Professional Documents

Culture Documents

Civil Engineering

Uploaded by

Godino ChristianOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Civil Engineering

Uploaded by

Godino ChristianCopyright:

Available Formats

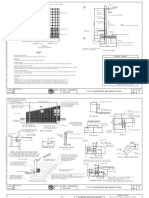

GENERAL STRUCTURAL NOTES

PART I - DESIGN CRITERIA (CONTINUED)

PART IV - REINFORCED CONCRETE (CONTINUED)

1.

4.

A.

GENERAL BUILDING CODE

1.

B.

The Construction Documents are based on the requirements of the

International Building Code 2006 with Houston Amendments to the 2006

International Building Code.

I.

Refer to the load plan sheets for all heavy partition loads and live

loading used on the project.

2.

1.

Partitions: An allowance of 20 PSF or the actual weight of the wall,

whichever is greater, has been made for partitions as a uniformly

distributed dead load. Refer to the load plan sheets for heavy partition

loads.

Hanging Ceiling and Mechanical Loads: An allowance of 15 PSF has

been made for hanging ceiling and mechanical equipment loads such as duct

work and sprinkler pipes.

LIVE LOADS

1.

Design live loads are based on the more restrictive of the uniform

load listed below or the concentrated load listed acting over an area 2.5

feet square. Refer to the load plan sheets for additional design live load

information.

a.

b.

c.

d.

e.

f.

g.

h.

i.

j.

k.

l.

Assembly Areas:

1)

Bench Seats: 100 PSF

2)

Fixed, Individual Seats: 60 PSF

3)

Lobbies: 100 PSF

4)

Movable Seats: 100 PSF

Exposed Exercise Areas Level 3: 100 PSF

Corridors, Except as Otherwise Indicated: 100 PSF

Elevator Machine Rooms: 125 PSF, Refer to Note b below.

Kitchens (Commercial): 150 PSF, Refer to Note b below.

Laboratories: 100 PSF

Mechanical Rooms:

1)

Air Handler Unit Rooms, Electrical and IT Closets: 100 PSF

and Refer to Note b Below.

Office Buildings:

1)

Corridors above First Floor: 80 PSF, 2,000 LBS

2)

Floors: 50 PSF, 2,000 LBS

3)

Lobbies and First Floor Corridors: 100 PSF, 2,000 LBS

Penal Institutions:

1)

Cell Blocks: 40 PSF

2)

Corridors: 100 PSF

Restrooms: Refer to Note a Below.

Roofs:

1)

Roofs subject to maintenance Workers: 20 PSF, 300 LBS

Stairs and Exits: 100 PSF, 300 LBS

Notes:

a.

Uniform load required is the same as the occupancy served.

b.

Design concentrated load is that required by assumed equipment

weight.

2.

J.

1.

K.

2.

1.

Wind pressures are based on the American Society of Civil Engineers,

Minimum Design Loads for Buildings and Other Structures, ASCE 7-05 and the

following criteria:

a.

Basic wind speed: 110 MPH (3 second gust)

b.

Wind importance factor (I): 1.15

c.

Building category: III 1

d.

Wind exposure category: B

e.

Internal pressure coefficient: +0.18/-0.18

Wind pressures used for the design of components and cladding are

shown in the following table:

P:\S03\2014\14023-00 HCCOH Joint Process & ST Center\3-Documentation\Drawings\Revit Structure\HCCOH JT PROCESSING CTR - R14.rvt

10/7/2015 1:22:36 PM

FILE NAME:

DATE STAMP:

CLADDING

TYPE

LOCATION

OR ZONE

Wall

Wall

Wall

Wall

Wall

Wall

Wall

Wall

Parapet

Parapet

Parapet

Parapet

Parapet

Parapet

Parapet

Parapet

Roof

Roof

Roof

Roof

Roof

Roof

Roof

Roof

Roof

Roof

Roof

Roof

Overhang

Overhang

Overhang

Overhang

Overhang

Overhang

Overhang

Overhang

Interior

Interior

Interior

Interior

End Zone

End Zone

End Zone

End Zone

Interior

Interior

Interior

Interior

End Zone

End Zone

End Zone

End Zone

Interior

Interior

Interior

Interior

Edge

Edge

Edge

Edge

Corner

Corner

Corner

Corner

Interior

Interior

Interior

Interior

Edge

Edge

Edge

Edge

EFFECTIVE

WIND AREA

(SQ-FT)

10

20

50

100

10

20

50

100

10

20

50

100

10

20

50

100

10

20

50

100

10

20

50

100

10

20

50

100

10

20

50

100

10

20

50

100

A.

Notes:

a.

Width of end zone/edge/corner strip: 24 feet

b.

Component and cladding pressures act normal to the surface.

Positive pressures act towards the surface and negative pressures act

away from the surface.

c.

Design pressure for components and cladding shall not be less

than 10 PSF acting in either direction normal to the surface.

d.

The effective wind area is the span length multiplied by an

effective width that need not be less than one-third the span length.

For cladding fasteners, the effective wind area shall not be greater

than the area that is tributary to an individual fastener.

e.

The design pressures listed above are calculated using a value

of Kd of 0.85.

1.

B.

A.

2.

Spandrel Beam Deflections. The following provision should be made

for superimposed load deflection of one floor relative to an adjacent floor

in the design, fabrication, and erection of the building cladding:

a.

Typical Spandrel Beam: 3/8

2.

3.

Floor Deflections: The following provision for superimposed load

deflections shall be made in the design, fabrication, and installation of

all partitions, glass walls, and other elements supported by and attached

to the structure:

a.

Typical Floor Members: Span/360 but not less than 3/8

b.

Typical Roof Members: Span/360 but not less than 3/8

1.

A.

HARRIS COUNTY ENGINEERING

DEPARTMENT

Reinforcing steel coverage should conform to the requirements

specified in details labeled TYPICAL CLEAR CONCRETE COVER on sheet

2-S1.20 unless noted otherwise on the drawings. Cover specified shall be

considered minimums that may require increasing where reinforcing steel

intersects for different member types. Cover in structural members not

specified in the details shall conform to the requirements of ACI 318

unless specified otherwise on the drawings. The reinforcing steel detailer

shall adjust reinforcing steel cage sizes at intersecting structural

members as required to allow clearance for intersecting reinforcing bar

layers with minimum specified cover.

1.

2"

2.

Reinforced concrete masonry shall be used as back-up for exterior

brick walls and elsewhere as indicated on the drawings. See architectural

wall sections.

PART VI - STRUCTURAL STEEL

Foundation design is based on the geotechnical investigation report

as follows Memorandum No. 2014-076-04, Foundation Design Conclusions and

Recommendations, Joint Processing Center, Houston, Texas, dated October 8,

2014 by Ulrich Engineers, 2901 Wilcrest, Suite 200, Houston, Texas 77042,

and Report No. 2014-076-01 Design Geotechnical Report Proposed COH and

Harris County Joint Processing Center, Houston, Texas dated October 1,

2014 by Ulrich Engineers.

C.

All concrete shall conform to the requirements of the Classes of

Concrete Matrix on sheet 2-S1.20 unless noted otherwise on the drawings.

E.

3.

Headed stud anchors used as shear connectors for composite beams

shall be AWS D1.1 Type B (Table 7.1) studs manufactured in conformance with

specification ASTM A 108 with a minimum tensile strength of 65,000 PSI.

B.

1.

Hot Rolled Structural Members: All hot rolled steel plates, shapes,

sheet piling, and bars shall be new steel conforming to ASTM Specification

A 6.

Notes:

IR:

Intermediate Rib, Type F

2.

ASTM Specification and Grade: Clearly mark the grade of steel on

each piece, with a distinguishing mark visible from floor surfaces, for the

purpose of field inspection of proper grade of steel. Unless noted

otherwise on the drawings, structural steel shall be as follows:

a.

W-Shape Beams: ASTM A 992.

b.

W-Shape Columns: ASTM A 992.

c.

M- and S-Shapes: ASTM A 36.

d.

C-Shapes: ASTM A 36.

e.

L-Shapes: ASTM A 36.

f.

Round HSS: ASTM A 500, Grade B (Fy=42 ksi).

g.

Rectangular HSS: ASTM A 500, Grade B (Fy=46 ksi).

h.

Base Plates:

1)

Plates to 4" thick inclusive: ASTM A 572 Grade 50.

i.

Edge Angles, Bent Plates, Angle Hangers, and Angle Kickers: ASTM

A 36.

j.

Connection Material:

1)

Beam Column Continuity Plates and Doubler Plates: ASTM A

572, Grade 50.

2)

All connection material, except as noted otherwise herein

or on the drawings, including bearing plates, gusset plates,

stiffener plates, filler plates, angles, etc. shall conform to

ASTM A 36 unless a higher grade of steel is required by strength

and provided the resulting sizes are compatible with the connected

members.

k.

Other Steel: Any other steel not indicated otherwise shall

conform to ASTM A 992 or ASTM A 572, Grade 50, except plates and

angles that shall be ASTM A 36.

C.

Attachment of Deck:

a.

Minimum Attachment at Supports: Steel deck units shall be

fastened to all support members at each rib (36/7) with 3/4" diameter

puddle welds, unless noted otherwise. At members parallel to deck

span, spacing of fasteners shall be 6.

b.

Minimum Attachment at Side Laps: Side laps of adjacent units

shall be fastened by welding, sheet metal screws, or button punching

at a maximum of 12, unless noted otherwise.

2.

3.

4.

5.

6.

All Reinforcing Steel with bar sizes from No. 7 to No. 18 shall

conform to ASTM A 615, Grade 75 unless noted otherwise on the drawings. All

other bar sizes shall conform to ASTM A 615, Grade 60 unless noted

otherwise on the drawings.

Reinforcing Steel: Provide reinforcing steel conforming to ASTM A

706 for all reinforcing steel required to be welded and where noted on the

drawings.

Galvanized Reinforcing Steel: Provide reinforcing steel galvanized

according to ASTM A 767 Class II (2.0 oz. zinc PSF where noted on the

drawings).

Connection details not completely detailed on the drawings including

material grade and sizes, weld sizes, and number of bolts shall be designed

by the Contractor per the specifications. Conceptual connection details

with the required member design forces are shown on the drawings and are

applicable to all connections not designed and fully detailed on the

drawings. The conceptual details are provided only to indicate the

connection type required and may not fully represent the complexity of the

connection as required by the final connection design for the forces they

must resist. Additional connection elements may not be specifically shown

in the conceptual details but may be required by the final connection

design, such as stiffener plates, doubler plates, supplement/ reinforcing

plates or other connection material. The fabricator is responsible for

engaging the services of a connection specialty engineer to prepare a final

connection design for submission that meets the requirements of the

conceptual connection details and resists the indicated design forces.

2.

Refer to the Specifications for additional requirements.

3.

Reactions noted on the plans are based on factored loads and are

intended for use with the Load and Resistance Factor design method.

A.

CONTRACT DOCUMENTS

1.

It is the responsibility of the General Contractor to obtain all

Contract Documents and latest addenda and to submit such documents to all

subcontractors and material suppliers prior to the submittal of shop

drawings, fabrication of any structural members, and erection in the field.

2.

The contract structural drawings and specifications represent the

finished structure, and, except where specifically shown, do not indicate

the method or means of construction. The Contractor shall supervise and

direct the work and shall be solely responsible for all construction means,

methods, procedures, techniques, and sequence.

3.

Openings through floors, roofs, and walls for ducts, piping, and/or

conduit shall be coordinated by the contractor. Contractor shall verify

sizes and locations of holes and openings with the Mechanical, Electrical,

Plumbing, and Fire Protection drawings and the respective subcontractors.

4.

Refer to drawings other than Structural for complete information

including: Types of floor slab finishes and their locations, floor slab

depressions and curbs, openings in structural walls, roofs and floors

required by Architectural and MEP features, stairs, ramps, etc.

5.

Where member locations are not specifically dimensioned, members are

either located on columns lines or are equally spaced between located

members.

6.

If certain features are not fully shown or specified on the drawings

or in the specifications, their construction shall be of the same character

as shown or specified in similar conditions.

B.

Unless noted otherwise, all steel deck shall be manufactured by

[Verco (LARR #23789)] [Valley Joist (LARR #25476)] [ASC Profiles (LARR

#23783)] [Consolidated Systems (LARR #25038)] [Wheeling Corrugating Company

(LARR #25508)].

1.

C.

1.

A 325 Bolts: All bolts in structural connections shall conform to

ASTM A 325 Type 1, unless indicated otherwise on the drawings.

2.

A 490 Bolts: See drawings for locations requiring ASTM A 490 Type 1

bolts.

WELDING

A.

B.

Unless noted otherwise, electrodes for welding shall conform to

E70XX (SMAW), F7XX-EXXX (SAW), ER70S-X (GMAW), or E7XT-X (FCAW).

The Owners testing laboratory shall provide special inspection services

in accordance with the International Building Code for the following items.

1.

Steel Construction:

a.

All Field Welding

b.

High-Strength Bolting

c.

Inspection of Structural Steel, Bolting, Welding Material

d.

Welding of Structural Steel

2.

Concrete Construction:

a.

Bolts Installed in Concrete

b.

Concrete Work

c.

Continuous Inspection of Reinforcing Steel Placing

d.

Epoxy Bolts

e.

Formwork

f.

Reinforcing Steel Placement

g.

Welding of Reinforcing Steel

ANCHOR RODS

7.

Smooth Welded Wire Reinforcement: ASTM A 185, yield strength 65,000

PSI.

8.

Deformed Welded Wire Reinforcement: ASTM A 497, yield strength

70,000 PSI.

1.

The General Contractor shall verify all dimensions and conditions of

the existing building at the job site and report any discrepancies from

assumed conditions shown on the drawings to the Architect and Engineer

prior to the fabrication and erection of any members.

2.

Work shown on the drawings is New, unless noted as Existing.

3.

Existing construction shown on the drawings was obtained from

existing construction documents and limited site observation. These

drawings of existing construction are available for contractor use.

However, the available drawings of existing construction are not

necessarily complete. The contractor shall field verify all pertinent

information.

4.

The contractor shall verify the location of existing utilities prior

to the start of construction and take care to protect existing utilities

that are to remain in service.

5.

The contractor shall repair all damage caused during construction

with similar materials and workmanship to restore conditions to levels

acceptable to the Architect.

E.

ADJACENT BUILDINGS AND PROPERTY

The General Contractor shall ensure that all construction methods

used will not cause damage to the adjacent buildings and property. This

shall include all foundation installation.

4.

Soils:

a.

Prepared Earth Fill

2.

5.

Sprayed Fire-Resistant Materials

The General Contractor is advised to perform all photographic

surveys and other documentation of the adjacent buildings before the start

of and during construction.

STATEMENT OF SPECIAL INSPECTIONS

1.

F.

Special inspection is required for the items listed above. Refer to

Specification Section 014529 for type and extent of each special inspection

and each test. The Specification also indicates whether continuous or

periodic inspection is required for the items listed above additional

information.

RESPONSIBILITY OF THE CONTRACTOR FOR STABILITY OF THE STRUCTURE DURING

CONSTRUCTION

1.

Unless indicated otherwise in the Column Schedule or on the

drawings, anchor rods shall conform to ASTM F 1554 Grade 55 (with

Supplementary Requirement S1) and the size shall be 3/4" diameter and shall

embed into the concrete foundation a distance of 1-0" with a heavy hex nut

at the embedded end. Strike bolt threads at the embedded end at two places

below the nut.

PART X - SUBMITTALS

A.

SUBMITTAL LIST AND SCHEDULE

1.

Wherever welded wire reinforcement is specified as reinforcement, it

shall be continuous across the entire concrete surface and not interrupted

by beams or girders and properly lapped per ACI 318, 12.18 and 12.19.

REINFORCEMENT IN TOPPING SLABS

Grout below structural steel base plates shall be non-metallic,

non-shrink grout with a minimum strength of 8,000 psi.

B.

1.

End Supports and End Anchorage:

a.

Provide standard depth of bearing for all joists as shown below

unless noted otherwise on the drawings:

1)

All K Series: 2 1/2"

2)

All LH Series: 5"

3)

DLH Series through chord size 17: 5"

4)

DLH Series for chord sizes 18 and 19: 7 1/2"

b.

Provide flat bearing for all joists unless noted otherwise on

drawings. Increase the depth of the seat on the high end of sloped

joists as required to provide clearance for the connection.

DESIGN

1.

All joist sizes indicated on the drawings shall be considered

minimums. Increased sizes or reinforcement may be required in the final

designed by the joist manager. Joists shall carry the design loads as

specified in the SJI load tables as the minimum requirement. Additionally,

the joists shall be designed to carry any other load types and patterns as

indicated on the drawings.

2.

Steel joists, bridging, and their connections shall be designed for

a net uplift as indicated on the structural drawings.

3.

Steel joists, bridging, and their connections shall be designed for

additional down force resulting from wind as shown on the structural

drawings. Down force wind loading in combination with dead and live loads

may control the design of these elements.

The General Contractor shall prepare a detailed list and schedule of

all submittal items to be sent to the Structural Engineer prior to the

start of construction. This list shall be updated and revised and kept

current as the job progresses. The submittal list shall be organized as

shown below:

a.

Shop Drawings

b.

Design Calculations

c.

Product Data, Certificates, Reports, and Other Literature

SUBMITTALS TO BE PROVIDED TO STRUCTURAL ENGINEER

FABRICATION AND ERECTION

PLACEMENT OF WELDED WIRE REINFORCEMENT

1.

PROJECT LOCATION

700 NORTH SAN JACINTO

ST. HOUSTON, TX 77002

EXISTING CONDITIONS

1.

1.

B.

HARRIS COUNTY - JOINT

COUNTY/CITY

PROCESSING CENTER

Where conflict exists among the various parts of the structural

contract documents, structural drawings, general notes, and specifications,

the strictest requirements, as indicated by the Engineer, shall govern.

Masonry Construction:

a.

High-Lift Grouting

b.

Masonry Work

GROUT

Headed Stud Anchors for Embedded Plates: AWS D1.1 Type A studs

manufactured in conformance with specification ASTM A 108 with a minimum

tensile strength of 61,000 PSI.

Headed Shear Studs for Shear Reinforcement: ASTM A 1044 with a

minimum yield strength of 51,000 PSI.

07/17/2015

10/09/2015

PROJECT TITLE

The General Contractor shall compare the Architectural and

Structural drawings and report any discrepancy between each set of drawings

and within each set of drawings to the Architect and Engineer prior to the

fabrication and installation of any structural members.

3.

Electrodes for Grade 60 or Grade 65 material shall conform to E80XX

(SMAW), F8XX-EXX-XX (SAW), ER80S-X (GMAW), or E8XT-X (FCAW).

PART VII - STEEL JOISTS

Deformed Bar Anchors: AWS D1.1 Type C (Table 7.1) studs manufactured

in conformance with specification ASTM A 496 with a minimum yield strength

70,000 PSI. Reinforcing bars shall not be substituted for deformed bar

anchors.

ISSUED FOR PERMIT

1 REVISED

CONFLICTS IN STRUCTURAL REQUIREMENTS

1.

D.

REVISIONS

DRAWING CONFLICTS

PART IX - SPECIAL INSPECTIONS

STRUCTURAL BOLTS AND THREADED FASTENERS

1.

A.

3131 BRIARPARK

SUITE 200

HOUSTON, TEXAS 77042

[T] 713 622 1444

[F] 713 968 9333

PGAL TBPE REG. No. F-2742

www.pgal.com

CONSULTANT

Flat, Ridge, and Valley Plates:

Unless noted otherwise, Contractor shall provide flat plates (20 gage

minimum) at all locations where roof deck changes direction and ridge

or valley plates (20 gage minimum) at all locations where roof slope

exceeds 1/2" per foot.

MANUFACTURER

1.

The use of electronic files or reproductions of these contract

documents by any contractor, subcontractor, erector, fabricator, or

material supplier in lieu of preparation of shop drawings signifies their

acceptance of all information shown hereon as correct, and obligates

themselves to any job expense, real or implied, arising due to any errors

that may occur hereon.

CONNECTIONS

There shall be no horizontal construction joints in any concrete

pours unless shown on the drawings. The Architect/Engineer shall approve

all deviations or additional joints in writing.

F.

E.

3.

ARCHITECT

REPRODUCTION

Schedule:

IR

REINFORCING STEEL

1.

D.

Attachment of Deck:

a.

Minimum Attachment at Supports: Steel deck units shall be welded

to the support members with 5/8 diameter puddle welds at each end of

sheet and each intermediate support at each low flute, unless noted

otherwise. At members parallel to deck span, spacing of puddle welds

shall be 12. A shear connector welded through the deck can replace a

required deck weld.

b.

Minimum Attachment at Side Laps: Side laps of adjacent units

shall be fastened by welding, sheet metal screws, or button punching

at a maximum of one-half the span or 36, whichever is less, unless

noted otherwise.

20

2.

713.755.4400

PART XI - MISCELLANEOUS

ROOF DECK

1.

1001 PRESTON, 5TH FLOOR

HOUSTON, TX 77002

Shear Connector Sizes For Composite Steel Deck Construction. Stud

diameter and length (before weld, BW) shall be as follows:

a.

6.5 total slab thickness 3/4" diameter x 5 3/16" BW

1 1/2

1.

HORIZONTAL CONSTRUCTION JOINTS IN CONCRETE POURS

1.

C.

C.

CLASSES OF CONCRETE

1.

B.

7- 8

All deck shall be 40 KSI unless noted otherwise.

All Roofs

2.

A.

Submittal Requirements:

a.

All shop drawings must be reviewed and electronically stamped by

the General Contractor prior to submittal.

b.

Contractor shall provide the submittal in electronic portable

document format (PDF) per the Specifications.

c.

The omission from the shop drawings of any materials required by

the Contract Documents to be furnished shall not relieve the

Contractor of the responsibility of furnishing and installing such

materials, regardless of whether the shop drawings have been reviewed

and approved.

1.

MATERIAL

1.

PART IV - REINFORCED CONCRETE

7- 5

Type

Approval of Subgrade.

a.

Proofroll exposed subgrade below building with appropriate

compaction equipment. Conduct proofrolling operations only in the

presence of the Owner's Testing Laboratory. Undercut areas that "pump"

or "rut" during operations to firm natural soil, and backfill and

compact as specified.

b.

If unsuitable soil materials are encountered at required

subgrade elevations, carry excavations deeper and replace excavated

material with cement stabilized sand, lean concrete, or select fill as

directed by Owner's Testing Laboratory.

Subgrade Preparation.

a.

Scarify the top six inches of subgrade. Remove all unsuitable

materials and soft spots and replace with select fill. Re-compact the

top six inches and compact each lift of select fill material as

required at the optimum moisture content (( 2%) to 95% maximum density

for cohesive material (ASTM D-698). Place select fill in 8-inch loose

lifts.

b.

Install the moisture retarder.

c.

No slab-on-grade concrete shall be poured against a final

prepared subgrade containing free water, ice, frost, mud, or other

unsuitable material.

d.

Refer to the Project Specifications for additional information.

0.401

Gage

1.

Clearing and Grubbing. Remove all existing slabs, pavements, trash,

rubbish, debris, trees, roots, stumps, underbrush, grass, shrubs, plants

and other vegetation from within the slab-on-grade construction area.

0.305

Depth

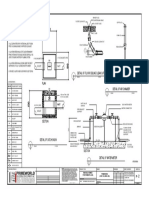

Grade Beams:

a.

Grade Beam Side Forms. Both sides of all grade beams shall be

formed for full beam depth.

b.

Bar Supports for Grade Beam Cages. Grade beam bottom steel shall

be chaired at 5-0" maximum centers using beam bolsters providing 3"

bottom cover to reinforcing steel. Beam bolsters used shall be

designed and manufactured for support on soil.

B.

0.334

Location

The geotechnical report is available to the General Contractor upon

request to the Owner. The information included therein may be used by the

General Contractor for his general information only. The Architect and

Engineer will not be responsible for the accuracy or applicability of such

data therein.

4.

Maximum Unshored Deck Span

(Two-Span)

(Three-Span)

2.

SCOPE

Refer to architects drawings for the extent of masonry walls.

Non-loadbearing walls may not be shown on the structural drawings.

20

I

[in^4]

Notes:

Sp = positive section modulus, inches^3

Sn = negative section modulus, inches^3

I = moment of inertia, inches^4

Splice Location And Type and Hooks For Unscheduled Beams and Slabs:

a.

Beams and Slabs. Unscheduled beams and slabs, including grade

beams, shall have continuous top bars lapped at midspan between

supports with a Class B tension splice. Bottom bars shall be lapped at

the supports with a Class B tension splice. All beam bars shall be

hooked at discontinuous end, unless noted otherwise.

1.

Submittals with Impact to Structure:

a.

Elevators

b.

Mechanical Equipment Weights

Schedule:

Depth Design

Minimum

of

Gage

Sp

Sn

Deck Thickness [in^3] [in^3]

PART V - CONCRETE MASONRY

A.

3.

COMPOSITE DECK

4.

D.

Superimposed load deflection is defined as all deflection anticipated

to occur after the cladding has been erected. The relative deflection

above does not include the floor deflection caused by the weight of

the cladding itself or the dead load deflection of the floor framing

itself, nor does it include any allowance for fabrication or erection

tolerances.

3.

All roof top equipment curbs, roof top mechanical equipment,

equipment tie downs, and connections of all equipment to building structure

for wind loading are to be designed and engineered by a registered

Specialty Engineer retained by the mechanical equipment supplier. Signed

and Sealed drawings and calculations are to be submitted to the engineer of

record for review and approval. The equipment manufacturer shall provide

the attachment of the unit to the structure and submit to the engineer

loads, locations, and methods of attachment. The structural engineer will

make provisions in the design of the primary structural frame to

accommodate the loads and attachments submitted by the manufacturer.

SLAB-ON-GRADE

BUILDING MOVEMENT AND DEFLECTIONS

The building movement specified herein is anticipated to occur and

should be considered by the Contractor in the performance of the work.

The handrail assemblies and guards shall be designed for 50 PLF or a

concentrated load of 200 pounds at any point applied in any direction at

the top and to transfer this load through the supports to the structure.

These loads need not be assumed to act concurrently.

OWNER

Refer to architectural drawings for fireproofing and/or UL rating

requirements.

PART VIII - STEEL DECKS

SPLICES AND HOOKS IN REINFORCING STEEL

PART III - BUILDING EARTHWORK

No provisions for any future expansions have been made in the

structural design.

1.

1.

H.

Provide minimum reinforcement as noted below in all housekeeping

pads supporting mechanical equipment unless specified otherwise on the

drawings.

a.

Welded smooth wire reinforcement 6x6-W2.9xW2.9.

REINFORCING STEEL COVERAGE

SHALLOW FOUNDATION TYPE

1.

FUTURE EXPANSION

1.

G.

GEOTECHNICAL REPORT

WIND LOAD

(PSF)

+27.9/-30.3

+26.7/-29.0

+25.1/-27.4

+23.8/-26.1

+27.9/-37.2

+26.7/-34.8

+25.1/-31.5

+23.8/-29.0

+69.8/-48.9

+63.1/-46.4

+54.3/-43.1

+47.6/-40.7

+69.8/-55.9

+63.1/-52.1

+54.3/-47.2

+47.6/-43.5

+12.4/-30.5

+11.6/-29.7

+10.6/-28.7

+10.0/-27.9

+27.9/-51.2

+26.7/-45.8

+25.1/-38.5

+23.8/-33.1

+27.9/-51.2

+26.7/-45.8

+25.1/-35.8

+23.8/-33.1

+10.0/-44.0

+10.0/-43.2

+10.0/-42.2

+10.0/-41.4

+10.0/-44.0

+10.0/-43.2

+10.0/-42.2

+10.0/-41.4

1.

A.

Reduction of Live Loads:

a.

Live loads have been reduced using the alternate procedure from

the building code.

b.

For live loads exceeding 100 pounds per square foot, no

reduction has been made, except that the design live load on members

supporting two or more floors has been reduced a maximum of 20 percent

but the live load is not to be less than that calculated by the

formula above.

Machine Beam, Car Buffer, Counterweight Buffer, and Guide Rail

Loads: Assumed elevator loads have been used in the design of the

supporting structure, including machine beam reactions, car buffer

reactions, counterweight buffer reactions, and horizontal and vertical

guide rail loads. The General Contractor shall submit to the Structural

Engineer final elevator shop drawings showing all loads to the structure

prior to the installation of the elevators for verification of load

carrying capacity.

The structural strength of grab bars, tub and shower seats,

fasteners, and mounting devices shall meet the following specification:

a.

Bending stress in a grab bar or seat induced by the maximum

bending moment from the application of 250 lbf shall be less than the

allowable stress for the material of the grab bar or seat.

b.

Shear stress induced in a grab bar or seat by the application of

250 lbf shall be less than the allowable shear stress for the material

of the grab bar or seat. If the connection between the grab bar or

seat and its mounting bracket or other support is considered to be

fully restrained, then direct and torsional shear stresses shall be

totaled for the combined shear stress, which shall not exceed the

allowable shear stress.

c.

Shear force induced in a fastener or mounting device from the

application of 250 lbf shall be less than the allowable lateral load

of either the fastener or mounting device or the supporting structure,

whichever is the smaller allowable load.

d.

Tensile force induced in a fastener by a direct tension force of

250 lbf plus the maximum moment from the application of 250 lbf shall

be less than the allowable withdrawal load between the fastener and

the supporting structure.

e.

Grab bars shall not rotate within their fittings.

official.

Deferred submittal items shall not be installed until the

deferred submittal documents have been approved by the building

official.

REINFORCEMENT IN HOUSEKEEPING PADS

PART II - FOUNDATION

1.

H.

FIRE RATING

ROOFTOP EQUIPMENT ANCHORAGE

WIND LOADS

1.

G.

C.

5.

ELEVATOR LOADS

1.

F.

F.

HANDRAILS AND GUARDS

2.

E.

c.

1.

TEXAS ARCHITECTURAL BARRIER ACT STANDARD

DEAD LOADS

1.

D.

Provide minimum reinforcement as noted below in all topping slabs

unless specified otherwise on the drawings.

a.

Welded smooth wire reinforcement 6x6-W2.9xW2.9.

PART X - SUBMITTALS (CONTINUED)

DEAD AND LIVE LOADS

1.

C.

Lateral Frame Wind Deflection (Drift): The following provision for

lateral frame deflection in the plane of the wall of one floor relative to

an adjacent floor shall be made in the design, fabrication and installation

of the building cladding:

a.

Typical Floor to Floor: Floor Height/400

The deflections listed above are based on wind loads with a 10-year

mean recurrence interval.

PART VII - STEEL JOISTS (CONTINUED)

Structural Submittals: In addition to the submittals required by the

structural specifications, the following submittals shall be provided:

a.

Layout of Embedded Items (Plates, Angles, Bolts, etc.) or Items

Attached to the Structural Frame for Building Cladding Attachment or

for Attachment of Other Items.

b.

Layout of Mechanical, Electrical, and Plumbing Openings in Floor

and Roof Structure.

c.

Layout of Penetrations in Beams.

G.

RESPONSIBILITY OF THE CONTRACTOR FOR CONSTRUCTION LOADS

1.

2.

Deferred Submittals:

a.

The following items are considered deferred submittals by the

registered design professional in responsible charge:

1)

Exterior Window Wall System (S&S, REC)

2)

Formwork, Shoring, and Backshoring (S&S, REC)

3)

Roof Top Equipment and Anchorages (S&S)

4)

Steel Joists (S&S)

5)

Steel Stairs (S&S)

6)

Structural Steel Connections (S&S)

7)

Window Washing and Fall Arrest Systems (S&S)

Notes:

(S&S)

Items marked thus shall have the shop drawings and delegated

design submittals (including calculations) sealed per the project

specifications by an engineer registered in the state where the

project is located.

H.

All structural elements of the project have been designed by the

Structural Engineer to resist the required code vertical and lateral forces

that could occur in the final completed structure only. The ability of the

structural frame to resist the required code forces derives from the

complete installation of the lateral force resisting systems and diaphragms

described below. It is the responsibility of the Contractor to provide all

required bracing during construction to maintain the stability and safety

of all structural elements during the construction process until the

lateral-load resisting or stability-providing system is completely

installed and all designated concrete elements (if any) have reached a

minimum of 75% of their design strength. The required structural elements

are:

a.

Steel Frames:

1)

Lateral-Force Resisting System

a)

Dual System, indicated on the drawings as a combination

of moment frames and braced frames.

2). Diaphragm

b)

A steel deck diaphragm that is completely attached to

all roof members according to specifications and that creates

a continuous element linking the lateral-force resisting

system to all other columns.

b.

Concrete Frames:

1)

Lateral-Force Resisting System

a)

Concrete Moment Frames

2)

Diaphragm: A concrete floor slab that creates a continuous

element linking the lateral-force-resisting elements to all other

columns.

c.

Slab-on-Grade:

1)

Diaphragm

a)

The slab-on-grade is not used as a structural diaphragm

The structure has been designed for the loads identified within

these structural drawings that are anticipated to be applied to the final

structure once completed and occupied. The Contractor shall not overload

the structure during construction. The Contractor shall be responsible for

checking the adequacy of the structure to support any applied construction

loads, including those due to construction vehicles or equipment, material

handling or storage, shoring or reshoring, or any other construction

activity. The Contractor shall submit calculations signed and sealed by an

engineer licensed in the state where the project is located verifying the

adequacy of the structure for any proposed construction loads that are in

excess of the stated design loads. The Structural Engineer is not

responsible to design or check the structure for loads applied to the

structure for any construction activity.

CONTRACTOR SUBSTITUTIONS

(REC)

Items marked thus shall be submitted to Engineer for Record

Only and will not have the Engineers shop drawing stamp affixed.

Any materials or products submitted for approval that are different

from the material or products specified in the structural contract

documents will be approved only if the following criteria are satisfied:

a.

A cost savings to the Owner is documented and submitted with the

request.

b.

b.

Documents for deferred submittal items shall be submitted to the

registered design professional and shall be forwarded to the building

1.

The material or product has been approved by the International

Code Council (ICC) and the ICC report is submitted with the request.

Alexandria Atlanta Austin Boca Raton Boston Dallas Houston Las Vegas Los Angeles New Orleans Mexico City Pierce Goodwin Alexander & Linville

PART I - DESIGN CRITERIA

KEY PLAN

REGISTRATION

COPYRIGHT 2015

10/09/2015

PROJECT NUMBER

1002005

CURRENT DOCUMENT STAGE

ISSUED FOR PRICING

CURRENT ISSUE DATE

10/09/15

ORIGINAL ISSUE DATE

07/17/15

SHEET TITLE

GENERAL NOTES

SHEET NUMBER

2-S1.00

You might also like

- Earthquake Lateral Forces Calculations According To UBC97: InputDocument10 pagesEarthquake Lateral Forces Calculations According To UBC97: InputOnurUmanNo ratings yet

- Concrete Estimate by Jack FajardoDocument67 pagesConcrete Estimate by Jack FajardojAck oяenseNo ratings yet

- Structural Load Design Criteria For Office BuildingDocument4 pagesStructural Load Design Criteria For Office Buildingnap_carinoNo ratings yet

- Design of RC Box-Culverts: A) Case 1 B) Case 2 C) Case 3Document6 pagesDesign of RC Box-Culverts: A) Case 1 B) Case 2 C) Case 3Haftom GebreegziabiherNo ratings yet

- WallSystems PDFDocument26 pagesWallSystems PDFEiz Zu DeenNo ratings yet

- Samson FootingDocument7 pagesSamson FootingJoseph Cloyd L. LamberteNo ratings yet

- Col PedDocument1 pageCol PedMark Christian EsguerraNo ratings yet

- 2 M High Free Standing WallDocument20 pages2 M High Free Standing WallAnonymous ciKyr0tNo ratings yet

- Steel Frame Structure Modeling by Staad-Pro (Example - 2) by Prof. Dr. Nabeel Al-BayatiDocument6 pagesSteel Frame Structure Modeling by Staad-Pro (Example - 2) by Prof. Dr. Nabeel Al-BayatiProfessor Dr. Nabeel Al-Bayati-Consultant Engineer100% (1)

- US Stair oDocument3 pagesUS Stair oRenvil PedernalNo ratings yet

- Roof DesignDocument1 pageRoof DesignJane RoNo ratings yet

- Magsalay Seismic Loading AnalysisDocument2 pagesMagsalay Seismic Loading AnalysisKarl HelbiroNo ratings yet

- Barrymore Steel TrussDocument3 pagesBarrymore Steel TrussJoseph Cloyd L. LamberteNo ratings yet

- Multilevel Parking BLDG FINALDocument46 pagesMultilevel Parking BLDG FINALMichael Bautista BaylonNo ratings yet

- Pedestal Design For Pedestal Marked As "P3" (500 MM X 400 MM)Document3 pagesPedestal Design For Pedestal Marked As "P3" (500 MM X 400 MM)NAYAN RANPURANo ratings yet

- Combined Footing Design1Document39 pagesCombined Footing Design1John Carlo Amodia0% (2)

- Dynamic: Arca South JSS Brgy. Western Bicutan, Arca South, Taguig City 9/14/2017 Bamberton Development Corporation 6Document26 pagesDynamic: Arca South JSS Brgy. Western Bicutan, Arca South, Taguig City 9/14/2017 Bamberton Development Corporation 6Jan LhesterNo ratings yet

- Design of Purlins: With Engr. Mark Lehi P. Palmes Faculty-RMMC Civil Engineering Program Review LecturerDocument5 pagesDesign of Purlins: With Engr. Mark Lehi P. Palmes Faculty-RMMC Civil Engineering Program Review LecturerMohammad Taha PumbayaNo ratings yet

- Column Design Rectangular Columns (Biaxial Bending)Document4 pagesColumn Design Rectangular Columns (Biaxial Bending)ahmadove1No ratings yet

- Structural ReportDocument13 pagesStructural ReportDan SantosNo ratings yet

- Grid 1 and 6Document29 pagesGrid 1 and 6Jonniel De GuzmanNo ratings yet

- Structural Steel Design by Jay Ryan SantosDocument19 pagesStructural Steel Design by Jay Ryan SantosjayryansantosNo ratings yet

- Lecture 2 - Reinforced Concrete - Design of Rectangular BeamDocument44 pagesLecture 2 - Reinforced Concrete - Design of Rectangular BeamChristopher PaladioNo ratings yet

- Steel Members DesignDocument26 pagesSteel Members DesignApple Grace S. ValenciaNo ratings yet

- Isolated Footing Design For Pipe Supports/Sliding Supports (SS) Serial NoDocument11 pagesIsolated Footing Design For Pipe Supports/Sliding Supports (SS) Serial NoNazeer NNo ratings yet

- Slab Design FlowDocument4 pagesSlab Design FlowLerie Lou R. PenarroyoNo ratings yet

- Detail of Floor/ Ceiling Clean Out: Plumbing NotesDocument1 pageDetail of Floor/ Ceiling Clean Out: Plumbing NotesRODEAN HOPE LACSINo ratings yet

- Reinforced Concrete One Way Slab DesignDocument7 pagesReinforced Concrete One Way Slab DesignEngr Benalito A Catap IIINo ratings yet

- Dimension Is 300mm X 300mm of Columns With 4pcs - Ø16mmDocument1 pageDimension Is 300mm X 300mm of Columns With 4pcs - Ø16mmMark Christian EsguerraNo ratings yet

- Roof DeckDocument2 pagesRoof DeckRayodcNo ratings yet

- Slab 1 DesignDocument1 pageSlab 1 DesignJoseph Cloyd LamberteNo ratings yet

- One Way Slab Design: Ref: Nilson-13Th Edition-418 Page ExampleDocument4 pagesOne Way Slab Design: Ref: Nilson-13Th Edition-418 Page Examplerasedul islamNo ratings yet

- Pile Cap Design For 3-Piles Pattern Based On ACI 318-14Document6 pagesPile Cap Design For 3-Piles Pattern Based On ACI 318-14Anjo BalucasNo ratings yet

- 55m Span Shed - Rev 02Document13 pages55m Span Shed - Rev 02Jagadeesh SundaramNo ratings yet

- 5417.ductile Special Beam Design As Per ACI 318MDocument4 pages5417.ductile Special Beam Design As Per ACI 318MNapoleon CarinoNo ratings yet

- CD1 - Introductory ConceptsDocument40 pagesCD1 - Introductory Conceptscharles guetaNo ratings yet

- Wind Load and Roof Load CalculationDocument20 pagesWind Load and Roof Load CalculationleodegarioporralNo ratings yet

- Dimension Is 300mm X 300mm of Columns With 4pcs - Ø16mmDocument1 pageDimension Is 300mm X 300mm of Columns With 4pcs - Ø16mmMark Christian Esguerra100% (1)

- H D E G: Male C.R. PWD C.R. Female C.R. Pump RMDocument1 pageH D E G: Male C.R. PWD C.R. Female C.R. Pump RMMark Christian EsguerraNo ratings yet

- 1-Load ParametersDocument97 pages1-Load ParametersJuNe RaMos JavierNo ratings yet

- Proportioning Concrete MixDocument4 pagesProportioning Concrete MixhahaduNo ratings yet

- Project Title: Location: Owner: Bill of Quantities: General RequirementsDocument4 pagesProject Title: Location: Owner: Bill of Quantities: General RequirementsTano ChavezNo ratings yet

- Windload AnalysisDocument6 pagesWindload AnalysisJerico Enriquez CacaoNo ratings yet

- Design Recommendations For Steel Deck Floor SlabsDocument32 pagesDesign Recommendations For Steel Deck Floor Slabswayzane100% (1)

- RW Part 3Document33 pagesRW Part 3Czarina SicatNo ratings yet

- Seismic AnalysisDocument13 pagesSeismic AnalysisJea Manguing-YubalNo ratings yet

- Building Permit Lis11111t SssDocument170 pagesBuilding Permit Lis11111t SsskanannnNo ratings yet

- Design of Long-Span TrussDocument51 pagesDesign of Long-Span TrussFeigyl Miro100% (4)

- Structural DesignDocument55 pagesStructural Designapril rose biluganNo ratings yet

- Theory StructureDocument2 pagesTheory StructurehallelNo ratings yet

- Rebar Take Off (Skyway)Document2 pagesRebar Take Off (Skyway)Allan SorianoNo ratings yet

- Design Criteria Stru.Document9 pagesDesign Criteria Stru.Ar John Bernard AbadNo ratings yet

- Materials For Construction (Eerc)Document18 pagesMaterials For Construction (Eerc)JOHN CARLO DE GUZMAN AMBAY (JCDGA)No ratings yet

- SECTION 05 12 00 Structural Steel FramingDocument6 pagesSECTION 05 12 00 Structural Steel FramingmiteshsuneriyaNo ratings yet

- Structural Design Calculation ReportDocument26 pagesStructural Design Calculation Reportjenomada buildesignNo ratings yet

- Steel Floor Deck Guide SpecificationsDocument5 pagesSteel Floor Deck Guide SpecificationsRafaArdiSyahrezaNo ratings yet

- FL Cold Formed Metal FramingDocument10 pagesFL Cold Formed Metal FramingTaher AmmarNo ratings yet

- Uniform General Conditions For Construction Contracts, State of Texas, 2010 (UGC) - ConstructionDocument10 pagesUniform General Conditions For Construction Contracts, State of Texas, 2010 (UGC) - ConstructionsbunNo ratings yet

- Uniform General Conditions For Construction Contracts, State of Texas, 2010 (UGC) - ConstructionDocument13 pagesUniform General Conditions For Construction Contracts, State of Texas, 2010 (UGC) - ConstructionTaher AmmarNo ratings yet

- 31 63 29 Drilled Concrete PiersDocument13 pages31 63 29 Drilled Concrete PierssbunNo ratings yet

- Additional NotesDocument7 pagesAdditional NotesGodino ChristianNo ratings yet

- Global Mapper TutorialDocument14 pagesGlobal Mapper TutorialGodino ChristianNo ratings yet

- GE 441 Course Syllabus-2008Document2 pagesGE 441 Course Syllabus-2008Godino ChristianNo ratings yet

- Decelaration Lane DesignDocument3 pagesDecelaration Lane DesignGodino ChristianNo ratings yet

- Chelsey EPPDocument3 pagesChelsey EPPGodino ChristianNo ratings yet

- Happy 4TH BirthdayDocument1 pageHappy 4TH BirthdayGodino ChristianNo ratings yet

- Drawing ListDocument1 pageDrawing ListGodino ChristianNo ratings yet

- Lot Information: Golden Bear Loop WestDocument1 pageLot Information: Golden Bear Loop WestGodino ChristianNo ratings yet

- Sample SmartviewDocument1 pageSample SmartviewGodino ChristianNo ratings yet

- No Sugar ChallengeDocument1 pageNo Sugar ChallengeGodino ChristianNo ratings yet

- RoofingDocument1 pageRoofingGodino ChristianNo ratings yet

- Regional Manager NIA Region 3, Tambubong, San Rafael, BulaacanDocument1 pageRegional Manager NIA Region 3, Tambubong, San Rafael, BulaacanGodino ChristianNo ratings yet

- FACADE MODELING Structural AnalysisDocument39 pagesFACADE MODELING Structural AnalysisGodino Christian100% (3)

- Asphalt and Concrete PavementDocument3 pagesAsphalt and Concrete PavementGodino ChristianNo ratings yet

- PHYSICAL WEATHERING - FrancesDocument5 pagesPHYSICAL WEATHERING - FrancesGodino ChristianNo ratings yet

- Vaccine - Ate FormDocument2 pagesVaccine - Ate FormGodino ChristianNo ratings yet

- Alang Drainage - CIVIL3D - Final-CS1Document1 pageAlang Drainage - CIVIL3D - Final-CS1Godino ChristianNo ratings yet

- Alang Drainage - CIVIL3D - Final-C-2Document1 pageAlang Drainage - CIVIL3D - Final-C-2Godino ChristianNo ratings yet

- Pavement AnalysisDocument19 pagesPavement AnalysisGodino ChristianNo ratings yet

- Form 09 01-02 APP For EMP CHRISTIAN GODINODocument5 pagesForm 09 01-02 APP For EMP CHRISTIAN GODINOGodino ChristianNo ratings yet

- Using Dropbox For Work? Try Dropbox Business!: Upgrade NowDocument1 pageUsing Dropbox For Work? Try Dropbox Business!: Upgrade NowGodino ChristianNo ratings yet

- Poblacion 7, Water System, Can AvidDocument142 pagesPoblacion 7, Water System, Can AvidGodino ChristianNo ratings yet

- Sabah Seismic Hazard MapDocument1 pageSabah Seismic Hazard MapAbu AimonNo ratings yet

- Structures 3 - Structures That Span Over A SpaceDocument9 pagesStructures 3 - Structures That Span Over A SpaceSarah HantonNo ratings yet

- 3S Structural Engineering Design Manual - Revision 5Document74 pages3S Structural Engineering Design Manual - Revision 5Lampard ChenNo ratings yet

- Zifeng Tower - Ramazan SariDocument2 pagesZifeng Tower - Ramazan SariNadya Pricilia100% (1)

- A Study On Properties of Foamed Concrete With Fly Ash and Marble Sludge PowderDocument4 pagesA Study On Properties of Foamed Concrete With Fly Ash and Marble Sludge PowderAnuraagNo ratings yet

- CIP 01 - Dusting Concrete SurfacesDocument2 pagesCIP 01 - Dusting Concrete Surfacesedward the iiiNo ratings yet

- Dynamic Behavior of Box Type Scaled Stabilized Earth and Fired Clay Block Masonry Building ModelsDocument12 pagesDynamic Behavior of Box Type Scaled Stabilized Earth and Fired Clay Block Masonry Building ModelsNanjund Rao KsNo ratings yet

- CHLORINATION BUILDING-ARCH-001.Rev BDocument1 pageCHLORINATION BUILDING-ARCH-001.Rev BtumuuNo ratings yet

- 2010 SJI Composite Joist COSP Final 25mar111Document15 pages2010 SJI Composite Joist COSP Final 25mar111Samir DjezzarNo ratings yet

- (Asce) 1084-0702 (2001) 6 3Document10 pages(Asce) 1084-0702 (2001) 6 3bistsushantNo ratings yet

- Bridge Inspection Manual NYDocument336 pagesBridge Inspection Manual NYcaradasca100% (2)

- TERA Joint-Floor Joint SystemDocument16 pagesTERA Joint-Floor Joint SystemAmir ZahirovicNo ratings yet

- Design of Combined FootingDocument26 pagesDesign of Combined FootingSujan SinghNo ratings yet

- Is 10297 1982 PDFDocument21 pagesIs 10297 1982 PDFakhilrajtvNo ratings yet

- Harga Lantai Kayu ParketDocument4 pagesHarga Lantai Kayu ParketAliNo ratings yet

- Truss - 1 Detail 1: See Spot Purlin DetailDocument1 pageTruss - 1 Detail 1: See Spot Purlin DetailEarl Vergille Petiluna ReveloNo ratings yet

- R2 - Design Formulae For Bending (2014!08!01)Document44 pagesR2 - Design Formulae For Bending (2014!08!01)Abhishek KumarNo ratings yet

- Design of Multi-Story Residential Building and Its FoundationDocument63 pagesDesign of Multi-Story Residential Building and Its FoundationpetalNo ratings yet

- Scope of Work - Commercial LineDocument2 pagesScope of Work - Commercial LinesalmanNo ratings yet

- Recommended Erection Instructions For Steel FramesDocument32 pagesRecommended Erection Instructions For Steel FramesYel DGNo ratings yet

- 303 - Soil and FoundationDocument97 pages303 - Soil and FoundationLei TaiNo ratings yet

- Concrete Structures For Retaining Aqueous Liquids - Code of PracticeDocument28 pagesConcrete Structures For Retaining Aqueous Liquids - Code of PracticeManvendra Nigam100% (3)

- Failures and Repair of Silo and BunkersDocument51 pagesFailures and Repair of Silo and BunkersBalan-Nogi Dan100% (1)

- Brochure MetalDocument28 pagesBrochure Metalonkar_kashyapNo ratings yet

- Jahada-Ward No-3 - 1croreDocument23 pagesJahada-Ward No-3 - 1crorenitish JhaNo ratings yet

- RCC Details of Terrace Floor PlanDocument1 pageRCC Details of Terrace Floor PlanS V ENTERPRISESNo ratings yet

- SRX07379 EC Retaining Wall Worked Example - 2016-1Document29 pagesSRX07379 EC Retaining Wall Worked Example - 2016-1Bhagwat RautelaNo ratings yet

- Cantilever Footing 1Document8 pagesCantilever Footing 1Hafiz Kamarudin100% (2)

- Methodology For Calculating Life Expectancy of Existing StructuresDocument6 pagesMethodology For Calculating Life Expectancy of Existing StructuresganeshNo ratings yet

- Chapter 1 RC II Columns Design NotesDocument17 pagesChapter 1 RC II Columns Design NotesMesfin Derbew100% (10)