Professional Documents

Culture Documents

Quality Alert # 01 Storage of Welding Consumables

Uploaded by

Gaurav Khamkar100%(1)100% found this document useful (1 vote)

231 views1 pageQuality Alert # 01 Storage of Welding Consumables

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentQuality Alert # 01 Storage of Welding Consumables

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

231 views1 pageQuality Alert # 01 Storage of Welding Consumables

Uploaded by

Gaurav KhamkarQuality Alert # 01 Storage of Welding Consumables

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 1

QUALITY ALERT

Title: Storage of Welding Consumables

No. NFPD- Q001

Description:

Precautions to be taken for storage of Welding Consumables on

account of Bad Weather Conditions predicted

How it can be eliminated:

Consumables

shall be stored under

correct climatic conditions.

The humidity level can be maintained

at low levels by ensuring a storage

temperature of at least 10C above the

Consequences :

outside temperature

Solid MIG / MAG wires, TIG rods and

1. The Covered electrodes are sensitive to

moisture

pick-up.

High

moisture

contents in the coating can cause

porosity or Hydrogen cracking.

2. Solid MIG/ MAG wires, TIG rods and SAW

wires will pick of the moisture form of

rain or the condensation of moisture on

a cold wire.

3. Immediate Rusting of Filler wires

SAW wires and Fluxes should be stored

in dry conditions, in original sealed

undamaged packaging as supplied and

properly sealed by polythene covers.

partly used spools should be replaced

into a plastic bags for storage to

prevent moisture pick up.

TIG wires should be stored in

4. Flux coating on dump electrodes will be

broken into loose powder when in use

after baking

5. High weld repair rate

6. Cost involvement for re- procurement

( Vendors / stockiest will not agree to

take

return

on account of poor

handling and storage )

7. Causes delay of Job completion

original packages or in polythene

covers or in dry boxes if they are

removed from the packaging.

You might also like

- 2018 Handling and Storage Recommendations - EN - Rev1!02!2018Document4 pages2018 Handling and Storage Recommendations - EN - Rev1!02!2018David Hortas CasasNo ratings yet

- Storing and Redrying Electrodes-Lincoln ElectricDocument3 pagesStoring and Redrying Electrodes-Lincoln ElectricjasminneeNo ratings yet

- Described As 1.7225 42crmo4 in en 10083 - 1: 2006 Previously 709M40 in PD 970: 2001Document2 pagesDescribed As 1.7225 42crmo4 in en 10083 - 1: 2006 Previously 709M40 in PD 970: 2001Trịnh Quốc TuyếnNo ratings yet

- CIGWELDDocument244 pagesCIGWELDrodastrid5653100% (1)

- Voestalpine Heavy Plate TTD ALDUR E 14012013Document13 pagesVoestalpine Heavy Plate TTD ALDUR E 14012013Dragan JerčićNo ratings yet

- Material Dissimilar JointsDocument7 pagesMaterial Dissimilar JointsPemburu JablayNo ratings yet

- 3.3.1-Basics of Weld Joint Design-9th Mar 21Document60 pages3.3.1-Basics of Weld Joint Design-9th Mar 21Vivek kmNo ratings yet

- Is 7310 RequirementsDocument4 pagesIs 7310 RequirementsRavichandran Tirupattur SubramaniamNo ratings yet

- WeldingDocument21 pagesWeldingprabhatkumar_6657012No ratings yet

- 3 Jim MansfieldDocument22 pages3 Jim MansfieldjoebriffaNo ratings yet

- GMAWDocument12 pagesGMAWsushant47No ratings yet

- IIW-ANB Refresher Course: Gas Welding, Brazing, Soldering and Cutting ProcessesDocument81 pagesIIW-ANB Refresher Course: Gas Welding, Brazing, Soldering and Cutting ProcessesAsad Bin Ala QatariNo ratings yet

- SF188 Rev 1 - Welder Qualification Test CertificateDocument1 pageSF188 Rev 1 - Welder Qualification Test CertificateMike BoyesNo ratings yet

- Penetrating TestingDocument20 pagesPenetrating TestingshiraniasgharNo ratings yet

- Duplex Stainless Steel - Part 2 - TWIDocument6 pagesDuplex Stainless Steel - Part 2 - TWItuanNo ratings yet

- IWCP: How To Apply For Qualifying by Alternative RouteDocument4 pagesIWCP: How To Apply For Qualifying by Alternative RoutearunkumarNo ratings yet

- By RPS Welding ConsultantsDocument41 pagesBy RPS Welding ConsultantsvairavnNo ratings yet

- Weld RepireDocument91 pagesWeld RepireالGINIRAL FREE FIRENo ratings yet

- LPT Method Guide for Surface Crack DetectionDocument29 pagesLPT Method Guide for Surface Crack DetectionSameer MohammadNo ratings yet

- (EW-471) - Gas Metal Arc Welding (2012 - 1998, Hobart Institute of Welding Technology)Document9 pages(EW-471) - Gas Metal Arc Welding (2012 - 1998, Hobart Institute of Welding Technology)Juan Diego AlvarezNo ratings yet

- BohlerThyssen PDFDocument386 pagesBohlerThyssen PDFElMacheteDelHuesoNo ratings yet

- Casting, Forming & Welding (ME31007) Lecture NotesDocument102 pagesCasting, Forming & Welding (ME31007) Lecture NotesramuNo ratings yet

- Welding 11-14%Cr IIW Document - Part 1Document20 pagesWelding 11-14%Cr IIW Document - Part 1Manuel CarreñoNo ratings yet

- Astm A514 GR SDocument9 pagesAstm A514 GR SMario GaytanNo ratings yet

- Welding BisplateDocument12 pagesWelding BisplateLim Senglin100% (1)

- Brochure IWCP ALL Routes July - 2011Document5 pagesBrochure IWCP ALL Routes July - 2011kumarvizayinNo ratings yet

- DIN EN ISO 9013 - Angular Deviation PDFDocument1 pageDIN EN ISO 9013 - Angular Deviation PDFflorinelvvNo ratings yet

- EN 288-3xDocument38 pagesEN 288-3xSyah Reza Maulana0% (1)

- Online & Blended IWE Course GuideDocument4 pagesOnline & Blended IWE Course GuideKamal HalawiNo ratings yet

- Course Module 4Document6 pagesCourse Module 4Makise AghataNo ratings yet

- Liquid Penetrant Test Level-IiDocument39 pagesLiquid Penetrant Test Level-IiAabhas UpadhyayaNo ratings yet

- c40 Carbon Steel Round Bar PDFDocument2 pagesc40 Carbon Steel Round Bar PDFRamNo ratings yet

- Wps PQRDocument7 pagesWps PQRsobariNo ratings yet

- Procedure for Flame Straightening Structural SteelDocument3 pagesProcedure for Flame Straightening Structural SteelAvishek Gupta100% (1)

- Gas Metal Arc WeldingDocument52 pagesGas Metal Arc WeldingBalakumarNo ratings yet

- Asme 1325-18 (2007)Document1 pageAsme 1325-18 (2007)Matthew TaylorNo ratings yet

- Welding Defects Method of Controlling Welding DefectsDocument21 pagesWelding Defects Method of Controlling Welding DefectsPrashant Handa100% (1)

- Gantrex Technical Bulletin Summarizes European Crane Rail StandardsDocument3 pagesGantrex Technical Bulletin Summarizes European Crane Rail StandardsLainhatanhNo ratings yet

- Defects Hydrogen Cracks IdentificationDocument5 pagesDefects Hydrogen Cracks Identificationarif maulanafNo ratings yet

- Validation Instructions: Kemppi OyDocument10 pagesValidation Instructions: Kemppi OyAlex AlexNo ratings yet

- DRAFT AS 3992:2019: Summary of Changes From As/Nzs 3992:2015Document18 pagesDRAFT AS 3992:2019: Summary of Changes From As/Nzs 3992:2015Osu AmpawanonNo ratings yet

- WPSGMAW90 102011ExamplePDFDocument1 pageWPSGMAW90 102011ExamplePDFBhavani PrasadNo ratings yet

- 121 T BW FPDocument4 pages121 T BW FPA. ΒρατσισταNo ratings yet

- En 15085-2 Procedure ManualDocument8 pagesEn 15085-2 Procedure ManualKDTNo ratings yet

- Spec Sheet - Handler 187Document4 pagesSpec Sheet - Handler 187Hobart Welding ProductsNo ratings yet

- Welding Metallurgy - Detailed PDFDocument28 pagesWelding Metallurgy - Detailed PDFkarcoepm100% (1)

- Hydro Aluminium - AlSi7Mg0.6Document2 pagesHydro Aluminium - AlSi7Mg0.6Raj PrasanthNo ratings yet

- Form Qw-482 Format For Welding Procedure Specification (WPS) (See QW-200,1, Section Ix, ASME Boiler and Pressure Vessel Code)Document4 pagesForm Qw-482 Format For Welding Procedure Specification (WPS) (See QW-200,1, Section Ix, ASME Boiler and Pressure Vessel Code)Rajkumar ArikumarNo ratings yet

- Minimizing Weld Defects in SAWDocument3 pagesMinimizing Weld Defects in SAWNalla Gane100% (1)

- A Brief Synopsis ofDocument54 pagesA Brief Synopsis ofNO ONENo ratings yet

- Valves For Cryogenic ServiceDocument1 pageValves For Cryogenic ServiceAnnamalai Ram JGCNo ratings yet

- Electro Slag Strip Cladding ProcessDocument5 pagesElectro Slag Strip Cladding ProcessIJMERNo ratings yet

- EN 15085 Update: Important Changes to Railway Welding Standard Effective April 2021Document2 pagesEN 15085 Update: Important Changes to Railway Welding Standard Effective April 2021Boran YelkenciogluNo ratings yet

- Gta+sma PQRDocument3 pagesGta+sma PQRRahul MoottolikandyNo ratings yet

- Weld ImperfectionsDocument11 pagesWeld Imperfections0502raviNo ratings yet

- QA-QC Welding Program evaluation TestDocument2 pagesQA-QC Welding Program evaluation TestSatish KeskarNo ratings yet

- WELDING CONSUMABLES STORAGE AND CAREDocument1 pageWELDING CONSUMABLES STORAGE AND CAREanouar82No ratings yet

- Asme Awareness Program - DesignDocument126 pagesAsme Awareness Program - DesignGaurav KhamkarNo ratings yet

- Icb v. 3.0Document0 pagesIcb v. 3.0mikayilrahimovNo ratings yet

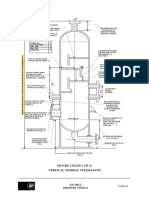

- Vessel Tolerance ChartDocument1 pageVessel Tolerance ChartGaurav KhamkarNo ratings yet

- Presure Testing GuidanceDocument15 pagesPresure Testing GuidanceMahmood EijazNo ratings yet

- Pmguru OnlineDocument167 pagesPmguru OnlineGaurav KhamkarNo ratings yet

- HSE Structure IMSDocument50 pagesHSE Structure IMSHazem KamalNo ratings yet

- Welding Cons EstimationDocument6 pagesWelding Cons EstimationGaurav KhamkarNo ratings yet

- Action Learning Project: Establish Productive Welding Process For Inconel 625 Clad Pipe Girth WeldsDocument6 pagesAction Learning Project: Establish Productive Welding Process For Inconel 625 Clad Pipe Girth WeldsGaurav KhamkarNo ratings yet

- Guidebook ULSANDocument67 pagesGuidebook ULSANGaurav KhamkarNo ratings yet

- Useful ShortcutDocument4 pagesUseful Shortcutshradha07No ratings yet

- Quality Alert # 01 Storage of Welding ConsumablesDocument1 pageQuality Alert # 01 Storage of Welding ConsumablesGaurav Khamkar100% (1)

- Handbook For Foreigners in ShenzhenDocument48 pagesHandbook For Foreigners in ShenzhenGaurav KhamkarNo ratings yet

- Control of Welding - en 1090Document3 pagesControl of Welding - en 1090Gaurav KhamkarNo ratings yet

- Offshore Oil and ProdDocument101 pagesOffshore Oil and ProdSuresh Erath100% (5)

- Quick Study For Computer Keyboard Short CutsDocument2 pagesQuick Study For Computer Keyboard Short Cutsmahazari100% (3)

- Is 883 1994 PDFDocument21 pagesIs 883 1994 PDFkrishnanunniNo ratings yet

- Piping Fundamentals for Beginners: A Guide to Piping Systems, Components, and DesignDocument29 pagesPiping Fundamentals for Beginners: A Guide to Piping Systems, Components, and DesignManoj Pratap SinghNo ratings yet

- Handbook For Foreigners in ShenzhenDocument48 pagesHandbook For Foreigners in ShenzhenGaurav KhamkarNo ratings yet

- Welding Good Engineering Practice PDFDocument1 pageWelding Good Engineering Practice PDFGaurav KhamkarNo ratings yet

- ASME Awareness Program Audit PreparationDocument25 pagesASME Awareness Program Audit PreparationGaurav KhamkarNo ratings yet

- Bench GrinderDocument6 pagesBench GrinderGaurav KhamkarNo ratings yet

- Electrode Selection and IndificationDocument1 pageElectrode Selection and IndificationGaurav KhamkarNo ratings yet

- ASME Awareness ProgramDocument9 pagesASME Awareness ProgramGaurav KhamkarNo ratings yet

- ASME Awareness Program Audit PreparationDocument25 pagesASME Awareness Program Audit PreparationGaurav KhamkarNo ratings yet

- ASME Awareness Program - 5Document40 pagesASME Awareness Program - 5Gaurav KhamkarNo ratings yet

- Reducer WeldoverlayDocument4 pagesReducer WeldoverlayGaurav KhamkarNo ratings yet

- Repair Procedure For Galvanized Gratings & Stair Treads - r2Document8 pagesRepair Procedure For Galvanized Gratings & Stair Treads - r2Gaurav KhamkarNo ratings yet

- Valve Testing, Preservation & Installation DocumentsDocument15 pagesValve Testing, Preservation & Installation DocumentsGaurav KhamkarNo ratings yet