Professional Documents

Culture Documents

Air Eliminator Location

Uploaded by

MULTIKARTHI07Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Air Eliminator Location

Uploaded by

MULTIKARTHI07Copyright:

Available Formats

Recommended position of Micro-bubble Air Eliminators in chilled water systems

The other decision to make is whether to install the air eliminator before or after

(a) the cooling coil and

(b) the circulating pump.

a) The water temperature inside the chiller coil, by virtue of its function, is decreasing. This means

that some of the air bubbles will dissolve back into the water. Therefore, it would be preferable to

install the Armstrong Holden Brooke Pullen air eliminator before the coil.

b) To prevent air bubbles from causing pump damage due to cavitation, the air eliminator

should also be installed before the pump.

See figure 8. The efficient functioning of the air eliminator, correctly positioned, provides virtually

air-free water after the cooling coil.

When the pressure rises, at lower elevations in the circuit, water becomes more and more

unsaturated (according to Henry's Law more air can be dissolved in the water at higher pressures).

This means that air present elsewhere in the system will be absorbed into the water. This

absorption effect is used to bind all the free-air in the system.

As water circulates and approaches the air eliminator the pressure is decreasing and the absorbed

air will appear as micro-bubbles in the water. These bubbles will be vented out to the atmosphere

by the action of the automatic air vent that forms part of the Armstrong Holden Brooke Pullen air

eliminator.

Pressurisation fig. 8

Unit

Air Eliminator

Circulating Pump

Air Handling

Top of Circuit Units

Expansion

Vessel

Chiller

Cooling Coil

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Food and Beverage Services in HotelDocument20 pagesFood and Beverage Services in HotelJay Lord Santos SalvadorNo ratings yet

- Aquarea User Guide PDFDocument68 pagesAquarea User Guide PDFDel MonteNo ratings yet

- Mechanical Strength and Thermal Properties of Refractory BricksDocument12 pagesMechanical Strength and Thermal Properties of Refractory BrickskazamNo ratings yet

- Lake Oroville California - Google SearchDocument1 pageLake Oroville California - Google SearchRoss RuckerNo ratings yet

- Steam vs Thermal Oil Heating: Which is BestDocument3 pagesSteam vs Thermal Oil Heating: Which is BestjoseNo ratings yet

- JWPCA 2006 Review Water CorpDocument75 pagesJWPCA 2006 Review Water CorpAnonymous e9xp1aQClONo ratings yet

- Service Manual Am15-2Document64 pagesService Manual Am15-2javier vilchez romeroNo ratings yet

- Pocket-Book of Aeronautics (1907)Document524 pagesPocket-Book of Aeronautics (1907)Aelfwine EinshpiedNo ratings yet

- Project Profile On White and Black PhenylDocument7 pagesProject Profile On White and Black PhenylSyedNo ratings yet

- Electrical Resistivity of Membrane-Pavement Systems: Standard Test Method ForDocument3 pagesElectrical Resistivity of Membrane-Pavement Systems: Standard Test Method Forara100% (1)

- Hive 1 Thermostat User GuideDocument3 pagesHive 1 Thermostat User GuideMateusz Poważny GraczNo ratings yet

- CIP Cycle Development Sep04Document7 pagesCIP Cycle Development Sep04John HigginsNo ratings yet

- Test Bank For Environment and You 1st Edition ChristensenDocument12 pagesTest Bank For Environment and You 1st Edition ChristensenPeggy Gebhart100% (33)

- Indonesia's Largest Island, Java, Home to Over Half the Country's PopulationDocument2 pagesIndonesia's Largest Island, Java, Home to Over Half the Country's PopulationGalih AnggoroNo ratings yet

- 01-HAZOP Worksheet Formaldehyde - (Corrosion)Document8 pages01-HAZOP Worksheet Formaldehyde - (Corrosion)Muhammad Zarif Amir100% (1)

- SWRO Design and OptimizationDocument27 pagesSWRO Design and OptimizationJames N Velinsky100% (1)

- Concept of Ecology and Ecosystem PresetationDocument58 pagesConcept of Ecology and Ecosystem PresetationPRASANT KUMAR BIPRA100% (1)

- QuantifyingTheGlobalNon RevenueWaterProblem LiembergerDocument18 pagesQuantifyingTheGlobalNon RevenueWaterProblem Liemberger劉洪光No ratings yet

- Running of Dopeless®connectionsDocument4 pagesRunning of Dopeless®connectionsHector BarriosNo ratings yet

- Skid Pack: Monoblock-FilterDocument55 pagesSkid Pack: Monoblock-FilterAsuncion Gomez-Cambronero LoroNo ratings yet

- XII - Biology - Module - 5 - Environmental Issues - SolutionsDocument17 pagesXII - Biology - Module - 5 - Environmental Issues - SolutionsShreyashNo ratings yet

- Sources & Uses of Water Lesson PlanDocument7 pagesSources & Uses of Water Lesson PlanPatria Hence GabuyaNo ratings yet

- Calculation BFWDocument22 pagesCalculation BFWDavid Lambert100% (1)

- Qatar PetroleumDocument22 pagesQatar PetroleumPrathmesh Uddhav Pawar100% (3)

- Huber Dissolved Air Flotation Plant HDFDocument5 pagesHuber Dissolved Air Flotation Plant HDFTrung HanNo ratings yet

- Economic Geology GuideDocument9 pagesEconomic Geology GuideJameel JameelNo ratings yet

- Today's Title: Miscible or Immiscible?: To Do: What Do These Words Mean? - Miscible - Immiscible - Fractional DistillationDocument20 pagesToday's Title: Miscible or Immiscible?: To Do: What Do These Words Mean? - Miscible - Immiscible - Fractional DistillationAbhinav AshishNo ratings yet

- Mithi RiverDocument12 pagesMithi RiverAtharva MahajanNo ratings yet

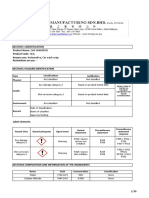

- Safety Data Sheet Car Shampoo: Type Classifications Justification Data Source PhysicalDocument10 pagesSafety Data Sheet Car Shampoo: Type Classifications Justification Data Source PhysicalmiradesNo ratings yet