Professional Documents

Culture Documents

AN1269 Application Note MPC555

Uploaded by

Ricky CoxCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AN1269 Application Note MPC555

Uploaded by

Ricky CoxCopyright:

Available Formats

AN1269

APPLICATION NOTE

Connecting the MPC555 Microcontroller

to the M58BF008 Series Flash Memory

CONTENTS

INTRODUCTION

ADVANTAGES OF FLASH

M58BF008 BUS

ARCHITECTURE

MPC555 BUS

ARCHITECTURE

Booting the MPC555

from External Flash

INTRODUCTION

This application note describes a method of to connecting the

M58BF008 Flash memory to the MPC555 microcontroller. The

M58BF008 is an advanced 8 Mbit Flash memory from STMicroelectronics, which can be configured as 256 Kbit x32 bus

width. The memory includes a burst interface for high speed

access, allowing code to be executed directly from the memory

without the need to shadow the code in RAM.

MPC555 TO M58BF008

CONNECTION

The MPC555 is a member of Motorolas PowerPC family of integrated microprocessors. It is a general purpose 32-bit microcontroller with a wide variety of application areas but it

particularly targeted towards automotive applications.

MPC555 Bus Configuration Registers

ADVANTAGES OF FLASH

EXAMPLE BUS

OPERATIONS

Asynchronous Read Example

Synchronous Burst Read

Example

Asynchronous Write Example

Synchronous Write Example

STMICROELECTRONICS

SOFTWARE DRIVERS

CONCLUSION

Flash memories can be used to store both code and data for

the MPC555 microcontroller. Unlike EPROMs the data in Flash

memories can be changed by the microcontroller. This enables

non-volatile user data to be stored in the Flash. Field upgrades

of the application code can be performed without any disassembly, unlike EPROM solutions.

It is usual to write separate boot and application programs so

that the application program can be upgraded without changing

the boot program. If the upgrade fails then the processor will

still boot and it will be possible to reattempt to upgrade the application. The boot code can be programmed into the Flash before the Flash is fitted to the circuit board or Debug Port can be

used to boot the microcontroller and then program the Flash.

The M58BF008 Flash memory has a special block, called the

overlay block, that can be used to store the boot program. This

is an extra 32 Kbyte block that is mapped in place of block 0 on

reset. The MPC555 can boot from this block, then disable it,

giving access to block 0. The memory is 8 Mbit plus 256 Kbit in

size.

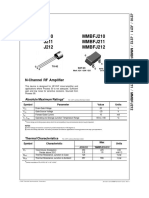

M58BF008 BUS ARCHITECTURE

Consider the bus on the M58BF008, Figure 1 shows the Logic

Diagram. The memory has separate Address and Data Buses

that can connect directly to the Address and Data Buses on the

MPC555. There are several control lines required for burst access, these are Chip Enable (E), Output Enable (G), Write Enable (W), System Clock (CLK), Load Burst Address (LBA),

Write/Read (WR) Burst Address Advance (BAA) and Output

Disable (GD). Also, Reset/Power-down (RP) is present.

February 2001

1/14

AN1269 - APPLICATION NOTE

Figure 1. M58BF008 Logic Diagram

VDD VDDQ VPP

18

32

A17-A0

DQ31-DQ0

CLK

RP

E

G

M58BF008

GD

W

LBA

WR

BAA

VSS

VSSQ

AI02656B

A burst read cycle is initiated on the rising edge of the System Clock when Chip Enable is Low to select

the memory, a valid address is on the Address Inputs, Latch Burst Address is Low to latch the address

and Write/Read is High to indicate a read. Chip Enable and Write/Read should remain constant throughout the read operation, whereas Load Burst Address should only be low during the cycle where the address is latched, after that the address can change. Output Enable must be Low to read the data when it

becomes valid (after the X-latency) and Burst Address Advance must be Low to increase the address and

output new data after the Y-latency expires. The Memory Controller in the MPC555 can be configured to

generate these signals without glue logic.

Unlike most RAM options, it is not possible to write a single byte or a single 16-bit word to the memory.

Only 32-bit writes are supported. (This applies equally to reads, but, for a read, the unwanted data can be

discarded). Commands are written on DQ0-DQ7 to the memory, with DQ8-DQ31 being ignored; the double-words are written to the memory array as part of the program operation.

The Reset/Power-down pin (RP) should be held High for normal operation of the memory, this is the memorys non-reset state. To ensure that the overlay block is always read during the boot process and the

memory is always in its read mode the Reset/Power-down should be Low when the MPC555 is reset. The

memory can be placed in a low-power mode by holding Reset/Power-down Low; after Reset/Power-down

is brought High again the memory returns to its reset state and may require configuration before being

accessed correctly.

In Asynchronous modes several pins are not used and their voltage is dont care. These are CLK, LBA,

WR and BAA. During asynchronous accesses the CPU does not need to control these pins, they can be

tied to VIL or VIH, or change through the access. This may be useful when trying to replace another memory with an M58BF008.

2/14

AN1269 - APPLICATION NOTE

MPC555 BUS ARCHITECTURE

The MPC555s bus architecture can be daunting on first appearance. There are many control lines to allow

for 8-bit accesses, 16-bit accesses, 32-bit accesses, bus arbitration, etc. Many applications do not need

to make use of these features. Only a simple connection is considered here.

The MPC555 can be configured as Big-Endian or Little-Endian, with the normal configuration being BigEndian. The M58BF008 part is Little-Endian insofar as the hexadecimal data used to control the command

interface uses D0 to equate to the LSB. To use the M58BF008 in the Big-Endian mode of the MPC555 the

Address bus and the Data bus should be reversed; A29 on the MPC555 should be connected to A0 of the

M58BF008, A28 to A1, A17 to A2, etc.; D31 on the MPC555 should be connected to D0 on the M58BF008,

D30 to D1, D29 to D2, etc. If this convention is followed then the standard C code drivers for the

M58BF008 will not have to be changed. If this convention is not followed then the data for the command

interface will need translating for the before the memorys Command Interface will respond correctly and

continuous data in the processors address space will cross through each block of the M58BF008 in turn.

The MPC555s memory controller includes control lines that are suitable for connecting to the M58BF008

in either synchronous or asynchronous mode, or both, without the need for glue logic. Each transfer is initiated with the address being placed on the address bus, Transfer Start (TS) Low and the Chip Select

(CSx) Low during the rising edge of the System Clock. Output Enable (OE) or Write Enable/Byte Enable

(WE/BE0) falls Low to indicate a read or a write. In burst read operations Burst Data In Progress (BDIP)

indicates that the memory should advance the address and Read/Write (RD/WR) gives advance notice

that the burst operation is a read or a write (the MPC555 never uses burst write operations, but other bus

masters are allowed to).

Burst operations on the MPC555 read from sequential (not interleaved) addresses. For example, if a 32bit wide burst operation starts from address 1234h, the next address read will be 1238h, followed by

123Ch. The MPC555 does not issue continuous or wrapped burst operations, so in the example the fourth

burst (to address 1240h) would only occur as part a separate operation. Up to four 32-bit reads are possible in one burst operation, but only when the four LSBs of the address start at 0000b (i.e. from address

1230h in the example).

Although the MPC555 is a 3.3V processor, its external bus is 5V tolerant. 5V parts can be connected to

the external bus without the need for transceivers. The short rise and fall times mean that the timings when

connecting to 5V parts are not significantly different, though some extra consideration may be required for

rising signals. Table 1 gives a summary of the Input/Output DC characteristics on the high and low voltage

levels and shows that they are compatible.

Table 1. Input/Output DC Characteristics Comparison

Comment

MPC555

M58BF008

MPC555 Low Input from M58BF008

VIL3M

0.8V max

VOL

0.2V max

MPC555 High Input from M58BF008

VIH3M

2V min

VOH

3.1V min

M58BF008 Low Input from MPC555

VOL3M

0.5V max

VIL

0.8V max

M58BF008 High Input from MPC555

VOH3M

2.4V min

VIH

2V min

Booting the MPC555 from External Flash

The boot mode of the MPC555 is selected by driving the data bus into a specific state during reset with

Reset Configuration (RSTCONF/TEXP) Low. To boot from an external memory (e.g. Flash) the internal

Flash should be disabled (D20 Low), the external boot should be enabled (D3 Low) and the Boot Port Size

should be set to the memory width (D4-5 both Low for 32-bit width).

3/14

AN1269 - APPLICATION NOTE

For an external boot the MPC555 uses Chip Select 0 (CS0) to select the boot memory; CS0 is active (Low)

for every memory address during the boot process until the registers that configure it are changed. 15 wait

states are selected and asynchronous read operations are used.

After a Hardware Reset (HRESET) the boot process executes the instruction at address 00000100h. Note

that this instruction is at memory location 00040h in the M58BF008s address space since it is a 32-bit

part. Generally the instruction at address 00000100h will be a jump to the location in the MPC555s memory space where the Flash will be mapped. From here the boot process can continue, the Base Registers

and Option Registers can be configured correctly so that other devices on the bus can be accessed.

MPC555 TO M58BF008 CONNECTION

Figure 2 shows a connection scheme for the MPC555 to M58BF008. In this configuration the M58BF008

can be the boot device. Note the reversal of the address bus and the data bus between the two devices

to account for the Big-Endian/Little-Endian change. Also note that A0 of the M58BF008 should be connected to A29 of the MPC555; A30 and A31 address words and bytes, they are not used for double-word

width devices. If the M58BF008 is not going to be the boot device then any of the other chip selects can

be used instead. Although GD is shown connected to VIH in this implementation, it can be left floating since

it has an internal pull-up resistor that will ensure correct operation.

To access the memory correctly the registers in the MPC555 should be set up according to Table 4. Note

that the Motorola definition for describing the X-latency and Y-latency is different to the STMicroelectronics

definition. Motorola count the number of clock cycles between two successive accesses, or wait-states,

whereas STMicroelectronics count the difference between the clock numbers. So, for example, a 2 waitstate access (SCY field of the Base Register set to 02h) with burst beats of 0 wait-states (BSCY field set

to 00h) is equivalent to a 3.1.1.1 burst access in STMicroelectronics terms. Care should be taken when

configuring the Memory Controller in the MPC555 to ensure that the correct and optimum values are used.

Figure 2. Connection between the MPC555 and the M58BF008

DATA31-DATA0

ADDR29-ADDR11

DQ0-DQ31

18

A0-A17

CS0

WE/BE0

OE

MPC555

M58BF008

VIH

GD

CLKOUT

CLK

TS

LBA

RD/WR

WR

BDIP

SRESET

BAA

RP

AI03458

4/14

AN1269 - APPLICATION NOTE

MPC555 Bus Configuration Registers

Three registers are used to configure the bus on the MPC555. For each chip select there are two registers,

a Base Register and an Option Register; additionally, to enable burst operations the BBC Module Configuration Register must be configured correctly. The bits in each of these registers is described in detail in

the MPC555 user manual; the description here is tailored specifically to using the MPC555 with an

M58BF008. Table 2 gives an description of the Base Register bits and Table 3 gives a description of the

Option Register bits.

5/14

AN1269 - APPLICATION NOTE

Table 2. Base Register Description

Bit(s)

Mnemonic

Name

Description

0-16

BA

Base Address

The upper bits of the address are compared to the bits in this register. Bits

that are masked in the Option Register do not affect the output of the

comparison. If all the unmasked bits match then the corresponding chip

MPC555 selected the device attached to it. Each chip select is active

throughout a 64 Kbyte or more section of the memory.

If the M58BF008 is using the chip select then these bits set the address

where the M58BF008 is mapped in the MPC555 memory space.

17-19

AT

Address Type

These bits select whether the device on the chip select should respond to all

types of access (Instruction/Data, User/Supervisor, etc.) or not. The mask in

the option register controls whether the address type is ignored or not.

20-21

PS

Port Size

The port size determines whether an 8-bit, 16-bit or 32-bit device is

connected to the data bus. The M58BF008 is a 32-bit memory and should

use the 32-bit port setting (00b).

22

Reserved

23

The device can be designated as read-only through this bit. The M58BF008

can be written to and, even if the user wanted to protect the memory, it is not

advisable to use this method to protect it as it would disable other features,

such as Read Electronic Signature. The M58BF008 should be configured as

a read/write part for usual operation.

WP

Write Protect

24-25

Reserved

Write-Enable/

Byte Select

The output pins WEn/BEn can either be used to select individual bytes in a

word or double-word or as a Write Enable line. In the M58BF008 it is not

possible to select individual bytes, therefore the pins should be configured

as Write Enable outputs.

26

WEBS

27

TBDIP

Toggle Burst

Determines how long the BDIP output will be Low during each data beat of a

Data in Progress burst cycle. The correct setting for the M58BF008 is 0.

LBDIP

Late Burst Data

in Progress

The BDIP output can be configured to go low at the start of the burst transfer

or after the X-Latency has expired. Some devices require BDIP late in order

to trigger the output of the data and update of their internal address register

at the correct time. The M58BF008 however will ignore the BAA input until

the preconfigured X-Latency has expired. The recommended setting is for

BDIP early, though both will work. (BDIP early alleviates the need to check

the timing!)

29

SETA

External Transfer

Acknowledge

Some devices can set the TA on the MPC555 pin to acknowledge the end of

a transfer. The M58BF008 does not generate this signal, the internally

generated signal from the MPC555 memory controller will terminate the

cycle at the correct time.

30

BI

Burst Inhibit

The memory controller in the MPC555 needs to be told whether the device

can support burst transfers or not. The MPC555 does support burst

transfers. When used in asynchronous mode this bit should be set to 1 to

inhibit the burst, in burst mode set this bit to 0 to enable the burst.

31

Valid Bit

The valid bit configures the memory controller to use this chip select. The bit

should be set to 1.

28

Note: The bits here are numbered according to the Motorola MPC555 definition; Bit 0 is the MSB and bit 31 is the LSB.

6/14

AN1269 - APPLICATION NOTE

Table 3. Option Register Description

Bit(s)

Mnemonic

Name

Description

0-16

AM

Address Mask

The Address Mask is used in conjunction with the Base Address in the Base

Register to select the address region where the chip select is active. A bit set

to 1 indicated that this address bit is used. Use these bits, in conjunction

with the Base Address to map the M58BF008 in the correct memory space.

The M58BF008 occupies an address space of 1 Mbyte in the memory space

of the MPC555, so typically the address mask would be set to FFF0h.

17-19

AMT

Address Type

Mask

The address mask allows more than one type of address space to be

assigned to a single chip select. If the M58BF008 is to be used for

Instructions and Data, in User and Supervisor modes and for Normal and

Special transfers then all bits should be masked (set to 0).

CSNT

Chip Select

Negation Time

The Chip Select Negation Time can be changed to ensure that the device

releases the bus in time for the next device to drive it and avoid bus

contention. The recommended setting for the M58BF008 is 0, normal

negation time.

ACS

Address to Chip

Select Setup

The chip select can be configured to be set up at the same time as the

address, or after the address has been set up. To meet the timings of the

M58BF008 it is essential to set the chip select up as early as possible,

therefore the 00 setting should be used.

23

EHTR

Extended Hold

Time on Read

It is possible to have an extra idle cycle inserted between reads and writes in

difference memory controller bank. This avoid bus contention for parts that

drive the bus sooner than others release it. The M58BF008 is fast enough so

that it does not require an additional cycle (though other devices may require

the extra cycle; their EHTR registers must be set correctly).

24-27

SCY

Cycle Length

The Cycle Length is the number of wait-states required to access the device.

In burst transfers this number is determined by the X-Latency.

See Table 4 for the recommended values.

28-30

BSCY

Burst Beats

Length

The Burst Beats Length is the number of wait-states required to access the

device between burst beats. It is determined by the Y-Latency.

See Table 4 for the recommended values.

31

TRLX

Timing Relaxed

Normal or Relaxed timings can be selected using this bit. The M58BF008

does not require relaxed timings (which are slower) so a value of 0 should

be used.

20

21-22

The recommended settings for the registers are summarized in Table 4.

Table 4. MPC555 Memory Controller Register Settings Summary

Asynchronous

Symbol

Register

Synchronous

Bits

2 wait-states 3 wait-states

3.1.1.1

4.1.1.1

BRx

Base Register

20-31

003h

003h

001h

001h

ORx

Option Register

20-31

020h

030h

020h

030h

18

BBCMCR

Burst Buffer Controller Module

Configuration Register

Note: The SCY field of the Option Register (bits 24-27) is set to 2 for 3-1-1-1 access and 3 for 4-1-1-1 access.

The M58BF008 can operate at 4-1-1-1 with a maximum clock frequency of 40MHz and at 3-1-1-1 with a

maximum clock frequency of 33MHz clock.

Other connection schemes can be used to control the M58BF008. This scheme is the recommended technique, but other connections are discussed in the examples that follow.

7/14

AN1269 - APPLICATION NOTE

EXAMPLE BUS OPERATIONS

The following sections go into detail regarding the bus operations and signal interactions between the

MPC555 and the M58BF008. Each section gives an example waveform and timing information. Some alternative connection details are shown for designers who are trying to use the M58BF008 as a replacement

part in an circuit containing an MPC555. For new designs the recommended connections should be used.

Asynchronous Burst Read Example

Figure 3 shows an asynchronous read access with three wait-states. The MPC555 sets up the address

and activates the chip select ready for cycle 1 of its synchronous clock. The M58BF008 does not wait for

the clock in asynchronous mode and starts fetching the data immediately. After tAVQV and tELQV (both

90ns) the data becomes valid; the MPC555 latches the data on the rising edge of clock cycle 5. Under

zero wait-state operation the data is latched on clock cycle 2.

The critical timing in this example is tELQV. For a 40MHz clock (and a 40MHz MPC555) the chip select

activates 14ns (timing 19) after clock cycle 0. The data must be setup 6ns (timing 17) before clock cycle

5. Using 3 wait-states clock cycle 5 is 125ns after clock cycle 0, with 14ns before the chip select and the

data needing to be ready 6ns before the clock rising tELQV needs to be 105ns or less. The M58BF008

guarantees tELQV less than 90ns. The tAVQV is not required for the analysis since the address is set up

13ns (timing 8) after clock cycle 0, 1ns before the chip select; tAVQV is also 90ns for the M58BF008. For

an MPC555 running at 33MHz only 2 wait-states are required.

At boot time the MPC555 uses 15 wait-states to read the boot memory. The M58BF008 boots in asynchronous

mode; the 15-wait state latency is more than sufficient to successfully boot the MPC555 using an M58BF008.

Figure 3. Example Asynchronous Read Access

M58BF008

Nomenclature

MPC555

Nomenclature

0

CLK

CLKOUT

A0-A17

ADDR29ADDR11

CS0

Q1

tAVQV, tELQV

G

OE

DQ0-DQ31

DATA31DATA0

Q1

AI03463

Synchronous Burst Read Example

The M58BF008 toggles between asynchronous and synchronous each time the 60h command is written

to the Command Interface; before the first synchronous access is performed the memory must be toggled

from asynchronous to synchronous mode. Figure 4 shows the waveforms for a synchronous burst read

access with four beats. The MPC555 starts by placing the address on the address bus, activating Transfer

Start (TS), Chip Select 0 (CS0), Output Enable (OE) and Burst Data In Progress (BDIP). The memory uses

TS to latch the address and latch the first address of the burst. After the X-latency Q1 is output on the data

bus; Q2, Q3 and Q4 follow on the subsequent clock cycles. Finally Chip Select 0 (CS0) rises to terminate

the burst.

8/14

AN1269 - APPLICATION NOTE

Figure 4. Example 3-1-1-1 Synchronous Burst Read Access with 4 Data Beats

M58BF008

Nomenclature

MPC555

Nomenclature

0

CLK

CLKOUT

A0-A17

ADDR29ADDR11

LBA

TS

CS0

OE

BAA

BDIP

DQ0-DQ31

DATA31DATA0

Q1

Q2

Q3

Q4

Q1

Late BDIP

AI03461

From Figure 4 it is clear that the signals generated by the MPC555 can be used to access the M58BF008.

By examining the timing requirements of the M58BF008 and comparing them to those of the MPC555 it

can be shown that both the 33MHz timings and the 40MHz timings match. Table 5 shows the timings of

the critical timing parameters.

Table 5. Synchronous Burst Timing Requirements

M58BF008

MPC555

Symbol

Timing

33MHz

40MHz

tAVCH

Min 8

15

12

tBLCH

Min 8

15

12

tCHBH

Min 3

tGLCH

Min 10

19

17

tELCH

Min 8

14

11

tWRHCH

Min 8

15

12

tCHQV

18

Max 24

Max 19

tCHQX2

Min 1

Min 1

9/14

AN1269 - APPLICATION NOTE

Asynchronous Write Example

All bus operations from the MPC555 are synchronous with its clock. However, M58BF008 parts that are

configured for asynchronous write operations ignore the CLK input and are accessed in an asynchronous

manner. Figure 5 shows the signal waveforms for the recommended connections; three wait-states are

shown. The MPC555 starts by placing the address on the address bus, activating Transfer Start (TS), Chip

Select 0 (CS0) and Read/Write (RD/WR). Write Enable (WE) is asserted (Low) after the address is latched

to indicate a write operation and the data to be written is placed on the data bus. After the wait-states have

expired the MPC555 drives WE0 and CS0 High to indicate the end of the cycle before changing the address and data on the bus.

From Figure 5 it is clear that the signals generated by the MPC555 can be used to access the M58BF008.

By examining the timing requirements of the M58BF008 and comparing them to those of the MPC555 the

number of wait-states required can be found; Table 2 shows the timings of the critical timing parameters.

Table 6. Asynchronous Write Timing Requirements

M58BF008

MPC555

Symbol

Timing

2-wait states, 33MHz

3-wait states, 40MHz

tAVAV

Min 70

112

113

tWLWH

Min 70

105

92

tDVWH

Min 70

75

87

tWHWL

Min 30

19

19

Note that the timings in Table 6 show that back-to-back write operations to the Flash are not possible, otherwise the tWHWL timing is violated. It will be necessary to ensure that software does not try to perform

back-to-back write operations, an extra delay (such as a non-cached NOP) may be required between

writes to ensure correct operation.

Also note that 3 wait-states are required to meet the asynchronous timing requirements at 40MHz and 2

wait-states at 33MHz.

If the M58BF008 used has been factory configured for asynchronous write operations then WR, BAA and

LBA are ignored during write operations. This allows various changes to the recommended connection

technique to be made without loss of performance. For example:

1. The WR pin on the M58BF008 can be left disconnected. A weak pull-up inside the M58BF008 will ensure that the internal level is VIH, enabling the read operations to be performed correctly.

2. The WR pin on the M58BF008 can be connected to WE0 pin on the MPC555. Since the WR input is

ignored in asynchronous operations it will not affect the write operation.

3. The W pin on the M58BF008 can be connected to the RD/WR pin of the MPC555, though in this case

back-to-back writes are still not possible. Care should be taken because there are situations where CS0

is only high for the briefest instant of time and this can be missed by the M58BF008. So long as other

accesses are performed in the meantime this solution will work correctly.

Note that tying the W pin on the M58BF008 to ground will not allow the part to work correctly since a write

operation will be selected whenever the part is accessed, including when read operations are intended.

10/14

AN1269 - APPLICATION NOTE

Figure 5. Example Asynchronous Write Access

M58BF008

Nomenclature

MPC555

Nomenclature

0

CLK

CLKOUT

A0-A17

ADDR29ADDR11

LBA

TS

CS0

WE0

OE

WR

RD/WR

BAA

BDIP

DQ0-DQ31

DATA31DATA0

Q1

Q1

AI03462

Synchronous Write Example

From the perspective of the MPC555 all writes are synchronous. The waveforms for synchronous write

are the same as those for asynchronous writes. Therefore, the waveforms in Figure 5, Asynchronous

Write Access, are equally valid for synchronous write operations.

The timing of the M58BF008 parts that have been factory configured for synchronous write operations

have different timing requirements. Table 7 shows the timings of the critical parameters for synchronous

write operations.

11/14

AN1269 - APPLICATION NOTE

Table 7. Synchronous Write Timing Requirements

M58BF008

MPC555

Symbol

Timing

33MHz

40MHz

tAVCH

Min 8

15

12

tBLCH

Min 8

15

12

tCHBH

Min 3

tWRLCH

Min 8

15

12

tWLCH

Min 8

19

17

tCHWH

Min 3

11

tQVCH

Min 8

15

12

tCHQX

Min 5

tELCH

Min 8

16

14

If the M58BF008 used has been factory configured for synchronous write operations then all the connections are required for correct operation. However, there are still times when some of the pins are ignored.

This allows various changes to the recommended connection technique to be made without loss of performance. For example:

1. The W pin of the M58BF008 can be connected to the RDWR pin of the MPC555. This solution will correctly control the Write Enable signal of the M58BF008, so long as back-to-back writes are not performed to the M58BF008 by the MPC555.

2. The W pin may be tied to ground. The M58BF008 will work correctly because the RDWR pin will initiate

the correct read or write cycle, W will be ignored. The MPC555 can still boot from the M58BF008 since

RDWR is high during reset and remains high while the boot code is executed.

It is essential to have WR connected, otherwise the addresses cannot be latched correctly during a write

cycle (the internal pull-up would always select a read operation). WR cannot be connected to WE0 because WE0 is too late for the addresses to be latched correctly during a write cycle.

12/14

AN1269 - APPLICATION NOTE

STMICROELECTRONICS SOFTWARE DRIVERS

STMicroelectronics provide a set of drivers, written in C, manipulating all of the functions of the

M58BF008. These are contained in a separate application note. In order to use the C code drivers two

additional C functions have to be written by the developer, FlashRead() is used to tell the software drivers how to read from the memory and FlashWrite() is used to tell the software drivers how to write to

the memory.

The drivers include example FlashRead() and FlashWrite() functions and these, combined with setting the correct BASE_ADDR macro are suitable for use with the MPC555. The example functions are:

#define BASE_ADDR ((volatile unsigned long*)0x00000000L)

.

unsigned long FlashRead( unsigned long ulOff )

{

return BASE_ADDR[ulOff];

}

static unsigned long FlashWrite( unsigned long ulOff, unsigned long uVal )

{

return BASE_ADDR[ulOff] = uVal;

}

.

The drivers also provide an example of these functions as macros to speed up the code execution (since

no function call overhead is required). When used with the MPC555 the FlashRead() function can be

replaced with the macro:

#define FlashRead( ulOff ) ( BASE_ADDR[ulOff] )

The FlashWrite() function should not be replaced with a macro or an inline function (C++). The use of

a function call for each write to the Flash will prevent back-to-back writes from occurring; even with this

measure, C programmer should look carefully at the assembled code to ensure that no back-to-back

writes occur. The time taken to put the parameters on the stack and make the call will be sufficient for the

M58BF008 to recover. In terms of the CPU overhead this causes it will be minimal; programming is the

time when the most write accesses to the Flash occur and each double-word takes about 10s to program

compared to an additional 200ns (roughly) in the write access.

CONCLUSION

The M58BF008 can be connected to the MPC555 in a glue-less configuration, providing burst performance. The Flash can be used to boot the MPC555 and does not require shadow RAM, code can be executed directly from the Flash without loss of performance.

REVISION HISTORY

Date

Version

Revision Details

December 2000

-01

First Issue

February 2001

-02

Addition of the DC Characteristics comparison. Other minor corrections

13/14

AN1269 - APPLICATION NOTE

If you have any questions or suggestion concerning the matters raised in this document please send them

to the following electronic mail address:

ask.memory@st.com

(for general enquiries)

Please remember to include your name, company, location, telephone number and fax number.

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is registered trademark of STMicroelectronics

All other names are the property of their respective owners

2001 STMicroelectronics - All Rights Reserved

STMicroelectronics GROUP OF COMPANIES

Australia - Brazil - China - Finland - France - Germany - Hong Kong - India - Italy - Japan - Malaysia - Malta - Morocco Singapore - Spain - Sweden - Switzerland - United Kingdom - U.S.A.

www.st.com

14/14

This datasheet has been download from:

www.datasheetcatalog.com

Datasheets for electronics components.

You might also like

- Lab MC P1 1618200Document17 pagesLab MC P1 1618200luis gonzalezNo ratings yet

- 29F002 AflahjsdDocument22 pages29F002 AflahjsdGiapy Phuc TranNo ratings yet

- Data SheetDocument36 pagesData Sheetpeyuco3333No ratings yet

- Introduction of Moving Message Display Using Liquid Crystal Display and Micro Controller 8051 FamilyDocument13 pagesIntroduction of Moving Message Display Using Liquid Crystal Display and Micro Controller 8051 Familyishu58643No ratings yet

- At89c2051 Data SheetDocument44 pagesAt89c2051 Data SheetRavi AhirwarNo ratings yet

- At89lp2052 PDFDocument93 pagesAt89lp2052 PDFRisnoHamidNo ratings yet

- 8-Bit Microcontroller With 2K/4K Bytes Flash AT89S2051 AT89S4051Document46 pages8-Bit Microcontroller With 2K/4K Bytes Flash AT89S2051 AT89S4051Yoga Dwi CahyonoNo ratings yet

- M 29 F 200 BBDocument22 pagesM 29 F 200 BBThong ChanNo ratings yet

- 68 HC11 ManualDocument36 pages68 HC11 ManualГеорги МончевNo ratings yet

- Microcontroller:-: (Type Text)Document5 pagesMicrocontroller:-: (Type Text)Nitesh GamitNo ratings yet

- AT89C2051 Traffic Light ControllerDocument39 pagesAT89C2051 Traffic Light ControllerNagesh RayNo ratings yet

- Laboratory Exercise 8: Memory BlocksDocument11 pagesLaboratory Exercise 8: Memory BlocksHoàng Đại NghĩaNo ratings yet

- Industrial security system using microcontroller programmingDocument6 pagesIndustrial security system using microcontroller programmingnaveenraj111No ratings yet

- Understanding the Architecture of the 8051 MicrocontrollerDocument113 pagesUnderstanding the Architecture of the 8051 Microcontrollerpraneeth saiNo ratings yet

- Appendices A. Microcontroller A.1 Description of 8051 The AT89S51 Is A Low-Power, High-Performance CMOS 8-BitDocument28 pagesAppendices A. Microcontroller A.1 Description of 8051 The AT89S51 Is A Low-Power, High-Performance CMOS 8-BitChinna ThambiNo ratings yet

- Introduction To 68HC11 MICROCONTROLLERDocument72 pagesIntroduction To 68HC11 MICROCONTROLLERNarasimha Murthy Yayavaram100% (3)

- Introduction to the 8051 Microcontroller: Architecture & CapabilitiesDocument26 pagesIntroduction to the 8051 Microcontroller: Architecture & CapabilitiesSanjeev Kumar SahuNo ratings yet

- 8-Bit Microcontroller With 2K Bytes Flash AT89C2051: FeaturesDocument24 pages8-Bit Microcontroller With 2K Bytes Flash AT89C2051: FeaturesVibhor KaushikNo ratings yet

- AN1010Document20 pagesAN1010Eslam H. YehiaNo ratings yet

- Introducing The Motorola HC908 MicrocontrollerDocument26 pagesIntroducing The Motorola HC908 Microcontrollervinicius.camattaNo ratings yet

- 8085 MicroprocessorDocument38 pages8085 MicroprocessorPrateek PandeyNo ratings yet

- Chapter-6 Data MemoryDocument9 pagesChapter-6 Data MemoryPrathyusha ReddyNo ratings yet

- Automatic street light control using RTC microcontrollerDocument42 pagesAutomatic street light control using RTC microcontrollerSaravanan Viswakarma0% (2)

- PIC Microcontrollers: A Guide to Their Architecture and ApplicationsDocument3 pagesPIC Microcontrollers: A Guide to Their Architecture and ApplicationsSaurabh RastogiNo ratings yet

- AT89S52Document20 pagesAT89S52Bhargav GoudNo ratings yet

- Electronics Project Automatic Bike Controller Using Infrared RaysDocument16 pagesElectronics Project Automatic Bike Controller Using Infrared RaysragajeevaNo ratings yet

- Using External Data Memory With Pic24F/24H/Dspic33F Devices: Author: Vidyadhar Vivekananda Microchip Technology IncDocument34 pagesUsing External Data Memory With Pic24F/24H/Dspic33F Devices: Author: Vidyadhar Vivekananda Microchip Technology Incvietanh_askNo ratings yet

- Microcontroller Traffic Light ProjectDocument22 pagesMicrocontroller Traffic Light ProjectAyan Samanta80% (10)

- Hardware Lecture 16Document4 pagesHardware Lecture 16rinobiNo ratings yet

- MC 68hc11Document72 pagesMC 68hc11hulavanyaNo ratings yet

- EMISY Second Test Exemplary Questions Solved-3Document15 pagesEMISY Second Test Exemplary Questions Solved-3YANG LIUNo ratings yet

- Interfacing Devices Memory Devices and Interfacing Interfacing DevicesDocument14 pagesInterfacing Devices Memory Devices and Interfacing Interfacing DevicesShilpa ShettyNo ratings yet

- MicroprocessorDocument7 pagesMicroprocessorSanoxNo ratings yet

- 16K (2K X 8) Parallel Eeprom With Software Data ProtectionDocument19 pages16K (2K X 8) Parallel Eeprom With Software Data ProtectionAmado Castellanos RosasNo ratings yet

- ASSIGNMENT#5Document52 pagesASSIGNMENT#5mahnoor238705No ratings yet

- Rohini 90925466680Document6 pagesRohini 90925466680SubraNo ratings yet

- Microprocessor 8085Document25 pagesMicroprocessor 8085hetal_limbaniNo ratings yet

- MSP430 Microcontroller Architecture GuideDocument128 pagesMSP430 Microcontroller Architecture GuideasdsdNo ratings yet

- Memory Practicum PDFDocument11 pagesMemory Practicum PDFRollWindows DownNo ratings yet

- VHDLDocument11 pagesVHDLlizhi0007No ratings yet

- 8-Bit Microcontroller With 4K Bytes Flash AT89C4051: FeaturesDocument18 pages8-Bit Microcontroller With 4K Bytes Flash AT89C4051: FeaturesAri SoerjantoNo ratings yet

- Memory Interface InstructionDocument8 pagesMemory Interface InstructionSayan Kumar KhanNo ratings yet

- Pic MicrocontrollerDocument14 pagesPic Microcontrollermsubashece001No ratings yet

- Project Report On Microcontroller Based Traffic Light ControllerDocument22 pagesProject Report On Microcontroller Based Traffic Light ControllerMohitpariharNo ratings yet

- Microprocessor Lab Manual EE0310Document44 pagesMicroprocessor Lab Manual EE0310sathishkumar.vNo ratings yet

- Basic Concepts of Memory Interfacing - ComputerSCDocument7 pagesBasic Concepts of Memory Interfacing - ComputerSCParamartha BanerjeeNo ratings yet

- Lenze ModbusDocument2 pagesLenze ModbusHazar çintuğluNo ratings yet

- 16f8x Serial ProgDocument16 pages16f8x Serial ProgIgnacio MartiNo ratings yet

- s7-300 MMC Card Memory ResetDocument3 pagess7-300 MMC Card Memory Resetrigo_sk100% (1)

- Hardware Lecture 16Document4 pagesHardware Lecture 16Taqi ShahNo ratings yet

- K.Lalmuankima: Microcontroller Based System Design Unit - 3 & 4Document18 pagesK.Lalmuankima: Microcontroller Based System Design Unit - 3 & 4Lalmuankima KhawlhringNo ratings yet

- 8-Bit Microcontroller With 2K Bytes Flash AT89C2051: FeaturesDocument14 pages8-Bit Microcontroller With 2K Bytes Flash AT89C2051: FeaturesMinhdung PhanNo ratings yet

- Metal Gas Detec RoboDocument37 pagesMetal Gas Detec RoboVijay SaiNo ratings yet

- 8085 MCQs GuideDocument20 pages8085 MCQs GuideniteshNo ratings yet

- Project Report On Microcontroller Based Traffic Light ControllerDocument23 pagesProject Report On Microcontroller Based Traffic Light Controllerالموعظة الحسنه chanelNo ratings yet

- Preliminary Specifications: Programmed Data Processor Model Three (PDP-3) October, 1960From EverandPreliminary Specifications: Programmed Data Processor Model Three (PDP-3) October, 1960No ratings yet

- PLC Programming Using SIMATIC MANAGER for Beginners: With Basic Concepts of Ladder Logic ProgrammingFrom EverandPLC Programming Using SIMATIC MANAGER for Beginners: With Basic Concepts of Ladder Logic ProgrammingRating: 4 out of 5 stars4/5 (1)

- PLC: Programmable Logic Controller – Arktika.: EXPERIMENTAL PRODUCT BASED ON CPLD.From EverandPLC: Programmable Logic Controller – Arktika.: EXPERIMENTAL PRODUCT BASED ON CPLD.No ratings yet

- Nintendo 64 Architecture: Architecture of Consoles: A Practical Analysis, #8From EverandNintendo 64 Architecture: Architecture of Consoles: A Practical Analysis, #8No ratings yet

- TIPC400B DatasheetDocument1 pageTIPC400B DatasheetRicky CoxNo ratings yet

- ACCU-Torq® MotorsDocument2 pagesACCU-Torq® MotorsRicky CoxNo ratings yet

- JEFT Phillips J212Document7 pagesJEFT Phillips J212Ricky CoxNo ratings yet

- SFP Bidirectional Single Fiber TransceiversDocument4 pagesSFP Bidirectional Single Fiber TransceiversRicky CoxNo ratings yet

- High Efficiency SMD Power InductorsDocument1 pageHigh Efficiency SMD Power InductorsRicky CoxNo ratings yet

- J212 PDFDocument7 pagesJ212 PDFRicky CoxNo ratings yet

- SDK Redrat Com APIDocument17 pagesSDK Redrat Com APIRicky CoxNo ratings yet

- Stacked Multi-Chip ProductDocument15 pagesStacked Multi-Chip ProductRicky CoxNo ratings yet

- Mini TOP Views LEDsDocument11 pagesMini TOP Views LEDsRicky CoxNo ratings yet

- GN2470Document5 pagesGN2470Alejandro BandaNo ratings yet

- PowerMesh IGBT 120HDDocument13 pagesPowerMesh IGBT 120HDRicky CoxNo ratings yet

- STV0672 Datasheet PDFDocument2 pagesSTV0672 Datasheet PDFRicky CoxNo ratings yet

- DAC0808 DatasheetDocument12 pagesDAC0808 DatasheetRicky CoxNo ratings yet

- Cisco Icon LibraryDocument6 pagesCisco Icon LibraryYunow MendozaNo ratings yet

- Raster Graphics Drawing LinesDocument25 pagesRaster Graphics Drawing LinesVishal FalakeNo ratings yet

- Xfs Filesystem BackgroundDocument16 pagesXfs Filesystem BackgroundRicky CoxNo ratings yet

- Pic Timer0 Tutorial Part1Document18 pagesPic Timer0 Tutorial Part1ivan10mNo ratings yet

- Lvds Cable DataDocument20 pagesLvds Cable DataAnura MaddumageNo ratings yet

- VV6404 Datasheet PDFDocument54 pagesVV6404 Datasheet PDFRicky CoxNo ratings yet

- Differential Translator/Repeater: Features DescriptionDocument25 pagesDifferential Translator/Repeater: Features DescriptionRicky CoxNo ratings yet

- Temt600 Datasheet PDFDocument5 pagesTemt600 Datasheet PDFRicky CoxNo ratings yet

- ThePomodoroTechnique v1-3 PDFDocument45 pagesThePomodoroTechnique v1-3 PDFRebecca SalmanNo ratings yet

- Led Backlight Driver Panel Selection GuideDocument2 pagesLed Backlight Driver Panel Selection GuideRicky CoxNo ratings yet

- Duracell 9V Battery Performance DataDocument2 pagesDuracell 9V Battery Performance DataRicky CoxNo ratings yet

- Product Overview: LA6584M: BTL Driver Single-Phase Full-Wave Fan Motor DriverDocument1 pageProduct Overview: LA6584M: BTL Driver Single-Phase Full-Wave Fan Motor DriverRicky CoxNo ratings yet

- AsRock K7S41GX ManualDocument31 pagesAsRock K7S41GX ManualjamesNo ratings yet

- Atmel LED Driver-MSLB9082 LED Backlight Driver Module: DatasheetDocument20 pagesAtmel LED Driver-MSLB9082 LED Backlight Driver Module: DatasheetRicky CoxNo ratings yet

- 1.5 Amp Positive Voltage Regulator: EZ1086BC, EZ1086C & EZ1086IDocument6 pages1.5 Amp Positive Voltage Regulator: EZ1086BC, EZ1086C & EZ1086IRicky CoxNo ratings yet

- Shared MemoryDocument20 pagesShared Memoryf5598100% (1)

- Certified Ethical Hacker v10 PDFDocument3 pagesCertified Ethical Hacker v10 PDFGustavo FerreiraNo ratings yet

- Biometrics PresentationDocument35 pagesBiometrics PresentationberengerroshenNo ratings yet

- Online Complaint Management SystemDocument15 pagesOnline Complaint Management Systemrohithreddy1234No ratings yet

- TNCAcceleratorUserGuideV3 PDFDocument143 pagesTNCAcceleratorUserGuideV3 PDFwahibmNo ratings yet

- Report FypDocument75 pagesReport Fypsick edNo ratings yet

- Module4.2 PM Create N1 Notification ZIW21 24.02.2013 V1.0Document28 pagesModule4.2 PM Create N1 Notification ZIW21 24.02.2013 V1.0pganoelNo ratings yet

- Chapter 1 Assignment on Computer SecurityDocument2 pagesChapter 1 Assignment on Computer SecurityChuck Stevens100% (7)

- Data Structures and AlgorithmsDocument18 pagesData Structures and AlgorithmsabhiNo ratings yet

- Search Engine OptimizationDocument20 pagesSearch Engine OptimizationRitiz PandeyNo ratings yet

- CSE CompleteDocument126 pagesCSE CompleteSameer ChandraNo ratings yet

- Voice Translation Rules v2Document21 pagesVoice Translation Rules v2Ezo'nun BabasıNo ratings yet

- Ch6 - Part 3Document13 pagesCh6 - Part 3Yassir IbrahimNo ratings yet

- Android OSDocument19 pagesAndroid OSUjjaval VadviNo ratings yet

- 547f39f7a0142 Network AnalysisDocument38 pages547f39f7a0142 Network AnalysisYiğit TirkeşNo ratings yet

- Email Setup in JDEdwardsDocument12 pagesEmail Setup in JDEdwardsAtifNo ratings yet

- Latihan Soal IDocument25 pagesLatihan Soal IHudan RamadhonaNo ratings yet

- Mitsubishi QDocument31 pagesMitsubishi QcvdweNo ratings yet

- Sample ProblemsDocument4 pagesSample ProblemsShreepriya Indira Uma DograNo ratings yet

- 02 General 009Document15 pages02 General 009Youssef EBNo ratings yet

- SystemC IntroductionDocument21 pagesSystemC IntroductionMuhammad IsmailNo ratings yet

- Jquery ValidationDocument4 pagesJquery ValidationmohaideenNo ratings yet

- QPDF Manual: For QPDF Version 8.0.2, March 6, 2018Document49 pagesQPDF Manual: For QPDF Version 8.0.2, March 6, 2018ctrplieff2669No ratings yet

- Operation Research 2 Mark Questions For 5unitsDocument5 pagesOperation Research 2 Mark Questions For 5unitsM.Thirunavukkarasu100% (2)

- DSSDocument13 pagesDSSKeerthi PalariNo ratings yet

- 477 - Camunda BPM 7 Com Pared To JBossDocument17 pages477 - Camunda BPM 7 Com Pared To JBossManojBhangaleNo ratings yet

- System UnitDocument19 pagesSystem Unitizzul_125z1419No ratings yet

- TrueOS HandbookDocument266 pagesTrueOS HandbookLucrécio Ricco AlmeidaNo ratings yet

- Stefano Markidis, Erwin Laure - Solving Software Challenges For Exascale 2015Document154 pagesStefano Markidis, Erwin Laure - Solving Software Challenges For Exascale 2015Nguyen Thanh BinhNo ratings yet