Professional Documents

Culture Documents

Skirt Design - For Small Vessels

Uploaded by

Sakthi VelOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Skirt Design - For Small Vessels

Uploaded by

Sakthi VelCopyright:

Available Formats

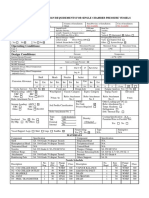

EQP. TAG No.

: ------------MSN

: -

DESIGN REF No - ----------

COVER PAGE

SHEET No.

REV No.

DATED

: 1 of 35

: 0

: 03/05/16

VENVEL THERMAL & MECHANICAL

DESIGNSERS,

VENNANDUR, NAMAKKAL (DT),

TAMILNADU, INDIA 637 505

SKIRT SUPPORT DESIGN FOR SMALLER

VESSELS (NOT PROVEN verify before use)

Visit www.venveldesigners.com

& mail @ sakthivel@venveldesigners.com

Mob : +91 99657 64325

EQP. TAG No. : ------------MSN

: -

DESIGN REF No - ----------

SHEET No.

REV No.

DATED

SKIRT SUPPORT CALCULATION

: 2 of 35

: 0

: 03/05/16

As per IS 1893 (Part I) 2002, IS 875 (Part 3) - 1987 WIND, SEISMIC CONDATION-INDIA

DESIGN INPUT

L

: T.L.TO T.L.LENGTH

:

1070

D

: OUTSIDE DIAMETER OF SKIRT

:

712

E

: EFFICIENCY OF SKIRT TO HEAD JOINT

:

0.7

As

: AREA WITHIN THE SKIRT

:

282600

Cs

: CIRCUMFERENCE ON O.D OF THE SKIRT

:

2236

Fb

:

SAFE BEARING LOAD ON CONCRETE

:

4

L1

: CANTILEVER INSIDE OR OUTSIDE, GREATER OF

:

60

:

MOMENT AT THE BASE DUE TO WIND OR EARTHQAUKE

:

860454.2

W

:

WEIGHT OF THE VESSEL DURING OPERATION OR TEST

:

7692

SUPPORT DESIGN

OPERATING

HYDROTEST

NEW&COLD

P

: INTERNAL DESIGN PRESSURE :

Pe

: EXTERNAL DESIGN PRESSURE :

D

: INSIDE DIAMETER OF SHELL

:

Do

: OUTSIDE DIAMETER OF SHELL :

R

: INSIDE RADIUS OF SHELL

:

ts

: SHELL THICKNESS

:

th

: DISH THICKNESS MINIMUM

:

C

: CORROSION ALLOWANCE

:

Es : MODULUS OF ELASTICITY OF SHELL:

S

ALLOWABLE STRESS

:

Sy

: YIELD STRESS FOR

:

W

: WEIGHT

:

1.5

N.A

700

712

350

6.0

5.0

0

189000

126

184

2792

1.95

N.A

700

712

350

6.0

5.0

0

195000

138

207

7692

mm

mm

mm

mm 2

mm

Nos

mm

N/mm2

N

EMPTY

NEW & COLD

1.5

N.A

700

712

350

6.0

5.0

0

195000

138

207

2786

UNIT

Mpa g

Mpa g

mm

mm

mm

mm

mm

mm

Mpa

Mpa

Mpa

N

DESIGN REF No - ---------SKIRT SUPPORT CALCULATION

FOR WIND AND SEISMIC

EQP. TAG No. : ------------MSN

: WIND LOAD

Vb :

K1

K2

K3

Vz

BASIC WIND SPEED

(Bangalore)

PROBABILITY FACTOR(RISK/COEFFICIENT)

OPERATING

HYDROTEST

NEW & COLD

33

33

EMPTY NEW

& COLD

0.8

0.8

0.8

TOPOGRAPHY FACTOR

26.4

26.4

Pd :

DESIGN WIND PRESSURE

418.18

Pd :

CONSIDERED DESIGN WIND PRESSURE

Cf :

SHAPE FACTOR TRANSVERSE

VbxK1XK2xK3

0.6XVz2

UNIT

m/sec

(CATEGORY-4,CLASS-A)

: 3 of 35

: 0

: 03/05/16

33

TERRAIN CATEGORY FACTOR

DESIGN WIND SPEED

Cf :

SHEET No.

REV No.

DATED

26.4

m/sec

418.18

418.18

N/m

420

420

420

N/m

0.50

0.50

0.50

SHAPE FACTOR LONGITUDINAL

0.70

LONGITUDINAL PROJECTED AREA

0.385

0.385

0.385

Aft :

TRANSVERSE PROJECTED AREA

1.26

1.26

1.26

Fwl :

LONGITUDINAL WIND FORCE ON SKIRT

0.34

0.34

0.34

Fwt:

TRANSVERSE WIND FORCE ON SKIRT

132.3

132.3

132.3

Afl :

0.7854 x (Do/1000)2

DoxLo

Afl x Cf(Long) X Pd

Aft x Cf(Tran)xPd/2

SEISMIC LOAD

:

I :

0:

h:

(SEISMIC COEFFICIENT METHOD)

0.70

0.70

SOIL- FOUNDATION SYSTEM FACTOR

1.00

1.00

1.00

BASIC SEISMIC COEFFICIENT

0.01

0.01

0.01

IMPORTANCE FACTOR

(ZONE-II)

(Bangalore)

1.00

1.00

1.00

DESIGN HORIZONTAL SEISMIC COEFFICIENT

0.01

0.01

0.01

LONG.SEISMIC FORCE

27.92

76.92

27.86

Fht :

TRANSVERSE SEISMIC FORCE

13.96

38.46

13.93

FT :

TRANSVERSE LOAD(MAX OF WIND/SEIS)

132.3

132.3

132.3

Fhl :

FL :

X 1X 0

hXW

( hxW)/2

LONGITUDINAL LOAD(MAX OF WIND/SEIS)

27.92

76.92

27.86

EQP. TAG No. : ------------MSN

: -

DESIGN REF No - ----------

SKIRT SUPPORT CALCULATION

BENDING MOMENT& SKIRT THICKNESS (OPERATING)

SKIRT SUPPORT DESIGNED WITH BASE PLATE AND GUSSET PLATES.

ALLOWABLE STRESS FOR BOLTS ON BASEPLATE( FROM TABLE3-34) Fs : 19 ksi (19,000 psi)

ALLOWABLE COMPRSSION ON CONCRETE (FROM TABLE 3-35) Fc : 800 psi

COEFFICIENT n (FROM TABLE 3-35) : 15

CONSTANT k : k = 1/(1+Fs/nFc)

= 1/(1+19000/15x800)

Cos = 1-2k

= 0.387

= 1-2x.387

= 0.227

OVERTURNING MOMENT AT TANGENT LINE (Mt):

=2xFX x t1 x r2 [((-) COS2 +3/2 (SIN COS) + ( -))/((-)COS + SIN))]

Fx = nFc,

Mt = 860454.2 N/mm2

THICKNESS CALCULATION FOR WIND (T1) :

T1 = 12xMt / (R2 x x S x E)

= 12 x 860454.2 / (3502 x 3.14 x 126 x 0.6)

= 0.355 mm

THICKNESS CALCULATION FOR WIND (T2) :

T2 = W / (D x x S x E)

= 2792 / (700 x 3.14 x 126 x 0.6)

= 0.014 mm

TOTAL SKIRT THICKNESS REQUIRED (T) FOR OPERATING CONDITIONS:

T = T1 + T2

= 0.355 + 0.014

= 0.369 mm

PROVIDED THICKNESS FOR SKIRT = 6.0 mm , HENCE PROVIDED THICKNESS IS OK.

BENDING MOMENT& SKIRT THICKNESS (EMPTY, NEW)

THICKNESS CALCULATION FOR WIND (T1) :

T1 = 12xMt / (R2 x x S x E)

= 12 x 860454.2 / (3502 x 3.14 x 126 x 0.6)

= 0.355 mm

SHEET No.

REV No.

DATED

: 4 of 35

: 0

: 03/05/16

EQP. TAG No. : ------------MSN

: -

DESIGN REF No - ----------

SKIRT SUPPORT CALCULATION

THICKNESS CALCULATION FOR WIND (T2) :

T2 = W / (D x x S x E)

= 2786 / (700 x 3.14 x 126 x 0.6)

= 0.014 mm

TOTAL SKIRT THICKNESS REQUIRED (T) FOR OPERATING CONDITIONS:

T = T1 + T2

= 0.355 + 0.014

= 0.369 mm

PROVIDED THICKNESS FOR SKIRT = 6.0 mm , HENCE PROVIDED THICKNESS IS OK.

BENDING MOMENT& SKIRT THICKNESS (HYDROTEST)

THICKNESS CALCULATION FOR WIND (T1) :

T1 = 12xMt / (R2 x x S x E)

= 12 x 860454.2 / (3502 x 3.14 x 126 x 0.6)

= 0.355 mm

THICKNESS CALCULATION FOR WIND (T2) :

T2 = W / (D x x S x E)

= 7692 / (700 x 3.14 x 126 x 0.6)

= 0.044 mm

TOTAL SKIRT THICKNESS REQUIRED (T) FOR OPERATING CONDITIONS:

T = T1 + T2

= 0.355 + 0.044

= 0.399 mm

PROVIDED THICKNESS FOR SKIRT = 6.0 mm , HENCE PROVIDED THICKNESS IS OK.

STRESS CHECK:

LOAD AREA = (3.14 x 356 x 100)

= 111784 mm2

ACTUAL STRESS = 3481.38 / 111784

= 0.0311 N / mm2 (ALLOWABLE STRESS = 126 MPa)

SHEET No.

REV No.

DATED

: 5 of 35

: 0

: 03/05/16

EQP. TAG No. : ------------MSN

: -

DESIGN REF No - ----------

SKIRT SUPPORT CALCULATION

SHEET No.

REV No.

DATED

STRESS VERIFICATION ON RIB PLATE :

PROVIDED BAS E PLATE THICKNESS = 10 mm

FOUR EQUALLY DISTANCED RIB PLATES THICKNESS = 10 mm

TOTAL LOAD APPLIED DURING HYDRO TEST IN BASE PLATE = 7692 N

B.C.D. OF BASE PLATE = 924 mm

NO OF RIBS ARRANGEMENT IN THE BASE PLATE = 4

LOAD APPLIED ON EACH RIB = 7692 /4 = 1923 N

AREA OF LOAD APPLIED = 100 x 100 = 10000 mm2

LOAD FACTOR ON SKIRT JOINT = 0.9

JOINT EFFIECIENCY OF SKIRT FILLET WELDING = 0.7

TRANSFER OF LOAD FROM SKIRT TO BASE PLATE IS THROUGH (AREA OF) = ( 10 x 100 ) x 2 = 2000 mm2

TRANSFER AREA ON EACH RIB ARRANGEMENT = 2000 x 2 = 4000 mm2

TOTAL STRESS CREATED ON THE RIBS = LOAD / AREA

= 1923 / 2000 = 0.96 N/mm2

= 0.96 MPa (g)

ALLOWABLE STRESS ON RIB PLATE = 126 MPa

STRESS CREATED ON THE RIB ARRANGEMENT DUE TO LOAD IS LESS THEN ALLOWABLE STRESS

126 > 0.96, HENCE DESIGN OF RIB PLATE IS ACCEPTABLE.

STRESS VERIFICATION ON BASE PLATE :

PROVIDED BAS E PLATE THICKNESS = 10 mm

TOTAL LOAD APPLIED DURING HYDRO TEST IN BASE PLATE = 7692 N

INSIDE DIAMETER OF BASE PLATE RING = 712 mm

OUTSIDE DIAMETER OF BASE PLATE RING = 924 mm

AREA AVAILABLE IN BASE PLATE

= (3.14 x R2) - (3.14 x r2)

= (3.14 x462 2) - ( 3.14 x 3562)

= 670214.16 397951.04

= 272263 mm2

: 6 of 35

: 0

: 03/05/16

DESIGN REF No - ----------

EQP. TAG No. : ------------MSN

: -

SKIRT SUPPORT CALCULATION

TOTAL STRESS APPLIED ON BASE PLATE

ALLOWABLE STRESS ON BASE PLATE

SHEET No.

REV No.

DATED

: 7 of 35

: 0

: 03/05/16

= LOAD / AREA

= 7692 / 272263

= 126 MPa

= 0.028 N/mm2 = 0.028 MPa

STRESS CREATED ON THE BASE PLATE DUE TO LOAD IS LESS THEN ALLOWABLE STRESS

126 > 0.028, HENCE DESIGN OF BASE PLATE IS ACCEPTABLE.

SUMMARY OF RESULTS (FOR MOST SEVERE CONDITION)

LOCATION OF LOAD

ACTUAL STRESS (MPa)

ALLOWABLE STRSS

ACCEPTABILITY

SKIRT RING

0.0311

126

ACCEPTABLE

BASE PLATE

0.028

126

ACCEPTABLE

RIB PLATES

0.96

(MPa)

126

ACCEPTABLE

ACTUAL STRESS IS LESS THAN ALLOWABLE STRESS,

HENCE SKIRT DESIGN IS OK.

You might also like

- Boiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFDocument4 pagesBoiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFAlexandru AsmarandeiNo ratings yet

- U Stamp - KK Form - SampleDocument5 pagesU Stamp - KK Form - SampleshazanNo ratings yet

- TubesheetDocument8 pagesTubesheetVaibhavNo ratings yet

- PV Newsletter - Skirt Connections PDFDocument5 pagesPV Newsletter - Skirt Connections PDFDivyesh PatelNo ratings yet

- WRC, PV Elite, NozzlePro Sign ConventionsDocument13 pagesWRC, PV Elite, NozzlePro Sign ConventionsADHIRAJ KOLINo ratings yet

- What Is An ASME Appendix 2 Flange Design PDFDocument1 pageWhat Is An ASME Appendix 2 Flange Design PDFMangesh BanaleNo ratings yet

- PV Elite ResultDocument239 pagesPV Elite ResultChaitanya Sai TNo ratings yet

- Etank Full ReportDocument108 pagesEtank Full ReportFaizal Sattu100% (1)

- Out of Roundnesscalculations:: Max MinDocument6 pagesOut of Roundnesscalculations:: Max MinAdekimi EmmanuelNo ratings yet

- Pad Type NozzleDocument2 pagesPad Type NozzleSajal Kulshrestha0% (1)

- Base Ring (Welded) - Vertical Vessel REV.1Document3 pagesBase Ring (Welded) - Vertical Vessel REV.1dskr fkshNo ratings yet

- Bab Iii: Re-Design Dan Hasil Perhitungan Horizontal Pressure VesselDocument36 pagesBab Iii: Re-Design Dan Hasil Perhitungan Horizontal Pressure VesselTri AgungNo ratings yet

- Compress EvaluateDocument23 pagesCompress EvaluateVishalDhiman100% (1)

- Jeddah South Thermal Power Plant Stage-I: ProjectDocument18 pagesJeddah South Thermal Power Plant Stage-I: ProjectAmr AbdeinNo ratings yet

- 28 Roark Flat PlatesDocument14 pages28 Roark Flat Platesgutmont0% (1)

- H200141 - Calculation of Basering Rev 0 PDFDocument9 pagesH200141 - Calculation of Basering Rev 0 PDFSani Adipura WinataNo ratings yet

- Foundation Load Table.Document1 pageFoundation Load Table.Lcm TnlNo ratings yet

- 94-QC20-J-414 - Curb Angle Check On L100X100X15Document92 pages94-QC20-J-414 - Curb Angle Check On L100X100X15Hgagselim SelimNo ratings yet

- ASME SecVIII Div-2 Hydro TestDocument2 pagesASME SecVIII Div-2 Hydro Testsouren1975No ratings yet

- TEMA Shell Bundle Entrance and Exit AreasDocument3 pagesTEMA Shell Bundle Entrance and Exit AreasArunkumar MyakalaNo ratings yet

- TBE Inlet Separator V 2100 FLNG2Document6 pagesTBE Inlet Separator V 2100 FLNG2halipzramlyzNo ratings yet

- Compress Report For Pressure VesselDocument394 pagesCompress Report For Pressure VesselgaurangNo ratings yet

- Tubesheet As Per ASME Sec. VIII-Div.1 UHXDocument1 pageTubesheet As Per ASME Sec. VIII-Div.1 UHXruponline1No ratings yet

- Skirt To Dish Joint PDFDocument64 pagesSkirt To Dish Joint PDFPrajwal ShettyNo ratings yet

- Spherical Tank PDFDocument1 pageSpherical Tank PDFevrim77No ratings yet

- E4.5.1 6 PTB 4 2015 PDFDocument50 pagesE4.5.1 6 PTB 4 2015 PDFKingston RivingtonNo ratings yet

- Anchor ChairDocument3 pagesAnchor ChairrsubramaniNo ratings yet

- SP-2069 Specification For Pressure VesselsDocument68 pagesSP-2069 Specification For Pressure Vesselsarjunprasannan7No ratings yet

- Support RingDocument13 pagesSupport RingvamsiNo ratings yet

- PV Elite Vessel Analysis Program HorizontalDocument55 pagesPV Elite Vessel Analysis Program HorizontalMarizta Perdani PutriNo ratings yet

- Weldment Strength Excel CalculationsDocument33 pagesWeldment Strength Excel CalculationsYl WongNo ratings yet

- Reinforcement For Multi OpeningsDocument1 pageReinforcement For Multi OpeningsSajal KulshresthaNo ratings yet

- Secondary Condensate B API650 Sloshing Impact RoofDocument22 pagesSecondary Condensate B API650 Sloshing Impact RoofFrancisco OrtuzarNo ratings yet

- Support Lug CalculationsDocument26 pagesSupport Lug CalculationsDinesh ChouguleNo ratings yet

- Calculation of Davit ArmDocument1 pageCalculation of Davit Armpiziyu100% (1)

- Api - 650 - 2007 - 40Document1 pageApi - 650 - 2007 - 40Raul GonzaloNo ratings yet

- PVElite RefDocument6 pagesPVElite RefakhilNo ratings yet

- ASME Formula DerivationDocument1 pageASME Formula Derivationvm153748763No ratings yet

- FinalDocument12 pagesFinalchompink6900No ratings yet

- Curb AngleDocument1 pageCurb Angle940623015859No ratings yet

- Header Box Stress CalculationsDocument2 pagesHeader Box Stress Calculationsrichward5No ratings yet

- Output Summary: SI UnitsDocument42 pagesOutput Summary: SI UnitsAkhil JoseNo ratings yet

- Conversion ASME Unit ConversionDocument3 pagesConversion ASME Unit ConversionMohdBadruddinKarimNo ratings yet

- Davit Cal 2251B Davit Arm CalculationDocument4 pagesDavit Cal 2251B Davit Arm Calculationnitin400No ratings yet

- Spreaer Beam&Lifting Line Beam p3Document2 pagesSpreaer Beam&Lifting Line Beam p3Sabrang LorNo ratings yet

- 7-12-0009 Rev 6Document2 pages7-12-0009 Rev 6cynideNo ratings yet

- Nozzle Interference Error SolvingDocument2 pagesNozzle Interference Error SolvingSakthi VelNo ratings yet

- Mechanical Calculation Storage Tank 110 KL (T-04)Document4 pagesMechanical Calculation Storage Tank 110 KL (T-04)Priyo Jati WahyonoNo ratings yet

- API 650 Baseplate DesignDocument3 pagesAPI 650 Baseplate DesignmjlazoNo ratings yet

- For Buildings and Other Structures For Wind LoadsDocument28 pagesFor Buildings and Other Structures For Wind LoadsMarinos Giannoukakis100% (1)

- Local Load Calculation of Shell Nozzles For Diesel Oil Storage Tank Tk-101 To Tk-108Document2 pagesLocal Load Calculation of Shell Nozzles For Diesel Oil Storage Tank Tk-101 To Tk-108NAVASNo ratings yet

- Load Case Explanation in PV EliteDocument2 pagesLoad Case Explanation in PV ElitekuselanmlNo ratings yet

- Dennis R Moss 4th EditionDocument5 pagesDennis R Moss 4th Editionsenthil kumarNo ratings yet

- Mozzle Repad Design ToolDocument2 pagesMozzle Repad Design ToolSiddiqui Muhammad AshfaqueNo ratings yet

- Design of Circular Flat Endplate With Stiffeners - Boiler and Pressure Vessel Engineering - Eng-TipsDocument2 pagesDesign of Circular Flat Endplate With Stiffeners - Boiler and Pressure Vessel Engineering - Eng-Tipsisrar khanNo ratings yet

- Torispherical Cone With KnuckleDocument2 pagesTorispherical Cone With KnuckleSajal KulshresthaNo ratings yet

- WIND MOMENT (Per API-650 SECTION 5.11)Document9 pagesWIND MOMENT (Per API-650 SECTION 5.11)ramu karri100% (1)

- Element Thickness 3Document24 pagesElement Thickness 3Vipul GandhiNo ratings yet

- Element Thickness 2Document20 pagesElement Thickness 2Vipul GandhiNo ratings yet

- Grade Slab ACI-150thkDocument7 pagesGrade Slab ACI-150thkMUTHUKKUMARAM100% (1)

- Cover Pages For PV Elite VenvelDocument14 pagesCover Pages For PV Elite VenvelSakthi VelNo ratings yet

- Technical Data Sheet For Shell and Tube Heat Exchager Design SpecificationDocument4 pagesTechnical Data Sheet For Shell and Tube Heat Exchager Design SpecificationSakthi VelNo ratings yet

- Is 803 Code CalcDocument5 pagesIs 803 Code CalcSakthi Vel50% (2)

- Plate Fabricated Pipe Calculation Sample PDFDocument4 pagesPlate Fabricated Pipe Calculation Sample PDFSakthi VelNo ratings yet

- Nozzle Interference Error SolvingDocument2 pagesNozzle Interference Error SolvingSakthi VelNo ratings yet

- Technical Data Sheet For Shell and Tube Heat Exchager Design SpecificationDocument5 pagesTechnical Data Sheet For Shell and Tube Heat Exchager Design SpecificationSakthi VelNo ratings yet

- Rectangular Tank Design - RoarksDocument3 pagesRectangular Tank Design - RoarksSakthi Vel100% (1)

- 4000 m3 Storage Tank - Data SheetDocument3 pages4000 m3 Storage Tank - Data SheetSakthi Vel100% (1)

- Condensate Tank - For 250Document3 pagesCondensate Tank - For 250Sakthi VelNo ratings yet

- Sulfuric Acid Tank - APIDocument4 pagesSulfuric Acid Tank - APISakthi VelNo ratings yet

- Oil Cooler - Pre Design Data SheetDocument3 pagesOil Cooler - Pre Design Data SheetSakthi VelNo ratings yet

- Design Calculations - I Beam SelectionDocument14 pagesDesign Calculations - I Beam SelectionSakthi VelNo ratings yet

- Design Calculations - I Beam SelectionDocument14 pagesDesign Calculations - I Beam SelectionSakthi VelNo ratings yet

- 5 MW Condenser PDFDocument133 pages5 MW Condenser PDFSakthi Vel100% (1)

- Overall - Finned TubeDocument14 pagesOverall - Finned TubeSakthi VelNo ratings yet

- IBR Book - FileDocument74 pagesIBR Book - FileSakthi VelNo ratings yet

- Mechanical Design Calculations of Pressure Vessel - SampleDocument27 pagesMechanical Design Calculations of Pressure Vessel - SampleSakthi Vel100% (1)

- Finned Tube Heat Exchanger - DetailsDocument7 pagesFinned Tube Heat Exchanger - DetailsSakthi VelNo ratings yet

- WRC 107 CalculationsDocument4 pagesWRC 107 CalculationsSakthi VelNo ratings yet