assesment Form ScaffoldRejin PradeepNo ratings yet

- Training Matrix بيردتلا ةفوفصم: PDWB-HSE-FRM-030Document1 pageTraining Matrix بيردتلا ةفوفصم: PDWB-HSE-FRM-030mahmoud nada100% (1)

- Sop LiftingDocument5 pagesSop LiftingShaiful AnnuarNo ratings yet

- Maeda-Onaka, Joint Venture: Generic Lifting PlanDocument4 pagesMaeda-Onaka, Joint Venture: Generic Lifting PlanJaycee Pagador100% (1)

- Manual Handling RisksDocument7 pagesManual Handling RisksDáithí O'LaoghaireNo ratings yet

- EHS RISK ASSESSMENT FOR MATERIAL HANDLINGDocument4 pagesEHS RISK ASSESSMENT FOR MATERIAL HANDLINGshamshu123100% (1)

- Mobile Elevated Work Platforms (MEWP) Program: Provo, UtahDocument14 pagesMobile Elevated Work Platforms (MEWP) Program: Provo, UtahStephanie ScottNo ratings yet

- Use of Hand ToolsDocument2 pagesUse of Hand Toolsvictor100% (1)

- Permit To Work - Mobile CraneDocument2 pagesPermit To Work - Mobile CraneMIDWEST BUILDING DEMOLITIONS100% (1)

- Planned Critical Lift Crane PermitDocument5 pagesPlanned Critical Lift Crane PermitsurnaikNo ratings yet

- Stop Work AuthortyDocument8 pagesStop Work AuthortyRonald Sarillana100% (1)

- Risk Assessment Hollowcore WF-ALLDocument8 pagesRisk Assessment Hollowcore WF-ALLChoubi ChoubacaNo ratings yet

- Fitness for Work PolicyDocument18 pagesFitness for Work PolicyNaba majeadNo ratings yet

- HSE Training MatrixDocument3 pagesHSE Training MatrixNasrullah Jan100% (1)

- Risk Analisis Ramming WorksDocument2 pagesRisk Analisis Ramming Worksdefidmsp39No ratings yet

- TRA of Lifting - TailDocument3 pagesTRA of Lifting - TailTharaka Perera100% (1)

- DLF PCC HiraDocument6 pagesDLF PCC HiraskfahimuddinNo ratings yet

- Risk assessment for logistics company loading and unloading vehiclesDocument2 pagesRisk assessment for logistics company loading and unloading vehiclesDanny100% (1)

- JSA For Crawler Crane Installation FormDocument3 pagesJSA For Crawler Crane Installation FormHu Man88% (8)

- Risk Assesment - Floor Chasing and ScreedingDocument3 pagesRisk Assesment - Floor Chasing and Screedingirfan vpNo ratings yet

- Hazardous Substances & Dangerous Goods WHSPRO-007 CMDocument7 pagesHazardous Substances & Dangerous Goods WHSPRO-007 CMJason McIntoshNo ratings yet

- Lifting Plan Site InspectionDocument5 pagesLifting Plan Site Inspectionkhaled redaNo ratings yet

- Risk Assessment for Lifting OperationsDocument2 pagesRisk Assessment for Lifting OperationsPrem Shiva100% (1)

- Risk Assessment For Repair of ManholeDocument5 pagesRisk Assessment For Repair of Manholeflmm09No ratings yet

- Safe crane lifting guideDocument26 pagesSafe crane lifting guideVenkadesh PeriathambiNo ratings yet

- HIRA For Pre-Commissionong Testing of Over Head Equipment (OHE)Document8 pagesHIRA For Pre-Commissionong Testing of Over Head Equipment (OHE)DEBASISH KHADANGA50% (2)

- Industrial Security and ManagementDocument48 pagesIndustrial Security and ManagementHadzmar P. Pantasan50% (4)

- RISK ASSESSMENT (Concrete Pouring & Vehicular Movement)Document2 pagesRISK ASSESSMENT (Concrete Pouring & Vehicular Movement)Raza Muhammad Soomro100% (1)

- RA - 11 - For Dewatering WorksDocument19 pagesRA - 11 - For Dewatering WorksIbrahim EsmatNo ratings yet

- 6003 400 450 02 - Rfs PDFDocument348 pages6003 400 450 02 - Rfs PDFShan Ahmad100% (3)

- Safe Use of Work PlatformsDocument5 pagesSafe Use of Work PlatformsFrancis Enriquez TanNo ratings yet

- MP-001 Change Head and Liner of Mud PumpDocument3 pagesMP-001 Change Head and Liner of Mud PumpkhurramNo ratings yet

- Rigging Plan Worksheet: 4.0/3b07e011.pdf 1 (11/2006)Document3 pagesRigging Plan Worksheet: 4.0/3b07e011.pdf 1 (11/2006)Cleiciane FrancoNo ratings yet

- JSARA - Fire Detection System InstallationDocument13 pagesJSARA - Fire Detection System InstallationUtku Can KılıçNo ratings yet

- 1st Quarter Exam in DRRRDocument3 pages1st Quarter Exam in DRRRNelmar Araneta100% (1)

- Work at Height Rescue Plan: Purpose of Working at Heights RescuesDocument4 pagesWork at Height Rescue Plan: Purpose of Working at Heights RescuesRajesh gp100% (1)

- IC 57 - Fire and Consequential Loss Insurance (Summary)Document20 pagesIC 57 - Fire and Consequential Loss Insurance (Summary)Mahendra Kumar YogiNo ratings yet

- Critical Lift Plan - ChecklistDocument4 pagesCritical Lift Plan - ChecklistDelia HarsanNo ratings yet

- JHA LiftingDocument4 pagesJHA Liftingsyamimi balkhisNo ratings yet

- TRA 13 Loading or Unloading Chems With ForkliftDocument2 pagesTRA 13 Loading or Unloading Chems With ForkliftPirlo Polo100% (1)

- Risk Assessment for Compressed Gas Cylinder UseDocument7 pagesRisk Assessment for Compressed Gas Cylinder UsejeffreyNo ratings yet

- ASQS Quick Ref Risk RegisterDocument15 pagesASQS Quick Ref Risk RegisterAdrian Sopon100% (1)

- Crane Assembly and Dismantling and ModificationDocument1 pageCrane Assembly and Dismantling and Modificationsrinibas mohapatraNo ratings yet

- Man-machine-interface-Training Module SAMIR 11 R4Document10 pagesMan-machine-interface-Training Module SAMIR 11 R4Sheri Diĺl0% (1)

- Safe Lifting InformationDocument4 pagesSafe Lifting InformationRa INNo ratings yet

- DLL Week 5Document3 pagesDLL Week 5Nen CampNo ratings yet

- Risk Assessment PDFDocument4 pagesRisk Assessment PDFAnonymous iI88LtNo ratings yet

- LKC - Lifting Risk AssessmentDocument4 pagesLKC - Lifting Risk AssessmentAdam EatonNo ratings yet

- PTW Critical Lifting OperationDocument5 pagesPTW Critical Lifting Operationfikadu alemiNo ratings yet

- Poultry Slaughter HACCP ModelDocument66 pagesPoultry Slaughter HACCP Modelpokhralikanchha0% (1)

- MEWP Lifting PlanDocument21 pagesMEWP Lifting Planalex100% (1)

- IR-II U&O DBN PRE-LIFT CHECKLISTDocument1 pageIR-II U&O DBN PRE-LIFT CHECKLISTmiaicarbaNo ratings yet

- TE550 Blending Controller: Installation, Use and Service ManualDocument89 pagesTE550 Blending Controller: Installation, Use and Service Manualm75% (4)

- MSDS Bisoprolol Fumarate Tablets (Greenstone LLC) (EN)Document10 pagesMSDS Bisoprolol Fumarate Tablets (Greenstone LLC) (EN)ANNaNo ratings yet

- 2.1 Precautions For Tower Crane Dismantle: Chapter II DismantlingDocument6 pages2.1 Precautions For Tower Crane Dismantle: Chapter II DismantlingYoutube SaleemNo ratings yet

- Flowchart Hpg1034Document1 pageFlowchart Hpg1034SharulNo ratings yet

- Heavy Lifting Safety ChecklistDocument1 pageHeavy Lifting Safety ChecklistMock ProjectNo ratings yet

- Job Hazard AssessmentDocument26 pagesJob Hazard AssessmentGeherson AbustanNo ratings yet

- Environmental, Health and Safety Risks AnalysisDocument3 pagesEnvironmental, Health and Safety Risks AnalysisKrishna PatilNo ratings yet

- RA-05-Office SafetyDocument5 pagesRA-05-Office Safetyamritha n krishnaNo ratings yet

- Sds SimploDocument19 pagesSds Simplomiguelangelo bubaNo ratings yet

- (Disaster Risk Reduction) Rajib Shaw, Hari Krishna Nibanupudi (Eds.) - Mountain Hazards and Disaster Risk Reduction-Springer Japan (2015)Document287 pages(Disaster Risk Reduction) Rajib Shaw, Hari Krishna Nibanupudi (Eds.) - Mountain Hazards and Disaster Risk Reduction-Springer Japan (2015)SuryakantDakshNo ratings yet

- REYES LU - Gender Dimension IJDRRDocument7 pagesREYES LU - Gender Dimension IJDRRDaniella ReyesNo ratings yet

- 2022 ISRM JournalDocument98 pages2022 ISRM JournalOlivinNo ratings yet

- NPA - SITXWHS007 Assessment 2 - Project FinalDocument25 pagesNPA - SITXWHS007 Assessment 2 - Project FinalJoshua Estrada AbellaNo ratings yet

- Fire Department Hazard Mitigation PlanningDocument40 pagesFire Department Hazard Mitigation PlanningMuzammil HabibNo ratings yet

- UPL Cornubia Fire Civil Society Action Group SAHRC SubmissionDocument30 pagesUPL Cornubia Fire Civil Society Action Group SAHRC SubmissionKrash KingNo ratings yet

- Health and Safety 1 (12 Batch)Document18 pagesHealth and Safety 1 (12 Batch)aye chan monNo ratings yet

- Manual Hmi SewDocument64 pagesManual Hmi SewASTECHNo ratings yet

- Iso26262 The Ecall System: Massimo ViolanteDocument21 pagesIso26262 The Ecall System: Massimo Violantearsalan inamNo ratings yet

- ANTIPOLO NATIONAL HIGH SCHOOL SUMMATIVE TEST COVERS KEY CONCEPTSDocument3 pagesANTIPOLO NATIONAL HIGH SCHOOL SUMMATIVE TEST COVERS KEY CONCEPTSrandyNo ratings yet

- Weekly Home Learning Plan For Modular Distance Learning: Grade 12 - A and BDocument3 pagesWeekly Home Learning Plan For Modular Distance Learning: Grade 12 - A and BJarven SaguinNo ratings yet

- ACS Rules For Offshore Fixed Platform InstallationDocument31 pagesACS Rules For Offshore Fixed Platform Installationsaeed ghafooriNo ratings yet

- WildfiresDocument4 pagesWildfiresHugoAñamuroNo ratings yet

- Fire Disaster GroupDocument17 pagesFire Disaster GroupChristian NyiNo ratings yet

- CL-1200i (1000P) Service Manual V2.0 enDocument799 pagesCL-1200i (1000P) Service Manual V2.0 ensandeep ntNo ratings yet