Professional Documents

Culture Documents

Flexural Strength Properties of Recycled Aggregate Concrete

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flexural Strength Properties of Recycled Aggregate Concrete

Copyright:

Available Formats

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 5, Issue 5, May 2016

ISSN 2319 - 4847

Flexural Strength Properties of Recycled

Aggregate Concrete

K. Usha Nandhini1, S. Jayakumar2, S.Kothandaraman3

1

Research Scholar of Civil Engineering Department, Pondicherry Engineering College, Pondicherry,

2

Professor of Civil Engineering Department, SMV College of Engineering, Pondicherry, India

Professor of Civil Engineering Department, Pondicherry Engineering College, Pondicherry, India

ABSRACT

Today construction industry faces shortage of aggregate. Construction industry produces 40% of total waste each year. This

causes the severe environmental hazards and causes land fill issue. The possible solution is to reuse recycled concrete

aggregate in place of natural aggregate, which reduces landfill disposal, conserving the primary resources and reducing the

transportation cost and promote the sustainable development. Hence its need to study the structural properties of recycled

aggregate concrete. Recycled aggregate are easily available and economical compared to other natural resources. Demolished

structures, site tested concrete, pile cap demolished concrete are the good sources of recycled aggregate. This paper presents the

findings of site tested RC Beam used as recycled aggregate with 100% replacement of natural aggregate. The flexural strength

of RCA beam states higher deflection and higher strain than natural aggregate.

Keywords: Recycled aggregate concrete (RAC), Natural aggregate concrete (NAC), Recycled Concrete (RC),

Conventional concrete (CC), Construction & waste(CW), Coarse Aggregate(CA), Fine Aggregate(FA), Recycle

Aggregate(RA), Construction and demolition waste(C&D), Interficial transition zone (ITZ), Technology, Information,

Forecasting and Assessment Council (TIFAC)

1 Introduction

Increase in industrial development causes serious problems all over the world such as deletion of natural resources,

increase in landfills with enormous construction and demolition activities. Scientific researchers studied recycled

aggregate and proved that recycled aggregate is reliable alternate aggregate in production of concrete. Today

construction faces the shortage of aggregate, as per (CPHEEO) central public health & environment engineering, the

construction industry facing shortage of 55000million cubic meter aggregate. In addition, 750million cubic meter of

aggregate would be required to achieve the target of road construction sector, which will lead to pressure to natural

resource. Construction industry consumed high volume of raw materials and its impact caused to the Environment in

very large. (CPHEEO Solid Waste Technical advisory, 2015).

In construction industry the material cost is nearly 40-60% of project cost. This cost saving potential for India is

expected by adopting measure for C&D waste. The total quantity of C&D waste generated in India is estimated to 11.4

to 14.69 million tons per annum, out of which 7 8 million are construction and brick waste. [Job Thomas ,Wilson

P.M (2013)].

Technology information forecast assessment council (TIFAC, 2000) the total construction work in the country 5 year

plan during 2006-2011 has estimated $847 billion. One of the way to arrest the natural aggregate shortage for the

construction industry and reduce the C&D waste inland fill is to utilize the recycled aggregate in production of

concrete. Concrete strength is affected by the coarse aggregate, hence it is necessary to study the mechanical properties

of recycled aggregate concrete.

2 ROLE OF RECYCLED AGGREGATE IN THE WORLD

Globally, cities generate about 1.3 billion tones of solid waste per year and this is expected to be 2.2 billion tons by

2025, says a 2012 report by worldbank. As per ministry of environmental and forest (MOEF) 2008 estimate 0.53

million tons per day of waste generated in country. Central pollution control board has estimated current quantum of

social waste generation in India to tune of 48million per annum and out of which construction industry only accounts

for more than 25%. Hong Kong has serious land constraints and reduced needing disposal at landfills by 60%.

Singapore has recycling rate of 98% of its C&D waste. South Korea, has effective recycling rate of 36% with target of

increase 45% by 2016. European Union has rules EU2004 regulation for aggregate from natural, recycled and

Volume 5, Issue 5, May 2016

Page 6

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 5, Issue 5, May 2016

ISSN 2319 - 4847

manufactured material and reported that 20% of national consumption is from recycle material. In United Kingdom,

Northern Ireland has set agency for production of aggregate from waste and achieved 28% of C&D waste reused every

year. US, New York has stringent measure like forces developers to segregate waste at site, dismantle and not demolish.

In 2010 ministry of environmental and forest (MOEF) shows Scotland have recycled about 63% in 2000. Denmark and

Nether land has 80% of C&D waste. In Japan 95% of waste concrete reused. [C&D waste India, 2014].

3 Properties of concrete with recycled concrete aggregates:

The research of structural members made of recycled aggregate concrete (RAC) was conducted from the 90s in many

countries. In 1994, in Osnabruck, Germany built the first apartment building constructed with recycled aggregate

concrete. At the turn of 1993/94, Switzerland was the first country with the normalized standards of the use of RCA.

Beams made of RAC cracked earlier and showed greater deflection as compared to natural aggregate. The concrete

strains in the most stressed compressive zone of such beams, were higher by about 45% of the strains in the reference

beams made of natural aggregate with lower flexural capacity of 5 to 7%. Based on this research studies, model RC

beams were prepared with High Strength-High Performance Concrete (HSC-HPC). Test result shows that decreasing

values of deflections in the range 12 to 22% compared natural aggregate. Inclusion of HSC-HPC in the compressive

zone of RC beams revealed that flexural capacity greater about 34% and significantly increase flexural stiffness

influencing strains and lesser deflections in the range of 20 - 40% deflections compared to natural aggregate. [Andrzej

Lapko, Robert Grygo, 2013]

European standard for aggregate in concrete EN 12620 states recycled aggregate defined as aggregates resulting from

processing of inorganic material previously used in construction. Standard method of mix design used for natural

aggregate can be used for design of RAC mixes. Due to high water absorption, it is recommended to saturate recycled

aggregate and used water reducing admixture to achieve desired workability. RA obtained from good quality recycled

concrete have water absorption up to 5 to 6%. [Marinkovic Ignjatovic, Radonjanin, 2013]

Recycled concrete aggregate beam with 0% NAC, 50 % RAC, and 100 % RAC with three different reinforcement

ratios (0.28, 1.46, and 2.54 %) were casted and tested. Modulus of elasticity of RAC test result shows slightly lower

value than corresponding NAC elastic modulus because of RAC lower density values. The ductility, defined as the ratio

of mid-span deflection at failure to the mid-span deflection at yield, decreased as reinforcement ratio increased. With

the increase in recycled aggregate content, the size of failure surface and the level of the concrete destruction increased

and this is due to the new ITZ between RCA and the new cement paste is usually porous and loose, and forms a weak

link in RAC. SEM image shows micro cracks probably cause the higher level of concrete destruction of RAC beams at

failure when compared to NAC beams. The measured beams deflections at service load are almost always larger for

RAC beams than for the control NAC beams. Cracking moment of RAC beams is lower than cracking moment of

corresponding NAC beams by 10 % lower cracking load and 13 % higher service deflection. The ultimate flexural

capacity of RAC beams is practically the same as the ultimate flexural capacity of NAC. RA obtained from good quality

concrete shows same compressive strength and workability for 50 % RAC. For 100% RAC with high cement content

(3%) and the compressive strength is same as NAC. The size of the failure surface and the level of concrete destruction

at beams flexural failure are highly affected by the quantity of coarse recycled aggregate in the concrete. With the

increase in recycled aggregate content, the size of failure surface and the level of the concrete destruction increases.

Flexural behaviour of RAC beams is satisfactory when compared to the behaviour of NAC beams, for both service and

ultimate load. The short-term service deflections of RAC beams can be larger than deflections of corresponding NAC

beams, but within reasonable limits. [Ivan S. Ignjatovic' Snezana B. Marinkovic,Zoran M. Miskovic Aleksandar

R. Savic].

Studies on mechanical properties particularly stress strain curve of RAC is similar to NAC. Experimental studies

show that with increase in amount of recycled aggregate, the values of compressive strength, peak strain, toughness,

plastic energy capacity and elastic energy and elastic modulus decreases, which becomes barrier for the application of

RAC structures. However, composite structure can reduce the demerits of RAC. Steel tubes filled with RAC have

favorable results and bright future in composite structures. Due to lower density of RAC, it is advantage to increase the

span of structure and improving the earth quake resistant with good heat preservation and insulation properties. The

stiffness of RAC beams are lower than the NAC beams with increase in RA content. RA content has no influence on

bending capacity while immediate deflection tend to increase. The 30% decrease in shear capacity of with increase in

RA content from 0 to 100%. Failure mode of RAC Column are similar to NAC column and no significant influence

with RA content. The RAC frame structures meet the requirement of NAC structures as per the present code. [Shi

Xiao-shuang, Wang Qing-yuan, Qiu Ci-chang, Zhao Xiao-ling, IEEE, 2010].

Volume 5, Issue 5, May 2016

Page 7

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 5, Issue 5, May 2016

ISSN 2319 - 4847

4 Experimental program

4.1 Materials

Ordinary Portland cement (OPC) 43 grade conforming to IS: 8112 (1989) was used for research work. Physical

properties of cement with specific gravity 3.14 and specific surface area 250 square meter per kg is used. The

compressive strength of cement motor at 3 days, 7 days and 28days are 28.0Mpa, 36.9Mpa and 46.0Mpa.

The natural coarse aggregate obtained locally were tested in accordance with IS: 2386(1963) for gradation and other

physical properties. The locally available natural sand conforming to grading Zone II (IS: 383) is used in both normal

and recycled aggregate concrete.

4.1.1Source of Recycled aggregates

The recycled coarse aggregate obtained from the demolished RC beam specimen in Department of Civil Engineering,

Pondicherry Engineering College. Using Jaw crusher the RC beam were broken into smaller pieces and sieved through

4.75mm and 20mm sieve sizes. The physical properties of Aggregates are shown in Table 3.1.

Table 3.1 Physical properties of Aggregates

Test Results

Property

Water absorption (%)

Specific gravity

NA

0.80

2.77

RCA

3.8

2.41

Fineness modulus

9.15

7.53

Impact value (%)

Crushing value (%)

23.83

20.30

30.88

33.72

FA

0.12

2.65

2.28

(Zone- II)

-----

4.1.2 Concrete Mixtures

Two concrete mixes are designed for different grades of concrete such as M20 and M40 with the replacement of RCA

in 0%, 100% with recycled aggregate. To reduce the water demand Super plasticizer super flow is added as

admixture in concrete mixture. The details of mixture proportions are tabulated in Table 3.2

Table 3.2 Details of Mixture proportions for M20&M40

4.1.3 Preparation of concrete mixes

In this research work, eight concrete mixture for M20 and M40 grade are prepared with RCA in 0% and 100% with

recycle aggregate. The specimens were cured under wet curing and tested for 28days.

5 STRUCTURAL PROPERTIES

5.1.1 Flexure behavior of RC beams

The flexure behavior of RC beams are studied on concrete using RCA is to evaluate the structural suitability of RCA

concrete. This study shows study on the usage of RCA concrete in determining structural behavior. The evaluation of

Flexure test on RC concrete beams is carried out using Linear Variable Displacement Transducers (LVDT) apparatus

which obtains computerized values. The Reinforced concrete beams of size 250mm 150mm 2250mm were casted

for required concrete mixes and cured for 28 days.

5.1.2 Test specimens

Four beams of size 150 mm 250 mm with an effective span of 2100 mm were cast, damp cured for four weeks and

tested to determine the flexural behavior of RC beams with Recycled Concrete Aggregate (RCA). Of these, two beams

were reference beams (B1 & B2) with natural aggregate. The other two beams were beams with RCA. The beams were

mm provided with two members of 16 as flexural reinforcement and 8 mm diameter stirrups at 100 mm spacing as

shear reinforcement. Details of test specimens are shown diameter in Table 5.1

Volume 5, Issue 5, May 2016

Page 8

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 5, Issue 5, May 2016

ISSN 2319 - 4847

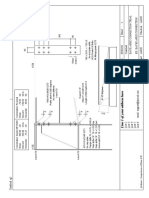

Fig. 5.1 Testing of RC beams under loading frame

5.1.3 Experimental set-up

The flexure test on the beams was carried on a loading frame of capacity 300kN, which was equipped with a hydraulic

jack of capacity 500kN as shown in Fig 5.1. The load readings were measured using load cell of capacity 680kN.

Beams were tested for two points loading at a distance of 700 mm from either support. During the process of loading,

the beams were monitored for deflection at mid-span. LVDTs were used for monitoring the deflection. Strains at the

mid-span were noted at four points using DEMEC (Demountable Mechanical Strain Gauge) of gauge length 200 mm

with a deformation least count of 0.002 mm. The load was applied in increments of 5kN until failure occurred and the

crack patterns were drawn on the beam.

Table 5.1 Physical properties of Aggregates

Where,

RC20 RC beam of M20 grade concrete

RC20-100% RC beam of M20 grade concrete with 100% RCA

RC40 RC beam of M40 grade concrete

RC40-100% RC beam of M40 grade concrete with 100% RCA

5.1.4 STRUCTURAL PROPERTY

5.1.5 Flexure behavior of RC beams

The flexure RC beams are tested and their results are tabulated in Table 5.2. The mode of failure occurred in the beams

was the flexural failure. Test resulted that the beams with 100% replacement of RCA obtained higher cracks and lower

in deflection.

Volume 5, Issue 5, May 2016

Page 9

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 5, Issue 5, May 2016

ISSN 2319 - 4847

Table 5.2 Test Results of RC Beam

Fig 5.1 Test Results of RC Beam

Fig 5.3 Load Deflection curve for M20 and M40 grade RC beams

5.1.6 Deflection and Strain

1. The deflection and strain in concrete were noted for every 5 kN load increment.

2. Deflections of RC beams with RCA were larger than those with NA under the condition of same load. RCA beams

indicated 3.57% higher deflection at the same load when compared to NA beams.

3. The load versus strain diagram was plotted from the DEMEC strain gauge measurements for all beams. The load

versus strain graph shows that at the compression faces the compressive strain for all the four beams at a particular

Volume 5, Issue 5, May 2016

Page 10

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 5, Issue 5, May 2016

ISSN 2319 - 4847

load was more or less equal, but at the tension face RCA beams indicated 13.7% higher strain when compared with

NA beams.

6 Conclusion

1. The RC beams using 100% of RCA obtains higher deflection than the control concrete. The deflection occurred is

3.57% higher because the strains occurred 13.7% higher in the tension zone of the beams which results in higher

deflection of the beams. There is also formation of more cracks found in the beams with higher deflection.

2. RA extracted from good quality concrete without impurities impart higher strength than normal aggregates.

6.1 SCOPE FOR FURTHER STUDY

1. The RAC Beam may be studied with the incorporation of high strength rebar to reduce deflection and improve the

flexural behavior of concrete.

2. The studies on strength of Concrete using RCA may also be extended by conducting durability studies. The

durability properties of concrete may provide the further knowledge on RCA concrete at various circumstances.

REFERENCES

[1]. Andrzej Lapko, Robert Grygo, Studies of RC Beams Made of Recycling Aggregate Concrete Strengthened with

the HSC-HPC Inclusions 11th International Conference on Modern Building Materials, Structures and

Techniques, MBMST 2013, Procedia Engineering 57 ( 2013 ) 678 686, Science Direct.

[2]. C & D waste, Construction and Demolition waste, Center for Science and Environment, New Delhi, Retrieved

from: www.cseindia.org.

[3]. CPHEEO Solid Waste Technical wing of Ministry of Urban Development, Govt of India, manual, 2015, retrieved

from: cpheeo.nic.in.

[4]. Ivan S. Ignjatovic' Snezana B. Marinkovic,Zoran M. Miskovic Aleksandar R. Savic, Flexural behavior of

reinforced recycled aggregate concrete beams under short-term loading , Materials and Structures (2013)

46:10451059, DOI 10.1617/s11527-012-9952-9, Published online: 9 October 2012_ RILEM 2012.

[5]. Job Thomas, Wilson P.M Construction waste management in India, American Journal of Engineering Research

(AJER), Volume -2 pp-06-09 (2013).

[6]. S.B Marinkovic and I.Ignjatovic, V. Radonjanin

Life cycle assessment (LCA) of concrete with Recycled

aggregate (RAs) Hand Book Of Recycled Concrete and Demolition Waste Wood head Publication, pp569-604.

[7]. Shi Xiao-shuang, Wang Qing-yuan, Qiu Ci-chang, Zhao Xiao-ling , Recycling Construction and Demolition waste

as sustainable Environment Management in post-earthquake Reconstruction, IEEE Standard Association, 2010.

[8]. TIFAC (2000), Utilization of waste from construction industry Department of Science & Technology New Delhi,

Retrieved from: http://www.tifac.org.in/index.php?option=com_content&view=article&id=710&Itemid=205 on

07.11.2013.

Volume 5, Issue 5, May 2016

Page 11

You might also like

- An Importance and Advancement of QSAR Parameters in Modern Drug Design: A ReviewDocument9 pagesAn Importance and Advancement of QSAR Parameters in Modern Drug Design: A ReviewInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- THE TOPOLOGICAL INDICES AND PHYSICAL PROPERTIES OF n-HEPTANE ISOMERSDocument7 pagesTHE TOPOLOGICAL INDICES AND PHYSICAL PROPERTIES OF n-HEPTANE ISOMERSInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Customer Satisfaction A Pillar of Total Quality ManagementDocument9 pagesCustomer Satisfaction A Pillar of Total Quality ManagementInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Experimental Investigations On K/s Values of Remazol Reactive Dyes Used For Dyeing of Cotton Fabric With Recycled WastewaterDocument7 pagesExperimental Investigations On K/s Values of Remazol Reactive Dyes Used For Dyeing of Cotton Fabric With Recycled WastewaterInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Study of Customer Experience and Uses of Uber Cab Services in MumbaiDocument12 pagesStudy of Customer Experience and Uses of Uber Cab Services in MumbaiInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Detection of Malicious Web Contents Using Machine and Deep Learning ApproachesDocument6 pagesDetection of Malicious Web Contents Using Machine and Deep Learning ApproachesInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Analysis of Product Reliability Using Failure Mode Effect Critical Analysis (FMECA) - Case StudyDocument6 pagesAnalysis of Product Reliability Using Failure Mode Effect Critical Analysis (FMECA) - Case StudyInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- THE TOPOLOGICAL INDICES AND PHYSICAL PROPERTIES OF n-HEPTANE ISOMERSDocument7 pagesTHE TOPOLOGICAL INDICES AND PHYSICAL PROPERTIES OF n-HEPTANE ISOMERSInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Analysis of Product Reliability Using Failure Mode Effect Critical Analysis (FMECA) - Case StudyDocument6 pagesAnalysis of Product Reliability Using Failure Mode Effect Critical Analysis (FMECA) - Case StudyInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Study of Customer Experience and Uses of Uber Cab Services in MumbaiDocument12 pagesStudy of Customer Experience and Uses of Uber Cab Services in MumbaiInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Customer Satisfaction A Pillar of Total Quality ManagementDocument9 pagesCustomer Satisfaction A Pillar of Total Quality ManagementInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Synthetic Datasets For Myocardial Infarction Based On Actual DatasetsDocument9 pagesSynthetic Datasets For Myocardial Infarction Based On Actual DatasetsInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Detection of Malicious Web Contents Using Machine and Deep Learning ApproachesDocument6 pagesDetection of Malicious Web Contents Using Machine and Deep Learning ApproachesInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Experimental Investigations On K/s Values of Remazol Reactive Dyes Used For Dyeing of Cotton Fabric With Recycled WastewaterDocument7 pagesExperimental Investigations On K/s Values of Remazol Reactive Dyes Used For Dyeing of Cotton Fabric With Recycled WastewaterInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Staycation As A Marketing Tool For Survival Post Covid-19 in Five Star Hotels in Pune CityDocument10 pagesStaycation As A Marketing Tool For Survival Post Covid-19 in Five Star Hotels in Pune CityInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- The Mexican Innovation System: A System's Dynamics PerspectiveDocument12 pagesThe Mexican Innovation System: A System's Dynamics PerspectiveInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Soil Stabilization of Road by Using Spent WashDocument7 pagesSoil Stabilization of Road by Using Spent WashInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- The Impact of Effective Communication To Enhance Management SkillsDocument6 pagesThe Impact of Effective Communication To Enhance Management SkillsInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- A Digital Record For Privacy and Security in Internet of ThingsDocument10 pagesA Digital Record For Privacy and Security in Internet of ThingsInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Design and Detection of Fruits and Vegetable Spoiled Detetction SystemDocument8 pagesDesign and Detection of Fruits and Vegetable Spoiled Detetction SystemInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Performance of Short Transmission Line Using Mathematical MethodDocument8 pagesPerformance of Short Transmission Line Using Mathematical MethodInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Challenges Faced by Speciality Restaurants in Pune City To Retain Employees During and Post COVID-19Document10 pagesChallenges Faced by Speciality Restaurants in Pune City To Retain Employees During and Post COVID-19International Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- A Deep Learning Based Assistant For The Visually ImpairedDocument11 pagesA Deep Learning Based Assistant For The Visually ImpairedInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- An Importance and Advancement of QSAR Parameters in Modern Drug Design: A ReviewDocument9 pagesAn Importance and Advancement of QSAR Parameters in Modern Drug Design: A ReviewInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- A Comparative Analysis of Two Biggest Upi Paymentapps: Bhim and Google Pay (Tez)Document10 pagesA Comparative Analysis of Two Biggest Upi Paymentapps: Bhim and Google Pay (Tez)International Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Secured Contactless Atm Transaction During Pandemics With Feasible Time Constraint and Pattern For OtpDocument12 pagesSecured Contactless Atm Transaction During Pandemics With Feasible Time Constraint and Pattern For OtpInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Advanced Load Flow Study and Stability Analysis of A Real Time SystemDocument8 pagesAdvanced Load Flow Study and Stability Analysis of A Real Time SystemInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Predicting The Effect of Fineparticulate Matter (PM2.5) On Anecosystemincludingclimate, Plants and Human Health Using MachinelearningmethodsDocument10 pagesPredicting The Effect of Fineparticulate Matter (PM2.5) On Anecosystemincludingclimate, Plants and Human Health Using MachinelearningmethodsInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Impact of Covid-19 On Employment Opportunities For Fresh Graduates in Hospitality &tourism IndustryDocument8 pagesImpact of Covid-19 On Employment Opportunities For Fresh Graduates in Hospitality &tourism IndustryInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Anchoring of Inflation Expectations and Monetary Policy Transparency in IndiaDocument9 pagesAnchoring of Inflation Expectations and Monetary Policy Transparency in IndiaInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Structures Subjected To Repeated Loading-Stability and Strength - R Narayanan, 1990 PDFDocument259 pagesStructures Subjected To Repeated Loading-Stability and Strength - R Narayanan, 1990 PDFtmaNo ratings yet

- Determination of Young's Modulus: ApparatusDocument3 pagesDetermination of Young's Modulus: ApparatusharshankNo ratings yet

- Boscardin 1990Document17 pagesBoscardin 1990mahdNo ratings yet

- Structural Steel Design According To LRFD: September 2012Document6 pagesStructural Steel Design According To LRFD: September 2012Pj B UriatNo ratings yet

- Shear Test Methods CompositeDocument3 pagesShear Test Methods CompositeBittuNo ratings yet

- Study and Observation of Process Parameters For Spheroidal Graphite (SG) Iron CastingDocument4 pagesStudy and Observation of Process Parameters For Spheroidal Graphite (SG) Iron CastingIJSTENo ratings yet

- E702 2Document15 pagesE702 2werdubob8944No ratings yet

- R C C Beam DesignDocument6 pagesR C C Beam DesignediezelNo ratings yet

- Blasius PDFDocument2 pagesBlasius PDFsanketdange2007No ratings yet

- Modern Aspects of Electrochemistry No. 31 - J. o M. BockrisDocument365 pagesModern Aspects of Electrochemistry No. 31 - J. o M. BockrisNemo Nero100% (1)

- Ignacio, Fernand Lui B. Generoso, John Michael IDocument18 pagesIgnacio, Fernand Lui B. Generoso, John Michael IAnonymous aWxiNE7w100% (1)

- AUTODYN - Chapter 9 - Material - Models PDFDocument47 pagesAUTODYN - Chapter 9 - Material - Models PDFFabiano OliveiraNo ratings yet

- MEC411 2012 - 03 Test 1 PDFDocument2 pagesMEC411 2012 - 03 Test 1 PDFAmirulHanif AlyahyaNo ratings yet

- LSM - Neutral Axis Depth CalculationDocument2 pagesLSM - Neutral Axis Depth CalculationHimal KafleNo ratings yet

- Spe 36761 MSDocument13 pagesSpe 36761 MSKarla CotesNo ratings yet

- Apex Connection - Ver W3.0.03 - 06 Apr 2016 Title: Code of Practice: Created: Notes and AssumptionsDocument6 pagesApex Connection - Ver W3.0.03 - 06 Apr 2016 Title: Code of Practice: Created: Notes and AssumptionsYam BalaoingNo ratings yet

- BucklingDocument11 pagesBucklingwsNo ratings yet

- Presentation On 2D-3D PSCsDocument21 pagesPresentation On 2D-3D PSCsmahfuz13bdNo ratings yet

- Aircraft Structures Notes 1Document200 pagesAircraft Structures Notes 1WizardWannabeNo ratings yet

- Lesson 3 SoADocument5 pagesLesson 3 SoAJaneccaNo ratings yet

- 1 s2.0 S0020740301000832 MainDocument20 pages1 s2.0 S0020740301000832 MainashrayvalsanNo ratings yet

- Materials I: Lecture Course 5 Phase Diagrams. Fe-C Diagram. Crystallisation of Alloys in Fe - Fe C SystemDocument24 pagesMaterials I: Lecture Course 5 Phase Diagrams. Fe-C Diagram. Crystallisation of Alloys in Fe - Fe C SystemTiger ClaudiuNo ratings yet

- Quikjoint - ResultsDocument15 pagesQuikjoint - ResultsvtalexNo ratings yet

- EC2 Bending With or Without Axial ForceDocument11 pagesEC2 Bending With or Without Axial ForceselinaNo ratings yet

- d4 Som Unit 1Document51 pagesd4 Som Unit 1Ritik shewaleNo ratings yet

- Fatigue of MaterialsDocument40 pagesFatigue of MaterialsnitinNo ratings yet

- TECHNICAL PAPER03 2015 Design of Fillet Welds To Rectangular HSS June2015Document5 pagesTECHNICAL PAPER03 2015 Design of Fillet Welds To Rectangular HSS June2015ZebNo ratings yet

- Enabling Assessment 2 - T-CEET325 - TO1 Abitona CEE31&ESE31 2S AY 20-21 - DLSU-D College - GSDocument3 pagesEnabling Assessment 2 - T-CEET325 - TO1 Abitona CEE31&ESE31 2S AY 20-21 - DLSU-D College - GSLotis KeeNo ratings yet

- Bar Pullout Tests and Seismic Tests of Small-Headed Barsin Beam-Column JointsDocument11 pagesBar Pullout Tests and Seismic Tests of Small-Headed Barsin Beam-Column JointsProfessor Dr. Nabeel Al-Bayati-Consultant EngineerNo ratings yet

- Fatigue Strength Prediction of Truck Cab by CaeDocument7 pagesFatigue Strength Prediction of Truck Cab by CaemeDC123No ratings yet