Professional Documents

Culture Documents

Combined Cycle Gas Turbine.

Uploaded by

Shailesh Sankdasariya100%(6)100% found this document useful (6 votes)

4K views9 pagesREFERANCE.

CONCLUSION.

STATUS

ADVANTAGES & DISADVANTAGES.

VARIOUS FACTOR

VARIOUS TYPES

WORKING

BLOCK DIAGRAM&IT’S COMPONANTS.

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentREFERANCE.

CONCLUSION.

STATUS

ADVANTAGES & DISADVANTAGES.

VARIOUS FACTOR

VARIOUS TYPES

WORKING

BLOCK DIAGRAM&IT’S COMPONANTS.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

100%(6)100% found this document useful (6 votes)

4K views9 pagesCombined Cycle Gas Turbine.

Uploaded by

Shailesh SankdasariyaREFERANCE.

CONCLUSION.

STATUS

ADVANTAGES & DISADVANTAGES.

VARIOUS FACTOR

VARIOUS TYPES

WORKING

BLOCK DIAGRAM&IT’S COMPONANTS.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 9

COMBINED CYCLE POWER PLANT

ENERGY SYSTEMS,

BY SHAILESH B. PATEL -090760111025

COMBINED CYCLE

POWER PLANT

CONTENTS

BLOCK DIAGRAM & IT’S COMPONANTS.

WORKING OF COMBINED CYCLE POWER PLANT.

ADVANTAGES & DISADVANTAGES.

CLASSIFICATION OF COMBINED CYCLE POWER PLANT.

SITE SELECTION COMBINED CYCLE POWER PLANT.

STATUS OF COMBINED CYCLE POWER PLANT IN INDIA.

CONCLUSION.

REFERANCE.

aggagaaaga

COMBINED CYCLE POWER PLANT

ENERGY SYSTEMS

SANKDASARIYA SHAILESH B.

ENRL NO-090760111025

‘SSASIT (E.C. DEPARTMENT)

SSASIT

| BYSHALESH PATE DEPARTMENT)

COMBINED CYCLE POWER PLANT

ENERGY SYSTEMS

BY SHAILESH B. PATEL -090760111025

IMBINED CYCLE POWER PLANT

@AIM:- TO STUDY ABOUT COMBINED CYCLE POWER PLANT.

Combined cycle is an electric generating technology that creates additional electri

from heat exiting gas turbines. The exhaust heat from the gas turbines is routed to a

conventional boiler or to a heat recovery steam generator for utilization by a steam

turbine in the production of electricity.

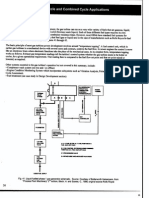

BLOCK DIAGRAM:-

GAS TURBINE COMBINED CYCLE fescrmcat svenTARoe

Power Plant System Schematic f jh

cone A

: ih i

GQicauene

©The schematic arrangement of a gas turbine power plant is shown in figure.The main

components of plants are given below:-

(i) Compressor

(ii)Regenerator

Combustion Chamber

(iv)Gas Turbine

(v)Alternator

(vi) Starting motor

ssasiT | BY SHAILESH B, PATEL(E.C. DEPARTMENT)

COMBINED CYCLE POWER PLANT

ENERGY SYSTEMS

BY SHAILESH B. PATEL -090760111025

\COMPRESSOR

©The compressor used in the plant is generally of rotatory type.The air at atmospheric

pressure is drawn by the compressor via the filter which removes the dust from the

air.The rotatory blades of the compressor push the air between stationary blades to

raise its pressure.Thus air at high pressure is available at the output of the compressor.

(IDREGENERATOR

"A regenerator is a device which recovers heat from the the exhaust gases of the

turbine.The exhaust is passed through the regenerator before wasting to atmosphere.A

regenerator consists of a nest of tubes contained in ashell.the compressed air from the

compressor passes through the tubes on its way to the combustion chamber.In this

way compressor is heated by the hot exhaust gases.

LII)COMBUSTION CHAMBER

©The air at high pressure from the compressor is led to the combustion chamber via

the regenerator.In the combustion chamber,heat is added to the air by burning oil. The

oil is injected through the burner into the chamber at high pressure ensure atomisation

of oil and its through mixing with air.The result is that the chamber attains a very high

temperature(about 3000F).The combustion gases are suitably cooled to 1300F to 1500F

then delivered to gas turbine.

(IV)GAS TURBINE

©The products of combustion consisting of a mixture of gases at high temperature and

pressure are passed to the gas turbine. These gases in passing over the turbine blades

‘expand and thus do the mechanical work.The temperature of the exhaust gases from

the turbine is about 900 F.

(V)ALTERNATOR,

©The gas turbine is coupled into the alternator. The alternator converts the mechanical

energy of the turbine into electrical energy. The output of the alternator is given to the

bus-bars through transformers, isolators and circuit breakers.

(VI) STARTING MOTOR

© Before starting the turbine,compressor has to be started.For this purpose,an electric

motor is mounted on the same shaft as that of the turbine.The motor is energised by

the batteries.Once the unit starts, a part of the mechanical power of the turbine drives

the compressor and there is no need of the motor now.

ssasiT | BY SHAILESH 8, PATEL. DEPARTMENT) [ER

COMBINED CYCLE POWER PLANT

ENERGY SYSTEMS

BY SHAILESH B. PATEL -090760111025

@WORKING OF COMBINED CYCLE POWER PLANT :-

Wiiater Purp

Ont

SH _ Heat Recover

‘Steam Generator

Gas Turbine

Electricity

Compressor

fae Air

©>First step is the same as the simple cycle gas turbine plant. Burning of gas, the thrust

rotating a gas turbine and the coupled generator produces Electricity. In the second

step the hot gases leaving the gas turbine passes into boiler to produce steam. This

boiler is called the ‘Heat Recovery Steam Generator (HRSG). The steam then rotates

the steam turbine and coupled generator to produce Electricity. The hot gases leave the

HRSG at around 140 degrees centigrade and are discharged into the atmosphere. The

steam condensing, and water recycling system is the same as in the steam power

plant.

“Roughly the steam turbine cycle produces one third of the power and gas turbine

cycle produces two thirds of the power output of the CCPP. Normally there will be two

generators, one driven by the gas turbine and one driven by the steam turbine. There

are also systems with one generator connected through a single shaft to both the gas

turbine and steam turbine.

"Even though this system is having the best efficiency, it has limitations. The gas

turbine can only use Natural gas or high grade oils like aviation or diesel fuel. Because

of this the combined cycle can be operated only in locations where these fuels are

available and cost effective.

"Developments for gasification of coal and use in the gas turbine are in advanced

stages. Once this is proven, Coal as the main fuel can also be used in the combined

cycle power plant.

ssasiT | BY SHAILESH B, PATEL(E.C. DEPARTMENT)

COMBINED CYCLE POWER PLANT

ENERGY SYSTEMS

BY SHAILESH B. PATEL -090760111025

@ADVANTAGES & DISADVANTAGES OF COMBINED CYCLE POWER PLANTS:-

ADVANTAGES:

eeeee

eeoe

*

Very high power-to-weight ratio, compared to reciprocating engines.

‘Smaller than most reciprocating engines of the same power rating.

Moves in one direction only, with far less vibration than a reciprocating engine.

Fewer moving parts than reciprocating engines.

Low operating pressures.

High operation speeds.

Low lubricating oil cost and consumption.

It is simple to design & construct compared to a Steam Power station, since no

boilers are required.

Much smaller compared to Steam Power station of same capacity.

Lower operating costs.

Less water used since there is no need for a condenser.

Maintenance charges are low

Can be started quickly

No stand-by losses.

‘© DISADVANTAGES:

Cost is much greater than for a similar-sized reciprocating engine since the

materials must be stronger and more heat resistant. Machining operations are

also more complex.

Usually less efficient than reciprocating engines, especially at idle.

Delayed response to changes in power settings.

Problem of starting. Compressor needs to be operating thus external source of

power is necessary.

Net output is low since greater power is used to drive compressor.

Overall efficiency of plant is low ~ 20% because of exhaust gases still containing

heat. only efficient in a Combined cycle configuration.

Temperature of combustion chamber is too high thus resulting in a lower life.

#CLASSIFICATION OF COMBINED CYCLE POWER PLANT:-

The gas turbine power plants which are used in electric power industry are classified

into two groups as per the cycle of operation

(a) Open cycle gas turbine.

(0) Closed cycle gas turbine.

SSASIT

‘OPEN CYCLE GAS TURBINE POWER PLANT:

Fue Suppyy

+

‘Compressor Tube Ef

; +

a Extaustto

oe Aimosphere

(OPEN OYCLE GAS TURBINE POWER PLANT

COMBINED CYCLE POWER PLANT

ENERGY SYSTEMS

BY SHAILESH B. PATEL -090760111025

=A simple open cycle gas turbine consists

of a compressor, combustion chamber and a

turbine as shown in fig.The compressor

takes in ambient air and raises its pressure

Heat is added to the air in combustion

chamber by burning the fuel and raises its

temperature.

The heated gases coming out of

combustion chamber are then passed to the

turbine where it expands doing mechanical

work. Part of the power developed by the

turbine is utilized in driving the compressor

and other accessories and remaining is used

for power generation. Since ambient air

enters into the compressor and gases

coming out of turbine are exhausted into the atmosphere, the working medium must be

replaced continuously. This type of cycle is known as open cycle gas turbine plant.

‘© CLOSED CYCLE GAS TURBINE POWER PLANT:

>In closed cycle gas turbine plant, the working fluid (air or any other suitable gas)

chambers Heat “TS uct Supt A Supply

Exchanger 4 ie wa

oS =>)

t ames Il

ee Water out

coming out from compressor is heated

a heater by an external source at

constant pressure. The high

temperature and high-pressure air

coming out from the external heater is,

passed through the gas turbine. The

fluid coming out from the turbine is

cooled to its original temperature in the

cooler using external cooling source

before passing to the compressor. The

working fluid is continuously used in the

system without its change of phase and

the required heat is given to the

working fluid in the heat exchanger.

The arrangement of the components of

the closed cycle gas turbine plant is

shown in Fig.This types of cycle is

known as closed cycle gas turbine

power plant.

SSASIT

| BY SHAILESH B, PATEL(E.C. DEPARTMENT) [iq

COMBINED CYCLE POWER PLANT

ENERGY SYSTEMS

BY SHAILESH B. PATEL -090760111025

@SITE SELECTION FOR COMBINED CYCLE POWER PLANT:-

1)AVAILABILITY OF RAW MATERIAL:it is necessary to locate the plant as far as possible

near the natural gas sources to reduce the cost of transportation of fuel. If the plant is

located away from souces of fuel field it may create problems due to failure of

transportation system

2)NATURE OF THE LAND & ITS COST:The site selected should have high bearing

capacity of at least 10N/mm2 to withstand dead load of the plant. It would reduce the

cost of foundation of the plant.

3)LOAD CENTRE:-A power plant must be located near the load to which the power is

supplied. The location of power plant at C.G. of loads reduces the cost of transmission

lines & the losses occurring in it.

4)AVAILABILITY OF LABOUR:-Large men power is needed during the construction of

plant. therefore, labour should be available near the construction site at cheap cost.

5 )ACCESSIBILITY TO SITE:- The power plant should have rail and road transportation

facilities.

@STATUS OF COMBINED CYCLE POWER PLANT IN INDI

POWER PLANT NAME CAPACITY(MW) STATE

Godavari (Kakinada) Gas CCPP 208 ‘Andhra Pradesh

Lakwa Gas Turbine 120 Assam

Konaseema CCGT Gas 445 ‘Andhra Pradesh

Viljeswaran Gas CCT 272 Andhra Pradesh

GMMR Vernagiri Gas CCGT 389 ‘Andhra Pradesh

Samalkot/Peddapuram Gas CCGT 220 Andhra Pradesh

LANCO Kondapalli Gas CCGT 601 ‘Andhra Pradesh

GVK Jegurupadu Il Gas CCT 220 Andhra Pradesh

GVK Jegurupadu | Gas CCGT 235 ‘Andhra Pradesh

Gautami Gas CCGT 464 ‘Andhra Pradesh

Namrup Gas CCGT 1335 Assam

Kathalguri (Assam) Gas CCGT 291 Assam

Pragati Gas CCGT 330 Delhi

Indraprastha (Delhi) CCGT 282 Delhi

Vatwa Gas CCGT 100 Gujarat

Utran II CCGT Power Station 375 Gujarat

Utran | Gas CCGT 135 Gujarat

COMBINED CYCLE POWER PLANT

ENERGY SYSTEMS,

BY SHAILESH B. PATEL -090760111025

POWER PLANT NAME CAPACITY(MW) STATE

SUGEN (Torrent Power) CCT 1475 Gujarat

Paguthan Gas CCGT 655 Gujarat

Kawas Gas CCGT 644 Gujarat

Jhanor-Gandhar Gas CPP 648 Gujarat

Jamnagar RIL. Gas PP 300 Gujarat

Hazira RIL Gas CHP Plant 250 Gujarat

Hazira GSEG Gas CCGT 156.1 Gujarat

Hazira (Essar) Gas CCGT 515 Gujarat

Essar Hazira Gas CPP 32 Gujarat

Dhuvaran (GSECL) Gas CCT 219 Gujarat

Dhuvaran Oil GT Power Station 220 Gujarat

Bhandar (Essar Hazira) Gas CCGT 500 Gujarat

Vadodara Station Il (GIPCL) Gas CCGT 165 Gujrat

Vadodara Station | (GIPCL) Gas CCT 14s Gujarat

Faridabad NTPC Gas CCGT 430 Haryana

Pampore Gas Turbine 175 Jammu and Kashmir

Tanir Bavi Barge Gas CCPP 220 Kamataka

Kayamkulam (Rajiv Gandhi) Gas CCPP 360 Kerala

BSES Kochi Gas CCGT 167 Kerala

Uran Gas CCGT 912 Maharashtra

Trombay Gas CCGT 180 Maharashtra

South Bassein Gas PP 152 Maharashtra

Ratnagiri Ill (Dhabol) Gas CGT 740 Maharashtra

Ratnagiri ll (Ohabol) Gas CCGT 740 Maharashtra

Ratnagiri | (Dhabol) Gas CCGT 740 Maharashtra

Karaikal Gas CCGT 33 Puducherry

Ramgarh Gas CCGT 1138 Rajasthan

Dholpur Gas CCGT 330 Rajasthan

Anta Gas CCGT 413 Rajasthan

Sai Regency CCGT Power Plant 58 Tamil Nadu

Karuppur (APCL) CGT Power 198 Tamil Nadu

Valuthur (Perungulam) Gas CCGT 186.2 Tamil Nadu

Pillaiperumainallur Gas CCGT 3305 Tamil Nadu

Kuttalam Gas CCGT India 100 Tamil Nadu

Basin Bridge Gas Power Station 120 Tamil Nadu

Rokhia Gas Thermal Station "4 Tripura

Baramura Gas Thermal Station a Tripura

Agartala Gas Turbine Power Station 84 Tripura

Dadri Gas CCGT 817 Uttar Pradesh

Auraiya Gas CGT 652 Uttar Pradesh

‘Aonla Gas PP 100 Uttar Pradesh

ssasiT | BY SHAILESH 8, PATEL(E.. DEPARTMENT) EA

COMBINED CYCLE POWER PLANT

ENERGY SYSTEMS

BY SHAILESH B. PATEL -090760111025

@CONCLUSION:

Combine Cycle systems are efficient low cost systems that provides assurances of

performance and operating objectives. Combine Cycle systems can be customized to

the utility needs and preferences. They offer attractive economical reliable power

generation. Operating flexibility of Combine Cycle power generating warrant their

consideration for most power generation applications.

@REFERANCE :-

WWW, GLOBALENERGYOBSERVATORY.ORG

WWW, ELECTRICALANDELECTRONICS.ORG

> WWW.EN.WIKIVERSITY.ORG

‘POWER PLANT ENGINEERING (NEW_AGE_INTERNATIONAL) BY A.K. RAJA & AMIT P.

SRIVASTAVA & MANISH DWIVEDI.

ssasiT | BY SHAILESH 8, PATEE.c, DEPARTMENT) EI

You might also like

- Modern Power Station Practice: Mechanical Boilers, Fuel-, and Ash-Handling PlantFrom EverandModern Power Station Practice: Mechanical Boilers, Fuel-, and Ash-Handling PlantA. SherryRating: 4 out of 5 stars4/5 (5)

- Combine Gas Cycle TurbineDocument20 pagesCombine Gas Cycle Turbinekts700175% (4)

- Performance Improvement of Combined Cycle Power Plant Based On The Optimization of The Bottom Cycle and Heat RecuperationDocument6 pagesPerformance Improvement of Combined Cycle Power Plant Based On The Optimization of The Bottom Cycle and Heat Recuperationwgxiang100% (4)

- Training Report CCPPDocument38 pagesTraining Report CCPPTaresh MittalNo ratings yet

- Introduction To Combined Cycle Power Plants PDFDocument4 pagesIntroduction To Combined Cycle Power Plants PDFtagliya100% (1)

- Gas Turbine Control & Protection: Presentation ONDocument46 pagesGas Turbine Control & Protection: Presentation ONrahulNrana100% (2)

- Gas Turbine StartupDocument9 pagesGas Turbine StartupSturovo TurboNo ratings yet

- Combined Cycle FundamentalsDocument76 pagesCombined Cycle FundamentalsVinnu89% (9)

- Combined Cycle Power PlantDocument15 pagesCombined Cycle Power PlantAbd Muhaimin Amms100% (1)

- HRSG StartupDocument19 pagesHRSG Startuptpplant100% (1)

- Single Shaft Design of Power PlantDocument12 pagesSingle Shaft Design of Power PlantSrinivasa Rao PallelaNo ratings yet

- Combined Cycle PrinciplesDocument43 pagesCombined Cycle PrinciplesFazalur Rehman Babar100% (1)

- Combined Cycle Power Plant PDFDocument1 pageCombined Cycle Power Plant PDFboyzes100% (1)

- Combined Cycle Power PlantDocument4 pagesCombined Cycle Power PlantdndudcNo ratings yet

- Presentation of Gas TurbineDocument40 pagesPresentation of Gas TurbineMohammed Al-samarrae100% (1)

- Gas TurbineDocument57 pagesGas TurbineMajid Sattar100% (1)

- Biomass in BoilerDocument13 pagesBiomass in Boilermbkluimp100% (1)

- Degradation Effects On Comined Cycle Power Plant PerformanceDocument10 pagesDegradation Effects On Comined Cycle Power Plant Performancewolf_ns100% (2)

- PowerFactor GE TM2500 SpecificationsDocument2 pagesPowerFactor GE TM2500 Specificationscg7316100% (1)

- GE Frame 9Document4 pagesGE Frame 9Umar Saeed100% (1)

- Combine Cycle Power Plant Design InformationDocument47 pagesCombine Cycle Power Plant Design Informationkalasivan0% (1)

- Coal Fired Power Plant Heat Rate ReductionDocument48 pagesCoal Fired Power Plant Heat Rate Reductionraharjoitb0% (1)

- Harbin Electric InternationalDocument14 pagesHarbin Electric Internationalawais khanNo ratings yet

- Gas Turbines:: Moving To Prime TimeDocument4 pagesGas Turbines:: Moving To Prime TimeBharatSubramonyNo ratings yet

- Combined Cycle Power Plant and TurbinesDocument21 pagesCombined Cycle Power Plant and TurbinescruzleenoNo ratings yet

- Solar Gas TurbineDocument4 pagesSolar Gas TurbineHamdi Makni100% (1)

- Turbine Protection System: Presentation OnDocument24 pagesTurbine Protection System: Presentation OnAbhishek Bansal100% (1)

- Optimizing Duct Burner ReliabilityDocument10 pagesOptimizing Duct Burner ReliabilityPajooheshNo ratings yet

- 5 Gas Turbine - Turbine and Exhaust SystemDocument142 pages5 Gas Turbine - Turbine and Exhaust SystemMohamed Balbaa100% (3)

- Gas Turbine in Simple Cycle and Combined Cycle ApplicationsDocument46 pagesGas Turbine in Simple Cycle and Combined Cycle Applicationssevero97100% (2)

- PB Thermal PowerDocument62 pagesPB Thermal PowerrakeshNo ratings yet

- Design of Gas Turbine Power Plant For University of LagosDocument29 pagesDesign of Gas Turbine Power Plant For University of LagoseazydammyNo ratings yet

- Various Components of Thermal Power Plant - BasicsDocument17 pagesVarious Components of Thermal Power Plant - BasicsMohammed Kabiruddin95% (21)

- Gas Turbine Class PresentationDocument183 pagesGas Turbine Class PresentationMohammad Ibnul Hossain83% (18)

- HRSG - Basic UnderstandingDocument30 pagesHRSG - Basic Understanding이영준100% (23)

- HRSG StartupDocument20 pagesHRSG Startupsujiv_sujiv1278100% (2)

- GAS Turbine PresentationDocument266 pagesGAS Turbine Presentationagiba100% (6)

- Tarahan Coal Fired Steam Power Plant ProjectDocument19 pagesTarahan Coal Fired Steam Power Plant ProjectAnonymous zMWvcTNo ratings yet

- Gas Turbine Question & AnswersDocument1 pageGas Turbine Question & AnswersRavichandra TummaNo ratings yet

- 4 Dfe 84 Fa 1 CB 20Document310 pages4 Dfe 84 Fa 1 CB 20Harsono HadiNo ratings yet

- How To Calculate Overall Thermal Efficiency of Combined Cycle Power PlantsDocument10 pagesHow To Calculate Overall Thermal Efficiency of Combined Cycle Power PlantsManoj SharmaNo ratings yet

- Gas Turbine Power PlantsDocument8 pagesGas Turbine Power Plantssakibsultan_308No ratings yet

- Chapter Five Gas Turbine Power PlantDocument23 pagesChapter Five Gas Turbine Power PlantBese Mat100% (1)

- Gas TurbineDocument53 pagesGas TurbinedipakbagNo ratings yet

- Lec 05Document21 pagesLec 05Shamsuzzaman SharifNo ratings yet

- A Gas Turbine UnitDocument9 pagesA Gas Turbine UnitTITU NATHNo ratings yet

- Summer Internship Report: ST THDocument70 pagesSummer Internship Report: ST THHardeep PenugondaNo ratings yet

- Lecture 17Document27 pagesLecture 17Saleem KhanNo ratings yet

- Gas Turbine Power Plant PresentationDocument126 pagesGas Turbine Power Plant Presentationjehadyam100% (1)

- Gas Turbine 1Document21 pagesGas Turbine 1Md. Adnan NabibNo ratings yet

- Gas Turbine Thermal Power PlantDocument7 pagesGas Turbine Thermal Power PlantAkshay ManzaNo ratings yet

- Introduction To Gas Turbine:: Land Based Gas Turbines Are of Two TypesDocument9 pagesIntroduction To Gas Turbine:: Land Based Gas Turbines Are of Two TypesTahir MuneebNo ratings yet

- EEC 122 CompleteDocument34 pagesEEC 122 CompleteAdeniji OlusegunNo ratings yet

- Gas Turbine Power Station: American International University-Bangladesh (AIUB)Document35 pagesGas Turbine Power Station: American International University-Bangladesh (AIUB)Ahasan Ulla100% (2)

- Combined Gas and Steam Power PlantDocument8 pagesCombined Gas and Steam Power Planttushar1128100% (1)

- Working Principle Gas Turbine and Combined Cycles, Auxiliary SystemsDocument27 pagesWorking Principle Gas Turbine and Combined Cycles, Auxiliary SystemsRey Danielle Navea100% (2)

- How Does A Gas Turbine Power Plant Work?: 1. CompressorDocument8 pagesHow Does A Gas Turbine Power Plant Work?: 1. CompressorSuresh Ram R100% (1)

- Unit - IvDocument62 pagesUnit - Ivchegg study100% (2)

- Combined Cycle Power PlantDocument11 pagesCombined Cycle Power PlantPGPalomaNo ratings yet

- Pasgt Module Prelim To FinalDocument100 pagesPasgt Module Prelim To FinalKyle100% (1)

- 8051 Based Simple Digital ClockDocument7 pages8051 Based Simple Digital ClockShailesh SankdasariyaNo ratings yet

- 8051 Project LCD InterfacingDocument7 pages8051 Project LCD InterfacingShailesh Sankdasariya100% (5)

- 8051 Based Digital ClockDocument15 pages8051 Based Digital ClockShailesh SankdasariyaNo ratings yet

- Buck BoostDocument18 pagesBuck BoostYang QianNo ratings yet

- Chetan Bhagat - Three Mistakes of My LifeDocument144 pagesChetan Bhagat - Three Mistakes of My LifeGayathri ParthasarathyNo ratings yet

- Display Devices and PrintersDocument9 pagesDisplay Devices and PrintersShailesh SankdasariyaNo ratings yet

- ATMEL MCS 8051 Instruct SetDocument50 pagesATMEL MCS 8051 Instruct Setand3botNo ratings yet

- 131701-1 Gtu 3rd Sem PaperDocument1 page131701-1 Gtu 3rd Sem PaperShailesh SankdasariyaNo ratings yet

- Matlab Finite Element Modeling For Materials Engineers Using MATLABDocument74 pagesMatlab Finite Element Modeling For Materials Engineers Using MATLABPujara ManishNo ratings yet

- 131101-1 Gtu 3rd Sem PaperDocument2 pages131101-1 Gtu 3rd Sem PaperShailesh SankdasariyaNo ratings yet

- 130904-2 Gtu 3rd Sem PaperDocument1 page130904-2 Gtu 3rd Sem PaperShailesh SankdasariyaNo ratings yet

- 130001Document2 pages130001Ashwin PatelNo ratings yet

- 130904-3 Gtu 3rd Sem PaperDocument3 pages130904-3 Gtu 3rd Sem PaperShailesh SankdasariyaNo ratings yet

- 130901-1 Circuit & Networks Gtu 3rd Sem PaperDocument3 pages130901-1 Circuit & Networks Gtu 3rd Sem PaperShailesh SankdasariyaNo ratings yet

- 130310-130701-Digital Logic Design PDFDocument2 pages130310-130701-Digital Logic Design PDFjayant_2222143No ratings yet

- 131101-2 Gtu 3rd Sem PaperDocument4 pages131101-2 Gtu 3rd Sem PaperShailesh SankdasariyaNo ratings yet

- 130901-2 Circuit & Networks Gtu 3rd Sem PaperDocument2 pages130901-2 Circuit & Networks Gtu 3rd Sem PaperShailesh SankdasariyaNo ratings yet

- Gujarat Technological University: InstructionsDocument3 pagesGujarat Technological University: InstructionsJainish JariwalaNo ratings yet

- 130701-1 Digital Logic Design Gtu 3rd Sem PaperDocument1 page130701-1 Digital Logic Design Gtu 3rd Sem PaperShailesh SankdasariyaNo ratings yet

- Combined Cycle Gas Turbine.Document9 pagesCombined Cycle Gas Turbine.Shailesh Sankdasariya100% (6)

- Hydro Magnetic Power PlantDocument7 pagesHydro Magnetic Power PlantShailesh SankdasariyaNo ratings yet

- Wind Turbine Power PlantDocument8 pagesWind Turbine Power PlantShailesh SankdasariyaNo ratings yet

- Wind Turbine Power PlantDocument8 pagesWind Turbine Power PlantShailesh SankdasariyaNo ratings yet

- Hydro Magnetic Power PlantDocument7 pagesHydro Magnetic Power PlantShailesh SankdasariyaNo ratings yet

- Wind Turbine Power PlantDocument8 pagesWind Turbine Power PlantShailesh SankdasariyaNo ratings yet

- Combined Cycle Gas Turbine.Document9 pagesCombined Cycle Gas Turbine.Shailesh Sankdasariya100% (6)

- Power DistributionDocument6 pagesPower DistributionShailesh SankdasariyaNo ratings yet

- Thermal Power PlantDocument8 pagesThermal Power PlantShailesh Sankdasariya100% (3)

- Solar Power PlantDocument8 pagesSolar Power PlantShailesh Sankdasariya50% (2)

- Study of Manufacture of Steam Turbine Blades: A Mini Project Report OnDocument68 pagesStudy of Manufacture of Steam Turbine Blades: A Mini Project Report OnSaketh Varma MudunuriNo ratings yet

- IECM User Manual PDFDocument583 pagesIECM User Manual PDFVishnu UppalakkalNo ratings yet

- List of Tables and FiguresDocument6 pagesList of Tables and FiguresRhona Liza CruzNo ratings yet

- Kawasaki Gas TurbinDocument16 pagesKawasaki Gas TurbinBams Arifin100% (1)

- Gas Turbine: Jump To Navigationjump To SearchDocument9 pagesGas Turbine: Jump To Navigationjump To SearchArctic BearNo ratings yet

- HP LP Bypass SystemsDocument8 pagesHP LP Bypass SystemsSSSNo ratings yet

- Thermoeconomic Optimization of A Kalina Cycle For A Central Receiver ConcentratingDocument22 pagesThermoeconomic Optimization of A Kalina Cycle For A Central Receiver Concentratingy_durNo ratings yet

- Chapter 5-Slides PDFDocument92 pagesChapter 5-Slides PDFMonaElabbassiNo ratings yet

- 00 Full Grid Code I5r21Document700 pages00 Full Grid Code I5r21Bogdan VicolNo ratings yet

- Domage 9fa Aux MondesDocument7 pagesDomage 9fa Aux MondeskatibraNo ratings yet

- SyllabusDocument178 pagesSyllabusPonnaiahKannanNo ratings yet

- CCJ Issue 55 PDFDocument94 pagesCCJ Issue 55 PDFMariano Salomon PaniaguaNo ratings yet

- Unit IV MCQDocument14 pagesUnit IV MCQArun PatilNo ratings yet

- Academic Regulations Course Structure and Detailed Syllabus: (Two Years Full Time Programme)Document55 pagesAcademic Regulations Course Structure and Detailed Syllabus: (Two Years Full Time Programme)Vincent LinzieNo ratings yet

- Practical Training ReportDocument26 pagesPractical Training ReportNishant SharmaNo ratings yet

- Carbon Capture UtilisationDocument86 pagesCarbon Capture UtilisationArshilkarim khanNo ratings yet

- Gas Turbines Siemens InteractiveDocument22 pagesGas Turbines Siemens InteractiveBony DiazgNo ratings yet

- ATCo Company Profile 2021 R0Document43 pagesATCo Company Profile 2021 R0wheng nemensoNo ratings yet

- Introduction To Gas Turbines: Aero Derivative AndDocument52 pagesIntroduction To Gas Turbines: Aero Derivative And121710801027 HARI KRISHNAN SURESHNo ratings yet

- Three-Pressure-Level Combined CycleDocument41 pagesThree-Pressure-Level Combined CycleGianluca Castoldi QuintanoNo ratings yet

- Abb PB - Power-En - e PDFDocument16 pagesAbb PB - Power-En - e PDFsontungNo ratings yet

- Gas Turbine MaintenanceDocument146 pagesGas Turbine MaintenanceMamoun1969100% (9)

- Envr-S335 U2Document88 pagesEnvr-S335 U2Peter LeeNo ratings yet

- Reference List Nuova FimaDocument51 pagesReference List Nuova FimaAhmedSaadNo ratings yet

- Analysis and Optimization of A Cascading Power Cycle With Liquefied Natural Gas (LNG) Cold Energy RecoveryDocument7 pagesAnalysis and Optimization of A Cascading Power Cycle With Liquefied Natural Gas (LNG) Cold Energy RecoveryDuyên LêNo ratings yet

- NTPC New ProfileDocument60 pagesNTPC New ProfileRavindra Chowdary GudapatiNo ratings yet

- A Study of Manufacturing of Steam TurbinesDocument40 pagesA Study of Manufacturing of Steam TurbinesSaketh Varma MudunuriNo ratings yet

- Power Plant Engineering - NodrmDocument1,142 pagesPower Plant Engineering - NodrmTalat Orhan100% (2)

- X10683allegato1-1915X Turboden OilGas PDFDocument16 pagesX10683allegato1-1915X Turboden OilGas PDFMaxiSanchezNo ratings yet

- Mitsubishi Power, Ltd. - Power Plants: Gas Turbine Combined Cycle (GTCC) Power PlantsDocument2 pagesMitsubishi Power, Ltd. - Power Plants: Gas Turbine Combined Cycle (GTCC) Power PlantsKR PANo ratings yet