Professional Documents

Culture Documents

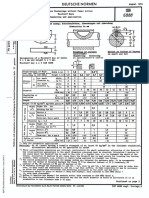

ANSI-ASME B17.1-1967 (R 2003) Keys and Keyseats

Uploaded by

Christian PazmiñoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ANSI-ASME B17.1-1967 (R 2003) Keys and Keyseats

Uploaded by

Christian PazmiñoCopyright:

Available Formats

~~~

~~~~~

I N D D B37.3 b 7 m 2595532 0078092 003 m

ANSI-B17.1

ADOPT ION NOTICE

ANSI-B17.1, "Keys and Keyseats," was adopted on October 3, 1994,

for use by the Department of Defense (DoD). Proposed changes by

DoD activities must be submitted to the DoD Adopting Activity:

Commander, Defense Industrial Supply Center, Attn: DISC-EF,

Philadelphia, PA 19111-5096. DoD activities may obtain copies

of this standard from the Standardization Document Order Desk,

700 Robbins Avenue, Building 4D, Philadelphia, PA 19111-5094.

The private sector and other Government agencies may purchase

copies from the American National Standards Institute, 11 West

42nd Street, New York, NY 10036.

Custodians:

Army - AL

Navy - YD1

Air Force - 99

Adopting Activity

DLA - IS

FSC 5315

DISTRIRUTION STATEMENT A. Approved for public release;

distribution is unlimited.

KEYS AND KEYSEATS

USAS B17.1- 1967

S,OiadOP

The American Society of Mechanical Engineers

THE

A M E R I C A N

SOCIETY

United E n g i n e e r i n g Center

OF

M E C H A N I C A L

345 East 4 7 t h Street

(www.bzxzw.com)

E N G I N E E R S

N e w Y o r k , N. Y. 10017

ASME B 1 7 . 1 67

0757670 0042527 4

U SA STAN DARD

This USA Standard is one of nearly 3000 standards approved a s American Standards

by the American Standards Association. On August 24, 1966, the.ASA was reconstituted a s the United States of America Standards Institute. Standards approved

a s American Standards are now designated USA Standards. There is no change in

their index identification or technical content.

A n y part of this standard may be quoted. Credit lines should read: Extracted

from USA Standard K e y s and Keyseats (USAS B17.1-1967), with the permission of

the publisher, The American Society of Mechanical Engineers, United Engineering

Center, 345 E a s t 47th Street, New York, N.Y. 10017.

UDC 621.886.6

Copyright, 1968, by

THE AMERICAN SOCJETY PF MECHANICAL ENGINEERS

Printed in U.S.A.

ASME B 2 7 * 2 b 7

0759670 0042528 b

Foreword

T HE individual USA Standards on Keys were first issued in the late

1920's. These were consolidated with the shafting standards in the 1934

publication, Standard Shafting and Stock Keys. A revised i s s u e was

published in 1943 and withdrawn in 1955 as it w a s not being sufficiently

supported. However, a separate standard on Woodruff Keys, Keyslots, and

Cutters (B17f-1930) was reaffirmed in 1955.

In i962 the USA Standards Committee B17 was reactivated and a subcommittee developed and established this stan'dard based on current industry standards.

Following approval by the USA Standards Committee B17 and the

sponsor, the proposed revision was approved on September 15, 1967 by

.

the USA Standards Institute, and designated B17.1-1967.

iii

(www.bzxzw.com)

ASME 6 1 7 - 1 b 7 W 0 7 5 7 6 7 0 0 0 4 2 5 2 7 8 S

USA Standards Committee BI7

Keys

and

Keyseats

OF FI%E R S

U. P. Jennings, Chaiman

Roger Daniels, Secretary

COMMITTEE MEMBERS

AMERICAN GEAR MANUFACTURERS ASSOCIATION

G. L. Scott, American Gear Manufacturers Association, Washington, D.C.

D. F. Wild, General Electric Company, Paterson, New Jersey

AMERICAN SOCIETY O F MECHANICAL ENGINEERS, THE

U. P. Jennings, E. I. DuPont de Nemours & Company, Inc., Wilmington, Delaware

AMERICAN SOCIETY O F TOOL AND MANUFACTURING ENGINEERS

W. M. Houck, New Holland Machine Company, New Holland, Pennsylvania

AMERICAN SPROCKET CHAIN MANUFACTURERS ASSOCIATION

R. A. Anderson, Roller Chain Division, Rex Chainbelt Company, Worcester, Massachusetts

CONVEYOR EQUIPMENT MANUFACTURERS ASSOCIATION

C. R. Davis, Rex Chainbelt Inc., Milwaukee, Wisconsin

A. N'. Lemmon, Alternate, The Jeffrey Manufacturing Company, Columbus, Ohio

R. C. Sollenberger, Alternate, Conveyor Equipment Manufacturers Association, Washington, D.C.

MECHANICAL POWER TRANSMISSION ASSOCIATION

D: C. Currier, Dodge Manufacturing Company, Mishawaka, Indiana

METAL CUTTING TOOL INSTITUTE

Perry L. Houser, Metal Cutting Tool Institute, New York, N.Y.

NATIONAL ELECTRICAL MANUFACTURERS ASSOCIATION

C. F. Schwan, Reliance Electric & Engineering, Cleveland, Ohio

SOCIETY O F AUTOMOTIVE ENGINEERS

E. J. Flewelling, Massey-Fergusson, Inc., Detroit, Michigan

INDIVIDUAL COMPANIES

J . W. Gillen, John Gillen Company, Cicero, Illinois

G. W. Andrews, Alternate, John Gillen Company, Cicero, Illinois

Roger Daniels, Formsprag Company, Warren, Michigan

W. C. Sheers, Standard Horse Nail Corporation, New Brighton, Pennsylvania

Personnel of Subcommittee 1, Rectangular Keys

C. R. Davis, Chaiman, Manager of Engineering, Conveyor Equipment, Rex Chainbelt Inc., 4701 West Greenfietd

Avenue, Milwaukee, Wisconsin 53214

J. W- Gillen, President, John Gillen Co., Subsidiary of Stanray Corp., 2540 South 50th Avenue, Cicero,

Illinois 60650

C. F. Schwan, Chief Mechanical Engineer, Reliance Electric h Engineering o., 24701 Euclid Avenue,

Cleveland, Ohio 44117

D. F, Wild, Manager-Engineering, Gearmotor Business Section, General Electric Co., 845 E a s t 25th Street,

Paterson, New Jersey 07513

Donald C. Currier, Chief of Standards and Statistics, Dodge Manufacturing Coaporation, Mishawaka, Indiana 46544

iv

ASME B L 7 - 1 67

= 0759b70

0042530 4

TABLE OF CONTENTS

Page

1. Introduction. . . . . . .. . .. . . . . . . . . . . .. . .. . .. . . . . . . . . . . . , . . . . . . . . . , 1

2. Definitions. . . . . . . _. . . . . . .: . . . , . . . .:. . . . . . . . . . . . . . . . . . . . . 1

3. Key Size Versus Shaft Diameter. . . . _.. . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

4. Key Dimensions and Tolerances. . . . . . . . . . . . . . . . . . . . . . . . . . , . . . . . . . . 3

5 . Depth Control Formulas.

. . . . . . . . . . . . . . . . . . , . . . . . . .. . . . . . . . . . . . 5

6. Key-Keyseat Assemblies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . , . . . 8

7. Alignment Tolerances. . . . . . . . . . . .. .. . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

8. Chamfered Keys and Filleted Keyseats. . . . . . . . . . . . . . . . . . . . . . . . . . . 11

9. Set Screws For Use Over Keys. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

.

. .

Table 1 Key SizeVersus Shaft Diameter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Table 2 Key Dimensions and Tolerances. . . . . . . . . . . . . . . .. . . . , . . . . . . . . . 3

Table2A Gib Head Nominal Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Table 3 Depth Control Values-Values for S and T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 4 C l a s s 1-Fit for Parallel Ke-ys . . . . , . . . . . . . . . .

.. ........ ... 8

Table 5 C l a s s 2 - F i t for Parallel and Taper Keys. . . . . . . . . . . . . . . . . . . . . . 9

Table 6 Keyseat Tolerances for Electric Motor and Generator Shaft Extensions . . . . . 9

Table 7 Suggested Fillet Radii and Key Chamfer.. . . . . . . . . . . . . . . . . . . . . . . . . , . . . 11

Table 8 Set Screws for Use Over Keys. . . . . . . . . . , . . . . . . . . . . , . . . . . . . . . 12

..

(www.bzxzw.com)

,-

ASME BL7.L 67

0757670 0042533 b

USA STANDARD

Keys and Keyseats

1. INTRODUCTION

T h i s standard establishes a uniform relationship between shaft s i z e and key s i z e for parallel

and taper keys retaining similar basic sizing a s

found in the withdrawn B17.1-1943 standard.

T h i s standard covers the size, type and tolerances of parallel and taper keys and keyseats,

and their relationship to shaft diameters and bore

diameters. The s i z e s and tolerances contained

in this standard are intended for single key applications only.

Key strength and steel analysis entering into

the makeup of stock for keys is not within the

scope of this standard. Shaft diameters are listed

for identification of various key s i z e s and a r e not

intended to establish shaft dimensions, tolerances

o r selections,

This standard recognizes that there are two

c l a s s e s of stock for parallel keys presently used

by industry. One is a broad negative toleranced

bar stockand the other is a close plus toleranced

keystock. Each is combined with appropriate keys e a t tolerances to establish assemblies, respectively, designated a s C l a s s e s 1 and 2.

Taper keys are established for C l a s s -2 assembly only.

2. DEFINITIONS

2.1 Key - A demountable machinery part which,

when assembled into keyseats, provides a posi-

tive means for transmitting torque between the

shaft and hub. Tolerances are shown in Table 2.

2 . 1 . 1 Bar Stock - General purpose, negative toieranced, cold finished steel stock for

parallel keys.

- A close plus toleranced, cold

finished steel stock for parallel keys.

2.2. Keyseat - An axially located rectangular

groove in a shator hub. This may also be written

a s shaft keyseat or hub keyseat when describing

the exact application. Hub keyseat has been

sometimes referred to a s a keyway.

2.2.2 Keystock

2.3 Keyseating - The operation of producing keyseats.

3. KEY SIZE VERSUS SHAFT DIAMETER

For a stepped shaft, the size of a key is determined by the diameter of the shaft a t the point

of location of the key, regardless of the number

of different diameters on the shaft.

Square keys are preferred through 6x-inch

diameter shafts and rectangular keys for larger

shafts. Sizes and dimensions in unshaded area

are preferred.

If special considerations dictate the u s e of

a keyseat in the hub shallower- than the preferred

nominal depth shown in Table 1, it is recommended that the tabulated preferred nominal

standard keyseat be used in the s h a f t in all

cases.

USA STANDARD

Table

NOMINAL SHAFT DIAMETER

Key Size Versus Shaft Diameter

NOMINAL KEY SIZE

*Some key standards show 1-1/4 in. Preferred s i z e is l - l / Z

Shaded areas: See Part 3, page 1.

Ali dimensions given i n inches.

in.

(www.bzxzw.com)

NOMINAL KEYSEAT D E P T H

KEYS AND KEYSEATS

4. KEY DIMENSIONS AND TOLERANCES

H U B LENGTH

PARALLEL

GIB HEAD TAPER

P L A I N TAPER

ALTERNATE P L A I N T A P E R

Plain and Gib Head Taper Keys Have a 1/8" Taper in 12"

Table 2

Key Dimensions and Tolerances

NOMINAL KEY SIZE

Wid t

Over

To (incl)

3/4

1-1/2

1-1/2

2-1/2

2-1/2

3-1/2

KEY

Bar Stock

Square

1-174

Parallel

i74

1-1/2

3

Bar Stock

Rectangular

Keystock

Taper

Plain or Gib Head

Square or Rectangular

*For locating position of dimension H . Tolerance does not apply,

See Table 2A for dimensions on gib heads.

A l l dimensions given in inches.

1-1/4

3

1-;4

3

Width, W

1-1 /4

3

7

Height, H

I _

tO.000 -0.002

tO.000 -0.003

M.000 -0.004

+O.OOO -0.006

tO.001 -0.000

tO.002 -0.000

M.003 -0.000

542

3/z - --- +O.OOO -0.003

1-1/2

tO.000 -0.004

tO.000 -0.005

3

4

tO.000 -0.006

6

+O.OOO -0.008

7

+O.OOO -0.013

M.001 -0.000

i-1/4

M.002 -0.000

3

7

tO.003 -0,000

1-1/4

Keys tock

TOLERANCE

tO.000 . -0.002

tO.000 -0.003

tO.000 -0.004

+O.OOO -0.006

tO.001

+0.002

tO.003

M.000

-0.OOD

-0.000

-0.000

.-0.003

tO.000 -0.004

tO.000 -0.005

+o.ooo -0.006

tO.000

+O.OOO

-0.008

-0.013

tO.005 -0.005

+0.005 -0.005

+0.005

-0.005

0759670 0042534 L

ASME B17.L 67

USA STANDARD

Table

Nominal

Key Size

2A

SQUARI

Width. W

1/8

1/4

1/4

3/16

5/16

7/16

1/4

5/i 6

1/2

5/8

3/4

7/8

1-1/4

1-1/2

1-3 / 4

2

2-1 / 2

3-1/2

*For local

1-1/4

1-3 /8

1-5/8

2

2-3/8

2-3/4

3-1/2

4

-1/2

3/16

1/ 4

1/2

1/ 4

3 /8

3/4

7/8

7/16

5/8

1/2

5 /8

3/ 4

7/8

REI ANGU

H

A

3/32

3/16

1/8

1/4

5/16

3 /8

7/16

5/16

3/8

3/8

Gib Head Nominal Dimensions

5

6

1

1-1/8

1-7/16

5/8

1/ 2

7/16

5/8

7/8

314

1-1/4

1-3/8

1-3/4

2

2-1 / 4

L-1/2 2-3/8

3-1/2

4

g posit. n of dimension

1-5/8

2-3/8

2-3/4

3-1/2

4

3/8

3 /8

3/4

1

1-1/2

i -3 / 4

?

!-1/2

5/16

7/16

7/16

1/ 2

5 /8

7/8

iR

3/4

7/8

.-1 /8

-3 / 4

-3 / 4

.

.

i-1/4

H.

For larger s i z e s the following relationships are suggested a s guides

for establishing A and B.

A = 1.8H

B =

1.2

A l l dimensions given in inches.

(www.bzxzw.com)

ASME BL7.L 67

0757670 OOLt2535 3

KEYS AND KEYSEATS

5. DEPTH CONTROL FORMULAS

The chordal height Y is determined from the

following formula:

CHORDAL HEIGHT

Y =

D - dD2 - A V 2

2

The distance from the bottom of the shaft

keyseat to the opposite side of the shaft is

specified by dimension S. The following formula

may be used for calculating this dimension:

S = D - Y - - =H

2

D - H

-

+ d m

2

Tabulated values of S for specific .shaft diameters

are given in Table 3.

DEPTH OF SHAFT KEYSEAT

The distance from the bottom of the hub keythe opposite s i d e o f the hub bore is

specified by dimension T. For taper keyseats, T

i s measured a t the deeper end. The following formula may be used for calculating this dimension:

seat to

H

T=D-Y+-+C=

2

I

+ d D 2 -IV2

2 -

Tabulated values of T for parallel and taper keyseats for specific bores are given in Table 3.

Symbols

C = Allowance

-k 0.005 inch clearance for parallel keys

- 0.020 inch interference for taper keys

D = Nominal shaft or bore diameter, inches

H = Nominal key height, inches

W = Nominal key width, inches

Y = Chordal height, inches

DEPTH OF HUB KEYSEAT

-W+

D +H

Y H/2

ASME BL7.L b7 W 0757670 0042536 5

USA STANDARD

DEPTHCONTROLVALUES

Tablc 3 Values for 5 and T

Nominal

Shaft

Diameter

Parallel and Taper

Taper

.E

Square

Rectangular

S

Square

'T

Rectangular

T

Square

T

Rectangular

1/2

9/16

5[8

11/16

3/4

0.430

0.493

0.517

0.581

0.644

0.445

0.509

0.548

0.612

0.676

0.560

0.623

0.709

0.773

0.837

0.544

0.607

0.678

0.742

0.806

0.535

0.598

0.684

0.748

0.812

0.519

0.582

0.653

0.717

0.781

13/16

7/8

15/16

0.739

0.802

0.827

0.890

0.954

0.900

1

1-1/16

0.708

0.771

0.796

0.859

0.923

0.964

1.051

1.114

1.178

0.869

0.932

1.019

1.083

1.146

0.875

0.939

1.026

1.O89

1.153

0.844

0.907

0.994

1.058

1-1/8

1-3/16

1-1/4

1-5/16

1-3/8

0.986

1.O49

1.112

1.137

1.201

1.017

1.080

1.144

1.169

1.232

1.241

1.304

1.367

1.455

i ;5i8

1.210

1.273

1.336

1A24

1A87

1.216

1.279

1.342

1.430

1A93

1.I 85

1.248

1.311

1.399

1.462

1-7/16

1.225

1.289

1.352

1.416

1.479

1.288

1.351

1.415

1.478

1.541

1.605

1.669

1.732

1.796

1.859

1.543

1.606

1.670

1.733

1.796

1.580

1.644

1.707

1.771

. 1.834

1.518

1.581

1.645

1.708

1.771

1,>42

1.605

1.590

1.654

1.717

1.781

1$22

1.527

1.591

1.655

1.718

2.032

2.0.96

2.160

2.223

1.860

1.970

2.034

2.097

2.161

1.897

2.007

2.071

2.135

2.198

1.835

1.945

2.009

2.072

2.136

1.782

1.845

1.909

1.972

1.957

1.844

1.908

1.971

2.034

2.051

2.287

2.350

2.414

2.477

2.587

2.224

2.288

2.351

2.414

2.493

2.262

2.325

2.389

2.452

2.562

2.199

2.263

2.326

2.389

2.468

2.021

2.084

2.148

2.21

2.275

2.114

2.178

2.242

2.305

2.369

2.651

2.714

2.778

2.841

2.905

2.557

2.621

2.684

2.7'48

2.811

2.626

2.689

2.753

2.816

2.880

2.532

2.596

2.659

2.723

2.786

2.338

2.402

2.387

2.450

2.514

2.432

2.495

2.512

2.575

2.639

2.968

3.032

3.142

3.205

3.269

2.874

2.938

3.017

3.080

3.144

2.943

3.007

3.117

3.180

3.244

2.849

2.913

2.992

3.055

3.119

2.577

2.641

2.704

2.702

2.766

2.829

3.332

3.3.96

3.459

..--.---. *

3.207

3.271

3.334

3.307

3.371

3.434

3.182

3.246

3.309

1-1/2

1-9/16

1-5/8

1-11/16

1-3/4

1-13/16

1-7/8

1-15/16

2

2-1/16

2-1/8

2-3/16

2-1/4

2-5/16

2-3/8

2-7/16

2-1/2

2-9/16

2-5/8

2-11/16

2-3/4

2-13/16

2-7/8

2-15/16

3

3-1/16

3-1/8

-e

r

/------

tolerances. All dimensions given in inches.

6

*

(www.bzxzw.com)

1.121

_.

!.I.

ASME B17-L 67

0759b70 0 0 4 2 5 3 7 7

KEYS AND KEYSEATS

Table

3 Values for

@!p

@i$

$v

-c

Nominal

Shaft

Diameter

S and T - (Continued)

Parallel and Taper

Parallel

Taper

Square

Rectangular

Square

Rectangular

Square

Re c tang u1 ar

T

3-3/16

3-1/4

3-5/16

3-3/8

3-7/16

2.768

2.831

2.816

2.880

2.943

2.893

2.956

2.941

3.005

3.068

3.523

3.586

3.696

3.760

3.823

3.398

3.461

3.571

3.635

3.698

3 A98

3.561

3.671

3.735

3.798

3.373

3.436

3.546

3.610

3.673

3-1/2

3-9/16

3-5/8

3-11/16

3-3/4

3.007

3.070

3.134

3.197

3.261

3.132

3.195

3.259

3.322

3.386

3.887

3.950

4.014

4.077

4.141

3.762

3.825

3.889

3.952

4.016

3.862

3.925

3.989

4.052

4.116

3.737

3.800

3.864

3.927

3.991

3-13/16

3-7/8

3-15/16

4-3/16

3.246

3.309

3.3 73

3.436

3.627

3.371

3.434

3.498

3.561

3-752

4.251

4.314

4.378

4.441

4.632

4.126

4.189

4.253

4.316

4.507

4.226

4.289

4.353

4.416

4.607

4.101

4.164

4.228

4.291

4.482

4-1/4

4-3/8

4-7/16

4-1/2

4-3 /4

4-7/8

4-15/16

3.690

3.817

3.880

3.944

4.041

4.169

4.232

3.815

3.942

4.005

4.069

4.229

4.356

4.422

4.675

4.822

4.885

4.949

5.2 96

5.424

5.487

4.570

4.697

4.760

4.824

5.109

5.236

5.300

4.670

4.797

4.860

4.924

5.271

5.399

5.462

4.545

4.672

4.735

4.799

5.084

5.211

5.275

5

5-3/16

5-1/4

5-7/16

5-1/2

4.296

4.486

4.550

4.740

4.803

4.483

4.674

4.737

4.927

4.971

5.551

5.741

5.805

5.995

6.058

5.363

5.554

5.617

5.807

5.871

5.526

5.716

5.780

5.970

6.033

5.338

5.529

5.592

5.782

5.846

5-3/4

5-15/16

6

6-1/4

6-1/2

4.900

5.091

5.155

5 A09

5.662

5.150

5.341

5.405

5.659

5.912

6.405

6.596

6.660

6.914

7.167

6.155

6.346

6.410

6.664

6.917

6.380

6.571

6.635.

6.889

7.142

6.130

6-321

6.385

6.639

6.892

6-3/4

7

7-1/4

7-1/2

7-3/4

5.760

6.014

6.268

6.521

6.619

*5.885

*6.139

*6.393

*6.646

6.869

7.515

7.769

8.023

8.276

8.624

*7.390

*7.644

*7.898

*&I51

8.374

7.490

7.744

7.998

8.251

8.599

*7.365

*7.619

*7.873

*8.126

8.349

6.873

7.887

8.591

9.606

10.309

7.123

8.137

8.966

9.981

10.807

8.878

9.892

11.096

12.111

13.314

8.628

9.642

10.721

11.736

12.814

8.853

9.867

11.071

12.086

13.289

8.603

9.617

10.696

11.711

12.789

11.325

12.028

13.043

11.825

12.528

13.543

14.330

15.533

16.548

13.830

15.033

16.048

14.305

15.508

16.523

13.805

15.008

16.023

9

10

11

12

13

14

15

S and T

Values are calculated from formulas on page 5 . See Tables 4 and 5 for tolerances.

A l l dimensions given in inches,

*1-3/4 x L l / Z key.

~

7

-~

- -~

ASME BL7.L

67

m '

0759670 0092538 9

USA STANDARD

6 , KEY-KEYSEAT ASSEMBLIES

6'1 C l a s s 1 - A clearance or metal to metal side

fit obtained by using bar stock keys and keyseat

relatively

tolerances a s shown in Table 4-a

free fit. T h i s fit applies only to parallel keys.

6.2 C l a s s 2 - A side fit (possible interference or

clearance) obtained by using keystock and keyrelatively

tight fit.

seat tolerances a s shown in Table 5-a

- A third type of fit not tabulated is

an interference side fit. Since the degree of interference is not readily standardized for these applications, no specific values are included. However, it is suggested that the top and bottom fit

range shown for parallel- keys in Table 5 be used,

6.3 C l a s s 3

Table 4 Class 1

' J "

KE.Y WIDTH

- F i t for Parallel

Keys

T O P AND BOTTOM F I T

SIDE F I T

Key

+o.ooo

i/2

3/4

u 2

3/4

Square

+o.002

-0.000

-0.002

+o.ooo

+0.003

-0.002

-0,000

+0.003

-0,000

+0.004

-0.000

+0.004

-0.000

+0.004

+o.ooo

. -0.003

1-1/2

+o.ooo

-0.003

i-1/2

2-1/2

+o.ooo

-0.004

2-1/2

3-1/2

1/2

3 /4

Rec-

M.OOO

-0.006

+o,ooo

1/2

-0.003

3/4

-0.003

+o.ooo

+o.ooo

+o.ooo

-0.004

tangular

1-1/2

+o.ooo

-0.005

+o.ooo

-0.006

+o.ooo

-0.008

-0.013

CL

Fit

Range*

+o.ooo

-0.015

+0.010

-0.000

0.032 CL

0.005 C L .

CL

CL

CL

0.010 CL

-0.000

0.000

+0,002

0.005 CL

0.000

0.006 CL

0.000

+o.ooo

+0.000

-0.004

-0,015

+o.ooo

+o.ooo

-0.006

+o.OOO

-0.015

-0.003

-0.015

+0.000

-0.003

f0,OOO

+o.ooo

-0.015

+0.010

-0.000

+o.Ol

-0.000

+0.010

-0.000

+0.010

-0.000

0.034 C L

0.005 C L

0,036 C L

0.005 C L

0.033 C L

0.005 C L

0.033 C L

0.005 C L

0.007 CL

0.000

0.008 CL

0.000

0.009 CL

0.000

0.010 CL

-0.000

0.000

+o.004

-0.000

0.012 CL

t0.004

-0.000

+o.ooo

-0.002

0.000

0.008 CL

0.000

-0.000

+0,003

-0.000

+0.003

-0.000

+0.004

-0,000

+o.004

-0.00.0

+0.004

-0.004

1 4 2

0.004

0.000

0.005

0.000

0.006

0.000

0.007

Depth Tolerance

Shaft .

Hub

Keyseat

Keyseat

+o.ooo

-0.006

0.000

0.017 CL

0.000

*Limits of variation, C L = Clearance

All dimensions given in inches.

(www.bzxzw.com)

+o.ooo

-0.015

+o.oio

-0.000

0.036 CI;

0.005 C L

~~

ASME B L 7 - L b 7 M 0 7 5 7 6 7 0 0 0 4 2 5 3 7 O M

KEYS AND KEYSEATS

Table

Type

of

Key

KEY WIDTH

Parallel

1-1/4

I

I

Square

Class

- F i t for

SIDE F I T

\Vidth Tolerance

1-1/4

-0.000

M.002

-0.000

3-1/2

Rec t ang-

+0.003

-0.000

$0.001

-0.000

+0.002

-0,000

I

I

$0.003

-0.000

ular

1-1/4

+0'001

-0.000

+0.002

-0.000

1-1/4

$0.003

-0.000

*Limits of variation. CL= Clearance;

Parallel and Taper Keys

-._

I

r IC

Key

Parallel

Taper

-0.000

$0.002

-0.000

to.002

-0.000

$0.002

-0.000

$0.002

-0.000

$0.002

-0.000

to.002

-0.000

+0.002

-0.000

$0.002

-0.000

0.001 INT

I

I

0.002 C L

0.002 INT

0.002 C L

0.003 INT

0.002 C L

0.001 INT

0.002 C L

0.002INTI

0.002 C L

0.003 INT

0.002 C L

0.001 INT

TOP AND BOTTOM FIT

DeDth Tolerance

Shaft

Hub

Keyseat

Keyseat

-0.000

-0.015

$0.002

~+O,OOO

-0,000

+0.003

-0.000

+0.005

-0.005

+0.005

-0.005

-0.015

+O.OOO

-0.015

t0.000

-0.015

+O.OOO

-0.015

$0.005

+O.OOO

-0.005

+0.005

-0,000

,M.O05

-0.000

+0.005

-0.000

-0.015

-0.000

+0.010

-0.000

-+0.01 o

-0.000

+0.010

-0.000

+0.010

-0,000

+O.OOO

-0.015

+O.OOO

-0.015

+O.OOO

-0.015

$0.010

-0.000

+0.010

-0.000

$0.010:

-0.000

+0.010

-0.000

INT =interference

T o (Incl) 3-1/2 Square and 7. Rectangular key widths.

AU dimensions given in inches.

Table

Keyseat Tolerances for Electric Motor and Generator Shaft Extensions

KEYSEAT WIDTH

To (Incl)

Over

1/4 -

Width Tolerance

1/4

3/4

i /4

i -i/4

+0.001

+o.ooo

$0.000

-0.002

-0.01 5

+o,ooo

-0.003

Depth Tolerance

$0.000

+o.ooo

-0.015

'-

Fit

Range*

0.030

0.004

0.030

O.OQ3

0.030

0.002

0.035

0.000

0.035

0.000

0.035

0.000

0.005

0.025

0.005

0.025

0.005

0.025

CL

CL

CL

CL

CL

CL

CL

CL

CL

CL

CL

CL

CL

INT

CL

INT

CL

INT

ASME B L 7 - 1 67

0757670 0042540 7

USA STANDARD

7. ALIGNMENT TOLERANCES

OFFSET

SHAFT

-T-T

0.010 MAX

_I

-@

-i @KEYSEAT

LEAD

*SHAFT-

$ KEYSEAT1

: EYS EAT

KEYSEAT LENGTH

.&BORE

MAXIMUM

LEAD

0.002

LLEAD

10

0.005

LEAD-J

PARALL E L I SM

AS RESTRICTED BY TOLERANCE

ON S AND T DIMENSIONS

AS RESTRICTED BY KEYSEAT

WIDTH AND DEPTH TOLERANCE

ALL DIMENSIONS GIVEN IN INCHES

10

(www.bzxzw.com)

A S I E BL7.L

67 W 0759670 0 0 4 2 5 4 3 9 W

KEYS-AND KEYSEATS

8. CHAMFERED KEYS AND FILLETED

KEYSEATS

In general practice, chamfered keys and filleted keyseats are not used. However, Xis recognized that filets in keyseats decrease stress

cancentratians a t corners. When used, fillet radii

should be as large a s possible without causing

excessi<e bearing s t r e s s e s due to reduced contact area between the key and its mating parts.

Keys must be chamfered or rounded to d e a r fillet

radii. Values i n Table 7 assume general conditions and should be used only a s a guide when

critical s t r e s s e s are encountered.

J-rt

4!jCHAMFER

FILLET RADIUS

Table 7 Suggested Fillet Radii and Key Chamfer

H/2 KEYSEAT DEPTH

Over

To (Incl)

7/8

1-1/4

1-3/4

All dimensions given in inches.

1-1/4

1-3 /4

2-1/2

Fillet Radius

3/16

1/4

3/8

45 Chamfer

7/?2

9/32

13/32

ASME BL7.L 67

0759670 0042542 O

USA STANDARD

9 . SET SCREWS FOR USE OVER KEYS

Set screw diameter selections listed below

are offered as a guide but their u s e shall be dependent upon design considerations.

Table 8 Set Screws for Use Over Keys

NOMINAL SHAFT DIAMETER

Nominal Key Width

S e t Screw Diameter

Over

To (Incl )

5/16

7/16

3/32

#10

1/8

#10

7/16

7/16

3/16

1/4

9/16

7/8

7/8

1-1/4

1/4

5/16

1-1/4

1-3/8

5/16

3/8

1-3/8

1-3/4

3/8

3/8

. 2-1/4

l/2

1/2

1-3/4

2-1/4

2-3/4

5/8

1/2

2-3/4

3-1/4

3/4

5/8

3-1/4

3-3/4

7/8

3/ 4

4-1/2

1

3/4

3-3/4

4-1/2

5-1/2

i-1/4

7/8

6-1/2

1-1/2

1

5-1/2

A l l dimensions given in inches.

(www.bzxzw.com)

ASME BL.1

67

= 0759670

0042543 2

USA Standards for

Machine Tools. Cutting Tools and Related Standards

TITLE O F STANDARD

Preferred Limits and Fits for Cylindrical Parts ........................................................................

B4.1-1967

T.Sl0t.s. Their Bolts. Nuts. Tongues. and Cutters ......................................................................

B5.1-1949

Milling Cutters ..................................................................................................................................

B5.3-1960

B5.5-1959

Rotating Air Cy1inder.s and Adapters ............................................................................................

B5.6-1962

J i g Bushings ....................................................................................................................................

B5.7-1954

Circular and Dovetailed Forming Tool Blanks ............................................................................

Chucks and Chuck Jaws ....................................................................................

B5.8-1954 (Reaffirmed 1959)

Spindle Noses for Tool Room L a t h e s , Engine Lathes, Turret Lathes,

and Automatic Lathes ......................................................................................................

B5.9-1967

Machine Tapers ................................................................................................................................ B5.10-1963

Spindle Noses and Adjustable Adapters for Multiple Spindle Drilling Heads ........................

B5.11-1964

Involute Splines, Serrations and Inspection ................................................................................ B5.15-1960

.............................

B5.16-1952

Accuracy of Engine and Tool Room Lathes ..............................................

B5.17-1958

Markings for Identifying Grinding Wheels and Other Bonded Abrasives ..................................

Spindle Noses and Arbors for Milling Machines ..........................................................................

B5.18-1960

B5.19-1946 (Reaffirmed 1953)

Life Tests of Single-Point Tools ................................................................

B5.20-1958

Machine P i n s ....................................................................................................................................

Single Paint Tools and Tool Posts ..............................................................................................

B5.22-1950

Punch and Die Sets for Two-Post Punch .Press Tools ..............................................................

B5.25-1950

B5.27-1959

Drill Drivers ......................................................................................................................................

B5.28-1958

Mounting Dimensions of Lubricating and Coolant Pumps for Machine Tools ..........................

Designation and Working Ranges of Grinding Machines ..................................................

B5.32 & 33-1953

B5.34-1956

Life Tests for Single-Point Tools of Sintered Carbide ..............................................................

Machine Mounting Specifications for Abrasive Discs a n d Plate Mounted Wheels .................. B5.35-1957

Driving and Spindle Ends for Portable Air and Electric Tools ................................................

B5.38-1958

Spindle Flanges for Precision Boring Machines ............................................

......................... B5.39-1961

Spindle Noses and Tool Shanks for Horizontal Boring Machines ..............................................

B5.40-1962

B94.1-1964

Blanks and Semi-Finished Blanks for Solid Carbide Taps ........................................................

B94.2-1964

Reamers ............................................................................................................................................

Straight Cut-Off Blades f0.r Lathes and Screw Machines ............................................................ B94.3-1965

B94.4-1965

Identification System for Throw Away Inserts for Cutting Tools ..............................................

Carbide Blanks and Cutting Tools ..............................................................................

......... B94.5-1966

Knurling ............................................................................................................................................ B94.6-1966

B94.7-1966

Hobs ..................................................................................................................................................

(Rev B5.23-1958) B94.8-1967

I-nserted Blade Milling Cutter Bodies ..........................................................

T a p s Cut and Ground Threads......................................................................

(Rev B5.4 -1959) B94.9-1967

High-speed Steel and Cast Nonferrous Single-Point Tools and

Tool Holders .................................................................................. (Rev B5.29-195 9) B94.10-1967

Twist Drills .................................................................................................... (Rev B5.12-1958) B94.11-1367

B17. 1-1967

Keys and Keyseats ..........................................................................................................................

Woodruff Keys ..................................................................................................................................

B 17.2-1967

.

.

Binders for holding standards are available

A compIete list of USA Standards published by The American Society of Mechanical Engineers

obtainable upon request

~-

-~

.

..

-.?

You might also like

- Asme B18.2.8Document14 pagesAsme B18.2.8MisliSlaluAdaNo ratings yet

- ANSI ASME B1.5 Acme StandardDocument123 pagesANSI ASME B1.5 Acme StandardRagesh VVNo ratings yet

- Asme B18.2.2 - 2010Document40 pagesAsme B18.2.2 - 2010Tri Vo100% (2)

- Asme B1.1Document177 pagesAsme B1.1Santosh Shetty100% (4)

- General Purpose Semi-Tubular Rivets, Full Tubular Rivets, Split Rivets, and End CapsDocument22 pagesGeneral Purpose Semi-Tubular Rivets, Full Tubular Rivets, Split Rivets, and End CapsIliyaNo ratings yet

- Spline Program Ver 1.1Document7 pagesSpline Program Ver 1.1Ozeias CardosoNo ratings yet

- Sae J514 090109Document1 pageSae J514 090109Jim RobinsonNo ratings yet

- Asme B4.1-1967 (2009)Document28 pagesAsme B4.1-1967 (2009)vijay pawar100% (3)

- Ansi Y14.7.2-1978Document27 pagesAnsi Y14.7.2-1978Oleg UshakovNo ratings yet

- Asme B18.3.2M 1982Document12 pagesAsme B18.3.2M 1982adilshahzad2001No ratings yet

- ASME B107.100-2010 Flat WrenchesDocument68 pagesASME B107.100-2010 Flat WrenchesNilton Santillan Ortega100% (1)

- Track Bolts and Nuts ASME B18.1f0-2006Document9 pagesTrack Bolts and Nuts ASME B18.1f0-2006ZoebairNo ratings yet

- B29-2M Edtn 2007Document46 pagesB29-2M Edtn 2007Arun Cherian75% (4)

- Norma ANSI+AGMA+6000-B96+ (R2002)Document28 pagesNorma ANSI+AGMA+6000-B96+ (R2002)Alex Ripoll100% (5)

- ANSI B4.2 - 1978 Preferred Metric Limits and FitsDocument72 pagesANSI B4.2 - 1978 Preferred Metric Limits and FitsBo Sun100% (2)

- Asme B18.3Document75 pagesAsme B18.3CamoColton100% (2)

- Ansiasme B1.2-1983 (Revision of Ansi B1.2-1974) PDFDocument190 pagesAnsiasme B1.2-1983 (Revision of Ansi B1.2-1974) PDFrzurabaezaNo ratings yet

- Asme-B18 2 2Document38 pagesAsme-B18 2 2Ross HartwigNo ratings yet

- Abbreviations and Acronyms For Use On Drawings and Related DocumentsDocument9 pagesAbbreviations and Acronyms For Use On Drawings and Related Documentssandip kulkarniNo ratings yet

- Agma Ansi 1006-A97Document56 pagesAgma Ansi 1006-A97ermaksan100% (2)

- Involute Splines, BasicsDocument12 pagesInvolute Splines, Basicsewillia13No ratings yet

- BS 4235-1-1972 Specification For Metric Keys and Keyways. Parallel and Taper KeysDocument26 pagesBS 4235-1-1972 Specification For Metric Keys and Keyways. Parallel and Taper Keysjaffliang100% (5)

- Agma 926-C99Document16 pagesAgma 926-C99Mehul Bansal100% (2)

- Ansi ABMADocument56 pagesAnsi ABMAAndres Antonio Moreno Castro100% (2)

- Asme Y14.13mDocument27 pagesAsme Y14.13mAmin Alisadeghi100% (2)

- X DIN 6885Document3 pagesX DIN 6885bee140676No ratings yet

- Standard For Industrial Enclosed Gear Drives (Metric Edition)Document67 pagesStandard For Industrial Enclosed Gear Drives (Metric Edition)Nicole Suarez50% (2)

- Asme B29.1M 1993 (R1999)Document59 pagesAsme B29.1M 1993 (R1999)J Ferreyra Libano100% (4)

- Agma 908-B89-1999Document79 pagesAgma 908-B89-1999Alex OliveiraNo ratings yet

- Din 3961 PDFDocument12 pagesDin 3961 PDFLuis Testa100% (1)

- Planetary Characteristics: © Sarajit Poddar, SJC AsiaDocument11 pagesPlanetary Characteristics: © Sarajit Poddar, SJC AsiaVaraha Mihira100% (11)

- Ayuda Asme B36.10M PDFDocument26 pagesAyuda Asme B36.10M PDFEdgargar100% (1)

- MD 2 MidtermDocument31 pagesMD 2 MidtermRea Rebenque100% (1)

- AGMA 1103-H07 Tooth Proportions For Fine - Pitch Spur and Helical Gearing (Metric Edition)Document32 pagesAGMA 1103-H07 Tooth Proportions For Fine - Pitch Spur and Helical Gearing (Metric Edition)simone.castagnetti100% (1)

- SAEDocument8 pagesSAEEnriqueGDNo ratings yet

- 19 Free Amigurumi Crochet Patterns: MaterialsDocument4 pages19 Free Amigurumi Crochet Patterns: MaterialsLucica Diaconu100% (1)

- Ansi-Agma 6034-B92-1992-Reaf. (2010) PDFDocument40 pagesAnsi-Agma 6034-B92-1992-Reaf. (2010) PDFDivoneiPauloNo ratings yet

- Analyzing Taper Fits For ManufacturingDocument7 pagesAnalyzing Taper Fits For Manufacturingsalgado_24No ratings yet

- ANSI ASME B17 1 1967 R 2003 Keys and Keyseats PDFDocument19 pagesANSI ASME B17 1 1967 R 2003 Keys and Keyseats PDFBraulio MartinezNo ratings yet

- Surface Vehicle Standard: Rev. AUG2004Document14 pagesSurface Vehicle Standard: Rev. AUG2004Engenheiro100% (1)

- ANSI B4.1-1967 Preferred Limits and Fits For Cylindrical PartsDocument25 pagesANSI B4.1-1967 Preferred Limits and Fits For Cylindrical Partsgiaphongn100% (5)

- 801 Aeronca PDFDocument17 pages801 Aeronca PDFVishveshNo ratings yet

- AGMA 2015 915-1-A02Document108 pagesAGMA 2015 915-1-A02danielk32100% (1)

- ENGINEERING STANDARD - Standard Piping Material SpecificationDocument33 pagesENGINEERING STANDARD - Standard Piping Material SpecificationGanesh Eshwar100% (2)

- BS 3790Document38 pagesBS 3790Simon LawNo ratings yet

- Anillos y Tipos de Tuercas y Longitudes para El EsparragosDocument27 pagesAnillos y Tipos de Tuercas y Longitudes para El EsparragosLevi Garcia UcNo ratings yet

- DIN 6892 - Key CalculationDocument21 pagesDIN 6892 - Key Calculationlucignolo71100% (1)

- DIN-6888-Wood Ruff Key Dim and ApplicatioinDocument2 pagesDIN-6888-Wood Ruff Key Dim and ApplicatioinManikandan Veerasekaran100% (3)

- Din 58405-1-1972Document12 pagesDin 58405-1-1972prasanna67% (3)

- ASME B1.13 Metric Screw Threads, M ProfileDocument75 pagesASME B1.13 Metric Screw Threads, M Profilesnakke0786% (7)

- VDIDocument19 pagesVDIBakkiyaraj VeluNo ratings yet

- Din 867Document3 pagesDin 867danielk32No ratings yet

- Iso 6336-6-2006 - Technical CorrigendumDocument2 pagesIso 6336-6-2006 - Technical Corrigendummagerote50% (2)

- DIN 5480-1-2006 Involute Splines Based On Reference Diameters GeneralDocument24 pagesDIN 5480-1-2006 Involute Splines Based On Reference Diameters GeneralFranciscoNo ratings yet

- ASME B17.1-1967 (2017) ScanDocument22 pagesASME B17.1-1967 (2017) Scanvijay pawarNo ratings yet

- BS ISO 3547-6-2007 Plain Bearings. Wrapped Bushes. Measurement of Wall Thickness of Thin-Walled BushesDocument14 pagesBS ISO 3547-6-2007 Plain Bearings. Wrapped Bushes. Measurement of Wall Thickness of Thin-Walled Bushesxuanphuong2710No ratings yet

- Ansi Agma 2015-1-A01Document1 pageAnsi Agma 2015-1-A01sabapahty chettiyarNo ratings yet

- B5-1M R2004 E1985Document13 pagesB5-1M R2004 E1985JCVV1No ratings yet

- Asme B36.19MDocument13 pagesAsme B36.19Mdongpc1No ratings yet

- Ansi b17 1 Keys and KeyseatsDocument20 pagesAnsi b17 1 Keys and KeyseatsAntonio CastroNo ratings yet

- Australian Standard: Split Cotter Pins (Metric Series)Document0 pagesAustralian Standard: Split Cotter Pins (Metric Series)Masih BelajarNo ratings yet

- The 2002 AISI ColdFormed Steel Design ManualDocument6 pagesThe 2002 AISI ColdFormed Steel Design ManualHariadi Yulianto100% (1)

- Electric Distribution Guy and Anchor PDFDocument29 pagesElectric Distribution Guy and Anchor PDFaswarNo ratings yet

- Air Cooler With Checking DoorDocument2 pagesAir Cooler With Checking DoorSuraj KumarNo ratings yet

- Integration of Phodi Process With Mutation in Bhoomi (Simultaneous Approval of Phodi and The Mutation)Document19 pagesIntegration of Phodi Process With Mutation in Bhoomi (Simultaneous Approval of Phodi and The Mutation)seshadrimn seshadrimnNo ratings yet

- Lecture Notes Unit-1 (Network Operating System) : Session: 2021-22Document17 pagesLecture Notes Unit-1 (Network Operating System) : Session: 2021-22Pradeep BediNo ratings yet

- RadarDocument65 pagesRadarAsifa LiaqatNo ratings yet

- Https - Threejs - Org - Examples - Webgl - Fire - HTMLDocument9 pagesHttps - Threejs - Org - Examples - Webgl - Fire - HTMLMara NdirNo ratings yet

- Electron Withdrawing and Electron Donating GroupsDocument2 pagesElectron Withdrawing and Electron Donating GroupsOmar Abd ElsalamNo ratings yet

- Green Engine 2 PDFDocument7 pagesGreen Engine 2 PDFharivardhanNo ratings yet

- Lexus JTJBT20X740057503 AllSystemDTC 20230702045631Document2 pagesLexus JTJBT20X740057503 AllSystemDTC 20230702045631Venerable DezzyNo ratings yet

- 4th Six Weeks RecoveryDocument8 pages4th Six Weeks RecoveryAshley HighNo ratings yet

- Travelsinvarious03clar BWDocument522 pagesTravelsinvarious03clar BWSima Sorin MihailNo ratings yet

- An Adaptive Power Oscillation Damping Controllerby STATCOM With Energy StorageDocument10 pagesAn Adaptive Power Oscillation Damping Controllerby STATCOM With Energy StorageChristian EmenikeNo ratings yet

- 2019 BMS1021 Practice Questions Answers PDFDocument12 pages2019 BMS1021 Practice Questions Answers PDFaskldhfdasjkNo ratings yet

- P eDocument22 pagesP eKiks AshNo ratings yet

- Paper 2 Phy 2019-2023Document466 pagesPaper 2 Phy 2019-2023Rocco IbhNo ratings yet

- 8 Field Quality PlanDocument18 pages8 Field Quality PlanRamaKrishna ANo ratings yet

- Alzheimer's Disease Inhalational Alzheimer's Disease An UnrecognizedDocument10 pagesAlzheimer's Disease Inhalational Alzheimer's Disease An UnrecognizednikoknezNo ratings yet

- Unit-3 DC Machines IMP QuestionsDocument30 pagesUnit-3 DC Machines IMP Questionskrishna Sai Atla VenkataNo ratings yet

- NMMT City Bus SystemDocument3 pagesNMMT City Bus Systemharish guptaNo ratings yet

- MFI 2 - Unit 3 - SB - L+SDocument10 pagesMFI 2 - Unit 3 - SB - L+SHoan HoàngNo ratings yet

- Nestle Internship ResumeDocument2 pagesNestle Internship ResumeHasnain AshrafNo ratings yet

- Attacks On Cryptosystems PDFDocument18 pagesAttacks On Cryptosystems PDFUjjayanta BhaumikNo ratings yet

- Blood Glucose Units Conversion Table: Endocrinology & Diabetes UnitDocument1 pageBlood Glucose Units Conversion Table: Endocrinology & Diabetes UnitDrFarah Emad AliNo ratings yet

- Sunday Afternoon, October 27, 2013: TechnologyDocument283 pagesSunday Afternoon, October 27, 2013: TechnologyNatasha MyersNo ratings yet

- PT3 Guided WritingDocument8 pagesPT3 Guided WritingDayang Haffizah Abg AbdillahNo ratings yet

- Hydrostatic, Deviatoric StressesDocument7 pagesHydrostatic, Deviatoric StressespanbuNo ratings yet

- HP Prodesk 400 G6 Microtower PC: Reliable and Ready Expansion For Your Growing BusinessDocument4 pagesHP Prodesk 400 G6 Microtower PC: Reliable and Ready Expansion For Your Growing BusinessPằngPằngChiuChiuNo ratings yet