Professional Documents

Culture Documents

9 - Comparative Test - Part II - Covermeters PDF

Uploaded by

askarahOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

9 - Comparative Test - Part II - Covermeters PDF

Uploaded by

askarahCopyright:

Available Formats

Non-Destructive Evaluation of the Penetrability and Thickness of the Concrete Cover

RILEM TC 189-NEC: State-of-the-Art Report May 2007

9.

COMPARATIVE TEST - PART II: "COVERMETERS"

C. Andrade (1), M. Alexander (2), M. Basheer (3), H. Beushausen(2), L. Fernndez Luco (1),

M. Fischli (4), A. F. Gonalves (5), F. Jacobs (6), R. Neves (7), J. Podvoiskis (8), R. Polder(9),

M. Romer (10) and R. Torrent (11)

(1) Instituto Eduardo Torroja de Ciencias de la Construccin, Serrano Galvache 4, 28033

Madrid, Spain

(2) Department of Civil Engineering, University of Cape Town, Private Bag Rondebosch,

7701 Cape Town, South Africa

(3) School of Civil Engineering, Queens University Belfast, BT7 1NN, Belfast, Northern

Ireland, United Kingdom

(4) Proceq S.A., Ringstrasse 2, Postfach 336, CH-8603 Schwerzenbach, Switzerland

(5) LNEC (National Laboratory of Civil Engineering), Avenida do Brasil 101, P-1799-066

Lisboa, Portugal

(6) TFB (Technical Research and Consulting for Cement and Concrete), CH-5103 Wildegg,

Switzerland

(7) Escola Superior de Tecnologia do Barreiro, Instituto Politcnico de Setbal, Rua Stinville,

n.14, Parque Empresarial do Barreiro - Quimiparque 2830 - 144 Barreiro, Portugal

(8) Elcometer Instruments Ltd, Edge Lane, Manchester M43 6BU, United Kingdom

(9) TNO Building and Construction Research, P.O.Box 49, NL-2600 AA Delft, The

Netherlands

(10) EMPA (Swiss Federal Laboratories for Materials Testing and Research),

Ueberlandstrasse 129, CH-8600 Duebendorf, Switzerland

(11) Holcim Group Support Ltd., Im Schachen, CH-5113 Holderbank, Switzerland

9.1

Objective of the Comparative Test, Part II

Cover depth has an important effect on the processes that lead to the corrosion of the steel

in concrete. The object of Part II of the Comparative Test was to determine the suitability of

some commercial covermeters to assess the cover depth to reinforcement, in a completely

non-destructive manner, applying them under different environmental conditions

187

Non-Destructive Evaluation of the Penetrability and Thickness of the Concrete Cover

RILEM TC 189-NEC: State-of-the-Art Report May 2007

(Temperature and Relative Humidity) and for different steel bar arrangements, embedded in

concretes of two different w/c ratios.

A condensed version of this report has already been published [9.1].

9.2 Experiment Design

Two groups of cover depths were included: normal cover, in the range 25-35 mm and deep

cover, in the range 70-80 mm. The latter, less common, represents situations where long

service lives are required in very aggressive environments.

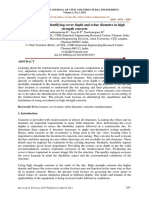

Four slabs (0,3 x 0,9 x 0,12 m) with conventional reinforcement bars were cast, according

to the detailing shown in Fig. 9.1. Nominal covers (in mm) of each bar are shown in brackets

and the distances from the left edge of the slab to the centre of the bar (in mm) are indicated

below each nominal cover.

1

2

3

4

5

6

7

8

9

16

12

(30)

60

(35)

140

(25)

205

(70)

(80)

(70)

(80)

(30)

305

405

505

640

780

Fig. 9.1 - Layout of slabs M, R, S and T

(25)

855

Table 9.1 shows the actual covers and distances from the left edge for slabs M, R, S and T,

as provided by EMPA by direct measuring on the saw-cut slabs.

As can be seen from the arrangement shown in Fig. 9.1, some of the situations might be

very demanding for the instruments, in particular, 12 mm-diameter bars and deep cover (70

and 80 mm). Moreover, for some instruments, the length of the bars (proximity of the

measurement to the bar endings) might cause some additional problems.

188

Non-Destructive Evaluation of the Penetrability and Thickness of the Concrete Cover

RILEM TC 189-NEC: State-of-the-Art Report May 2007

Table 9.1: Actual cover and position of the bars, in mm

Position

slab M

cover thickness

distance from edge

free spacing

30

58

34

138

68

25

205

55

70

306

89

81

404

86

71

506

88

81

638

116

32

778

124

26

856

62

slab R

cover thickness

distance from edge

free spacing

29

61

35

140

67

24

208

56

69

307

87

80

405

86

72

510

91

80

640

114

34

784

128

28

855

55

slab S

cover thickness

distance from edge

free spacing

31

59

36

140

69

26

208

56

68

304

84

80

406

90

72

510

90

80

638

112

32

782

128

27

858

60

slab T

cover thickness

distance from edge

free spacing

30

57

34

136

67

24

205

57

69

302

85

81

407

93

73

498

77

83

630

116

29

777

131

24

855

62

Table 9.2 gives the w/c ratios used for the different slabs, as well as the test conditions

(Temperature and Moisture). Further details about the curing and storage of the slabs can be

found in Annex A.

Table 9.2: Test conditions for Slabs M, R, S and T

w/c

Temperature

(C)

Moisture

condition

Slab M

0.55

20

Normal

Slab R

0.55

10

Normal

Slab S

0.40

20

Normal

Slab T

0.55

20

Moist

A further slab P, with similar testing conditions as for slab M, had special reinforcement

detailing to test the capability of the instruments to assess the cover depth under more

complex conditions.

These conditions were included to simulate different situations: bars too close (heavy

reinforcement), coupling of bars in different situations (horizontal, vertical), and the effect of

a mesh pattern. They all represent special situations and therefore are more challenging to the

instruments.

The distribution of the reinforcement for slab P was as sketched in Fig. 9.2. The nominal

cover (in mm) is indicated in brackets, while the distances from the left edge to the centre of

the bar (in mm) are indicated below each nominal cover

189

Non-Destructive Evaluation of the Penetrability and Thickness of the Concrete Cover

RILEM TC 189-NEC: State-of-the-Art Report May 2007

Suggested symbols

(30) (30)

107 157

(53)

258

00

(60)

84 / 404

00

(30)

507

(30)

550

(35)

564

(35)

662

(35)

755

Fig. 9.2 - Layout of Slab P

In the first round of measurements (Case A), no information was given to the participants

regarding position or cover depth of the bars.

In the second round (Case B) the participants were told that the bars had 12 mm or 16 mm

diameter, but not where they were nor their cover depths.

In the third round (Case C) the participants were told the approximate location of the bars

and their respective diameters but not their cover depths.

For the scope of this TC, the interest focuses on verifying the compliance of new

construction with performance-based specifications. Normally, the steel bar diameter and

approximate position will be known, and so case C is the most representative of the real

situation. Therefore, this report is concerned essentially with the analysis of the results for

case C.

After the results obtained by all participants were distributed for corrections, EMPA

personnel saw-cut the slabs and measured directly the actual cover of the bars.

190

Non-Destructive Evaluation of the Penetrability and Thickness of the Concrete Cover

RILEM TC 189-NEC: State-of-the-Art Report May 2007

9.3

Testing Instruments Applied

Only commercial covermeters were evaluated, using standard heads, suitable for common

(shallow) covers.

Table 9.3 shows the covermeters used and the Institute or company that performed the

tests. It must be mentioned that covermeter Hilti FS10 was used by two different participants;

only the results from TNO are considered because the Hilti representative could not perform

all the tests.

Table 9.3: List of equipment used

Institute or Company

Instruments used

TNO

HILTI FS10

HILTI

HILTI FS10

ELCOMETER

INSTRUMENTS Ltd.

PROTOVALE CM 52

PROTOVALE CM9

PROCEQ

PROFO 5

LNEC

PROFO 4

The assessments with Protovale instruments were made jointly by two persons, while in

the other cases, only one user operated the instruments.

9.4

Results Obtained

Large sheets of white paper, covering the entire surface of the slab, were provided for the

participants to record the results: position, diameter and cover of the bars; they remain at

EMPA, as back-up documents. From these sheets, the information was transcribed into tables,

which were sent to the participants for confirmation / correction.

After receiving a few corrections, the data were grouped by testing condition (M, R, S and

T) and testing equipment. These data, presented in Tables C.1 to C.5 of Annex C, are the

basis for the analysis of the results.

As mentioned before, three levels of previous knowledge were considered for each set of

data, ranging from A (location, diameter and cover were unknown for cover determination) to

C (only the cover was unknown).

Tables C.1 to C.5 show the recorded data as summarized from paper sheets. These values

include the corrections suggested by the participants, before the actual cover was disclosed to

them.

The results for cover assessment are expressed in mm. Measurement not performed are

reported as N.m. (not measured) and were excluded from the analysis.

Cases of uncertain measurements, where the cover depth was not reported, are identified as

U.r. (uncertain reading). These cases are included in the qualitative evaluation as non

191

Non-Destructive Evaluation of the Penetrability and Thickness of the Concrete Cover

RILEM TC 189-NEC: State-of-the-Art Report May 2007

success (see Section 9.5.1), but they were not included in the estimation of accuracy and

precision (see Section 9.5.2.).

LNEC (PROFO 4) used a small head (spot reading) and a big head (depth reading); and

they are informed as S/D in Tables 4. When both values were reported, they correspond to

spot/depth readings. In such cases, the value considered for the analysis is the spot reading

(the first one).

9.5

Analysis of the Results

The analysis of the results is restricted to Case C, i.e. the assessment of the cover depth

when there is knowledge of the diameter and of the approximate location of the bars.

Nevertheless, to consider the effect of lack of knowledge on the location and diameter of

the bars (Cases B and A), a separate analysis is presented at the end of this chapter.

Three levels of analysis are performed: shallow, deep (cover depth > 40 mm) and global

(i.e. all measurements).

te

te

te

te

Two sets of values resulted from the tests:

tr= real cover depth (mm), measured directly on the saw-cut slabs by EMPA

te= estimated cover depth (mm), reported by the different participants

The error d = te - tr is calculated for each bar at the centre of the slab.

9.5.1 Successful assessments

An assessment was considered successful when:

a) a value was reported and

b) the d value did not exceed 10 % of the actual cover, rounded to the next integer

value, which is more demanding than the tolerances stipulated by the fib Model Code

1990 and the ACI 318-02 ( 10 mm). In addition, the same relative error means the

same relative change in the duration of the incubation/initiation period (assuming it

progresses proportional to the square root of time).

192

Non-Destructive Evaluation of the Penetrability and Thickness of the Concrete Cover

RILEM TC 189-NEC: State-of-the-Art Report May 2007

Fig. 9.3 shows the percentage of successful assessments for slabs M, R, S and T for

Shallow and Global covers.

Case C - Shallow cover

Case C - All covers

Case C - Deep covers

100

90

% of success

80

70

60

50

40

30

20

10

0

HILTI PS10

(TN0)

PROTOVALE PROTOVALE

CM52

CM9

PROFO 5

(Proceq)

PROFO 4

(LNEC)

Fig. 9.3: Percent of success in the assessment of cover to reinforcement

9.5.2

Assessment of Accuracy and Precision

A measure of the bias of the NDT estimates is given by the mean value of d: the closer to

zero the mean value of d, the higher the accuracy of the measurements.

A measure of the variability of the NDT estimates is given by the mean quadratic error E,

calculated as:

E = ((d)2 /n)1/2 where n is the number of measurements considered

The closer E is to zero, the higher the Precision of the measurements.

Bias and variability of all slabs are indicated in Figs. 9.4 to 9.8.

In the calculation of bias and variability, all the reported values were considered. Some

users might have taken a very conservative approach, thus discarding unstable readings, while

others, with a more risky approach, have reported some approximate value, thus increasing

their bias and variability. For this reason, the proportion of reported values is included for

each case (e.g. 8/9 means eight values reported out of a possible nine).

193

Non-Destructive Evaluation of the Penetrability and Thickness of the Concrete Cover

RILEM TC 189-NEC: State-of-the-Art Report May 2007

BIAS

SLAB M, CASE C

10

9

8

7

6

5

4

3

2

1

0

-1

-2

-3

-4

-5

-6

8/9

HILTI FS10

(TN0)

9/9

PROTOVALE

CM52

9/9

PROTOVALE

CM9

VARIABILITY

8/9

PROFO 5

(Proceq)

9/9

PROFO 4

(LNEC)

Fig. 9.4 Bias and variability for Slab M

BIAS

SLAB R, CASE C

10

9

8

7

6

5

4

3

2

1

0

-1

-2

-3

-4

-5

-6

8/9

HILTI FS10

(TN0)

9/9

9/9

PROTOVALE PROTOVALE

CM52

CM9

VARIABILITY

8/9

PROFO 5

(Proceq)

Fig. 9.5 Bias and variability for Slab R

194

9/9

PROFO 4

(LNEC)

Non-Destructive Evaluation of the Penetrability and Thickness of the Concrete Cover

RILEM TC 189-NEC: State-of-the-Art Report May 2007

SLAB S, CASE C

10

9

8

7

6

5

4

3

2

1

0

-1

-2

-3

-4

-5

-6

BIAS

VARIABILITY

8/9

HILTI FS10

(TN0)

9/9

8/9

9/9

PROTOVALE PROTOVALE

CM52

CM9

9/9

PROFO 5

(Proceq)

PROFO 4

(LNEC)

Fig. 9.6 Bias and variability for Slab S

BIAS

SLAB T, CASE C

10

9

8

7

6

5

4

3

2

1

0

-1

-2

-3

-4

-5

-6

VARIABILITY

8/9

HILTI FS10

(TN0)

9/9

9/9

PROTOVALE PROTOVALE

CM52

CM9

8/9

PROFO 5

(Proceq)

Fig. 9.7 Bias and variability for Slab T

195

9/9

PROFO 4

(LNEC)

Non-Destructive Evaluation of the Penetrability and Thickness of the Concrete Cover

RILEM TC 189-NEC: State-of-the-Art Report May 2007

SLAB P, CASE C

10

9

8

7

6

5

4

3

2

1

0

-1

-2

-3

-4

-5

-6

BIAS

VARIABILITY

9/9

HILTI FS10

(TN0)

9/9

9/9

PROTOVALE PROTOVALE

CM52

CM9

9/9

9/9

PROFO 5

(Proceq)

PROFO 4

(LNEC)

Fig. 9.8 Bias and variability for Slab P

Fig. 9.9 shows the consolidated values of bias and variability for slabs M, R, S and T. The

consolidated bias is the average of the bias for the four slabs. The consolidated variability is

the square root of the average of the E2 of the four slabs.

ALL SLABS, CASE C

8

Bias (Average)

Variability (Average)

[mm]

4

2

0

-2

-4

HILTI FS10

(TN0)

PROTOVALE PROTOVALE

CM52

CM9

PROFO 5

(Proceq)

PROFO 4

(LNEC)

Fig. 9.9 Consolidated Bias and variability for Slabs M, R, S and T

196

Non-Destructive Evaluation of the Penetrability and Thickness of the Concrete Cover

RILEM TC 189-NEC: State-of-the-Art Report May 2007

9.5.3 Influence of test condition (slabs M, R, S and T)

The influence of test condition (M, R, S and T) on the variability of the NDT assessment of

the cover depth for each instrument is shown in Fig. 9.10. In most cases, the influence of

temperature, moisture and w/c ratio on the assessment of the cover depth was negligible,

except in one case, for which no explanation could be found (HILTI FS-10).

10

Slab M

Slab R

Slab S

Slab T

Variability (mm)

8

7

6

5

4

3

2

1

0

HILTI FS10

(TN0)

PROTOVALE

CM52

PROTOVALE

CM9

PROFO 5

(Proceq)

PROFO 4

(LNEC)

Fig. 9.10 Variability for all slabs, Case C

9.5.4 Comments on the results for Case C

Three aspects of the measurements are commented on: success rate, bias and variability.

Fig 9.3 shows that for covers below 40 mm, all the testing equipment had 100 % success in

assessing the cover depth within the adopted tolerances. When all covers are considered, the

degree of success varied with the instruments, with some of them achieving over 94 %

success rates.

Regarding Bias, as shown in Fig. 9.9, the average bias of all measurements is between 1

and 4 mm. These biases might eventually be corrected by an internal adjustment of the

instrument or by proper calibration procedures.

Regarding Variability, Fig. 9.9, it ranges from about 2 mm to 7 mm.

Taking into account the three aspects considered, the results obtained with the instruments

Protovale CM 52, Protovale CM 9 and Profometer 5 are superior to the other two.

9.5.5 Comparison between Cases A, B and C (effect of previous knowledge)

Fig. 9.11 shows the effect of previous knowledge on the percentage of successful

assessments of the cover depth for shallow covers, while Fig. 9.12 illustrates the same effect

for deep cover depths.

197

Non-Destructive Evaluation of the Penetrability and Thickness of the Concrete Cover

RILEM TC 189-NEC: State-of-the-Art Report May 2007

Case C

Case B

Case A

100

90

70

60

50

40

30

20

10

0

HILTI PS10

(TN0)

PROTOVALE PROTOVALE

CM52

CM9

PROFO 5

(Proceq)

PROFO 4

(LNEC)

Fig. 9.11 Effect of previous knowledge on % success for shallow covers

Case C

Case B

Case A

100

90

80

% of success

% of success

80

70

60

50

40

30

20

10

0

HILTI FS10 PROTOVALE PROTOVALE

(TN0)

CM52

CM9

PROFO 5

(Proceq)

PROFO 4

(LNEC)

Fig. 9.12 Effect of previous knowledge on % success for deep covers

198

Non-Destructive Evaluation of the Penetrability and Thickness of the Concrete Cover

RILEM TC 189-NEC: State-of-the-Art Report May 2007

The effect of lack of information on the actual bar diameter is greater for thicker covers,

while it is not so important for shallow covers. When some difficulties arise, the skills of the

operator come into consideration.

9.6

Conclusions

The Comparative Test proved that all the instruments are capable to measure with 100 %

success the depth of the concrete cover within an accuracy of 10 %, under the following

conditions:

The nominal diameter of the bars are known

The cover depth is below 40 mm.

For deep covers (cover depth above 65 mm), three instruments are still capable of

measuring with more than 80 % success the depth of the concrete cover within an accuracy of

10 %.

The accuracy of the instruments to assess the cover depth decreases with increasing covers

and with lack of information about diameter of the bars.

Even in situations where the arrangement of the bars is more complex, four out of five

instruments showed 100 % success in assessing the concrete cover, once the nominal bar

diameter was known.

In general, the accuracy of the assessment was not strongly affected by the temperature and

moisture conditions under which the measurements were made, nor by the w/c ratio of the

concrete.

Three instruments presented very good accuracy (bias below 1 mm) and precision

(variability around 2 mm).

.

REFERENCES

[9.1] Fernndez Luco, L., RILEM TC 189-NEC "Non-destructive evaluation of the concrete cover":

Comparative test - Part II: Comparative test of Covermeters, Materials and Structures (38),

284, Dec. 2005, pp. 907 - 911.

199

You might also like

- 2011 Retaining Wall Design Guide USFS Mohney 5 LVR Slope StabilityDocument559 pages2011 Retaining Wall Design Guide USFS Mohney 5 LVR Slope StabilitySima ViorelNo ratings yet

- AISC 186 Code of Standard Practice For Steel Buildings and Bridges 2000 PDFDocument94 pagesAISC 186 Code of Standard Practice For Steel Buildings and Bridges 2000 PDFaskarah75% (4)

- W.H.Mosley, J.H.Bungey. Reinforced Concrete DesignDocument199 pagesW.H.Mosley, J.H.Bungey. Reinforced Concrete DesignMG Xie100% (7)

- Friction and Wear of Polymer CompositesFrom EverandFriction and Wear of Polymer CompositesRating: 5 out of 5 stars5/5 (2)

- Draft Code for Design of Reinforced Concrete ChimneysDocument54 pagesDraft Code for Design of Reinforced Concrete Chimneysakshay chauhan67% (3)

- Agilent Vacuum Training GuideDocument27 pagesAgilent Vacuum Training GuidesinytellsNo ratings yet

- GeoTechnical DB Report 2203216Document8 pagesGeoTechnical DB Report 2203216wafikmh4No ratings yet

- Cladding Annex 1Document7 pagesCladding Annex 1dawg1503No ratings yet

- Limit Load Analysis of Bolted Flange ConnectionsDocument11 pagesLimit Load Analysis of Bolted Flange ConnectionsMansonNo ratings yet

- Gamma Scanning TechniqueDocument26 pagesGamma Scanning TechniqueWillykateKairu75% (4)

- Reliability of Engineering MaterialsFrom EverandReliability of Engineering MaterialsAlrick L SmithNo ratings yet

- Hydrogen Permeability and Integrity of Hydrogen Transfer PipelinesDocument52 pagesHydrogen Permeability and Integrity of Hydrogen Transfer PipelineslaercioudescNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Paper TubesDocument5 pagesPaper TubesRoxana MireaNo ratings yet

- Applied Metrology for Manufacturing EngineeringFrom EverandApplied Metrology for Manufacturing EngineeringRating: 5 out of 5 stars5/5 (1)

- Hotel Design ConsiderationsDocument6 pagesHotel Design ConsiderationsAlther DabonNo ratings yet

- Plane-Strain Slip-Line Fields for Metal-Deformation Processes: A Source Book and BibliographyFrom EverandPlane-Strain Slip-Line Fields for Metal-Deformation Processes: A Source Book and BibliographyNo ratings yet

- Composite Columns IDocument15 pagesComposite Columns IHeng Kimseng100% (1)

- Evaluation and Optimization of Linear Shaped Charges: AbstractDocument10 pagesEvaluation and Optimization of Linear Shaped Charges: AbstractGkcDedeNo ratings yet

- Is 459Document10 pagesIs 459AmbrishNo ratings yet

- An experimental investigation on surface quality and dimensional accuracy of FDM componentsDocument7 pagesAn experimental investigation on surface quality and dimensional accuracy of FDM componentsnewkid2202No ratings yet

- Multiple Stiffened Cold-Formed Steel Profiles For Cylindrical Vault Roofing SystemsDocument24 pagesMultiple Stiffened Cold-Formed Steel Profiles For Cylindrical Vault Roofing SystemsTiago LopesNo ratings yet

- ITA-Working Group Research - Guidelines For Design of Shield Tunnel LiningDocument49 pagesITA-Working Group Research - Guidelines For Design of Shield Tunnel LiningrasanavaneethanNo ratings yet

- The Effect of The Thickness of The Adhesive Layer On The Ballistic Limit of Ceramic/metal Armours. An Experimental and Numerical StudyDocument16 pagesThe Effect of The Thickness of The Adhesive Layer On The Ballistic Limit of Ceramic/metal Armours. An Experimental and Numerical StudyGustavoYippeekayyayGusNo ratings yet

- Paper Number XXXX: Relation Between Deformation Behavior and Wall Thinning Evaluation of Asme Code Case N-597 For PipesDocument6 pagesPaper Number XXXX: Relation Between Deformation Behavior and Wall Thinning Evaluation of Asme Code Case N-597 For PipesAnonymous 1hOgJqwZuzNo ratings yet

- Tests on column bases validate Eurocode 3 compression modelDocument8 pagesTests on column bases validate Eurocode 3 compression modelJose SilvaNo ratings yet

- Engineering Failure Analysis: J.A. Martins, I. Kövesdy, I. FerreiraDocument7 pagesEngineering Failure Analysis: J.A. Martins, I. Kövesdy, I. FerreiraEsteban CorderoNo ratings yet

- Lampa Ijcim Dalsanto 2014Document11 pagesLampa Ijcim Dalsanto 2014Sk.Abdul NaveedNo ratings yet

- Engineering Failure Analysis: A. Cornec, W. Schönfeld, K.-H. Schwalbe, I. ScheiderDocument18 pagesEngineering Failure Analysis: A. Cornec, W. Schönfeld, K.-H. Schwalbe, I. ScheiderAndrea CalderaNo ratings yet

- Guide To ICBO Evaluation Reports For Monokote MK6Document8 pagesGuide To ICBO Evaluation Reports For Monokote MK6Eric SoNo ratings yet

- Simulation Modelling Practice and Theory: Ahmed Abbadi, Y. Koutsawa, A. Carmasol, S. Belouettar, Z. AzariDocument15 pagesSimulation Modelling Practice and Theory: Ahmed Abbadi, Y. Koutsawa, A. Carmasol, S. Belouettar, Z. AzariOmkarKocharekarNo ratings yet

- Is 14443 1997Document26 pagesIs 14443 1997JGD123No ratings yet

- 2012 - Formability Studies On AA6061 For Automotive Body Structures Using DEFORM-2DDocument7 pages2012 - Formability Studies On AA6061 For Automotive Body Structures Using DEFORM-2DSupriya SahuNo ratings yet

- Study On Behaviour of Cold Formed Builtup Isection With Trapezoidal Corrugation in Web by Varying The Aspect Ratio and ADocument12 pagesStudy On Behaviour of Cold Formed Builtup Isection With Trapezoidal Corrugation in Web by Varying The Aspect Ratio and AAsr FlowerNo ratings yet

- Unipile Demo 223 PDFDocument10 pagesUnipile Demo 223 PDFNeil WilsnachNo ratings yet

- Numisheet 08 - Tailor Welded BlankDocument4 pagesNumisheet 08 - Tailor Welded BlankNgoc-Trung NguyenNo ratings yet

- Experiments of Bolted Cover Plate Connections With Slotted HolesDocument18 pagesExperiments of Bolted Cover Plate Connections With Slotted Holesapsapsaps1988No ratings yet

- 9 Shrinkage: Figure 9.1 Dimensional Changes As ADocument16 pages9 Shrinkage: Figure 9.1 Dimensional Changes As Avgascrib100% (1)

- Publication III: Manuscript Reprinted From Progress in Photovoltaics 14 (2006), P. 213-224Document16 pagesPublication III: Manuscript Reprinted From Progress in Photovoltaics 14 (2006), P. 213-224Emiliano BiosNo ratings yet

- Evaluation of PETG Mechanical Behavior For Application in Vehicle ProtectionDocument6 pagesEvaluation of PETG Mechanical Behavior For Application in Vehicle ProtectionGabrielMartinsNo ratings yet

- Design of liquid-storage tank: software vs Eurocode calculationsDocument13 pagesDesign of liquid-storage tank: software vs Eurocode calculationsSandeep BhatiaNo ratings yet

- Deterministic and Reliability-Based Optimization of A Belt-Conveyor BridgeDocument13 pagesDeterministic and Reliability-Based Optimization of A Belt-Conveyor BridgeKatherine JohnsonNo ratings yet

- Pile Cap Design Using Strut-and-Tie ModelingDocument8 pagesPile Cap Design Using Strut-and-Tie ModelingselvarajselvaaNo ratings yet

- Ikpjt (V: Tl-Fati-Ra-FDocument23 pagesIkpjt (V: Tl-Fati-Ra-FswabrightNo ratings yet

- Determination of Shrinkage Stresses in CDocument5 pagesDetermination of Shrinkage Stresses in CHaytham ElsayedNo ratings yet

- Ijert: Modeling and Stress Analysis of Aerospace Bracket Using ANSYS and Franc3DDocument11 pagesIjert: Modeling and Stress Analysis of Aerospace Bracket Using ANSYS and Franc3Dxaaabbb_550464353No ratings yet

- Comparison of A Steel Column Design Buckling ResistanceDocument10 pagesComparison of A Steel Column Design Buckling ResistanceGogyNo ratings yet

- Cover Meter Research PaperDocument7 pagesCover Meter Research PaperMrinal AgarwalNo ratings yet

- Determination of The Maximum Forming Angle of Some Carbon Steel Metal SheetsDocument4 pagesDetermination of The Maximum Forming Angle of Some Carbon Steel Metal Sheetsዘረአዳም ዘመንቆረርNo ratings yet

- ICC-ES Evaluation Report ESR-2218Document12 pagesICC-ES Evaluation Report ESR-2218Mark J LeingangNo ratings yet

- Shear Behavior of Self Compacting R.C. I-BeamsDocument16 pagesShear Behavior of Self Compacting R.C. I-BeamsThomás LimaNo ratings yet

- Rectangular Hollow Sections Bending Tests Examine Web Slenderness Effect on Rotation CapacityDocument8 pagesRectangular Hollow Sections Bending Tests Examine Web Slenderness Effect on Rotation CapacityKolumbán ZoltánNo ratings yet

- GeosyntheticsDocument15 pagesGeosyntheticsbloomdidoNo ratings yet

- I.Horsfall, E.Petrou and S.M.Champion - Shaped Charge Attack of Spaced and Composite ArmourDocument8 pagesI.Horsfall, E.Petrou and S.M.Champion - Shaped Charge Attack of Spaced and Composite ArmourGhoree23456No ratings yet

- ULTRASONIC INSPECTION OF CONCRETEDocument10 pagesULTRASONIC INSPECTION OF CONCRETEGeorgiana MatacheNo ratings yet

- Pullout Resistance of Roofing Fasteners Using Different MethodDocument19 pagesPullout Resistance of Roofing Fasteners Using Different MethodRocky XINNo ratings yet

- Shallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceFrom EverandShallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceNo ratings yet

- Civil Engineering Structures According to the Eurocodes: Inspection and MaintenanceFrom EverandCivil Engineering Structures According to the Eurocodes: Inspection and MaintenanceNo ratings yet

- Final Report Vol2Document242 pagesFinal Report Vol2askarahNo ratings yet

- R Islab OrderDocument1 pageR Islab OrderaskarahNo ratings yet

- Repair of Joint SealsDocument129 pagesRepair of Joint SealsAnonymous xC6bM4x6U6No ratings yet

- Backcalculation of Layer Parameters For LTPP Test Sections, Volume I: Slab On Elastic Solid and Slab On Dense-Liquid Foundation Analysis of Rigid PavementsDocument128 pagesBackcalculation of Layer Parameters For LTPP Test Sections, Volume I: Slab On Elastic Solid and Slab On Dense-Liquid Foundation Analysis of Rigid PavementsaskarahNo ratings yet

- Little BookDocument102 pagesLittle BooklauraNo ratings yet

- R Islab EvalDocument1 pageR Islab EvalaskarahNo ratings yet

- NCHRP 1-32Document202 pagesNCHRP 1-32askarahNo ratings yet

- FaultingDocument27 pagesFaultingaskarahNo ratings yet

- Guidelines and Decision Tables For Selecting The Appropriate Statistical ProcedureDocument5 pagesGuidelines and Decision Tables For Selecting The Appropriate Statistical ProcedureaskarahNo ratings yet

- S03 P1 DarterDocument19 pagesS03 P1 DarteraskarahNo ratings yet

- LTPP Data Analysis: Frequently Asked Questions About Joint Faulting AnswersDocument4 pagesLTPP Data Analysis: Frequently Asked Questions About Joint Faulting AnswersaskarahNo ratings yet

- C440 Test13Document11 pagesC440 Test13askarahNo ratings yet

- CRCPDocument15 pagesCRCPaskarahNo ratings yet

- CRCP Design2Document25 pagesCRCP Design2askarahNo ratings yet

- LTPP data analysis validates guidelines for k-value selection and concrete pavement performance predictionDocument4 pagesLTPP data analysis validates guidelines for k-value selection and concrete pavement performance predictionaskarahNo ratings yet

- Dependent Samples Statistical Tests: t, Wilcoxon, Binomial, McNemarDocument1 pageDependent Samples Statistical Tests: t, Wilcoxon, Binomial, McNemaraskarahNo ratings yet

- Test 18: The Wilcoxon Matched-Pairs Signed-Ranks TestDocument12 pagesTest 18: The Wilcoxon Matched-Pairs Signed-Ranks TestaskarahNo ratings yet

- C440 Inferen2Document1 pageC440 Inferen2askarahNo ratings yet

- 10Document3 pages10engrfarhanAAANo ratings yet

- Inferential Statistical Tests Employed With A SinglesampleDocument1 pageInferential Statistical Tests Employed With A SinglesampleaskarahNo ratings yet

- C440 Test4Document8 pagesC440 Test4askarahNo ratings yet

- Yarn definitions and propertiesDocument2 pagesYarn definitions and propertiesaskarahNo ratings yet

- Inferential Statistical Tests Employed With Two or More Independent Samples (And Related Measures ofDocument1 pageInferential Statistical Tests Employed With Two or More Independent Samples (And Related Measures ofaskarahNo ratings yet

- Inferential Statistical Test Employed With Factorial Design (And Related Measures ofDocument1 pageInferential Statistical Test Employed With Factorial Design (And Related Measures ofaskarahNo ratings yet

- Inferential Statistical Tests Employed With Two or More Dependent Samples (And Related Measures of Association/Correlation)Document1 pageInferential Statistical Tests Employed With Two or More Dependent Samples (And Related Measures of Association/Correlation)askarahNo ratings yet

- c440 MeasuresDocument1 pagec440 MeasuresaskarahNo ratings yet

- 17Document3 pages17askarahNo ratings yet

- Upholstery Cleaning: Xbi-DxbmDocument1 pageUpholstery Cleaning: Xbi-DxbmaskarahNo ratings yet

- 26Document2 pages26askarahNo ratings yet

- Cosmology, Physics and Philosophy: Benjamin Gal-OrDocument74 pagesCosmology, Physics and Philosophy: Benjamin Gal-Orapi-3835692No ratings yet

- CapsuleDocument7 pagesCapsuleNouman Khan KhanNo ratings yet

- ConsolidationDocument17 pagesConsolidationthak49100% (1)

- Buat Camera Thermal DGN ArduinoDocument4 pagesBuat Camera Thermal DGN ArduinoelkaNo ratings yet

- D Flip FlopDocument5 pagesD Flip FlopNaveen Kumar RavillaNo ratings yet

- Module 0 Resource Guide2014 Editionv5Document30 pagesModule 0 Resource Guide2014 Editionv5vamshids67% (3)

- Lab Report 5Document9 pagesLab Report 5Leo Marcelo Villalba100% (1)

- 9702 w22 Ms 23 PDFDocument14 pages9702 w22 Ms 23 PDFsangdeepNo ratings yet

- With Aerzen Turbos, Blowers and Compressors: Heat RecoveryDocument8 pagesWith Aerzen Turbos, Blowers and Compressors: Heat RecoveryBülent BulutNo ratings yet

- A - 1 - Product Overview - EN - 20190725 - W Botones AutonicsDocument10 pagesA - 1 - Product Overview - EN - 20190725 - W Botones Autonicsjcflores.mayaNo ratings yet

- StarFemto Data SheetDocument2 pagesStarFemto Data SheetstonezhouNo ratings yet

- Electric Theory of MatterDocument9 pagesElectric Theory of Matteralefs42296No ratings yet

- LM 78 L 05Document30 pagesLM 78 L 05Shakthi PriyaNo ratings yet

- Activated Carbon ASTM Test PackageDocument3 pagesActivated Carbon ASTM Test PackageHarizal HamidNo ratings yet

- Chapter 04Document3 pagesChapter 04gebreNo ratings yet

- Mechanical Engineering Third Semester Exam SolutionsDocument4 pagesMechanical Engineering Third Semester Exam SolutionsJASON CHERIAN MENo ratings yet

- Solid Solution HardeningDocument5 pagesSolid Solution HardeningVasantha SudasinghaNo ratings yet

- Heat Transfer Homework Solutions and CalculationsDocument4 pagesHeat Transfer Homework Solutions and CalculationsYELSI YAJAIRA QUICENO VILLANUEVANo ratings yet

- Simulate Power Plant Superheater in SimulinkDocument4 pagesSimulate Power Plant Superheater in SimulinkHendra Sutan Intan MarajoNo ratings yet

- Optical CommunicationDocument5 pagesOptical CommunicationSaiviswanth BoggarapuNo ratings yet

- Earth Air Heat Exchanger PerformanceDocument4 pagesEarth Air Heat Exchanger Performanceviraj shettyNo ratings yet

- Exercise 2-1-Calculate Time To Reach Radius of InvestigationDocument12 pagesExercise 2-1-Calculate Time To Reach Radius of InvestigationSohaibSeidNo ratings yet

- Drawdown Testing and Semilog AnalysisDocument35 pagesDrawdown Testing and Semilog AnalysisAssholeNo ratings yet

- Solved - Electrostatic Precipitator (ESP) Electrostatic Precipit... PDFDocument3 pagesSolved - Electrostatic Precipitator (ESP) Electrostatic Precipit... PDFAdeel ur RehmanNo ratings yet

- Radiation Heat Transfer: Chapter SevenDocument13 pagesRadiation Heat Transfer: Chapter SevenprasanthiNo ratings yet