Professional Documents

Culture Documents

Internal Coil

Uploaded by

whngomj0 ratings0% found this document useful (0 votes)

174 views2 pagesInternal Coil calculation

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentInternal Coil calculation

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

174 views2 pagesInternal Coil

Uploaded by

whngomjInternal Coil calculation

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

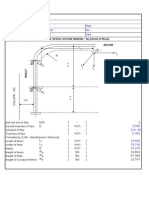

Internal Coil: Calculation

Input Echo, Component

1,

Description: Coil V1,2,3,4 - DN80

Design Internal Pressure

P

Temperature for Internal Pressure

User Entered Minimum Design Metal Temperature

Design External Pressure

PEXT

Temperature for External Pressure

External Pressure Chart Name

9.00

295.00

0.00

7.00

260.00

CS-2

Include Hydrostatic Head Components

Material Specification (Not Normalized)

Material UNS Number

Material Form used

Allowable Stress At Temperature

Allowable Stress At Ambient

Yield Stress At Temperature

Curve Name for Chart UCS 66

Joint efficiency for Shell Joint

bar

C

C

bar

C

NO

SA-333 6

K03006

Smls. & wld. pipe

S

117.905

SA

117.905

Sy

189.128

MPa

MPa

MPa

1.00

Design Length of Section

L

Length of Cylinder for Volume Calcs.

CYLLEN

Outside Diameter of Cylindrical Shell

D

(Minus Total Ext. Corrosion Allowance 6mm)

Minimum Thickness of Pipe or Plate

T

(Minus Ext. Corrosion Allowance 3mm)

Shell/Head Int. Corrosion Allowance

CA

45402.000

45402.000

82.900

mm

mm

mm

6.7388

mm

3.0000

mm

Skip UG-16(b) Min. thickness calculation

Type of Element:

NO

Cylindrical Shell

Internal pressure results, Shell Number

1, Desc.: Coil V1,2,3,4 - DN80

ASME Code, Section VIII, Division 1, 2013

Thickness Due to Internal Pressure (Tr):

= (P*(D/2-CAE)) / (S*E+0.4*P) per Appendix 1-1 (a)(1)

= (9.00*(82.9000/2-0.000)/(117.90*1.00+0.4*9.00)

= 0.3155 + 3.0000 = 3.3155 mm

= 1.5875 mm ( Per Ug 16b )

Max.

=

=

=

All. Working Pressure at Given Thickness (MAWP):

(S*E*(T-CA-CAE)) / ((D/2-CAE)-0.4*(T-CA-CAE)) per Appendix 1-1 (a)(1)

(117.90*1.00*(3.7388))/(82.9000/2-0.000-0.4*3.7388)

110.31 bar

Maximum Allowable Pressure, New and Cold (MAPNC):

= (SA*E*T) / (D/2-0.4*T) per Appendix 1-1 (a)(1)

= (117.90*1.00*6.7388)/(82.9000/2-0.4*6.7388)

= 204.99 bar

Actual stress at given pressure and thickness (Sact):

= (P*((D/2-CAE)-0.4*(T-CA-CAE))) / (E*(T-CA-CAE))

= (9.00*(((82.9000/2-0.000)-0.4*(3.7388)))/(1.00*(3.7388))

= 9.62 MPa

SUMMARY OF INTERNAL PRESSURE RESULTS:

Required Thickness plus Corrosion Allowance, Trca

Actual Thickness as Given in Input

Maximum Allowable Working Pressure

MAWP

Maximum Allowable Pressure, NC

MAPNC

Design Pressure as Given in Input

P

Hydrostatic Test Pressures ( Measured at High Point ):

Hydrotest per UG-99(b); 1.3 * P * SA / S

Hydrotest per UG-99(c); 1.3 * MAPNC

Pneumatic per UG-100 ; 1.1 * MAWP * Sa/S

4.5875

6.7388

110.313

204.986

9.000

mm

mm

bar

bar

bar

11.70

266.48

121.34

Percent Elongation per UCS-79 ( 50 * tnom/Rf * (1-Rf/Ro) )

bar

bar

bar

15.508 %

Internal Coil: Calculation

Note: Please Check Requirements of UCS-79 as Elongation is > 5%.

Minimum Design Metal Temperature :

Impact Test Temperature provided per Specification

Min. Metal Temp. w/o impact per UG-20(f)

-46

-29

C

C

External Pressure Results, Shell Number 1, Desc.: Coil V1,2,3,4 - DN80

ASME Code, Section VIII, Division 1, 2013

External Pressure Chart

Elastic Modulus for Material

CS-2

at

260.00

186167.77

C

MPa

Results for Max. Allowable External Pressure (Emawp):

Corroded Thickness of Shell

TCA

3.7388 mm

Outside Diameter of Shell

ODCA

82.900 mm

Design Length of Cylinder or Cone

SLEN

45402.000 mm

Diameter / Thickness Ratio

(D/T)

22.1732

Length / Diameter Ratio

LD

50.0000

Geometry Factor, A f(DT,LD)

A

0.0022374

Materials Factor, B, f(A, Chart)

B

80.6944 MPa

Maximum Allowable Working Pressure

48.52 bar

EMAWP = (4*B)/(3*(D/T)) = ( 4 *80.6944 )/( 3 *22.1732 ) = 48.5167

Results for Reqd Thickness for Ext. Pressure (Tca):

Corroded Thickness of Shell

TCA

1.4296 mm

Outside Diameter of Shell

ODCA

82.900 mm

Design Length of Cylinder or Cone

SLEN

45402.000 mm

Diameter / Thickness Ratio

(D/T)

57.9889

Length / Diameter Ratio

LD

50.0000

Geometry Factor, A f(DT,LD)

A

0.0003271

Materials Factor, B, f(A, Chart)

B

30.4493 MPa

Maximum Allowable Working Pressure

7.00 bar

EMAWP = (4*B)/(3*(D/T)) = ( 4 *30.4493 )/( 3 *57.9889 ) = 7.0002

Results for Maximum Length Calculation: No Conversion

Corroded Thickness of Shell

TCA

3.7388 mm

Outside Diameter of Shell

ODCA

82.900 mm

Design Length of Cylinder or Cone

SLEN

0.141E+30 mm

Diameter / Thickness Ratio

(D/T)

22.1732

Length / Diameter Ratio

LD

50.0000

Geometry Factor, A f(DT,LD)

A

0.0022374

Materials Factor, B, f(A, Chart)

B

80.6944 MPa

Maximum Allowable Working Pressure

48.52 bar

EMAWP = (4*B)/(3*(D/T)) = ( 4 *80.6944 )/( 3 *22.1732 ) = 48.5167

Summary of External Pressure Results:

Allowable Pressure at Corroded thickness

Required Pressure as entered by User

Required Thickness including Corrosion all.

Actual Thickness as entered by User

Maximum Length for Thickness and Pressure

Actual Length as entered by User

Weight and Volume Results, Original Thickness:

Volume of Shell Component

Weight of Shell Component

Inside Volume of Component

Weight of Water in Component

48.52

7.00

4.4296

6.7388

0.1410E+30

45402.00

bar

bar

mm

mm

mm

mm

VOLMET 0.7320E+08

WMET

5563.7

VOLID 0.1719E+09

WWAT

1684.5

mm ^3

N

mm ^3

N

Weight and Volume Results, Corroded Thickness:

Volume of Shell Component,

Corroded

VOLMETCA 0.4221E+08

Weight of Shell Component,

Corroded

WMETCA

3208.4

Inside Volume of Component,

Corroded

VOLIDCA 0.2028E+09

Weight of Water in Component, Corroded

WWATCA

1988.3

mm ^3

N

mm ^3

N

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2014

You might also like

- Asme Tubesheet (Heater 10m2)Document23 pagesAsme Tubesheet (Heater 10m2)Omil Rastogi100% (1)

- Design Calculations For Pressure ShellDocument33 pagesDesign Calculations For Pressure ShellGeorge GeorgianNo ratings yet

- PV Elite 2020 Licensee: Tubesheet Check CalculationDocument8 pagesPV Elite 2020 Licensee: Tubesheet Check CalculationAbhishek LadNo ratings yet

- Ejemplo Tubesheet Asme UHXDocument14 pagesEjemplo Tubesheet Asme UHXPedro Montes MarinNo ratings yet

- Heat Exchanger Specification SheetDocument1 pageHeat Exchanger Specification SheetGreisly MarrugoNo ratings yet

- Master CalculationsDocument37 pagesMaster Calculationsb89502164No ratings yet

- Studding Flange Calculations Gasket SelectionDocument6 pagesStudding Flange Calculations Gasket SelectionDarshan PanchalNo ratings yet

- Design of paddle type agitator for effluent agitationDocument4 pagesDesign of paddle type agitator for effluent agitationuttam prabhuNo ratings yet

- Flat HeadsDocument11 pagesFlat HeadsToniNo ratings yet

- Nozzle FEA CalculationDocument64 pagesNozzle FEA CalculationberylqzNo ratings yet

- Deaera DesignDocument13 pagesDeaera DesignBhanu K PrakashNo ratings yet

- 8.0 Torispherical Head Design Calculation Asme Sec. Viii Div. 1Document42 pages8.0 Torispherical Head Design Calculation Asme Sec. Viii Div. 1Muhamad Amar Hakimmie Suhaimi100% (1)

- Finite Element Analysis and ASME Code Calculations for Pressure VesselsDocument2 pagesFinite Element Analysis and ASME Code Calculations for Pressure Vesselsnaveen_86No ratings yet

- TubesheetDocument14 pagesTubesheethassnain iqbalNo ratings yet

- Sample FLG CalcDocument6 pagesSample FLG CalcameyyammaiNo ratings yet

- Output Summary: SI UnitsDocument42 pagesOutput Summary: SI UnitsAkhil JoseNo ratings yet

- Optional Integral With Hub Type Body Flange CalculationDocument13 pagesOptional Integral With Hub Type Body Flange Calculation9913489806No ratings yet

- Openings Reinforced by Elliptical or Obround Nozzles Normal To The Shell Wall (For Cylindrical and Conical Shells) EN13445-3 - 9.4.4.2-1Document1 pageOpenings Reinforced by Elliptical or Obround Nozzles Normal To The Shell Wall (For Cylindrical and Conical Shells) EN13445-3 - 9.4.4.2-1met-calcNo ratings yet

- Cone Development CalculationsDocument5 pagesCone Development CalculationssaudimanNo ratings yet

- Ligament Efficiency and Thickness of The Support PlateDocument10 pagesLigament Efficiency and Thickness of The Support PlatePankajDhobleNo ratings yet

- Elliptical Head DesignDocument1 pageElliptical Head Designrodriguez.gaytanNo ratings yet

- Heat ExchangerDocument11 pagesHeat ExchangerMangesh MandgeNo ratings yet

- Elliptical Head Design ToolDocument1 pageElliptical Head Design ToolSudjono BroNo ratings yet

- Thk. S.F. K.R.: Dish - Dish 2100Document3 pagesThk. S.F. K.R.: Dish - Dish 2100jayvant jadhavarNo ratings yet

- Vessel Heat LossDocument2 pagesVessel Heat LossakisdassasNo ratings yet

- Volume Calculation For Pressure Vessel TankDocument2 pagesVolume Calculation For Pressure Vessel Tanksai srikarNo ratings yet

- WI06-0260 Calculations For Obround Nozzle ConnectionsDocument4 pagesWI06-0260 Calculations For Obround Nozzle ConnectionskumarNo ratings yet

- Double FdexchangerDocument8 pagesDouble FdexchangerBoško IvanovićNo ratings yet

- Calculator - U Tubes - HSA & QtyDocument4 pagesCalculator - U Tubes - HSA & QtyRey Fiedacan100% (1)

- Weld stress check for FAVID clips and demister clipsDocument3 pagesWeld stress check for FAVID clips and demister clipsrsubramaniNo ratings yet

- Nozzle and ReinforcementDocument23 pagesNozzle and ReinforcementAzharyanto Fadhli100% (1)

- Tailing LugDocument2 pagesTailing Lugjagannadha varmaNo ratings yet

- Plate RectangularDocument8 pagesPlate RectangularRUBEN BARTOLOME GARCIANo ratings yet

- Vdocuments - MX Rectangular Tank CalculationDocument34 pagesVdocuments - MX Rectangular Tank CalculationAtilla TekinNo ratings yet

- Ansi B16.9-16.28-MSS SP-43Document3 pagesAnsi B16.9-16.28-MSS SP-43vangie3339515No ratings yet

- Titanium Bellows Design CalculationsDocument8 pagesTitanium Bellows Design CalculationsNamıkNo ratings yet

- Calculation Sheet: Design CodeDocument1 pageCalculation Sheet: Design CodeCak AndiNo ratings yet

- Mechanical Design SpreadsheetDocument1 pageMechanical Design SpreadsheetHoney TiwariNo ratings yet

- Xcalcs: Circular Flat Flanges Without Hubs: 2.7:+looseDocument2 pagesXcalcs: Circular Flat Flanges Without Hubs: 2.7:+looseayushNo ratings yet

- CalBOM - Formed ConicalDocument5 pagesCalBOM - Formed ConicalRey FiedacanNo ratings yet

- UHX - Osweiller - WhitePaper PDFDocument20 pagesUHX - Osweiller - WhitePaper PDFMichael BasaNo ratings yet

- Asme Viii Uhx Tubesheet CalcsDocument3 pagesAsme Viii Uhx Tubesheet CalcsjdfdfererNo ratings yet

- L-CV-155-VA-24XX01 Nitrogen: ASME Sec VIII Div 1+ PED97/23/ECDocument1 pageL-CV-155-VA-24XX01 Nitrogen: ASME Sec VIII Div 1+ PED97/23/ECevrim77No ratings yet

- API 650 Baseplate DesignDocument3 pagesAPI 650 Baseplate DesignmjlazoNo ratings yet

- Davit With ElbowDocument2 pagesDavit With Elbownitin400No ratings yet

- Studding Outlet Calculation - PV Elite 2016Document8 pagesStudding Outlet Calculation - PV Elite 2016Liu YangtzeNo ratings yet

- 7 PDFDocument26 pages7 PDFargaNo ratings yet

- TubesheetDocument8 pagesTubesheetVaibhavNo ratings yet

- PV Elite 2013 SP3 Licensee: ISGEC TubeSheet CalcDocument8 pagesPV Elite 2013 SP3 Licensee: ISGEC TubeSheet CalcMayank MittalNo ratings yet

- Design Calculations For V2703 Rev 0Document9 pagesDesign Calculations For V2703 Rev 0Dilip KatekarNo ratings yet

- Torispherical HeadDocument5 pagesTorispherical HeadLiaquat AliNo ratings yet

- Design Calculations For Pressure VesselsDocument30 pagesDesign Calculations For Pressure VesselsVinoth Rajendra100% (3)

- Pressure vessel design element thickness calculatorDocument30 pagesPressure vessel design element thickness calculatorPeña Eepesa100% (2)

- 31barg CalculationDocument10 pages31barg Calculationshani5573No ratings yet

- Design Calculations For Pressure VesselsDocument24 pagesDesign Calculations For Pressure VesselsMichael Lageman93% (15)

- Design Calculations For Pressure VesselsDocument32 pagesDesign Calculations For Pressure VesselsGeorge Georgian100% (3)

- Design Calculations For Pressure VesselsDocument73 pagesDesign Calculations For Pressure Vesselsshani5573No ratings yet

- Asme Viii Shell & Se HeadDocument5 pagesAsme Viii Shell & Se HeadSnr George RaczNo ratings yet

- Pipeextp-Asme Ug 28Document1 pagePipeextp-Asme Ug 28alvinchuanNo ratings yet

- Heater 10m2 (ASME Tubesheet)Document17 pagesHeater 10m2 (ASME Tubesheet)Omil RastogiNo ratings yet

- 12337-14ed Part 1Document24 pages12337-14ed Part 1whngomjNo ratings yet

- Nozzle reinforcement area calculations and weld strength reduction factorsDocument1 pageNozzle reinforcement area calculations and weld strength reduction factorswhngomjNo ratings yet

- Shell Data:: Input Echo, Tubesheet Number 1, Description: ASMEDocument1 pageShell Data:: Input Echo, Tubesheet Number 1, Description: ASMEwhngomjNo ratings yet

- Nozzle Cal - 15Document1 pageNozzle Cal - 15whngomjNo ratings yet

- Type of Element Connected To The Shell: Nozzle: The Pressure Design Option Was Design Pressure + Static HeadDocument1 pageType of Element Connected To The Shell: Nozzle: The Pressure Design Option Was Design Pressure + Static HeadwhngomjNo ratings yet

- Nozzle Cal - 15Document1 pageNozzle Cal - 15whngomjNo ratings yet

- Additional Data For Gasketed TubesheetsDocument1 pageAdditional Data For Gasketed TubesheetswhngomjNo ratings yet

- Nozzle Cal - 02Document1 pageNozzle Cal - 02whngomjNo ratings yet

- Dimensional Tolerances for Plate Length, Width and ThicknessDocument1 pageDimensional Tolerances for Plate Length, Width and ThicknesswhngomjNo ratings yet

- Tube DataDocument1 pageTube DatawhngomjNo ratings yet

- Nozzle Cal - 08Document1 pageNozzle Cal - 08whngomjNo ratings yet

- Threaded Half CouplingDocument1 pageThreaded Half CouplingwhngomjNo ratings yet

- Nozzle Cal - 13Document1 pageNozzle Cal - 13whngomjNo ratings yet

- Nozzle Cal - 06Document1 pageNozzle Cal - 06whngomjNo ratings yet

- Nozzle reinforcement area calculations and weld strength reduction factorsDocument1 pageNozzle reinforcement area calculations and weld strength reduction factorswhngomjNo ratings yet

- Nozzle Cal - 12Document1 pageNozzle Cal - 12whngomjNo ratings yet

- Nozzle Cal - 10Document1 pageNozzle Cal - 10whngomjNo ratings yet

- Nozzle Cal - 13Document1 pageNozzle Cal - 13whngomjNo ratings yet

- K1A&B, K2 3, K8: Type of Element Connected To The Shell: NozzleDocument1 pageK1A&B, K2 3, K8: Type of Element Connected To The Shell: NozzlewhngomjNo ratings yet

- Nozzle Cal - 08Document1 pageNozzle Cal - 08whngomjNo ratings yet

- Nozzle Cal - 04Document1 pageNozzle Cal - 04whngomjNo ratings yet

- UG-45 Minimum Nozzle Neck Thickness Requirement: (Int. Press.)Document1 pageUG-45 Minimum Nozzle Neck Thickness Requirement: (Int. Press.)whngomjNo ratings yet

- Nozzle Cal - 02Document1 pageNozzle Cal - 02whngomjNo ratings yet

- Nozzle Cal - 06Document1 pageNozzle Cal - 06whngomjNo ratings yet

- Nozzle reinforcement area calculations and weld strength reduction factorsDocument1 pageNozzle reinforcement area calculations and weld strength reduction factorswhngomjNo ratings yet

- Weld Strength 1Document1 pageWeld Strength 1whngomjNo ratings yet

- Nozzle Cal - 05Document1 pageNozzle Cal - 05whngomjNo ratings yet

- Type of Element Connected To The Shell: Nozzle: The Pressure Design Option Was Design Pressure + Static HeadDocument1 pageType of Element Connected To The Shell: Nozzle: The Pressure Design Option Was Design Pressure + Static HeadwhngomjNo ratings yet

- Weld Load (W) :: Weld Strength and Weld Loads Per UG-41.1, Sketch (A) or (B)Document1 pageWeld Load (W) :: Weld Strength and Weld Loads Per UG-41.1, Sketch (A) or (B)whngomjNo ratings yet

- ItilDocument11 pagesItilNarendar P100% (2)

- RHS NCRPO COVID FormDocument1 pageRHS NCRPO COVID Formspd pgsNo ratings yet

- Haematology Notes - 3rd EdDocument100 pagesHaematology Notes - 3rd EdSally Brit100% (1)

- InjectorDocument23 pagesInjectorBac Nguyen100% (1)

- Grade 3 science syllabus 1st and 2nd semesterDocument2 pagesGrade 3 science syllabus 1st and 2nd semesterelyzabeth SibaraniNo ratings yet

- Válvulas Flomatic USADocument40 pagesVálvulas Flomatic USAEfrain DuarteNo ratings yet

- Puskesmas Dua Puluh Tiga Ilir Publishes Vaccination Ticket ListDocument98 pagesPuskesmas Dua Puluh Tiga Ilir Publishes Vaccination Ticket ListLaboratorium PKM 23 IlirNo ratings yet

- Kertas Trial English Smka & Sabk K1 Set 2 2021Document17 pagesKertas Trial English Smka & Sabk K1 Set 2 2021Genius UnikNo ratings yet

- Chemical and Physical Properties of Refined Petroleum ProductsDocument36 pagesChemical and Physical Properties of Refined Petroleum Productskanakarao1No ratings yet

- Chapter 3 - CT&VT - Part 1Document63 pagesChapter 3 - CT&VT - Part 1zhafran100% (1)

- Case Report on Right Knee FuruncleDocument47 pagesCase Report on Right Knee Furuncle馮宥忻No ratings yet

- TA-Ingles IX - UAPDocument10 pagesTA-Ingles IX - UAPmanuel brennerNo ratings yet

- LAST CARGOES AND CLEANINGDocument1 pageLAST CARGOES AND CLEANINGAung Htet KyawNo ratings yet

- Manual de Referencia PlanmecaDocument288 pagesManual de Referencia PlanmecaJorge Escalona Hernandez100% (2)

- Esaote MyLabX7Document12 pagesEsaote MyLabX7Neo BiosNo ratings yet

- PERSONS Finals Reviewer Chi 0809Document153 pagesPERSONS Finals Reviewer Chi 0809Erika Angela GalceranNo ratings yet

- DVAIO R3 PRO HD Sound Quality In-Ear Wired Earphone Amazon - in ElectronicsDocument1 pageDVAIO R3 PRO HD Sound Quality In-Ear Wired Earphone Amazon - in Electronicsdinple sharmaNo ratings yet

- Hinduism Today April May June 2015Document43 pagesHinduism Today April May June 2015jpmahadevNo ratings yet

- Cap 716 PDFDocument150 pagesCap 716 PDFjanhaviNo ratings yet

- The Danger of Microwave TechnologyDocument16 pagesThe Danger of Microwave Technologyrey_hadesNo ratings yet

- Introduction To Animal Science For Plant ScienceDocument63 pagesIntroduction To Animal Science For Plant ScienceJack OlanoNo ratings yet

- Activity No 1 - Hydrocyanic AcidDocument4 pagesActivity No 1 - Hydrocyanic Acidpharmaebooks100% (2)

- Past The Shallows EssayDocument2 pagesPast The Shallows EssaycaitlinNo ratings yet

- Construction and Operation 1. Air Conditioning Control PanelDocument18 pagesConstruction and Operation 1. Air Conditioning Control PanelRoma KuzmychNo ratings yet

- Zygomatic Complex FracturesDocument128 pagesZygomatic Complex FracturesTarun KashyapNo ratings yet

- SCE Research Paper PDFDocument12 pagesSCE Research Paper PDFmuoi2002No ratings yet

- Week 6 Blood and Tissue FlagellatesDocument7 pagesWeek 6 Blood and Tissue FlagellatesaemancarpioNo ratings yet

- Classification of Nanomaterials, The Four Main Types of Intentionally Produced NanomaterialsDocument5 pagesClassification of Nanomaterials, The Four Main Types of Intentionally Produced NanomaterialssivaenotesNo ratings yet

- Lesson 1 CA 3Document13 pagesLesson 1 CA 3myndleNo ratings yet

- Montgomery County Ten Year Comprehensive Water Supply and Sewerage Systems Plan (2003)Document228 pagesMontgomery County Ten Year Comprehensive Water Supply and Sewerage Systems Plan (2003)rebolavNo ratings yet