Professional Documents

Culture Documents

Turbine Protections

Uploaded by

Pradipta Kumar MohantyOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Turbine Protections

Uploaded by

Pradipta Kumar MohantyCopyright:

Available Formats

Operating Instructions

2X125 MW CPP JSL Page No.1

System : Turbine

Sub System : Turbine Protection

All Turbine protections shall act to de-energise Turbine trip solenoids, thereby closing

the ESV’s and respective control valves.

The Turbine shall trip on the following conditions :

S.No Parameter Alarm Trip Remarks

value Value

1 a. Main Steam Temperature very low 480oC 450oC For MST>500oC

1 b. Main Steam Temperature very low. 330oC 320oC For MST<500oC

2. Main Steam Temperature very high. 545oC 565oC During Start-up,

varying wrt Tm

HP shaft.

3 a. Reheat Steam temperature very low 330oC o

320 C Arming at speed

> 1980 rpm

3 b. Reheat Steam Temperature very low 445oC o

430 C For IP inlet steam

temp > 500oC

4. Reheat Steam Temperature very high 545oC o

565 C During start-up,

varying wrt Tm

IP shaft.

5. HP Turbine Exhaust Temperature High. 470oC 480oC Varying wrt Tm

HP shaft temp.

6. HP Casing Top Bottom ΔT High. Variable Varying wrt to

Tripping Load.

7. LP Exhaust Temperature very High > 90oC > 110oC

8. LP Exhaust Pressure very High. Variable Varying wrt to LP

tripping inlet pressure.

9. Axial Displacement very High. + 0.5 + 1.0

mm mm

10. HP/IP FJB Shaft Vibration very High. 120 µ 160 µ

11. HP/IP RJB Shaft Vibration very High 120 µ 160 µ

12. LP RJB Shaft Vibration very High 120 µ 160 µ

13. Gen FJB Shaft Vibration very High 160 µ 240 µ

14. Gen RJB Shaft Vibration very High 160 µ 240 µ

2X125 MW CPP JSL Page No.2

System : Turbine

Sub System : Turbine Protection

15. Lube Oil Pressure very Low < 3.4 < 3.2

kg/cm2 kg/cm2

16. Control Oil Pressure very Low < 120 < 110

kg/cm2 kg/cm2

17. Boiler Drum Level very High > 200 > 225

mm mm

18. Boiler Master Fuel Trip -- --

19. Overspeed Protection. -- 3300 Speed probe

rpm

20. Generator protection -- Class

A/B

21. Fire protection Activated -- Push Field Push Button

Button

22. Trip from ATRS -- -- Shutdown

Sequence.

23. TSLLE Device Lower than 7.5 % -- --

You might also like

- Turbine O&M ManualDocument83 pagesTurbine O&M ManualMohammed MuzzamilNo ratings yet

- KM230CZ: Compressor Technical SpecificationDocument9 pagesKM230CZ: Compressor Technical SpecificationEsiNo ratings yet

- Aditya Tech Diary PDFDocument155 pagesAditya Tech Diary PDFSiddhant Satpathy100% (1)

- NE6188C NE6188C NE6188C NE6188CZ Z Z Z: CompressorDocument7 pagesNE6188C NE6188C NE6188C NE6188CZ Z Z Z: CompressorJesus GrilletNo ratings yet

- NE6188CZDocument9 pagesNE6188CZhobolghaniNo ratings yet

- SPESIFIKASI TEKNIS Doosan 650 kVA - Open TypeDocument9 pagesSPESIFIKASI TEKNIS Doosan 650 kVA - Open Typehafid CJSPNo ratings yet

- LC111CY: Compressor Technical SpecificationDocument8 pagesLC111CY: Compressor Technical SpecificationEsiNo ratings yet

- KM230CZDocument9 pagesKM230CZhobolghaniNo ratings yet

- Donper Ne6170bzDocument9 pagesDonper Ne6170bzriyowNo ratings yet

- Steam Turbine Description Construction, Speed & Steam PressureDocument20 pagesSteam Turbine Description Construction, Speed & Steam PressureKarthikeyanNo ratings yet

- NE1130BZ: Compressor Technical SpecificationDocument9 pagesNE1130BZ: Compressor Technical SpecificationIsidro MendozaNo ratings yet

- LC126CY: Compressor Technical SpecificationDocument8 pagesLC126CY: Compressor Technical SpecificationEsiNo ratings yet

- Presentation On Steam Turbine Operation by S ChandDocument36 pagesPresentation On Steam Turbine Operation by S Chandsomyaranjan das100% (1)

- Boiler Turbine Protection,,,EHC, Hydraullic-2Document21 pagesBoiler Turbine Protection,,,EHC, Hydraullic-2Balvir GangarNo ratings yet

- Settings and LimitsDocument3 pagesSettings and LimitsmuddasirmasoodNo ratings yet

- 30cza C o M P R e S S o R Technical SpecificationDocument9 pages30cza C o M P R e S S o R Technical SpecificationTiborNo ratings yet

- CW 5000 AgDocument11 pagesCW 5000 AgIgnacio rivera laraNo ratings yet

- Turbine Trip Protection: Description Set Valve SL NO Alarm Valve Time DelayDocument2 pagesTurbine Trip Protection: Description Set Valve SL NO Alarm Valve Time DelayShambhu MehtaNo ratings yet

- Turbine Trip LogicDocument2 pagesTurbine Trip Logicdilbagh_scribd50% (2)

- 500MW-Boiler - Salient FeatureDocument7 pages500MW-Boiler - Salient FeatureAhemadNo ratings yet

- Sinotec RB Poso-Jasmin EquipmentDocument18 pagesSinotec RB Poso-Jasmin EquipmentWaleedNo ratings yet

- Turbine EfficiencyDocument41 pagesTurbine EfficiencySouvik Datta100% (1)

- KJ290CYDocument8 pagesKJ290CYhobolghaniNo ratings yet

- BABCOCK BOILER 1 - 6 Instruction ManualDocument43 pagesBABCOCK BOILER 1 - 6 Instruction Manualashek ullah100% (1)

- Lear 31A LimitationsDocument3 pagesLear 31A Limitationsdrclive1No ratings yet

- PILLARD - Aktuell - YCC - MR - BoseDocument19 pagesPILLARD - Aktuell - YCC - MR - BosePradeep KumawatNo ratings yet

- Adani Power Limited: Rolling and Synchronising Check List For 660MW Steam Turbo GeneratorDocument4 pagesAdani Power Limited: Rolling and Synchronising Check List For 660MW Steam Turbo GeneratorBryan ScofieldNo ratings yet

- Flexible Operation in Coal Based Plant: By-SNEHESH BANERJEE, Operation Services, CCDocument27 pagesFlexible Operation in Coal Based Plant: By-SNEHESH BANERJEE, Operation Services, CCLakshmi NarayanNo ratings yet

- T 44 Condensed NATOPSDocument4 pagesT 44 Condensed NATOPSHikawa ChangNo ratings yet

- Data Teknik Peralatan UtamaDocument4 pagesData Teknik Peralatan UtamaObiNo ratings yet

- MGS1700R-50Hz-380V-CGT-7PD (G3 Class)Document5 pagesMGS1700R-50Hz-380V-CGT-7PD (G3 Class)bmemileniumNo ratings yet

- 500 TurbinecycleDocument8 pages500 TurbinecycleHemant PatilNo ratings yet

- Turbine Rolling-Tiroda PDFDocument11 pagesTurbine Rolling-Tiroda PDFs91No ratings yet

- Turbine RollingDocument15 pagesTurbine RollingAkhilesh VijayaKumar100% (2)

- Thermic Fluid Heater Data Sheet - Rev 0Document10 pagesThermic Fluid Heater Data Sheet - Rev 0Dhamotharan ChinnaduraiNo ratings yet

- P8082TB XESeries MotorLifeDocument1 pageP8082TB XESeries MotorLifejpdemesajrNo ratings yet

- Polypropylene Poy Spinning Plant - Yoc 2006 88dtex (80den) POY - Production Capacity 800 Kg/dayDocument9 pagesPolypropylene Poy Spinning Plant - Yoc 2006 88dtex (80den) POY - Production Capacity 800 Kg/dayildalilNo ratings yet

- Doosan Infracore Generator Engine: Ratings (KWM/PS)Document4 pagesDoosan Infracore Generator Engine: Ratings (KWM/PS)David J SandersNo ratings yet

- Rolls - Royce, B35-40 V12AG (5100 KW)Document3 pagesRolls - Royce, B35-40 V12AG (5100 KW)Dexterous EngineeringNo ratings yet

- A110WZ1Document9 pagesA110WZ1hobolghaniNo ratings yet

- Motor P222FE PDFDocument4 pagesMotor P222FE PDFMarco QuitoNo ratings yet

- 3406 Performance Specification PDFDocument2 pages3406 Performance Specification PDFaliNo ratings yet

- Technical Data Air Cooled Chiller 105 TRDocument3 pagesTechnical Data Air Cooled Chiller 105 TRHaris Siena100% (1)

- BP400 Diesel Generating Set: Standby Power 50Hz Prime Power 50HzDocument5 pagesBP400 Diesel Generating Set: Standby Power 50Hz Prime Power 50HzAlwinNo ratings yet

- Cep EmergencyDocument13 pagesCep EmergencyYogesh PNo ratings yet

- Engine Spec Sheet 3 - 6DWD-235A Rev B2Document2 pagesEngine Spec Sheet 3 - 6DWD-235A Rev B2yamahaNo ratings yet

- Turbine RollingDocument6 pagesTurbine RollingPraveen DwivediNo ratings yet

- 160 kVA Specification SheetDocument2 pages160 kVA Specification SheetAlex MohanNo ratings yet

- Diesel Generating Set BF-C395-60: Standby Power 60Hz Prime Power 60HzDocument5 pagesDiesel Generating Set BF-C395-60: Standby Power 60Hz Prime Power 60Hzkevindelmonte1996No ratings yet

- Endo Gas Generator Testing ProcedureDocument15 pagesEndo Gas Generator Testing Proceduresuhasphatak007No ratings yet

- Air Leak in Test of Esp ProcedureDocument5 pagesAir Leak in Test of Esp Procedurenetygen1No ratings yet

- Deviation Detail of Key EquipmentsDocument58 pagesDeviation Detail of Key EquipmentschetanmaleNo ratings yet

- Doosan Infracore Generator Engine: Ratings (KWM/PS)Document5 pagesDoosan Infracore Generator Engine: Ratings (KWM/PS)Jorge Eraldo Albarran PoleoNo ratings yet

- K390BZ1 CompressedDocument9 pagesK390BZ1 CompressedRefrigeración PinNo ratings yet

- #3 机汽轮机规范说明 Unit3 Turbine Specifications Description: Lecturer: Zhang YouquanDocument29 pages#3 机汽轮机规范说明 Unit3 Turbine Specifications Description: Lecturer: Zhang YouquansotoyoloNo ratings yet

- LM72CZ V01Document8 pagesLM72CZ V01hobolghaniNo ratings yet

- Technicalspecification: CompressorDocument9 pagesTechnicalspecification: Compressorأبو زينب المهندسNo ratings yet

- Technical Specification: CompressorDocument11 pagesTechnical Specification: Compressorjimmyfuller1234567890No ratings yet

- Sigma Insights: Project PlanningDocument8 pagesSigma Insights: Project PlanningPradipta Kumar MohantyNo ratings yet

- Aggregate Technical and Commercial (AT &C) Losses (In %)Document2 pagesAggregate Technical and Commercial (AT &C) Losses (In %)Pradipta Kumar MohantyNo ratings yet

- Generator Rotor Shorted Turn Analyzer: Instruction ManualDocument16 pagesGenerator Rotor Shorted Turn Analyzer: Instruction ManualSayan AichNo ratings yet

- Bzslo 18W WH-NW-WW-111275-276-277Document1 pageBzslo 18W WH-NW-WW-111275-276-277Pradipta Kumar MohantyNo ratings yet

- Abb VCB ManualDocument27 pagesAbb VCB ManualPradipta Kumar MohantyNo ratings yet

- Industrial Training Presentation: 132Kv SubstationDocument21 pagesIndustrial Training Presentation: 132Kv SubstationPradipta Kumar MohantyNo ratings yet

- List of Codeslist of ANSI CodesDocument3 pagesList of Codeslist of ANSI CodesPradipta Kumar MohantyNo ratings yet

- Best Practice Manual - DryersDocument43 pagesBest Practice Manual - DryersPradipta Kumar MohantyNo ratings yet

- Orissa ReviewDocument40 pagesOrissa ReviewPradipta Kumar MohantyNo ratings yet

- All India Top Solar Power Generation Figures For FY 2012-13Document2 pagesAll India Top Solar Power Generation Figures For FY 2012-13Pradipta Kumar MohantyNo ratings yet

- 6.0 High Voltage MeasurementDocument32 pages6.0 High Voltage MeasurementGopala VetsaNo ratings yet

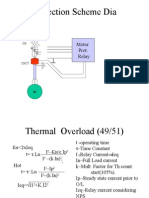

- Protection Scheme Dia: Motor Prot. RelayDocument9 pagesProtection Scheme Dia: Motor Prot. RelayPradipta Kumar MohantyNo ratings yet

- 2629Document24 pages2629Pradipta Kumar MohantyNo ratings yet

- Testsdumps: Latest Test Dumps For It Exam CertificationDocument7 pagesTestsdumps: Latest Test Dumps For It Exam CertificationSekharNo ratings yet

- Virtual InstrumentationDocument18 pagesVirtual InstrumentationAkansha Sharma67% (3)

- Unit1 - 2 - Unit1 - 3Document9 pagesUnit1 - 2 - Unit1 - 3Tshepang RadingoanisNo ratings yet

- Making of Prince of PersiaDocument333 pagesMaking of Prince of PersiaBarancsukÁdámNo ratings yet

- PrintUnit 2 ThroughputLogDocument2 pagesPrintUnit 2 ThroughputLogErick GómezNo ratings yet

- Session 2 - 01 (Energy Efficiency Potential Assessment of Chandrapura TPS, DVC)Document52 pagesSession 2 - 01 (Energy Efficiency Potential Assessment of Chandrapura TPS, DVC)pkumarNo ratings yet

- 3D Catalog HG11 31 enDocument47 pages3D Catalog HG11 31 enqwkerbk090909No ratings yet

- VI Own Escalation Matrix Month of Jun'22Document4 pagesVI Own Escalation Matrix Month of Jun'22Palash JainNo ratings yet

- Introduction of Shenzhen Water Cooled ProductsDocument25 pagesIntroduction of Shenzhen Water Cooled ProductsDidi AubarNo ratings yet

- Tls Master Key WindowsDocument5 pagesTls Master Key Windowsiiokojx386No ratings yet

- RP Magz NOV1Document6 pagesRP Magz NOV1Mangata AcaronarNo ratings yet

- Enhancement of Time-Based One-Time Password For 2-Factor AuthenticationDocument6 pagesEnhancement of Time-Based One-Time Password For 2-Factor AuthenticationInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- ApplicationDocument23 pagesApplicationGreen développementNo ratings yet

- Paramjeet ResumeDocument2 pagesParamjeet ResumeAditya BhargavaNo ratings yet

- Service Manual: Part No. 780005 (Rev. E)Document16 pagesService Manual: Part No. 780005 (Rev. E)Tony KututoNo ratings yet

- Sample Size CalculatorDocument6 pagesSample Size CalculatorSalman AwanNo ratings yet

- Pantone Color SwatchbookDocument10 pagesPantone Color Swatchbookdongu100% (1)

- GA and ANNDocument17 pagesGA and ANNini benNo ratings yet

- Table Top ExerciseDocument21 pagesTable Top ExerciseHala ElasriNo ratings yet

- FA Annual Report 2021Document28 pagesFA Annual Report 2021Charmaine SebastianNo ratings yet

- Oracle Licensing Contracts Part2Document69 pagesOracle Licensing Contracts Part2Mette StephansenNo ratings yet

- Stack: Lesson 04 DCIT25 - Data Structure and AlgorithmsDocument28 pagesStack: Lesson 04 DCIT25 - Data Structure and AlgorithmsCarlNo ratings yet

- Full Download Concepts of Database Management 9th Edition Starks Solutions ManualDocument35 pagesFull Download Concepts of Database Management 9th Edition Starks Solutions Manualal68xcarter100% (32)

- Lecture 8 - FlexRay - Event-Driven and Time-Driven CommunicationDocument21 pagesLecture 8 - FlexRay - Event-Driven and Time-Driven Communication김건정No ratings yet

- Machine GuardingDocument13 pagesMachine GuardingSwayam SARIT SatpathyNo ratings yet

- Neptune (Packet) V6.0 System SpecificationsDocument229 pagesNeptune (Packet) V6.0 System SpecificationsThe Quan BuiNo ratings yet

- Freightliner Electrical System and Main PDM OverviewDocument143 pagesFreightliner Electrical System and Main PDM Overviewedbox25868No ratings yet

- Contrast-Associated Acute Kidney Injury NEJMDocument4 pagesContrast-Associated Acute Kidney Injury NEJMJorge BalbinNo ratings yet

- NCM 110 Lec Act.1 Prelim VirayDocument4 pagesNCM 110 Lec Act.1 Prelim VirayJezzy VeeNo ratings yet

- Peavey PR15D Service ManualDocument12 pagesPeavey PR15D Service ManualMartín SayagoNo ratings yet