Professional Documents

Culture Documents

Chequered Plate

Uploaded by

saravanan4286Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chequered Plate

Uploaded by

saravanan4286Copyright:

Available Formats

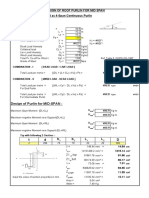

INPUT DATA FOR CHEQUERED PLATE DESIGN :

Case:1 Upper Floors

Sl.No

Description

Unit

Symbol

Values

Maximum Width of Plate

1.230

Thickness of Plate

0.006

Unit Weight of Steel

kN/m2

78.50

Live Load Considered over Chequered Plate

kN/m2

P1

Yield Stress of Steel

N/mm2

fy

275

Youngs Modulus of steel

kN/m2

200000

Unit

Symbol

Values

kN/m2

P2

0.471

kN/m2

P1

kN/m

5.471

Unit

Symbol

Values

= ( 5.471 x 1.23^2 ) / 8

kN.m

1.035

= (1000 x 6^3 ) / 12

mm4

18000

= ( 18000 / (6 / 2 ))

mm3

6000

N/mm2

fs

172.500

N/mm2

fb

220

(A)--LOADING CALCULATION:

Description

Self Weight of plate

Expression

= (0.006 x 78.5 )

Live Load over chequered plate

Total load on Plate

= P1 + P2

= ( 5 + 0.471)

Description

Expression

(B) --BENDING MOMENT CALCULATION:

Maximum Bending Moment

= ( W x B2 ) / 8

Moment of Inertia

Section Modulus

(C) --CHECK FOR BENDING STRESS:

Actual Bending Stress

=M/Z

= (1.035 x 10^6) / 6000

Permissible Bending Stress (As per BS 5950-1:2000 Clause 4.3.8)

= 0.8 x fy

= 0.8 x 275

fb > fs

HENCE SAFE

(D) --CHECK FOR DEFLECTION:

Actual Deflection

= (( 5 x W x B^4 ) / ( 384 x E x I ))

= (( 5 x 5.471 x 1.23^4 ) 10^9 / ( 384 x 200000 x

18000 ))

mm

0.045

mm

6.15

Allowable Deflection (As per BS 5950-1:2000 Table 8)

= B / 200

= 1230 / 200

a >

HENCE SAFE

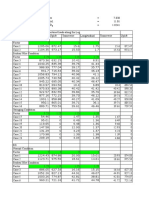

INPUT DATA FOR CHEQUERED PLATE DESIGN :

Case:2 Upper Floors

Sl.No

Description

Unit

Symbol

Values

Maximum Width of Plate

1.230

Thickness of Plate

0.008

Unit Weight of Steel

kN/m2

78.50

Live Load Considered over Chequered Plate

kN/m2

P1

20

Yield Stress of Steel

N/mm2

fy

275

Youngs Modulus of steel

kN/m2

200000

Unit

Symbol

Values

kN/m2

P2

0.628

kN/m2

P1

kN/m

5.628

Unit

Symbol

Values

= ( 0.628 x 1.23^2 ) / 8+(5 x 1.23)/4

kN.m

1.656

= (1000 x 8^3 ) / 12

mm4

42667

= ( 42666.667 / (8 / 2 ))

mm3

10667

N/mm2

fs

155.250

N/mm2

fb

220

(A)--LOADING CALCULATION:

Description

Self Weight of plate

Expression

= (0.008 x 78.5 )

Live Load over chequered plate

Total load on Plate

= P1 + P2

= ( 5 + 0.628)

Description

Expression

(B) --BENDING MOMENT CALCULATION:

Maximum Bending Moment

= ( P2 x B2 ) / 8 + (P1 * B)/4

Moment of Inertia

Section Modulus

(C) --CHECK FOR BENDING STRESS:

Actual Bending Stress

=M/Z

= (1.656 x 10^6) / 10666.667

Permissible Bending Stress (As per BS 5950-1:2000 Clause 4.3.8)

= 0.8 x fy

= 0.8 x 275

fb > fs

HENCE SAFE

Note:

1. The Chequered plate is designed for 500kg, whereas rest of the equipments loads

shall be load on Main & Secondary Beams

2. The seismic & Wind loads are taken care by the column & beams

(D) --CHECK FOR DEFLECTION:

Actual Deflection

= (( 5 x 0.628 x 1.23^4 ) 10^9 / ( 384 x 200000 x

= (( 5 x P2 x B^4 ) / ( 384 x E x I ))+

42666.667 ))+((5x1.23^3)x10^9/

(( P1 x B^3 ) / ( 48 x E x I ))

(48x200000x42666.667)

mm

0.025

mm

6.15

Allowable Deflection (As per BS 5950-1:2000 Table 8)

= B / 200

= 1230 / 200

a >

HENCE SAFE

8mm thk plate is required for 500kg Concetrated load

INPUT DATA FOR CHEQUERED PLATE DESIGN :

Case:2 Upper Floors "Reduced the width from 1.230 to 0.615m inorder to satisfy the 6mm thick"

Sl.No

Description

Unit

Symbol

Values

Maximum Width of Plate (Stiffener angle shall be added at the mid)

0.615

Thickness of Plate

0.006

Unit Weight of Steel

kN/m2

78.50

Live Load Considered over Chequered Plate

kN/m2

P1

20

Yield Stress of Steel

N/mm2

fy

275

Youngs Modulus of steel

kN/m2

200000

Unit

Symbol

Values

kN/m2

P2

0.471

kN/m2

P1

kN/m

5.471

Unit

Symbol

Values

= ( 0.471 x 0.615^2 ) / 8+(5 x 0.615)/4

kN.m

0.791

= (1000 x 6^3 ) / 12

mm4

18000

= ( 18000 / (6 / 2 ))

mm3

6000

N/mm2

fs

131.833

N/mm2

fb

220

(A)--LOADING CALCULATION:

Description

Self Weight of plate

Expression

= (0.006 x 78.5 )

Live Load over chequered plate

Total load on Plate

= P1 + P2

= ( 5 + 0.471)

Description

Expression

(B) --BENDING MOMENT CALCULATION:

Maximum Bending Moment

= ( P2 x B2 ) / 8 + (P1 * B)/4

Moment of Inertia

Section Modulus

(C) --CHECK FOR BENDING STRESS:

Actual Bending Stress

=M/Z

= (0.791 x 10^6) / 6000

Permissible Bending Stress (As per BS 5950-1:2000 Clause 4.3.8)

= 0.8 x fy

= 0.8 x 275

fb > fs

HENCE SAFE

Note:

1. The Chequered plate is designed for 500kg, whereas rest of the equipments loads

shall be load on Main & Secondary Beams

2. The seismic & Wind loads are taken care by the column & beams

(D) --CHECK FOR DEFLECTION:

Actual Deflection

= (( 5 x 0.471 x 0.615^4 ) 10^9 / ( 384 x 200000

= (( 5 x P2 x B^4 ) / ( 384 x E x I ))+

x 18000 ))+((5x0.615^3)x10^9/

(( P1 x B^3 ) / ( 48 x E x I ))

(48x200000x18000)

mm

0.007

mm

3.08

Allowable Deflection (As per BS 5950-1:2000 Table 8)

= B / 200

= 615 / 200

a >

HENCE SAFE

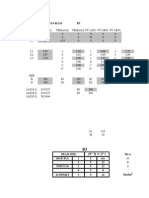

INPUT DATA FOR CHEQUERED PLATE DESIGN :

Case:2 Staitways

Sl.No

Description

Unit

Symbol

Values

Maximum Width of Plate

1.500

Thickness of Plate

0.008

Unit Weight of Steel

kN/m2

78.50

Live Load Considered over Grating

kN/m2

P1

Yield Stress of Steel

N/mm2

fy

275

Youngs Modulus of steel

kN/m2

200000

Unit

Symbol

Values

kN/m2

P2

0.628

kN/m2

P1

kN/m

5.628

Unit

Symbol

Values

kN.m

1.583

m4

42667

mm3

10667

N/mm2

fs

148.406

N/mm2

fb

220

(A)--LOADING CALCULATION:

Description

Self Weight of plate

Expression

= (0.008 x 78.5 )

Live Load over chequered plate

Total load on Plate

= P1 + P2

= ( 5 + 0.628)

Description

Expression

(B) --BENDING MOMENT CALCULATION:

Maximum Bending Moment

= ( W x B2 ) / 8

= ( 5.628 x 1.5^2 ) / 8

Moment of Inertia

= (1000 x 8^3 ) / 12

Section Modulus

= ( 42666.667 / (8 / 2 ))

(C) --CHECK FOR BENDING STRESS:

Actual Bending Stress

=M/Z

= (1.583 x 10^6) / 10666.667

Permissible Bending Stress (As per BS 5950-1:2000 Clause 4.3.8)

= 0.8 x fy

= 0.8 x 275

fb > fs

HENCE SAFE

(D) --CHECK FOR DEFLECTION:

Actual Deflection

= (( 5 x W x B^4 ) / ( 384 x E x I ))

= (( 5 x 5.628 x 1.5^4 ) 10^9 / ( 384 x 200000 x

42666.667 ))

mm

0.043

mm

7.50

Allowable Deflection (As per BS 5950-1:2000 Table 8)

= B / 200

= 1500 / 200

a >

HENCE SAFE

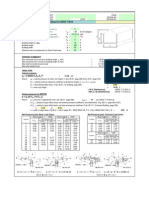

LARSEN & TOUBRO LIMITED

ECC Division - EDRC

Project :

220 Kv D/c Transmission Line From

Shahama East To Samha Sub Station

Title :

Wind Pressure & Sag Tension Calculcaion

DOCUMENT NO :

O1033.T.TL - Sag-01

Date : 07/06/2001

DESIGNED

CHECKED

ARA

SMP

Sheet

OF 3

WIND PRESSURE CALCULATIONS AS PER DIV VDE 0210 :

Wind Speed for Conductor/ Earthwire as per MOM Dated 26.05.01 in KMPH

150

= 41.67 in m/sec

Wind Speed for Insulator/Tower body as per MOM Dated 26.05.01 in KMPH

160

= 44.44 in m/sec

Basis Span for Sag Tension calculation as per Schedule C2 in M (L)

450

As per DIN VDE 0210 and their further clarification dated 24.11.95, the dynamic wind pressure (q) in Table 5 of DIN VDE 0210 is arrived for

a basic wind speed of 120 Kmph. Hence for a wind speed of 150 Kmph, the dynamic wind pressure in Table 5 is to be multiplied by a factor

= (150 / 120 )^2 = 1.563 in wind pressure calculation for Conductor/ Earthwire & with a factor =(160/120)^2 = 1.778 for Insulator/ Towerbody.

Wind Load on Conductor/Groundwire as per Clause 8.1.2.1 of DIN VDE 0210

Cf x q x d x ( 80 +0.6 x L)

Wind Pressure on Conductor/Groundwire.

Cf x q x ( 80 +0.6 x L) / L

(I) Wind Pressure On Conductors in Kg/m2 : Height of Attachment point in m

Conductor

Drag Coefficient for Conductor Diameter more than 15.80 mm refer Table 6 of DIN VDE 0210

0-40m

40-100m

Cfc

1.00

1.00

qc

0.53

0.68

Dynamic Wind Pressure As Per Table - 5 of DIN VDE 0210 in Kn/m2 for 120 KMPH

Dynamic Wind Pressure for 160 KMPH in Kg/m2

( Cfc * qc * ( 160 / 120 )^2 * 1000 / 9.81 ) =

Dynamic Wind Pressure for 150 KMPH in Kg/m2

( Cfc * qc * ( 150 / 120 )^2 * 1000 / 9.81 ) =

Wind Pressure on Conductor in Kg/m2

96.047

108.308

=

74.703

84.240

(II) Wind Pressure On Earthwire in Kg/m2 : Height of Attachment point in m

Groundwire

Drag Coefficient for Earthwire Diameter more than 15.80 mm refer Table 6 of DIN VDE 0210

Dynamic Wind Pressure As Per Table - 5 of DIN VDE 0210 in Kn/m2 for 120 KMPH

Dynamic Wind Pressure for 150 KMPH in Kg/m2

40-100m

Cfe

1.00

qe

0.68

( Cfe * qe * ( 150 / 120 )^2 * 1000 / 9.81 ) =

Wind Pressure On Earthwire in Kg/m2

108.308

=

84.240

(III) Effect of Aircraft Warning Sphere on the Earth wire :

Increase in wind pressure on earth wire due to Aircraft Warning Sphere :

Diameter of Warning sphere in M =

0.600

Centre to Centre Spacing of sphere in M

30

Diameter of earthwire in mm

18.600

Drag Coefficient for Aerial warning balls

0.4

Wind load on one sphere in Kn

= ( Pi / 4 * ( 0.6) ^2 * 0.4 * 0.68 * 1.563 )

Wind load on one sphere in Kn

Wind pressure on sphere in Kg/m2

= ( 0.12 * 1000 / ( 9.810 * 30 * 0.0186))

=

Total wind pressure on the earth wire including the effect

0.12

21.922

= ( 84.24 + 21.922)

LARSEN & TOUBRO LIMITED

ECC Division - EDRC

Project :

220 Kv D/c Transmission Line From

Shahama East To Samha Sub Station

Title :

Wind Pressure & Sag Tension Calculcaion

DOCUMENT NO :

O1033.T.TL - Sag-01

Date : 07/06/2001

DESIGNED

CHECKED

ARA

SMP

Sheet

of warning sphere in Kg/m2 For 450 M Span

106.162

Weight of earthwire in Kg/m

0.818

Weight of one sphere in Kg

7.200

Weight of Armour Rod in Kg

0.520

Equivalent unit weight of earthwire in Kg/m

= ( 0.818 + 7.2 / 30 + 0.52 / 450 )

OF 3

(For Sag Tension Calculation)

(IV) Increase in weight of earthwire due to Aircraft Warning Sphere :

1.059

(V) Effect of Spacer dampers on conductor :

Weight of spacer damper

= 2.40 + 5%

Max Weight of spacer damper in Kg

= 2.40 + (0.05 * 2.40) ]

Average centre to centre spacing of Damper in M

30

Weight of conductor in Kg/m

0.670

Equivalent weight of conductor including the weight of spacer

dampers in Kg/m

= ( 0.67 + ( 2.52 / ( 2 * 30 ) )

2.520

0.712

(VI) Wind Pressure On Insulator in Kg/m2 : Height of Attachment point in m

Insulator

Drag Coefficient for Insulator as per Table 6 of DIN VDE 0210

Dynamic Wind Pressure As Per Table - 5 of DIN VDE 0210 in Kn/m2 for 120 KMPH

Wind Pressure on insulator for 160 KMPH in Kg/m2

( Cfi * qi * ( 160 / 120 )^2 * 1000 / 9.81 )

0-40m

40-100m

Cfi

1.20

1.20

qi

0.7

0.9

152.226

195.719

0-40m

40-100m

(VII) Wind Pressure On Tower Body in Kg/m2 : Height of Towe Body in m

Tower Body

Drag Coefficient Cf is given in the Table 6 of DIN VDE 0210 for Square & rectangular towers

Cft

2.80

2.80

qt

0.7

0.9

355.193

456.677

0-40m

40-100m

2.80

2.80

(Cfdw = 2.8+10/100 * 2.8) =

3.08

3.08

0.7

0.9

45

45

Dynamic Wind Pressure As Per Table - 5 of DIN VDE 0210 in Kn/m2 for 120 KMPH

Wind Pressure on Tower Body for 160 KMPH in Kg/m2

( Cft * qt * ( 160 / 120 )^2 * 1000 / 9.81 )

(VIII) Wind Pressure On Tower Body in Kg/m2 ( For Diagonal Wind condition ) : Height of Towe Body in m

Tower Body

Drag Coefficient Cf is given in the Table 6 of DIN VDE 0210 for Square & rectangular towers

As per Cl.no 8.2.1.2 aerodynamical drag coefficient is to be increased by 10 % =

Dynamic Wind Pressure As Per Table - 5 of DIN VDE 0210 in Kn/m2 for 120 KMPH

Angle of Incidence of wind in deg

Cft

qdw

LARSEN & TOUBRO LIMITED

ECC Division - EDRC

Project :

220 Kv D/c Transmission Line From

Shahama East To Samha Sub Station

Title :

Wind Pressure & Sag Tension Calculcaion

Wind Pressure tower in Kg/m2 (In Trans. & Long.Face) =

DOCUMENT NO :

O1033.T.TL - Sag-01

Date : 07/06/2001

DESIGNED

CHECKED

ARA

SMP

Sheet

Cfdw*qdw*( 160/120 )^2 *1000/9.81*Cos(45) =

276.275

OF 3

355.211

BASIC SPAN FOR SAG TENSION CALCULATION : 450 M

DESCRIPTION

Name / Code

Stranding Aluminium & Steel

Diameter in MM

Unit Weight (Kg / m)

CONDUCTOR

GROUND WIRE

AAAC ALDREY

O.P.G.W " FOCAS "

61/ 2.25

32 Fibres

20.200

18.600

(## )

0.712

(* *)

1.059

Ultimate Strength in Kg

6910

11173

Cross Sectional Area in (mm2)

242.5

194.08

Coefficient of Linear Expansion ( / C)

23 x 10-6

17.3 x 10-6

Final Modulus of Elasticity in Kg /mm2

5697

10227

Minimum Temperature

5C

5C

Everyday Temperature

35C

35C

Maximum Temperature

80C

80C

(* * ) Weight of Warning Sphere and armor rod added to

O.P.G.W

(# # ) Weight of Spacer Damper Added to conductor

Conductor

Earthwire

Sl No

Combination of

Temperature

& Wind

Wind

Pressure

in Kg/m2

Tension

in Kg

Sag

in M

Factor

of

Safety

Tension

in Kg

Sag

in M

Factor

of

Safety

35 & Nil wind

1126.00

16.006

6.137

1834.30

($) 14.614

6.091

5 & Nil Wind

1243.00

14.499

5.559

1996.11

13.429

5.597

80 & Nil wind

995.70

($) 18.100

6.940

1645.29

16.292

6.791

40 & Nil wind

1109.2

16.248

6.230

1810.49

14.806

6.171

5 & Full wind

(For conductors less

than 40 m)

74.703

2521.80

16.752

2.740

----

----

----

5 & Diagonal wind

(For conductors less

than 40 m)

59.762

2190.50

16.189

3.155

----

----

----

5 & Full wind

(For conductors

more than 40 m)

84.240

2732.10

17.094

2.529

----

----

----

5 & Diagonal wind

(For conductors

more than 40 m)

67.392

2359.60

16.477

2.928

----

----

----

5 & Full wind

(For groundwire

more than 40 m)

106.162

----

----

----

3637.41

15.595

3.072

LARSEN & TOUBRO LIMITED

ECC Division - EDRC

Project :

220 Kv D/c Transmission Line From

Shahama East To Samha Sub Station

Title :

Wind Pressure & Sag Tension Calculcaion

5 & Diagonal wind

(For Earthwier more

than 40 m)

84.930

----

($) Refers Initial Condition For Conductor and Groundwire

DOCUMENT NO :

O1033.T.TL - Sag-01

DESIGNED

CHECKED

ARA

SMP

----

3199.51

Date : 07/06/2001

Sheet

----

15.039

OF 3

3.492

LARSEN & TOUBRO LIMITED

ECC DIVISION - EDRC

Project :

400/220 Kv D/c Transmission Line From

Al Ain Southwest to Abu Dhabi

Document No :

T1175.T.TL - Sag-02

Title :

Wind Pressure & Sag Tension Calculcaion

(For 220 kv Lines)

Date : 27/07/2001

Designed

Checked

Ara

Smp

Sheet

OF 3

WIND PRESSURE CALCULATIONS AS PER DIV VDE 0210 :

Wind Speed for Conductor,Earthwire,Insulator&Tower body in KMPH

Basis Span for Sag Tension calculation as per Schedule C2 in M (L)

160

=

= 44.44 in m/sec

450

As per DIN VDE 0210 and their further clarification dated 24.11.95, the dynamic wind pressure (q) in Table 5 of DIN VDE 0210 is arrived for

a basic wind speed of 120 Kmph. Hence for a wind speed of 160 Kmph, the dynamic wind pressure in Table 5 is to be multiplied by a factor

= (160 / 120 )^2 = 1.778 in wind pressure calculation for Conductor,Earthwire,Insulator &Towerbody.

Wind Load on Conductor/Groundwire as per Clause 8.1.2.1 of DIN VDE 0210

Cf x q x d x ( 80 +0.6 x L)

Wind Pressure on Conductor/Groundwire.

Cf x q x ( 80 +0.6 x L) / L

(I) Wind Pressure On Conductors in Kg/m 2 : Height of Attachment point in m

Conductor

Drag Coefficient for Conductor Diameter more than 15.80 mm refer Table 6 of DIN VDE 0210

0-40m

Cfc

1.00

qc

0.53

Dynamic Wind Pressure As Per Table - 5 of DIN VDE 0210 in Kn/m2 for 120 KMPH

Dynamic Wind Pressure for 160 KMPH in Kg/m2

( Cfc * qc * ( 160 / 120 )^2 * 1000 / 9.81 )

Dynamic Wind Pressure for 160 KMPH in Kg/m2

( Cfc * qc * ( 160 / 120 )^2 * 1000 / 9.81 )

Wind Pressure on Conductor in Kg/m2

96.047

74.703

(II) Wind Pressure On Earthwire in Kg/m2 : Height of Attachment point in m

Groundwire

Drag Coefficient for Earthwire Diameter more than 15.80 mm refer Table 6 of DIN VDE 0210

Dynamic Wind Pressure As Per Table - 5 of DIN VDE 0210 in Kn/m2 for 120 KMPH

Dynamic Wind Pressure for 160 KMPH in Kg/m2

40-100m

Cfe

1.00

qe

0.68

( Cfe * qe * ( 160 / 120 )^2 * 1000 / 9.81 )

Wind Pressure On Earthwire in Kg/m2

123.230

=

95.846

(III) Effect of Aircraft Warning Sphere on the Earth wire :

Increase in wind pressure on earth wire due to Aircraft Warning Sphere :

Diameter of Warning sphere in M =

0.600

Centre to Centre Spacing of sphere in M

30

Diameter of earthwire in mm

18.600

Drag Coefficient for Aerial warning balls

0.4

Wind load on one sphere in Kn

= ( Pi / 4 * ( 0.6) ^2 * 0.4 * 0.68 * 1.778 )

Wind load on one sphere in Kn

Wind pressure on sphere in Kg/m 2

= ( 0.137 * 1000 / ( 9.810 * 30 * 0.0186))

=

Total wind pressure on the earth wire including the effect

0.137

25.027

= ( 95.846 + 25.027)

LARSEN & TOUBRO LIMITED

ECC DIVISION - EDRC

Project :

400/220 Kv D/c Transmission Line From

Al Ain Southwest to Abu Dhabi

Title :

Wind Pressure & Sag Tension Calculcaion

(For 220 kv Lines)

Document No :

T1175.T.TL - Sag-02

Date : 27/07/2001

Designed

Checked

Ara

Smp

Sheet

of warning sphere in Kg/m2 .

120.873

(For Sag Tension Calculation)

Weight of earthwire in Kg/m

0.818

Weight of one sphere in Kg

7.200

Weight of Armour Rod in Kg

0.520

Equivalent unit weight of earthwire in Kg/m

= ( 0.818 + 7.2 / 30 + 0.52 / 450 )

(IV) Increase in weight of earthwire due to Aircraft Warning Sphere :

1.059

(V) Effect of Spacer dampers on conductor :

Weight of spacer damper

= 2.40 + 5%

Max Weight of spacer damper in Kg

= 2.40 + (0.05 * 2.40) ]

Average centre to centre spacing of Damper in M (Assumed)

30

Weight of conductor in Kg/m

1.085

No. of conductors per phase

Equivalent weight of conductor including the weight of spacer

dampers in Kg/m

= ( 1.085 + ( 2.52 / ( 30 * 2 ) )

2.520

nos

=

1.127

(VI) Wind Pressure On Insulator in Kg/m2 : Height of Attachment point in m

Insulator

Drag Coefficient for Insulator as per Table 6 of DIN VDE 0210

Dynamic Wind Pressure As Per Table - 5 of DIN VDE 0210 in Kn/m2 for 120 KMPH

Wind Pressure on insulator for 160 KMPH in Kg/m2

( Cfi * qi * ( 160 / 120 )^2 * 1000 / 9.81 )

0-40m

Cfi

1.20

qi

0.7

152.226

(VII) Wind Pressure On Tower Body in Kg/m2 : Height of Towe Body in m

Tower Body

Drag Coefficient Cf is given in the Table 6 of DIN VDE 0210 for Square & rectangular towers

Dynamic Wind Pressure As Per Table - 5 of DIN VDE 0210 in Kn/m2 for 120 KMPH

Wind Pressure on Tower Body for 160 KMPH in Kg/m2

( Cft * qt * ( 160 / 120 )^2 * 1000 / 9.81 )

0-40m

Cft

2.80

qt

0.7

355.193

(VIII) Wind Pressure On Tower Body in Kg/m2 ( For Diagonal Wind condition ) : Height of Towe Body in m

Tower Body

Drag Coefficient Cf is given in the Table 6 of DIN VDE 0210 for Square & rectangular towers

As per Cl.no 8.2.1.2 aerodynamical drag coefficient is to be increased by 10 % =

Dynamic Wind Pressure As Per Table - 5 of DIN VDE 0210 in Kn/m2 for 120 KMPH

Cft

0-40m

=

2.80

(Cfdw = 2.8+10/100 * 2.8) =

3.08

qdw

0.7

OF 3

LARSEN & TOUBRO LIMITED

ECC DIVISION - EDRC

Project :

400/220 Kv D/c Transmission Line From

Al Ain Southwest to Abu Dhabi

Document No :

T1175.T.TL - Sag-02

Title :

Wind Pressure & Sag Tension Calculcaion

(For 220 kv Lines)

Designed

Checked

Ara

Smp

Date : 27/07/2001

Sheet

Angle of Incidence of wind in deg

Wind Pressure tower in Kg/m2 (In Trans. & Long.Face) =

Cfdw*qdw*( 160/120 )^2 *1000/9.81*Cos(45) =

OF 3

45

276.275

BASIC SPAN FOR SAG TENSION CALCULATION : 450 M

DESCRIPTION

CONDUCTOR

GROUND WIRE

Name / Code

AL/AlClad Steel

O.P.G.W " FOCAS "

Stranding Aluminium & Steel

26/3.72 , 7/2.89

32 Fibres

23.550

18.600

Diameter in MM

Unit Weight (Kg / m)

(## )

Ultimate Strength in Kg

1.127

(* *)

1.059

9990

11173

328.52

194.08

Coefficient of Linear Expansion ( / C)

20.0 x 10-6

17.3 x 10-6

Final Modulus of Elasticity in Kg /mm2

7727

10227

Minimum Temperature

5C

5C

Everyday Temperature

35C

35C

Maximum Temperature

80C

80C

Cross Sectional Area in (mm2)

(* * ) Weight of Warning Sphere and armor rod added to

O.P.G.W.

(# # ) Weight of Spacer Damper Added to conductor

Conductor

Earthwire

Sl No

Combination of

Temperature

& Wind

Wind

Pressure

in Kg/m2

Tension

in Kg

Sag

in M

Factor

of

Safety

Tension

in Kg

Sag

in M

35 & Nil wind

1798.20

($) 15.865

5.556

1770.30

15.142

60 & Nil wind

1686.10

16.921

5.925

1668.21

16.069

80 & Nil wind

1608.01

17.730

6.213

1597.10

16.786

5- Full wind

(For conductors

less than 40 m)

74.703

3331.50

15.872

2.999

----

----

5- Diagonal wind

(For conductors

less than 40 m)

59.762

2943.60

15.504

3.394

----

----

5 & Full wind

(For conductors

more than 40 m)

95.846

3894.80

16.397

2.565

----

----

5- Diagonal wind

(For conductors

more than 40 m)

76.677

3383.70

15.926

2.952

----

----

5 - Full wind

(For groundwire

more than 40 m)

120.873

----

----

----

3836.21

($) 16.397

LARSEN & TOUBRO LIMITED

ECC DIVISION - EDRC

Project :

400/220 Kv D/c Transmission Line From

Al Ain Southwest to Abu Dhabi

Title :

Wind Pressure & Sag Tension Calculcaion

(For 220 kv Lines)

5 - Diagonal wind

(For groundwire

more than 40 m)

96.698

----

($) Refers Initial Condition For Conductor and Groundwire

Document No :

T1175.T.TL - Sag-02

Designed

Checked

Ara

Smp

----

3341.61

Date : 27/07/2001

Sheet

----

15.817

OF 3

N & TOUBRO LIMITED

ECC DIVISION - EDRC

Date : 27/07/2001

Sheet

OF 3

ALCULATIONS AS PER DIV VDE 0210 :

= 44.44 in m/sec

11.95, the dynamic wind pressure (q) in Table 5 of DIN VDE 0210 is arrived for

160 Kmph, the dynamic wind pressure in Table 5 is to be multiplied by a factor

40-100m

1.00

0.68

123.230

95.846

40-100m

1.00

0.68

123.230

95.846

N & TOUBRO LIMITED

ECC DIVISION - EDRC

Date : 27/07/2001

Sheet

OF 3

40-100m

1.20

0.9

195.719

40-100m

2.80

0.9

456.677

40-100m

2.80

3.08

0.9

N & TOUBRO LIMITED

ECC DIVISION - EDRC

Date : 27/07/2001

Sheet

OF 3

45

355.211

GROUND WIRE

O.P.G.W " FOCAS "

32 Fibres

18.600

(* *)

1.059

11173

194.08

17.3 x 10-6

10227

5C

35C

80C

(* * ) Weight of Warning Sphere and armor rod added to

O.P.G.W.

Earthwire

Factor

of

Safety

6.311

6.698

6.996

----

----

----

----

2.913

N & TOUBRO LIMITED

ECC DIVISION - EDRC

Date : 27/07/2001

Sheet

OF 3

3.344

You might also like

- Chequered-Plate CALCULATIONDocument19 pagesChequered-Plate CALCULATIONRamuAlagappan100% (2)

- Chequered PlateDocument23 pagesChequered PlateMythili BysaniNo ratings yet

- Chequered PlateDocument3 pagesChequered Platerammohan100% (4)

- Chequer Plate DesignDocument1 pageChequer Plate Designmanish_chhuganiNo ratings yet

- Design of Chequered Plates BS QCS PDFDocument1 pageDesign of Chequered Plates BS QCS PDFEddySyahputraBenSyahrenNo ratings yet

- Car Park Shed Structural Design Basis ReportDocument23 pagesCar Park Shed Structural Design Basis ReportMdShahbazAhmed0% (1)

- Chequered Plate PlatformDocument3 pagesChequered Plate PlatformFilip RisteskiNo ratings yet

- Chequered DesignDocument2 pagesChequered DesignSaravana N100% (1)

- Chequered Plate 1250mm-cDocument28 pagesChequered Plate 1250mm-casvenk309100% (3)

- End-Plate-Design BS CodeDocument15 pagesEnd-Plate-Design BS CodeRaymond SabadoNo ratings yet

- End Plate DesignDocument4 pagesEnd Plate DesignAgnon Fung100% (4)

- Chequered Plate DesignDocument2 pagesChequered Plate Designraj vaddiNo ratings yet

- Base PlateDocument48 pagesBase PlatePrantik Adhar Samanta0% (1)

- BS5950 End Plate DesignDocument4 pagesBS5950 End Plate DesignSimon Lsm67% (3)

- Design of Sleeper Pedestal Reinforcement in CulvertDocument2 pagesDesign of Sleeper Pedestal Reinforcement in Culvertmunishant10% (1)

- Lifting Design Using Rebars: Details of PanelDocument3 pagesLifting Design Using Rebars: Details of PanelAsaru Deen100% (2)

- Grade Slab DesignDocument6 pagesGrade Slab DesignMALAY MRIDHANo ratings yet

- Z-Purlin Technical Data SheetDocument22 pagesZ-Purlin Technical Data SheetSBNo ratings yet

- Lifting Hook Calculation: 90° Standard Hook Development LengthDocument2 pagesLifting Hook Calculation: 90° Standard Hook Development LengthSi Chini100% (3)

- Design Spreadsheet Gusset Plate Connection For TrussDocument4 pagesDesign Spreadsheet Gusset Plate Connection For TrussMatumbi Naito100% (1)

- Design of Shear KeyDocument13 pagesDesign of Shear Keynhulugalla100% (1)

- Indian Codes - Steel Design Per IS 800:2007Document3 pagesIndian Codes - Steel Design Per IS 800:2007dineshNo ratings yet

- DG FoundationDocument4 pagesDG Foundationbollasudarshan100% (2)

- Composite Metal Deck Slab Design As Per EC4Document86 pagesComposite Metal Deck Slab Design As Per EC4asubhash110% (1)

- Design of Embeded Plate (INDIAN STANDARD)Document3 pagesDesign of Embeded Plate (INDIAN STANDARD)Shubham Verma100% (2)

- Design of Pedestal ReinforcementDocument2 pagesDesign of Pedestal Reinforcementsaravanan4286No ratings yet

- Load Table for Durbar and Chequer Plate FlooringDocument1 pageLoad Table for Durbar and Chequer Plate Flooringanuj3936No ratings yet

- Design of CHQRD PlateDocument20 pagesDesign of CHQRD PlateRagavanNo ratings yet

- Design of Base Plate and Bolts FinalDocument4 pagesDesign of Base Plate and Bolts FinalManoj Jaiswal100% (1)

- Lifting Hook Design JWN3C30ADocument16 pagesLifting Hook Design JWN3C30AjudeNo ratings yet

- Duct Bank DesignDocument18 pagesDuct Bank DesignFeroz Khan Patthan100% (1)

- Design of Base PlateDocument4 pagesDesign of Base PlateBenjun Balbin100% (5)

- Plinth Beam Design CalculationDocument4 pagesPlinth Beam Design CalculationVinod NairNo ratings yet

- SHS and RHSDocument16 pagesSHS and RHSOuseppachan AmbookenNo ratings yet

- Wind Load As Per ASCE-7-10Document17 pagesWind Load As Per ASCE-7-10Tri huỳnhNo ratings yet

- Sample Design Calculations of Foundation For Vertical VesselDocument23 pagesSample Design Calculations of Foundation For Vertical VesselonlyikramNo ratings yet

- BASE PLATE DESIGNDocument4 pagesBASE PLATE DESIGNvinujohnpanickerNo ratings yet

- Insert Plate Design LugsDocument8 pagesInsert Plate Design Lugsvrajan1988No ratings yet

- Design of Purlins per IS800 and SP38Document2 pagesDesign of Purlins per IS800 and SP38MM93% (29)

- MBMA-96load Combinations PDFDocument2 pagesMBMA-96load Combinations PDFsonofalexander100% (1)

- Base Plate Design (Fixed Base)Document3 pagesBase Plate Design (Fixed Base)Saravana NNo ratings yet

- Fixed Base Plate Design - ArhDocument3 pagesFixed Base Plate Design - Arhmaheshbandham100% (1)

- Water Tank Design (Aci 318-05)Document8 pagesWater Tank Design (Aci 318-05)arnoldNo ratings yet

- Calculation Sheet: Design PhilosophyDocument36 pagesCalculation Sheet: Design Philosophyrammohan100% (1)

- PURLIN - DESIGN - AS - PER - IS - CODE LatestDocument22 pagesPURLIN - DESIGN - AS - PER - IS - CODE Latestnitin chaudharyNo ratings yet

- Block Foundation DesignDocument1 pageBlock Foundation DesigndantevariasNo ratings yet

- MOMENT EndplateDocument10 pagesMOMENT EndplateALPHYL BALASABASNo ratings yet

- Design of CorbelDocument5 pagesDesign of CorbelrammohanNo ratings yet

- Purlin For 2 Bays RNDDocument64 pagesPurlin For 2 Bays RNDStephen JamesNo ratings yet

- Lighting Pole (H 9.00M) - Structural Design Calculations Report Rev.00Document32 pagesLighting Pole (H 9.00M) - Structural Design Calculations Report Rev.00Der3'am Al m7armeh71% (7)

- Chimney Calculation SheetDocument12 pagesChimney Calculation SheetVinoth Rajendra40% (5)

- 8 M PoleDocument1 page8 M Polevj85840% (2)

- Design of MonorailDocument9 pagesDesign of MonorailAnonymous Q8XIGqHyCNo ratings yet

- Trafo Found DesignDocument6 pagesTrafo Found DesignIrshad Khan100% (1)

- 35 KL DesignDocument10 pages35 KL DesigneduardoambientalNo ratings yet

- Warehouse Roof Design and AnalysisDocument51 pagesWarehouse Roof Design and AnalysisAnonymous q0irDXlWAm100% (2)

- BOX Culvert Load DetailsDocument7 pagesBOX Culvert Load Detailsragalwar100% (1)

- E4.5 Flange Cover CalcDocument10 pagesE4.5 Flange Cover CalcTanCM100% (1)

- Column Skirt Support Design CalculationDocument5 pagesColumn Skirt Support Design CalculationRitesh VishambhariNo ratings yet

- Two Way Slab DesignDocument9 pagesTwo Way Slab DesignChan Kin Cheung100% (1)

- Tower Type B: HT of Null Point From BotDocument5 pagesTower Type B: HT of Null Point From Botsaravanan4286No ratings yet

- 380kv Tower WeightDocument3 pages380kv Tower Weightsaravanan4286No ratings yet

- TL Tower Footing Design For Reference ACI With Single PadDocument48 pagesTL Tower Footing Design For Reference ACI With Single Padsaravanan4286No ratings yet

- IEC60826Document123 pagesIEC60826saravanan4286No ratings yet

- DBRDocument5 pagesDBRsaravanan4286No ratings yet

- Back to Back, Sub-Bracing Length & Stub Setting CalculationsDocument12 pagesBack to Back, Sub-Bracing Length & Stub Setting Calculationssaravanan4286No ratings yet

- Detailed Specification of The BuildingDocument5 pagesDetailed Specification of The Buildingsaravanan4286100% (3)

- Residential Building DesignDocument2 pagesResidential Building Designsaravanan4286No ratings yet

- Design of 400-220kV SubstationDocument62 pagesDesign of 400-220kV SubstationboopelectraNo ratings yet

- Analysis of 2 Span Beam-FinalDocument20 pagesAnalysis of 2 Span Beam-Finalsaravanan4286No ratings yet

- Iso v.2008 To v.2015 Transition by Iso!Document10 pagesIso v.2008 To v.2015 Transition by Iso!LNo ratings yet

- Weight ControlDocument43 pagesWeight ControlParthiban VaratharajNo ratings yet

- Tower Slope ReferenceDocument1 pageTower Slope Referencesaravanan4286No ratings yet

- Tower B-BDocument3 pagesTower B-Bsaravanan4286No ratings yet

- Guidelines For The Dimensions and Design of WaterwaysDocument129 pagesGuidelines For The Dimensions and Design of Waterwayssaravanan4286No ratings yet

- Chapter 2 - Shear Design SP 17-09-07Document37 pagesChapter 2 - Shear Design SP 17-09-07Alex FerrariNo ratings yet

- Tower SolutionsDocument50 pagesTower Solutionssaravanan4286100% (1)

- IEC60826Document123 pagesIEC60826saravanan4286No ratings yet

- Weight of Standard SectionDocument1 pageWeight of Standard Sectionsaravanan4286No ratings yet

- A New Method To Design End Plate Moment ConnectionsDocument31 pagesA New Method To Design End Plate Moment Connectionsjihu1170No ratings yet

- StairDocument22 pagesStairsaravanan4286No ratings yet

- Pole Foundation ConceptDocument1 pagePole Foundation Conceptsaravanan4286No ratings yet

- Wind Pressure CalculationDocument30 pagesWind Pressure Calculationsaravanan4286No ratings yet

- How to Protect Cells in Excel: A Step-by-Step GuideDocument11 pagesHow to Protect Cells in Excel: A Step-by-Step Guidesaravanan4286No ratings yet

- Design of Pedestal ReinforcementDocument2 pagesDesign of Pedestal Reinforcementsaravanan4286No ratings yet

- Crack Width Check BS5400 4Document5 pagesCrack Width Check BS5400 4saravanan4286100% (1)

- Water Tank Resting On GroundDocument4 pagesWater Tank Resting On Groundsaravanan4286No ratings yet

- Three Span BeamDocument6 pagesThree Span Beamsaravanan4286No ratings yet

- Wind Asce7 10Document5 pagesWind Asce7 10saravanan4286100% (1)

- Localization Strategy in Vietnamese Market: The Cases ofDocument25 pagesLocalization Strategy in Vietnamese Market: The Cases ofHồng Thy NguyễnNo ratings yet

- Presentation Pineda Research CenterDocument11 pagesPresentation Pineda Research CenterPinedaMongeNo ratings yet

- Nucleic Acid Isolation System: MolecularDocument6 pagesNucleic Acid Isolation System: MolecularWarung Sehat Sukahati100% (1)

- Job Hazard Analysis TemplateDocument2 pagesJob Hazard Analysis TemplateIzmeer JaslanNo ratings yet

- Shubh AmDocument2 pagesShubh AmChhotuNo ratings yet

- Road Safety GOs & CircularsDocument39 pagesRoad Safety GOs & CircularsVizag Roads100% (1)

- Amos Code SystemDocument17 pagesAmos Code SystemViktor KarlashevychNo ratings yet

- FZ16 9B 1KD2 (Patada) PDFDocument62 pagesFZ16 9B 1KD2 (Patada) PDFPanthukalathil Ram100% (1)

- Method Statement of Static Equipment ErectionDocument20 pagesMethod Statement of Static Equipment Erectionsarsan nedumkuzhi mani100% (4)

- What Role Can IS Play in The Pharmaceutical Industry?Document4 pagesWhat Role Can IS Play in The Pharmaceutical Industry?Đức NguyễnNo ratings yet

- The Basic New Keynesian Model ExplainedDocument29 pagesThe Basic New Keynesian Model ExplainedTiago MatosNo ratings yet

- Current Affairs Q&A PDF June 9 2023 by Affairscloud 1Document21 pagesCurrent Affairs Q&A PDF June 9 2023 by Affairscloud 1Yashika GuptaNo ratings yet

- Bajaj 100bDocument3 pagesBajaj 100brmlstoreNo ratings yet

- Company's Profile Presentation (Mauritius Commercial Bank)Document23 pagesCompany's Profile Presentation (Mauritius Commercial Bank)ashairways100% (2)

- PDF Problemas Ishikawa - Free Download PDF - Reporte PDFDocument2 pagesPDF Problemas Ishikawa - Free Download PDF - Reporte PDFNewtoniXNo ratings yet

- Lesson 3 - Materials That Undergo DecayDocument14 pagesLesson 3 - Materials That Undergo DecayFUMIKO SOPHIA67% (6)

- Formal 17 12 04 PDFDocument184 pagesFormal 17 12 04 PDFJose LaraNo ratings yet

- SABIC Ethanolamines RDS Global enDocument10 pagesSABIC Ethanolamines RDS Global enmohamedmaher4ever2No ratings yet

- HetNet Solution Helps Telcos Improve User Experience & RevenueDocument60 pagesHetNet Solution Helps Telcos Improve User Experience & RevenuefarrukhmohammedNo ratings yet

- Critical Values For The Dickey-Fuller Unit Root T-Test StatisticsDocument1 pageCritical Values For The Dickey-Fuller Unit Root T-Test Statisticswjimenez1938No ratings yet

- Air Cycle Refrigeration:-Bell - Coleman CycleDocument21 pagesAir Cycle Refrigeration:-Bell - Coleman CycleSuraj Kumar100% (1)

- Axtraxng™: Networked Access Control Management Software V27.XDocument2 pagesAxtraxng™: Networked Access Control Management Software V27.XChiluvuri VarmaNo ratings yet

- GE Supplier Add Refresh FormDocument1 pageGE Supplier Add Refresh FormromauligouNo ratings yet

- Final Project Report: Uop, LLCDocument165 pagesFinal Project Report: Uop, LLCSiddharth KishanNo ratings yet

- Schedule of Charges General Banking 2022Document18 pagesSchedule of Charges General Banking 2022Shohag MahmudNo ratings yet

- Sampling Fundamentals ModifiedDocument45 pagesSampling Fundamentals ModifiedArjun KhoslaNo ratings yet

- The Power of Flexibility: - B&P Pusher CentrifugesDocument9 pagesThe Power of Flexibility: - B&P Pusher CentrifugesberkayNo ratings yet

- Vallance - Sistema Do VolvoDocument15 pagesVallance - Sistema Do VolvoNuno PachecoNo ratings yet

- Proprietar Utilizator Nr. Crt. Numar Inmatriculare Functie Utilizator Categorie AutovehiculDocument3 pagesProprietar Utilizator Nr. Crt. Numar Inmatriculare Functie Utilizator Categorie Autovehicultranspol2023No ratings yet

- Anomaly Sell Out Remap December 2019 S SUMATRA & JAMBIDocument143 pagesAnomaly Sell Out Remap December 2019 S SUMATRA & JAMBITeteh Nha' DwieNo ratings yet