Professional Documents

Culture Documents

AMS - Branson - B452R TDS

Uploaded by

sshaffer_90 ratings0% found this document useful (0 votes)

1K views2 pagesCopyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

1K views2 pagesAMS - Branson - B452R TDS

Uploaded by

sshaffer_9Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 2

OVERVIEW

‘The Branson B452R Ultrasonic Vapor Degreaser isthe larest in a series of.

environmentally sound, cost effective precision depreasers, Ie integrates 50

years of degreasing experience with the demanding needs of a changing

‘marketplace to offer you a functional solvent solution ro your cleaning

needs, Similar in operation to a traditional two sump unit, it incorporates

all of the important environmental and safety features you need, including

‘onboard compressors for both primary and sub-zero cooling. All controls,

are clustered on a compact, front-mounted, digital control panel. Iris ideal

for use with low-cost solvents like trichloroethylene, perchloroethylene,

and methylene chloride, 2s well as many of the newer materials including

AK225, HFC, HFE, N-propyl bromide and more.

ENVIRONMENTAL FEATURES.

“The BAS2R is designed ro comply with Federal and local regulations on

solvent emissions, an important environmental and economic

consideration. Some of these features can also facilitate OSHA

compliance. ‘The unit includes, as standatd, a number of enginecsed

improvements designed specifically 10 minimize solvent losses, The

following lise details some of these more important features:

Freeboard ratio of greater than 120% to eliminate diffusion Iosses

Sub-zero freeboard condenser to provide a cold air barter

minimizing fugitive losses

Bulletin S-1061

ULTRASONIC

VAPOR DEGREASERS

MODEL B452R

Primary condensing coil to condense the

bulk of the vapors preventing them from

reaching the sub-zero condenser

Captured sliding cover to eliminate deafts

and seal the unit duting periods of

inactivity

Stainless plumbing for cotzosion

Internal water separator keeps all solvent

within the unit at all times

‘SAFETY FEATURES

In addition to the benefits associated with

keeping solvent away from the operator, the

B452R has other which

contribute to safety and relibility. Key among

these are:

‘mai features

Low voltage controls for operator safety

"Ready"

ight co assure the unit is set to

Coolant indicator indicates the

refrigeration equipment is functional

High vapor level sensor to prevent

accidental solvent boil off

Heater Over Temp sensor to prevent

solvent degradation and heater damage

Early warning contamination indicator

to signal the need for solvent replacement

‘STVIISLYH SAY

WP AFR ORT

801S-Z22-998

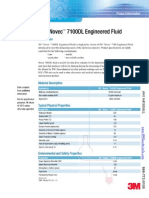

‘SPECIFICATIONS

>

Ultrasonic sump | 10" X 12"X &

Boil sump 10" X12" X 8"D 3

Vapor zone X15.25"W X 8.5"D R

Overall 5.5" X 845" H =

Solvent capacity +

Recirculation 1 gpm @ 10u

Boil sump heat _| 2000 immersion heat ig

Distillation rate*_| 7 gph if

Load capacity” | 150# stecl/hr i=

Ultrasonics 250W @ 40 kHz ik

Control voltage 24 volts, iS

Input power 208 or 230V, 3ph, 254 IR

N

3

Based on HCEC, HEE, and HEC solvenes

Specifications subject 0 change without novice

BRANSON ULTRASONICS CORPORATION

41 age Road, Danbury, CT 06813196113) 7966400 FAX 08) 796200 wewhhansonClanng

801LS-ZL2-998

Banton SE Aris Beaton Exrope Brom span Beason UR Bisson de Meco

Hong Kong Diewenbieh,Gemmany —Tokyo,Japan Landon, gang Nuevo Laredo, Mexico

© Branson Uewonies Corporation 1998 S:106- Revised ad Pred in USA, 69

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- AMS - V-Works 24 StandardDocument2 pagesAMS - V-Works 24 Standardsshaffer_9No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- AMS - 3M - Fluorinert FC-3284Document4 pagesAMS - 3M - Fluorinert FC-3284sshaffer_9No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- AMS - SQL - CFC Naming ConventionDocument10 pagesAMS - SQL - CFC Naming Conventionsshaffer_9No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- AMS - SQL - Refrigerant Ref TableDocument6 pagesAMS - SQL - Refrigerant Ref Tablesshaffer_9No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- AMS - 3M - Fluorinert FC-3283Document4 pagesAMS - 3M - Fluorinert FC-3283sshaffer_9No ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- AMS - 3M - Fluorinert FC-43Document4 pagesAMS - 3M - Fluorinert FC-43sshaffer_9No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- AMS - SQL - Eric Bank Quick GuideDocument6 pagesAMS - SQL - Eric Bank Quick Guidesshaffer_9No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- AMS - Bransonic General BrochureDocument8 pagesAMS - Bransonic General Brochuresshaffer_9No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Ams - 3M - PF-5060Document4 pagesAms - 3M - PF-5060sshaffer_9No ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- AMS - 3M - Cool Under FireDocument8 pagesAMS - 3M - Cool Under Firesshaffer_9No ratings yet

- AMS - 3M - Fluorinert FC-70Document4 pagesAMS - 3M - Fluorinert FC-70sshaffer_9No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- AMS - 3M - VPS BrochureDocument4 pagesAMS - 3M - VPS Brochuresshaffer_9No ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Ams - 3M - PF-5070Document4 pagesAms - 3M - PF-5070sshaffer_9No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Ams - 3M - PF-5060-DLDocument6 pagesAms - 3M - PF-5060-DLsshaffer_9No ratings yet

- AMS - 3M - Novec MedicalDocument4 pagesAMS - 3M - Novec Medicalsshaffer_9No ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- AMS - 3M - Novec 7300DLDocument4 pagesAMS - 3M - Novec 7300DLsshaffer_9No ratings yet

- AMS - 3M - Novec 71DADocument4 pagesAMS - 3M - Novec 71DAsshaffer_9No ratings yet

- AMS - 3M - Novec 7000Document6 pagesAMS - 3M - Novec 7000sshaffer_9No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- AMS - 3M - Novec 7100DLDocument4 pagesAMS - 3M - Novec 7100DLsshaffer_9No ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- AMS - 3M - Novec 7100DLDocument4 pagesAMS - 3M - Novec 7100DLsshaffer_9No ratings yet

- AMS - 3M - Novec 7500Document8 pagesAMS - 3M - Novec 7500sshaffer_9No ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Data Sheet HFE-7300Document4 pagesData Sheet HFE-7300sshaffer_9No ratings yet

- AMS - 3M - Boiling Enhancement CoatingDocument2 pagesAMS - 3M - Boiling Enhancement Coatingsshaffer_9No ratings yet

- AMS - Chemicals GP PowderDocument1 pageAMS - Chemicals GP Powdersshaffer_9No ratings yet

- AMS - Chemcials GP FormulaDocument1 pageAMS - Chemcials GP Formulasshaffer_9No ratings yet

- 3M - Boiling Enhancement CoatingDocument2 pages3M - Boiling Enhancement Coatingsshaffer_9No ratings yet

- AMS - Chemicals EC FormulaDocument2 pagesAMS - Chemicals EC Formulasshaffer_9No ratings yet

- AMS - Chemicals BC FormulaDocument1 pageAMS - Chemicals BC Formulasshaffer_9No ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- AMS - Chemicals IS FormulaDocument1 pageAMS - Chemicals IS Formulasshaffer_9No ratings yet

- AMS - Chemicals LRS FormulaDocument1 pageAMS - Chemicals LRS Formulasshaffer_9No ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)