Professional Documents

Culture Documents

Lasting FAQ

Uploaded by

aryanboxer786100%(1)100% found this document useful (1 vote)

144 views4 pagesToe puff used in hand lasting? solvent based. Chemical used for softening the hand last toe puff? Toluene / Acetone. How much margin should be toe puff placed inside the upper? 9-10 mm.

Original Description:

Original Title

lasting FAQ.docx

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentToe puff used in hand lasting? solvent based. Chemical used for softening the hand last toe puff? Toluene / Acetone. How much margin should be toe puff placed inside the upper? 9-10 mm.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

144 views4 pagesLasting FAQ

Uploaded by

aryanboxer786Toe puff used in hand lasting? solvent based. Chemical used for softening the hand last toe puff? Toluene / Acetone. How much margin should be toe puff placed inside the upper? 9-10 mm.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 4

Lasting FAQ

Q.1 what are the tools required in hand lasting?

Pincer, tack puller, nail lifter, hammer, Scissor, Acrylic hammer, Mock lifter.

Q.2 what is the toe puff used in hand lasting?

Solvent based.

Q.3 what is the chemical used for solvent toe puff?

Nitro cellulose based.

Q.4 what is the chemical used for softening the hand last toe puff?

Toluene / Acetone.

Q.5 why you have to do the hand lasting quickly?

Because toe puff-stiffener dry quickly.

Q.6 How much margin should be toe puff placed inside the upper?

9-10 mm from the upper.

Q.7 how much pulls are there in hand lasting / Drafting?

12.

Q.8 Where 7 & 8 pulls come in hand drafting?

7 Inside ball joint

8 Outside ball joint According to Stretch requirement

Q.9 Why pull is done in the inside first and followed by the outside?

Since the inside part of the last is curvature is more the inside part is draft as first.

Q.10 What is the difference between outside & inside quarter in the top line?

Inside quarter should be 3 mm above from the outside quarter.

Q.11 Why inside quarter is bigger than the outside quarter?

Inside ankle bone is little above the outside ankle bone.

Q.12 what will happen if the upper is lesser in back height?

It will irritate the foot while walking.

Q.13 What is gape between the eyelet facing top line before lasting for quarter in derby shoe?

10 (If bagged topline then 10-12 mm).

Q.14 What is toe spring of the shoe?

The gape between the ground & the bottom of the sole in toe area is called the toe

spring.

Q.15 What is the temperature in Upper/Toe Conditioning M/C?

90 120oc (depend up on the material).

Q.16 What is the temperature for toe puff attaching M/C?

90 120oc (depend up on the Material).

Q.17 What is the material used in covering the top mould & bottom pad for toe puff attaching

M/C?

UP Teflon paper

Down Felted cloth

Q.18 What is temp. of counter moulding M/C?

Heat 90 to 120oc, Cold 15 to 19 oc

Q.19 What is the system & pressure used in counter moulding M/C.

Pneumatic system with 4 to 6 bar pressure (depend up on the Material).

Q.20 What is the need for toe mulling?

It makes the upper & toe puff soft, while lasting it does not crack.

Q.21 What is the temperature of wiper plate of toe lasting M/C?

60-80 oc

Q.22 What is the melting temperature of polyester & Polyimide road?

Polyester 200-220 oc

Polyimide 180-200oc

Q.23 Why polyester adhesive used in toe lasting?

Polyester is not flexible so it is used in toe area.

Q.24 Why polyamide adhesive used in seat & side lasting?

Polyamide is flexible while walking it provide comfort .

Q.25 Why humidifier used before seat lasting?

Stiffener & leather become soften because of hot air humidity.

Q.26 What is the temperature of heat setting?

Air 90-120 oc Stem 100-120 oc (depend up on the Material).

Q.27 What type of air is used in heat setting?

Synthetic- Hot air (without moisture)

Leather- Hot air (with moisture).

Q.28 What is the dwell time is used in heat setting?

1.2- 2.5 minute.

Q.29 What is heel crowning M/C?

It is a roller with heat which hammers the seat area to get very sharp feather edge in the

seat area.

Q.30 What are the two types of material used in roughing M/C?

Roller paper grit emery (24 & 60 No.)

Q.31 How many coats of adhesive is given in upper material why?

Two coats of adhesive are given in upper material one for penetrate inside the leather &

second coat for bonding with sole.

Q.32 Why MEK wipe is done for sole?

To clean the silicone & dust practical which is the mould releasing agent during PVC/

PU/ Airmix sole preparation it makes bonding proper.

Q.33 Why hardner is mixed in P.U?

For reduce the drying time & increase heat resistance property.

Q.34 What is the drying time for PU Adhesive?

15-17 Mnt.

Q.35 What is halogenation?

Chlorine powder is mix with solvent (ethyl acetate ) so that the rubber based sole stick

to the upper properly while bonding, After halogenation drying time is 35-40 mnt.

Q.36 What is the temperature PU adhesive Reaction?

65 - 700c

Q.37 What is balloon sole pressing M/C?

Balloon sole attaching M/C act on the principal of vacuum so that the sole attached to

the upper, it is used generally for walled sole.

Q.38 Which M/C is used in leather sole bonding / pressing?

Hydraulic sole press.

Q.39 What is construction?

Method of attaching the sole .

Q.40 What is lasting?

Process of pulling & give the shape of upper toward the Last.

Q.41 What is stuck on/cemented/ flat lasting?

The process of securing the upper to the bottom of the insole.

Q.42 What is flange /veldtschoen /stitch down lasting?

The upper is spread around the feather edge in a perpendicular manner & secured to

runner or the insole.

Q.43 What is sanscripno construction?

Here the upper is flanged out on the runner & flange (runner) lasted to insole and the

second stage it is flat lasted to runner.

Q.44 What is California /slip lasting?

The insole & the upper & the plat form cover stitch near feather line something like

stroble stitching and the upper is forced in to the last and upon the insole a platform

layer is attach and platform cover is stretched and lasted on to the platform bottom.

Q.45 What is Goodyear welted construction?

The upper is lasted to the ribbed insole and temporally stuck to the rib a welt is stitched

on to the lasted upper & the rib than sole is attach & the stitching is done threw the welt

& the sole.

Q.46 What is stroble construction?

The upper & the insole socks cover is stitch on the feather line by stroble stitching

machine & it is force in to the last here dont need for lasting to hide stitch feather edge a

walled sole or injection moulding is given.

Q.47 What is string lasting?

A tubular stitching is done on edge of the upper and the string inserted during stitching &

the stitch upper is forced in to the last and two end of the string is pulled & tie like

pajama and injection moulding is done and no need for lasting in this construction.

Q.48 Methods of lasting?

Force lasting- string lasting, stroble lasting, moccasin lasting, California lasting.

Lasting down- veldtschoen, flat lasting, sanscripno construction, Goodyear welted

construction.

Lasting up- moccasin lasting

Q.49 what is DIP?

Direct injection process (DIF) in this process the lasted upper with the last is placed over

the sole mould & hot extrusion of PU/ PVC/ EVA material / granules is injected in liquid

form in to the bottom cavity on solidifying it stuck to the lasting margin.

Q.50 what is DVP?

Direct volcanizing process in a mould sole cavity the rubber pieces are placed & it turns

in to liquid the lasted upper with the last is kept over the mould and it stuck to the lasted

upper.

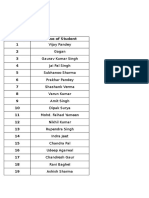

Bottom Section :

1

Insole attaching Machine

Counter Moulding

Toe puff attaching Machine

Lasting margin Roughing Machine

Upper Conditioning

Fore part lasting

Side lasting

Seat Lasting

Seat Conditioning

10

Side and Seat Lasting machine

11

Seat Crowning machine

12

Heat Setter

13

Pounding Machine

14

Roughing & Scoring Machine

15

Adhesive re-activator Machine

16

Sole Press Machine

17

Chiller

18

Edge Cleaning Machine

19

Combined Finishing Machine

20

De-lasting machine

21

Spray Booth

22

Heal Nailing Machine

23

Preforming machine

24

V.T. Leather Spiting machine

You might also like

- 8th Semester Construction-TheoryDocument27 pages8th Semester Construction-TheoryMadhumitha SureshNo ratings yet

- LASTING TameemDocument40 pagesLASTING Tameemaryanboxer786100% (1)

- Lasting Handout 1Document27 pagesLasting Handout 1Tes KingNo ratings yet

- Materials For Athletic and Sports Shoes Upper, Midsoles and OutsolesDocument4 pagesMaterials For Athletic and Sports Shoes Upper, Midsoles and OutsolesH S EngineersNo ratings yet

- Basic Styles and Parts of FootwearDocument32 pagesBasic Styles and Parts of Footwear17044 AZMAIN IKTIDER AKASHNo ratings yet

- Thread: Threads RequirementDocument17 pagesThread: Threads RequirementVarun GuptaNo ratings yet

- Automation of Shoe Last ModificationDocument16 pagesAutomation of Shoe Last ModificationIlamparithiNo ratings yet

- Different Types of Lasting ConstructionDocument27 pagesDifferent Types of Lasting ConstructionAzmain Iktedar100% (1)

- CADCAM Lecture NotesDocument223 pagesCADCAM Lecture NotesAnish KulkarniNo ratings yet

- Shoe Construction and Modification GuideDocument21 pagesShoe Construction and Modification GuidejohnjkjkNo ratings yet

- Footwear MaterialsDocument6 pagesFootwear MaterialsShima EsmaeiliNo ratings yet

- Unit 2 Introduction To Lasting: StructureDocument18 pagesUnit 2 Introduction To Lasting: StructurePrabu Sankar100% (1)

- Chapter 4: Footwear Manufacturing Technology: Shoe LastDocument30 pagesChapter 4: Footwear Manufacturing Technology: Shoe LastGarvit GargNo ratings yet

- Manual of Shoe Maki 00 Do OlDocument372 pagesManual of Shoe Maki 00 Do Olomotoshoayoola6No ratings yet

- How Shoes Are Made Step-by-Step GuideDocument7 pagesHow Shoes Are Made Step-by-Step GuideMohammed AlqahtanyNo ratings yet

- Shoes Sizing & Fitting - SADocument27 pagesShoes Sizing & Fitting - SAEtu piaNo ratings yet

- Dev of Shoe LastsDocument15 pagesDev of Shoe LastsTanveer AhmedNo ratings yet

- Shoe Finishing Unit-5Document14 pagesShoe Finishing Unit-5Harry AryanNo ratings yet

- FootwearindustryDocument110 pagesFootwearindustryTaru SharmaNo ratings yet

- Affordable Shoe Styles for WomenDocument30 pagesAffordable Shoe Styles for WomenGary EvangelistaNo ratings yet

- 68-Grading of Shoe ComponentsDocument11 pages68-Grading of Shoe ComponentsSadikul IslamNo ratings yet

- The Organization of the Boot and Shoe Industry in Massachusetts Before 1875From EverandThe Organization of the Boot and Shoe Industry in Massachusetts Before 1875No ratings yet

- The Soldier's Foot and the Military Shoe - A Handbook for Officers and Non commissioned Officers of the LineFrom EverandThe Soldier's Foot and the Military Shoe - A Handbook for Officers and Non commissioned Officers of the LineNo ratings yet

- TE Catalogue 2014Document48 pagesTE Catalogue 2014Raheel WalaniNo ratings yet

- Stitch TecDocument2 pagesStitch TecNery LopezNo ratings yet

- 6 Construction of ShoeDocument33 pages6 Construction of ShoevedNo ratings yet

- Royal Canadian Rubber Footwear - Illustrated Catalogue - Season 1906-07From EverandRoyal Canadian Rubber Footwear - Illustrated Catalogue - Season 1906-07No ratings yet

- Footwear GlossaryoftermsDocument22 pagesFootwear GlossaryoftermschienNo ratings yet

- Making ShoesDocument12 pagesMaking Shoesranzhao chenNo ratings yet

- History of Footwear: Figure 1:-1991 - Stone Age FootwearDocument11 pagesHistory of Footwear: Figure 1:-1991 - Stone Age FootwearShaluNo ratings yet

- Unit 8 Documentation in Cutting Room: StructureDocument11 pagesUnit 8 Documentation in Cutting Room: StructureHarry AryanNo ratings yet

- The Bark Tanning Process - A Collection of Historical Articles on Leather ProductionFrom EverandThe Bark Tanning Process - A Collection of Historical Articles on Leather ProductionNo ratings yet

- Footwear Machinery Part IIDocument13 pagesFootwear Machinery Part IIsanjana sadhukhanNo ratings yet

- NEEDLE POINTS AND FUNCTIONSDocument13 pagesNEEDLE POINTS AND FUNCTIONSAsif AnwarNo ratings yet

- Cfti Agra FDPD Curriculum PDFDocument49 pagesCfti Agra FDPD Curriculum PDFSingh Singh100% (1)

- Shoes of All Kinds and Styles - Men's and Boys' ShoesFrom EverandShoes of All Kinds and Styles - Men's and Boys' ShoesRating: 4 out of 5 stars4/5 (1)

- 4 Boot 3d Modelling and Pattern Making Using Cad Technology PDFDocument16 pages4 Boot 3d Modelling and Pattern Making Using Cad Technology PDFlepiNo ratings yet

- Indian Leather Industry Is The Core Strength of The Indian Footwear IndustryDocument3 pagesIndian Leather Industry Is The Core Strength of The Indian Footwear IndustrySubhro SarkarNo ratings yet

- Patrones para Calzado DeportivoDocument24 pagesPatrones para Calzado DeportivoGustavo RuizNo ratings yet

- Basic of ShoesDocument5 pagesBasic of ShoesVishnu TejaNo ratings yet

- Khulna University of Engineering & TechnologyDocument49 pagesKhulna University of Engineering & Technology17044 AZMAIN IKTIDER AKASHNo ratings yet

- Footwear History and Introduction (30sep2016) PDFDocument59 pagesFootwear History and Introduction (30sep2016) PDFChou Sheng-ChiaNo ratings yet

- Custom Shoe Order FormDocument1 pageCustom Shoe Order FormFBM Technologies LtdNo ratings yet

- Cutting Material TypesDocument40 pagesCutting Material TypesSruthi Maravana BhaskaranNo ratings yet

- J&H-Catalogue-Shoe Soles-2019Document23 pagesJ&H-Catalogue-Shoe Soles-2019LEONo ratings yet

- History of Shoemaking From Ancient Craft to Mechanized IndustryDocument3 pagesHistory of Shoemaking From Ancient Craft to Mechanized IndustryJuan Jose100% (1)

- Loake 2018Document22 pagesLoake 2018martin9947No ratings yet

- Unit 3 Lasting Process Control Systems: StructureDocument11 pagesUnit 3 Lasting Process Control Systems: StructureHarry AryanNo ratings yet

- Shose PDFDocument11 pagesShose PDFhemaliNo ratings yet

- Chukka Full Patterns FreeDocument71 pagesChukka Full Patterns FreeSergey CheNo ratings yet

- Footwear Sourcing and Development DirectorDocument3 pagesFootwear Sourcing and Development Directorapi-77266701No ratings yet

- Arsutoria School Footwear Courses 2018 1Document12 pagesArsutoria School Footwear Courses 2018 1Shahriar H DiptoNo ratings yet

- Pu Soling Dip Vs PouringDocument13 pagesPu Soling Dip Vs PouringahsanfahadNo ratings yet

- Dopp Kit Pattern Free PDFDocument8 pagesDopp Kit Pattern Free PDFNarendra KumawatNo ratings yet

- Handouts For Application of ColourDocument13 pagesHandouts For Application of ColourMalika LunganiNo ratings yet

- Different Shoes Materials and Their FeaturesDocument20 pagesDifferent Shoes Materials and Their FeaturesAnamikaNo ratings yet

- EEM403 Footwear MachineryDocument1 pageEEM403 Footwear MachineryashutoshNo ratings yet

- AmitDocument2 pagesAmitaryanboxer786No ratings yet

- Mba105 - Managerial EconomicsDocument2 pagesMba105 - Managerial Economicsaryanboxer786No ratings yet

- Mba105 - Managerial EconomicsDocument2 pagesMba105 - Managerial Economicsaryanboxer786No ratings yet

- Clicking FAQDocument4 pagesClicking FAQaryanboxer786No ratings yet

- SurjeetDocument5 pagesSurjeetaryanboxer786No ratings yet

- Avaneesh SainiDocument3 pagesAvaneesh Sainiaryanboxer786No ratings yet

- Syllabus For Testing of Footwear Materials & Complete FootwearDocument4 pagesSyllabus For Testing of Footwear Materials & Complete Footweararyanboxer786No ratings yet

- Syllabus For Testing of Footwear Materials & Complete FootwearDocument4 pagesSyllabus For Testing of Footwear Materials & Complete Footweararyanboxer786No ratings yet

- Purpose of SkiviingDocument2 pagesPurpose of Skiviingaryanboxer786No ratings yet

- What Is A TextureDocument3 pagesWhat Is A Texturearyanboxer786No ratings yet

- Name Dipartment Mobile Raw MaterialDocument2 pagesName Dipartment Mobile Raw Materialaryanboxer786No ratings yet

- Two Year Diploma Cource In: Msme-Technology Development CenterDocument1 pageTwo Year Diploma Cource In: Msme-Technology Development Centeraryanboxer786No ratings yet

- StructureDocument8 pagesStructurearyanboxer786No ratings yet

- Inplant EditDocument23 pagesInplant Editaryanboxer786No ratings yet

- Candidates For Placenment: S.No. Name BatchDocument4 pagesCandidates For Placenment: S.No. Name Batcharyanboxer786No ratings yet

- PDFDocument44 pagesPDFaryanboxer786No ratings yet

- CFTIDocument1 pageCFTIaryanboxer786No ratings yet

- AbhishekDocument2 pagesAbhishekaryanboxer786No ratings yet

- CFTIDocument1 pageCFTIaryanboxer786No ratings yet

- Closing FAQDocument5 pagesClosing FAQaryanboxer786No ratings yet

- U Lip MutualDocument87 pagesU Lip Mutualaryanboxer786No ratings yet

- 597183Document4 pages597183Tusharr AhujaNo ratings yet

- HasanDocument13 pagesHasanaryanboxer786No ratings yet

- MK0010-sales DistributionDocument10 pagesMK0010-sales Distributionaryanboxer786No ratings yet

- MB0052 - Strategic Management and Business PolicyDocument6 pagesMB0052 - Strategic Management and Business Policyaryanboxer786No ratings yet

- Technology Management PDFDocument2 pagesTechnology Management PDFaryanboxer786No ratings yet

- MK0013Document7 pagesMK0013aryanboxer786No ratings yet

- Management Information SystemDocument7 pagesManagement Information Systemaryanboxer786No ratings yet

- Incompatibilities in Prescription 4e (1917)Document334 pagesIncompatibilities in Prescription 4e (1917)Benjel AndayaNo ratings yet

- Physical and Chemical ChangesDocument25 pagesPhysical and Chemical Changesshreshtha rachakondaNo ratings yet

- np38 12b Product Data SheetDocument2 pagesnp38 12b Product Data Sheetapi-170472102No ratings yet

- Bohr-Sommerfeld QuantizationDocument6 pagesBohr-Sommerfeld QuantizationabihagulNo ratings yet

- Lect - 10 External Forced ConvectionDocument45 pagesLect - 10 External Forced ConvectionVivaan SharmaNo ratings yet

- Dietrich 2017Document10 pagesDietrich 2017Zulfi Nur Amrina RosyadaNo ratings yet

- Accuracy Precision Significant Digits PDFDocument5 pagesAccuracy Precision Significant Digits PDFnkar037No ratings yet

- Analyzer Sample Systems Ver HappenDocument12 pagesAnalyzer Sample Systems Ver HappenIñaki Eseberri100% (1)

- April 2010 One FileDocument296 pagesApril 2010 One FileSaad MotawéaNo ratings yet

- MCQ Gad 2Document8 pagesMCQ Gad 2AlhanNo ratings yet

- 50 Years After The Nobel Prize Ziegler Natta Catalysis - Claverie2013Document6 pages50 Years After The Nobel Prize Ziegler Natta Catalysis - Claverie2013Erika AndradeNo ratings yet

- Book Print Gunastar Final - 1528261270Document103 pagesBook Print Gunastar Final - 1528261270santoshNo ratings yet

- QIAexpress Detection and Assay HandbookDocument104 pagesQIAexpress Detection and Assay HandbookghadbaneNo ratings yet

- Inlab MC X5 Accessories: Order FormDocument1 pageInlab MC X5 Accessories: Order FormCiprian SarivanNo ratings yet

- Soal BIOKIM Nomor 3Document4 pagesSoal BIOKIM Nomor 3Siti RositahNo ratings yet

- IJCE v5n1p48 enDocument18 pagesIJCE v5n1p48 enAslam HutagiNo ratings yet

- Chapter 31Document31 pagesChapter 31Karen LovedorialNo ratings yet

- Power Engineering FundamentalsDocument5 pagesPower Engineering FundamentalsShriram SinghNo ratings yet

- Synthesis of Para-Red and 1-Iodo-4-Nitrobenzene ExperimentDocument2 pagesSynthesis of Para-Red and 1-Iodo-4-Nitrobenzene ExperimentMaryNo ratings yet

- The Triple Point of Water (TPW)Document24 pagesThe Triple Point of Water (TPW)vebriyantiNo ratings yet

- Standby battery product overviewDocument2 pagesStandby battery product overviewHillary McgowanNo ratings yet

- The Reactivity Series NotesDocument8 pagesThe Reactivity Series NotesTHEVINESHNo ratings yet

- Weld StudsDocument24 pagesWeld StudsDGWNo ratings yet

- Weberdry 130 PR Grey-WhiteDocument2 pagesWeberdry 130 PR Grey-WhiteabbNo ratings yet

- 4-Quinolone Hybrids and Their Antibacterial ActivitiesDocument11 pages4-Quinolone Hybrids and Their Antibacterial ActivitiesKevin ArechigaNo ratings yet

- Moldavite Ukazka PDFDocument15 pagesMoldavite Ukazka PDFNeven Žižić100% (1)

- Types of PumpsDocument68 pagesTypes of PumpsVicky JeganNo ratings yet

- Ramesh Kumar Guduru CV and Research ProfileDocument8 pagesRamesh Kumar Guduru CV and Research ProfileAnonymous v9cXHdjNo ratings yet

- Cutting Fluids and Machining ProcessesDocument19 pagesCutting Fluids and Machining Processescasey rimNo ratings yet

- 26-12-19 - SR - IIT - N-SUPER CHAINA&N-CHAINA - Jee-Main - GTM-12 - Key & Sol'sDocument15 pages26-12-19 - SR - IIT - N-SUPER CHAINA&N-CHAINA - Jee-Main - GTM-12 - Key & Sol'smahesh tNo ratings yet