Professional Documents

Culture Documents

Nozzle Reinforcing Calculations For A Pressure Vessel Design - by Abdel Halim Galala

Uploaded by

paaryOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nozzle Reinforcing Calculations For A Pressure Vessel Design - by Abdel Halim Galala

Uploaded by

paaryCopyright:

Available Formats

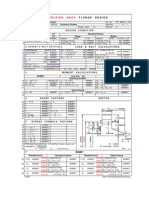

DESIGN CALCULATIONS OF PRESSURE VESSEL Page : 31 of 126

According to ASME Code, Section VIII, Division 1, Edition 2001, Addenda 2002 Shee t : 1 of 5

Designed by : Eng. Abdel Halim Galala, Design General Manager (assist.) Rev. : 1

Project : Design & Procurement of ASME Pressure Vessel Date : 18.2.2004

Job Name : Demineralization Plant Job No. : 7434-33

Serial No. : 7434-33-U-2006 Dwg. No. : 7434-33-3A, Rev. 1 Client : APRC

Vessel : Deputanizer Reflux Receiver Drum Item No. : 1-D-5 Capacity : 10.152 M3 Type : Horizontal

M4. Nozzle Mark : N1 8"NPS, Sch. 80, 300# WNRF (Located at Shell)

No. of nozzles, n 1

Nozzle Neck Thickness Calculation [UG-45, UG-27 & APPENDIX 1-1]

Nozzle Size, NPS 8 INCH 200 DN

Nozzle Material ASME SA 106 Grade B

Design Pressure, P 257.898 PSIG 18.156 Kg/CM2G

o o

Design Temperature 149 F 65 C

For nominated Design Pressure & Temperature, Flange Rating 300#

[ANSI/ASME B16.5-1996]

Max. Allowable Stress of Nozzle Material @ Design Temp.(75 oC), Sn 17100 PSIG 1203.84 Kg/CM2G

Max. Allowable Stress of Nozzle Materiall @ Test Temp.(40 oC), Snt 17100 PSIG 1203.84 Kg/CM2G

[Table 1A, SubPart 1, ASME Sec. II, Part D]

Outside Radius of Nozzle, Ron 4.3125 INCH 109.5375 MM

Joint Efficiency of Nozzle, En (Seamless Pipe) 1

Nozzle Corrosion Allowance, Can 0.23622 INCH 6 MM

Nozzle Thickness Calculation :

Longitudinal Stress, t = PRon /(Sn*En + 0.4 P) 0.06465 INCH 1.642111 MM

[APPENDIX 1.1]

By adding Corrosion Allowance, t [UG-25] 0.30087 INCH 7.642111 MM

By adding Pipe Tolerance 12.5% to the Thickness of Nozzle, t 0.33848 INCH 8.597375 MM

Use Nozzle 8" NPS with Selected Neck Sch. 80, 0.5 INCH 12.7 MM

with Thickness 0.5" ( 12.7 MM ). [Table 2 of ANSI B 36.10M-1985-(R-1994)]

Nozzle Neck Maximum Working Pressure, MWP (New & Operating)

Nozzle wall thickness less tolerance 12.5% 0.4375 INCH 11.1125 MM

Nozzle wall thickness less tolerance 12.5% - Corrosion allowance 0.20128 INCH 5.1125 MM

MWP, New & cold (9.271 MM) P = Snt E t /(Ron - 0.4 t) [App. 1.1] 1808.16 PSIG 127.2943 Kg/CM2G

MWP, Operating & corroded (4.289 MM) P = Sn E t /(Ron - 0.4 t) 813.301 PSIG 57.25639 Kg/CM2G

Nozzle Flange Maximum Working Pressure, MWP (New & Operating)

MWP, New & cold, 300# @ 100 oF [ASME B.165, Table 2] 740 PSIG 52.096 Kg/CM2G

MWP, Operating & corroded, 300# @ 149 oF [ANSI B16.5, Table 2] 708.15 PSIG 49.85376 Kg/CM2G

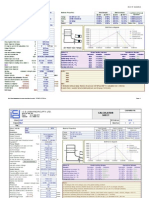

DESIGN CALCULATIONS OF PRESSURE VESSEL Page : 32 of 126

According to ASME Code, Section VIII, Division 1, Edition 2001, Addenda 2002 Sheet : 2 of 5

Designed by : Eng. Abdel Halim Galala, Design General Manager (assist.) Date : 18.2.2004

Project : Design & Procurement of ASME Pressure Vessel Client : APRC

Job Name : Demineralization Plant Job No. : 7434-33

Serial No. : 7434-33-U-2006 Dwg. No. : 7434-33-3A, Rev. 1 Client : APRC

Vessel : Deputanizer Reflux Receiver Drum Item No. : 1-D-5 Capacity : 10.152 M3 Type : Horizontal

M4. Nozzle Mark : N1 8" 300# WNRF (located at shell) (cont.)

Nozzle Opening Calculation With Reinforcing [UG-27(c) & APPENDIX 1-1]

Nozzle Pipe Size, NPS 8 INCH 200 DN

Nozzle Pipe Sch. 80

Design Pressure, P 257.898 PSIG 18.15602 Kg/CM2G

o o

Design Temparture 149 F 65 C

Shell Material ASME SA516 Grade 70

Nozzle Material ASME SA 106 Grade B

Reinforcing Pad Material ASME SA516 Grade 70

Allowable Stress of Shell Material, Sv 20000 PSIG 1408 Kg/CM2G

Allowable Stress of Nozzle Material, Sn 17100 PSIG 1203.84 Kg/CM2G

Allowable Stress of Pad Material, Sp 20000 PSIG 1408 Kg/CM2G

Shell Thickness 0.86614 INCH 22 MM

Shell Corrosion Allowance, Cas 0.23622 INCH 6 MM

Shell Thickness less Pipe Tolerance 12.5% (12.5% NA) 0.86614 INCH 22 MM

Shell Thickness less Corrosion Allowance & 12.5%, t (12.5% NA) 0.62992 INCH 16 MM

Nozzle Wall Nominal Thickness 0.5 INCH 12.7 MM

Nozzle Wall Thickness less Pipe Tolerance 12.5% 0.4375 INCH 11.1125 MM

Nozzle Corrosion Allowance, Can 0.23622 INCH 6 MM

Nozzle Wall Thick. less Corr. Allowance & 12.5% , tn 0.20128 INCH 5.1125 MM

Nozzle Wall Thick.of Internal Projection (less Corr. Allowance & 12.5%), ti 0.20128 INCH 5.1125 MM

Reinforced Pad Thickness, te 0.86614 INCH 22 MM

Joint Efficiency of Shell, E 1

Joint Efficiency of Nozzle, En 1

Correction Factor, F [UG-37(a)] 1

E1 [Nozzle in solid plate] 1

Shell Outside Diameter, OD 62.9921 INCH 1600 MM

Shell Inside Diameter in Corroded Condition, 2R = OD - 2 t 61.7323 INCH 1568 MM

Shell Inside Radius in Corroded Condition, R 30.8661 INCH 784 MM

Nozzle Outside Diameter, OD 8.625 INCH 219.075 MM

Nozzle Inside Diameter, ID 7.625 INCH 193.675 MM

Nozzle Projection beyond Inner Vessel Wall, h = min. (h1,h2) 0 INCH 0 MM

h1 = 2.5 t 1.5748 INCH 40 MM

h2 = 2.5 ti 0.5032 INCH 12.78125 MM

Nozzle ID Without Corrosion Allowance & 12.5% , d = OD - 2*tn 8.22244 INCH 208.85 MM

Finished Radius of Circular Opening, Rn 4.11122 INCH 104.425 MM

DESIGN CALCULATIONS OF PRESSURE VESSEL Page : 33 of 126

According to ASME Code, Section VIII, Division 1, Edition 2001, Addenda 2002 Sheet : 3 of 5

Designed by : Eng. Abdel Halim Galala, Design General Manager (assist.) Rev. : 1

Project : Design & Procurement of ASME Pressure Vessel Date : 18.2.2004

Job Name : Demineralization Plant Job No. : 7434-33

Serial No. : 7434-33-U-2006 Dwg. No. : 7434-33-3A, Rev. 1 Client : APRC

Vessel : Deputanizer Reflux Receiver Drum Item No. : 1-D-5 Capacity : 10.152 M3 Type : Horizontal

M4. Nozzle Mark : N1 8" 300# WNRF (located at shell) (cont.)

Nozzle Opening Calculation With Reinforcing (cont.) [UG-27(c) & APPENDIX 1-1]

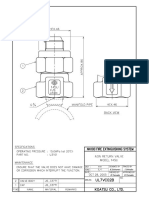

* Outside Diameter of Reinforced Pad [UG-40(b)&FIG.UG-37.1]

Dp1 = 2 d 16.4449 INCH 417.7 MM

Dp2 = 2 (Rn + nozzle wall thk. , tn + vessel wall thk. , t ) 9.88484 INCH 251.075 MM

OD of Reinf. Pad, Dp = the greater of Dp1 or Dp2 16.4449 INCH 417.7 MM

Calculating Size of Fillet Welds : [UW-16(c)(2)&FIG.UW-16.1]

* For Outward Nozzle Weld [UW-16(c)(2)&FIG.UW-16.1SKETCH (c)]

Calculation of tmin. :

tmin.1 = 0.75 inch 0.75 INCH 19.05 MM

tmin.2 (nozzle wall nominal thickness) 0.5 INCH 12.7 MM

tmin.3 (shell wall thickness) 0.47244 INCH 12 MM

tmin. = lesser of tmin.1, tmin. & tmin.3 0.47244 INCH 12 MM

Calculation of tc : tc1 = 0.25 inch 0.25 INCH 6.35 MM

tc2 = 0.7 t min. 0.33071 INCH 8.4 MM

tc = lesser of tc1 & tc2 0.25 INCH 6.35 MM

By Considering Equal Legs Fillet Welds :

Leg 41 Leg of Outward Nozzle Weld = SQRT2 * tc 0.35355 INCH 8.980256 MM

Use Leg with Dimension E in Dwg. No. 7434-33-3A 0.35433 INCH 9 MM

* For Outer Reinforcing Pad Weld [FIG.UW-16 SKETCH (c)]

tmin.1 = 0.75 inch 0.75 INCH 19.05 MM

tmin.2 ( te = thk. of reinforcing element) 0.86614 INCH 22 MM

tmin.3 ( shell wall thickness) 0.86614 INCH 22 MM

tmin. = lesser of tmin.1, tmin. 2 & tmin.3 0.75 INCH 19.05 MM

1/2 t min. 0.375 INCH 9.525 MM

By Considering Equal Legs Fillet Welds :

Leg of Outer Pad Weld = SQRT(2)*(tmin./2) 0.53033 INCH 13.5 MM

Leg 42 Use Leg with Dimension D in Dwg. No. 7434-33-3A 0.55118 INCH 14 MM

* Wall Thickness Required : [UG-27(c)(1)]

Shell tr = PR / (SE - 0.6 P) 0.47256 INCH 12.0029 MM

Nozzle trn = PRn /(SnEn - 0.6 P) 0.06257 INCH 1.589294 MM

* Strength Reduction Factors : Sp / Sv 1

fr1 = Sn / Sv 0.855

fr2 = Sn / Sv 0.855

fr3 = lesser of Sn/Sv or Sp/Sv 0.855

fr4 = Sp / Sv 1

DESIGN CALCULATIONS OF PRESSURE VESSEL Page : 34 of 126

According to ASME Code, Section VIII, Division 1, Edition 2001, Addenda 2002 Sheet : 4 of 5

Designed by : Eng. Abdel Halim Galala, Design General Manager (assist.) Rev. : 1

Project : Design & Procurement of ASME Pressure Vessel Date : 18.2.2004

Job Name : Demineralization Plant Job No. : 7434-33

Serial No. : 7434-33-U-2006 Dwg. No. : 7434-33-3A, Rev. 1 Client : APRC

Vessel : Deputanizer Reflux Receiver Drum Item No. : 1-D-5 Capacity : 10.152 M3 Type : Horizontal

M4. Nozzle Mark : N1 8" 300# WNRF (located at shell) (cont.)

Min. Nozzle Neck Wall Thickness Check Per UG-45

A. Wall Thickness per UG-45(a) : trna = trn + Can 0.29879 INCH 7.589294 MM

B. Wall Thickness per UG-45(b) : trnb = Min. (trnb1, trnb2, trnb3, trnb4) 0.32997 INCH 8.38125 MM

Wall Thickness per UG-45(b)(1), trnb1 = Min. (trnb11, trnb12) 0.32997 INCH 8.38125 MM

trnb11 = tr + Cas (tr for shell or head at E=1) 0.70878 INCH 18.0029 MM

trnb12 = Min Wall Thickness per UG-16(b), see below 0.32997 INCH 8.38125 MM

Wall Thickness per UG-45(b)(2), trnb2 (apply to external pressure only), NA INCH #VALUE! MM

Wall Thickness per UG-45(b)(3), trnb3 (apply to internal & external pressure)

= Max. (trnb1, trnb2) 0.32997 INCH 8.38125 MM

Wall Thickness per UG-45(b)(4), trnb4

= Min. thickness of std. wall pipe (1-0.125)+ Can 0.51797 INCH 13.15645 MM

(Under tolerance12.5% in accordance with ASME B36.10M)

Nominal thickness of std. pipe wall thickness, NPS 8", Sch. Std. 0.322 INCH 8.1788 MM

Wall Thickness per UG-16(b), trnb12

I - Min. Wall Thickness 1/16" + Cas 0.29872 INCH 7.5875 MM

II - Min. Wall Thickness of Unfired Steam Boilers = 1/4" + Cas 0.48622 INCH 12.35 MM

III - Min. Wall Thickness of Shell/Head in Compressed Air

Service, Steam Service, and Water Service = 3/32" + Cas 0.32997 INCH 8.38125 MM

Selected Vessel Service in our case is : Case III (compressed air)

So, the Min. Wall Thickness per UG-16(b), trnb12 0.32997 INCH 8.38125 MM

The min. nozzle wall thk. = Max. thk. determined by UG-45(a), or by UG-45(b) 0.32997 INCH 8.38125 MM

The nominal nozzle pipe wall thk. 0.5 INCH 12.7 MM

The min. nozzle thk. provided = t (1-0.125) 0.4375 INCH 11.1125 MM

So, the thickness provided meets the rules of UG-45. OK

Since there is no superimposed loads, the vessel doesn't require

a calculationon shear stresses caused by UG-22(c).

DESIGN CALCULATIONS OF PRESSURE VESSEL Page : 35 of 126

According to ASME Code, Section VIII, Division 1, Edition 2001, Addenda 2002 Sheet : 5 of 5

Designed by : Eng. Abdel Halim Galala, Design General Manager (assist.) Rev. : 1

Project : Design & Procurement of ASME Pressure Vessel Date : 18.2.2004

Job Name : Demineralization Plant Job No. : 7434-33

Serial No. : 7434-33-U-2006 Dwg. No. : 7434-33-3A, Rev. 1 Client : APRC

Vessel : Deputanizer Reflux Receiver Drum Item No. : 1-D-5 Capacity : 10.152 M3 Type : Horizontal

M4. Nozzle Mark : N1 8" 300# WNRF (located at shell) (cont.)

Nozzle Opening Calculation With Reinforcing (cont.) [UG-27]

Area of Reinforcement (with reinforcing Element) :

Required Area, A = d tr F + 2 tn tr F(1-fr1) 3.91314 INCH2 2524.602 MM2

Area Available in Shell, A1:

A11 = d (E1 t - F tr) - 2tn (E1 t - F tr)(1-fr1) 1.28475 INCH2 828.8676 MM2

A12 = 2 (t + tn)(E1 t - F tr) - 2tn (E1 t - F tr)(1-f r1) 0.25242 INCH2 162.8512 MM2

A1 = The Greater of A11 or A12 1.28475 INCH2 828.8676 MM2

Area Available in Nozzle Projecting Outward, A2 :

A21 = 5 (tn - trn) fr2 t 0.37353 INCH2 240.9873 MM2

A22 = 2 (tn - trn)(2.5tn+te) fr2 0.3248 INCH2 209.546 MM2

A2 = The Lesser of A21 or A22 0.3248 INCH2 209.546 MM2

Area Available in Inward Nozzle, A3 : (Not applicable)

A31 = 5 t ti fr2 0.54203 INCH2 349.695 MM2

A32 = 5 ti ti fr2 0.17319 INCH2 111.7385 MM2

A33 = 2 h ti fr2 0 INCH2 0 MM2

A3 = The Greater of A31, A32 or A33 0 INCH2 0 MM2

Area Available in Outward Nozzle Weld, A41:

A41 = (LEG)2 fr3 0.10735 INCH2 69.255 MM2

Area Available in Outer Reinforcing Pad Weld, A42:

A42 = (LEG)2 fr4 0.3038 INCH2 196 MM2

Area Available in Inward Nozzle Weld, A43 :

A43 = (LEG)2 fr2 0.10735 INCH2 69.255 MM2

Area Available in Reinforcing Pad, A5 :

A5 = (Dp - d - 2tn) te fr4 6.77313 INCH2 4369.75 MM2

Total Area Available, AT :

AT = A1 + A2 + A41 + A42 + A43 + A5 8.90116 INCH2 5742.674 MM2

AT is greater than A, therefore opening is adequately reinforced.

NOTE. No need for Strength Path Calculations.

You might also like

- FRP RF CalcDocument1 pageFRP RF CalcmukeshNo ratings yet

- Nozzle Reinf Calc (Rough)Document12 pagesNozzle Reinf Calc (Rough)Sajal Kulshrestha100% (1)

- Design Calculation of Nozzle Junction Based On ASME Pressure Vessel Design CodeDocument8 pagesDesign Calculation of Nozzle Junction Based On ASME Pressure Vessel Design CodeYakubu100% (1)

- Mechanical Design Calculations of Pressure Vessel - SampleDocument27 pagesMechanical Design Calculations of Pressure Vessel - SampleSakthi Vel100% (1)

- Nozzle Repad Design SpreadsheetsDocument2 pagesNozzle Repad Design SpreadsheetsArt G. EnziNo ratings yet

- Nozzle Neck CalculationDocument4 pagesNozzle Neck CalculationAkshat JainNo ratings yet

- Pressure Vessel Asme Strength Calculation ManualDocument38 pagesPressure Vessel Asme Strength Calculation ManualEsapermana Riyan80% (5)

- Pd5500 Flange CalculationDocument6 pagesPd5500 Flange CalculationMakrand SakpalNo ratings yet

- Small Vertical Pressure Vessel Leg Support Design - Boiler and Pressure Vessel Engineering - Eng-Tips PDFDocument6 pagesSmall Vertical Pressure Vessel Leg Support Design - Boiler and Pressure Vessel Engineering - Eng-Tips PDFhussamammarNo ratings yet

- Design of HCL FRP Storage TANKDocument21 pagesDesign of HCL FRP Storage TANKHaries Bugarin GarciaNo ratings yet

- 10.1 Asme Viii A-13 Rectangular VesselDocument2 pages10.1 Asme Viii A-13 Rectangular Vesselpastyl100% (1)

- Saddle Support Calculation PD 5500,2000 Annex.G)Document26 pagesSaddle Support Calculation PD 5500,2000 Annex.G)Neeraj Kumar33% (3)

- FIRE WATER TANK-API-650-Calculation-Report - RVDDocument42 pagesFIRE WATER TANK-API-650-Calculation-Report - RVDahmed aboyosefNo ratings yet

- Operating Case Trunnion Calculation Sheet: Input DataDocument1 pageOperating Case Trunnion Calculation Sheet: Input DataJagadish JasNo ratings yet

- Gasket Dimension (ASME B16.5 & B16.47)Document4 pagesGasket Dimension (ASME B16.5 & B16.47)amaNo ratings yet

- Calculation - ASME VIII Div.1Document10 pagesCalculation - ASME VIII Div.1bargez100% (1)

- Pressure Vessel Design Calc - ASME VIII Div 1Document22 pagesPressure Vessel Design Calc - ASME VIII Div 1aauppalNo ratings yet

- ASME B31.3 - 2008 PipeCalculationDocument6 pagesASME B31.3 - 2008 PipeCalculationArt G. Enzi100% (8)

- Nozzle ReinforcementDocument8 pagesNozzle ReinforcementHafizi HZnumismatic0% (1)

- Pressure Vessel Nozzle Calc - ASME VIII Div 1Document20 pagesPressure Vessel Nozzle Calc - ASME VIII Div 1aauppal100% (1)

- Pressure Vessel Design CalculationsDocument2 pagesPressure Vessel Design CalculationsMohan VarkeyNo ratings yet

- Flange CalculationsDocument3 pagesFlange CalculationssanjaysyNo ratings yet

- Top Pipe MomentDocument2 pagesTop Pipe MomentrsubramaniNo ratings yet

- Pressure Vessel ExampleDocument48 pagesPressure Vessel ExamplemohamedNo ratings yet

- Calcu Nozzle NeckDocument15 pagesCalcu Nozzle Necksachmaya0% (1)

- Expansion Loop Flexibility Analysis (Weaver)Document3 pagesExpansion Loop Flexibility Analysis (Weaver)bakelly100% (1)

- Shell Design Variable Point Method PDFDocument9 pagesShell Design Variable Point Method PDFBNRNo ratings yet

- Flange CalculationsDocument5 pagesFlange CalculationsswapnavattemNo ratings yet

- Tank Design: EN 1993 4 2 Eurocode 3Document31 pagesTank Design: EN 1993 4 2 Eurocode 3אחמד סלאח כאמלNo ratings yet

- Nozzle Load T1011 12Document12 pagesNozzle Load T1011 12koyahassanNo ratings yet

- FlangeCalc AS1210 v1.5Document28 pagesFlangeCalc AS1210 v1.5Ben100% (1)

- Shell CalculationsDocument3 pagesShell CalculationsBaher Elsheikh100% (7)

- Bspd5500 Nozzle CalculationDocument24 pagesBspd5500 Nozzle CalculationrsubramaniNo ratings yet

- Leg CalculationDocument21 pagesLeg CalculationBahtiar Anak LaNangNo ratings yet

- Api 620 - 2002Document12 pagesApi 620 - 2002ductaiutc100% (1)

- ASME B31.8 Riser CalcDocument12 pagesASME B31.8 Riser CalcSalz EngineeringNo ratings yet

- Sample4 PVEliteDocument66 pagesSample4 PVEliteSourav Hait100% (1)

- Solution: WE1 12 Nov 2008Document9 pagesSolution: WE1 12 Nov 2008aauppalNo ratings yet

- H200141 - Calculation of Basering Rev 0 PDFDocument9 pagesH200141 - Calculation of Basering Rev 0 PDFSani Adipura WinataNo ratings yet

- Rectangular TankDocument4 pagesRectangular Tankknsaravana0% (1)

- Nozzle CalculationsDocument2 pagesNozzle CalculationsBaher Elsheikh100% (3)

- External Pressure CalculationsDocument40 pagesExternal Pressure Calculationsmisterdavi50% (2)

- Skirt Support Analysis Per en 13445Document13 pagesSkirt Support Analysis Per en 13445karthik1amarNo ratings yet

- PV Elite Heat Exchanger CalculationsDocument99 pagesPV Elite Heat Exchanger CalculationscbousmuNo ratings yet

- Piping Engineering - Tank Nozzle Loads 1Document1 pagePiping Engineering - Tank Nozzle Loads 1Nasrul AdliNo ratings yet

- C.G. CalculationDocument7 pagesC.G. CalculationraveemakwanaNo ratings yet

- Leg CalculationDocument10 pagesLeg Calculationmashudi_fikriNo ratings yet

- MDMT Calculations For A Pressure Vessel - Abdel Halim GalalaDocument12 pagesMDMT Calculations For A Pressure Vessel - Abdel Halim Galalabego00No ratings yet

- Stresses in Vessel On Two Sad... Ports Using ZICK Analysis PDFDocument8 pagesStresses in Vessel On Two Sad... Ports Using ZICK Analysis PDFanishNo ratings yet

- Blind Flange Design Calculations - by Abdel Halim GalalaDocument6 pagesBlind Flange Design Calculations - by Abdel Halim GalalaNirmalraj Manoharan67% (3)

- Design of Saddle Supports & Stresses in Vessel On Two Saddles Using ZICK's Method - by Abdel Halim GalalaDocument16 pagesDesign of Saddle Supports & Stresses in Vessel On Two Saddles Using ZICK's Method - by Abdel Halim GalalaRaymond Metselaar83% (6)

- Code Calcs Rev1Document11 pagesCode Calcs Rev1Tauqeer AhmedNo ratings yet

- ASME Air Tank DesignDocument2 pagesASME Air Tank Designchethan100% (1)

- Irjet V4i1053 PDFDocument6 pagesIrjet V4i1053 PDFdynamo ShaikhNo ratings yet

- Design Data: 4" Weldolet CalculationDocument2 pagesDesign Data: 4" Weldolet Calculationgrabetty100% (2)

- Data Sheet 2 Less 800#-BV - FB - SW - NT-76 PDFDocument1 pageData Sheet 2 Less 800#-BV - FB - SW - NT-76 PDFSachin KumarNo ratings yet

- 02 - Vessel Pressure & Thickness CalculationDocument3 pages02 - Vessel Pressure & Thickness CalculationPankaj SinglaNo ratings yet

- K1A&B, K2 3, K8: Type of Element Connected To The Shell: NozzleDocument1 pageK1A&B, K2 3, K8: Type of Element Connected To The Shell: NozzlewhngomjNo ratings yet

- FlangeDocument6 pagesFlangekamardheen majithNo ratings yet

- Grain, Forage and Feed StructuresDocument4 pagesGrain, Forage and Feed StructurespaaryNo ratings yet

- Collapse and The Local Buckling of Structures PDFDocument14 pagesCollapse and The Local Buckling of Structures PDFlyeshiunNo ratings yet

- GGrain Storage in IndiaDocument6 pagesGGrain Storage in IndiapaaryNo ratings yet

- Circular PrecastDocument65 pagesCircular PrecastpaaryNo ratings yet

- Sec 25Document17 pagesSec 25amolmanave6049No ratings yet

- Non-Return For Loop PipeDocument1 pageNon-Return For Loop PipepaaryNo ratings yet

- Design of SilosDocument7 pagesDesign of SilospaaryNo ratings yet

- ASCE ASD Load CombinationsDocument2 pagesASCE ASD Load Combinationsrodriguez.gaytanNo ratings yet

- Metal Steel Technology Summary: Pipe Dimension (Diameter Nominal (DN) - Nominal Bore (NB) - Nominal Pipe Size (NPS)Document1 pageMetal Steel Technology Summary: Pipe Dimension (Diameter Nominal (DN) - Nominal Bore (NB) - Nominal Pipe Size (NPS)paaryNo ratings yet

- Metal Steel Technology Summary: Pipe Dimension (Diameter Nominal (DN) - Nominal Bore (NB) - Nominal Pipe Size (NPS)Document1 pageMetal Steel Technology Summary: Pipe Dimension (Diameter Nominal (DN) - Nominal Bore (NB) - Nominal Pipe Size (NPS)paaryNo ratings yet

- World Jet Fuel Specifications 2005Document51 pagesWorld Jet Fuel Specifications 2005Richo Crb100% (2)

- World Jet Fuel Specifications 2005Document51 pagesWorld Jet Fuel Specifications 2005Richo Crb100% (2)

- RaghuDocument1 pageRaghupaaryNo ratings yet

- Metal Steel Technology Summary: Pipe Dimension (Diameter Nominal (DN) - Nominal Bore (NB) - Nominal Pipe Size (NPS)Document1 pageMetal Steel Technology Summary: Pipe Dimension (Diameter Nominal (DN) - Nominal Bore (NB) - Nominal Pipe Size (NPS)paaryNo ratings yet

- CFMIsiloDocument4 pagesCFMIsilopaaryNo ratings yet

- Tank & Vessel Engineer IDocument11 pagesTank & Vessel Engineer IpaaryNo ratings yet

- New Storage Tanks Design GuidelinesDocument6 pagesNew Storage Tanks Design GuidelinespaaryNo ratings yet

- RaghuDocument1 pageRaghupaaryNo ratings yet

- Critical DepthDocument3 pagesCritical DepthpaaryNo ratings yet

- Piping Info - Piping Stress Related Design FactorsDocument3 pagesPiping Info - Piping Stress Related Design Factorspaary100% (1)

- RaghuDocument1 pageRaghupaaryNo ratings yet

- Oisd 117Document18 pagesOisd 117paaryNo ratings yet

- Welding Facilities WDFDocument30 pagesWelding Facilities WDFpaaryNo ratings yet

- Pipe HangersDocument8 pagesPipe HangerspaaryNo ratings yet

- NOV23 Nomura Class 6Document54 pagesNOV23 Nomura Class 6JAYA BHARATHA REDDYNo ratings yet

- Synchronous Machines-1Document41 pagesSynchronous Machines-1Rouxcel abutoNo ratings yet

- Weekly Lesson Plan: Pry 3 (8years) Third Term Week 1Document12 pagesWeekly Lesson Plan: Pry 3 (8years) Third Term Week 1Kunbi Santos-ArinzeNo ratings yet

- 2008 Kershaw CatalogDocument38 pages2008 Kershaw CatalogDANILA MARECHEKNo ratings yet

- Nuttall Gear CatalogDocument275 pagesNuttall Gear Catalogjose huertasNo ratings yet

- April 8/91: All GroupsDocument33 pagesApril 8/91: All Groupsreza mirzakhaniNo ratings yet

- Oral Com Reviewer 1ST QuarterDocument10 pagesOral Com Reviewer 1ST QuarterRaian PaderesuNo ratings yet

- Ocr A Level History Russia CourseworkDocument7 pagesOcr A Level History Russia Courseworkbcrqhr1n100% (1)

- Adding and Subtracting FractionsDocument4 pagesAdding and Subtracting Fractionsapi-508898016No ratings yet

- Rolling TechnologyDocument4 pagesRolling TechnologyFrancis Erwin Bernard100% (1)

- Text Extraction From Image: Team Members CH - Suneetha (19mcmb22) Mohit Sharma (19mcmb13)Document20 pagesText Extraction From Image: Team Members CH - Suneetha (19mcmb22) Mohit Sharma (19mcmb13)suneethaNo ratings yet

- Ce Licensure Examination Problems Rectilinear Translation 6Document2 pagesCe Licensure Examination Problems Rectilinear Translation 6Ginto AquinoNo ratings yet

- Iit-Jam Mathematics Test: Modern Algebra Time: 60 Minutes Date: 08-10-2017 M.M.: 45Document6 pagesIit-Jam Mathematics Test: Modern Algebra Time: 60 Minutes Date: 08-10-2017 M.M.: 45Lappy TopNo ratings yet

- PP Checklist (From IB)Document2 pagesPP Checklist (From IB)Pete GoodmanNo ratings yet

- Philpost RRDocument6 pagesPhilpost RRGene AbotNo ratings yet

- Work Permits New Guideline Amendments 2021 23.11.2021Document7 pagesWork Permits New Guideline Amendments 2021 23.11.2021Sabrina BrathwaiteNo ratings yet

- Agency Procurement Request: Ipil Heights Elementary SchoolDocument1 pageAgency Procurement Request: Ipil Heights Elementary SchoolShar Nur JeanNo ratings yet

- SAP HCM Case StudyDocument17 pagesSAP HCM Case StudyRafidaFatimatuzzahraNo ratings yet

- Service Letter Service Letter Service Letter Service Letter: Commercial Aviation ServicesDocument3 pagesService Letter Service Letter Service Letter Service Letter: Commercial Aviation ServicesSamarNo ratings yet

- AWS Compete CustomerDocument33 pagesAWS Compete CustomerSergeyNo ratings yet

- Combining Wavelet and Kalman Filters For Financial Time Series PredictionDocument17 pagesCombining Wavelet and Kalman Filters For Financial Time Series PredictionLuis OliveiraNo ratings yet

- Technology ForecastingDocument38 pagesTechnology ForecastingSourabh TandonNo ratings yet

- Course Outline Cbmec StratmgtDocument2 pagesCourse Outline Cbmec StratmgtskyieNo ratings yet

- Steve Jobs TalkDocument3 pagesSteve Jobs TalkDave CNo ratings yet

- Verilog GATE AND DATA FLOWDocument64 pagesVerilog GATE AND DATA FLOWPRIYA MISHRANo ratings yet

- Java Edition Data Values - Official Minecraft WikiDocument140 pagesJava Edition Data Values - Official Minecraft WikiCristian Rene SuárezNo ratings yet

- Project On Mahindra BoleroDocument35 pagesProject On Mahindra BoleroViPul75% (8)

- Thompson, Damon - Create A Servitor - How To Create A Servitor and Use The Power of Thought FormsDocument49 pagesThompson, Damon - Create A Servitor - How To Create A Servitor and Use The Power of Thought FormsMike Cedersköld100% (5)

- Atoll 1400Document2 pagesAtoll 1400David M. SeoaneNo ratings yet

- Eaai S 23 02045 PDFDocument28 pagesEaai S 23 02045 PDFAnjali JainNo ratings yet