Professional Documents

Culture Documents

Column Base Plate Design

Uploaded by

_jessecaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Column Base Plate Design

Uploaded by

_jessecaCopyright:

Available Formats

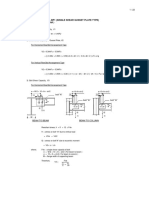

COLUMN BASE PLATE DESIGN (BS5950-1:2000)

TEDDS calculation version 1.0.09;

Base plate reference;

Tension + moment;

Design forces and moments

Axial force;

Fc = ;120.0; kN (Tension)

Bending moment;

M = 21.0 kNm; (about major axis)

Shear force;

Fv = 18.0 kN

Column details

Column section;

SHS 150x150x8.0 (Grade S275)

Depth;

D = 150.0 mm

Breadth;

B = 150.0 mm

Flange thickness;

T = 8.0 mm

Web thickness;

t = 8.0 mm

Design strength;

pyc = 275 N/mm2

Column flange to base plate weld;

8 mm FW;

Column web to base plate weld;

8 mm FW;

Baseplate details

Steel grade;

S275

Depth;

Dp = 300 mm

Breadth;

Bp = 300 mm

Thickness;

tp = 20 mm

Design strength;

pyp = 265 N/mm2

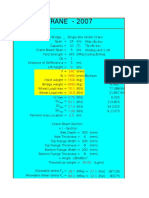

Holding down bolt and anchor plate details

Total number of bolts;

4 No. M20 Grade 8.8

Bolt spacing;

sbolt = ;200; mm

Edge distance;

e1 = 40 mm

Anchor plate steel grade;

S275

Anchor plate dimension (square);

bap = 135 mm

Anchor plate thickness;

tap = 20 mm

Design strength;

pyap = 265 N/mm2

Embeddment to top of anchor plate;

E = 300 mm

Characteristic strength of concrete;

fcu = 50 N/mm2

Concrete compression force and bolt tension force

Plate overhang beyond face of flange;

L1 = (Dp - D)/2) = ;75.0; mm

Effective width of plate;

Bpc = min(Bp, B + 2L1) = ;300.0; mm

Distance from bolts to compression edge;

h = Dp - e1 = 260 mm

Assuming a rectangular compression block of width bpc, length x and intensity 0.6fcu then:From static equilibrium;

M = 0.6fcuBpcx(h-x/2) - Fc(h-Dp/2)

Rearranging the quadratic equation;

0.3fcuBpcx2 - 0.6fcuBpchx + Fc(h-Dp/2) + M = 0

Factor a;

a = 0.3 fcu Bpc = 4500.0 N/mm

Factor b;

b = -0.6 fcu Bpc h = -2340000.0 N

Constant c;

c = Fc (h-Dp/2) + M = 7800000.0 Nmm

Depth of compression block;

x = [-1.0b - (b2 - 4ac)]/(2a) = 3.4 mm

Compression force in concrete;

Cf = 0.6 fcu Bpc x = 30.2 kN

Tension force in bolts;

Tf = Cf - Fc = 150.2 kN

Therefore the bolts are in tension

Compression side bending

Moment in plate;

mc = 0.6 fcu x (L1 - 0.8swf - x/2) = ;6736 Nmm/mm;

Plate thickness required;

tpc = (4 mc/pyp) = 10.1 mm

Tension side bending

Lever arm;

m = L1 - e1 - 0.8swf = 28.6 mm

Moment in plate;

mt = Tf m = 4295572 Nmm

Distance from bolt cl. to face of column;

Lf = L1 - e1 = 35.0 mm

Effective plate width;

Bpt = min(Bp, sbolt(Nbolt/2-1) + 2Lf) = 270.0 mm

Plate thickness required;

tpt = (4 mt/(pypBpt)) = 15.5 mm

Plate thickness

Plate thickness required;

tp_req = max(tpc, tpt) = ;15.5 mm;

Plate thickness provided;

tp = 20 mm

PASS - Plate thickness provided is adequate (0.775)

Flange weld

Tension capacity of flange;

Ptf = B T pyc = ;330.0; kN

Force in tension flange;

Ftf = M/(D - T) - Fc (BT)/A = ;180.1; kN

Flange weld design force;

Ff = min(Ptf, max(Ftf, 0 kN)) = 180.1 kN

Weld force per mm;

fwf = Ff/B = ;1.200; kN/mm

Transverse capacity of 8 mm fillet weld;

pwf = 1.540 kN/mm; (Cl. 6.8.7.3)

PASS - Flange weld capacity is adequate (0.779)

Longitudinal capacity of web weld

Weld force per mm;

Longitudinal capacity of 8 mm fillet weld;

fwwl = Fv/(2(D-2t)) = ;0.067; kN/mm

pwwl = 1.232 kN/mm; (Cl. 6.8.7.3)

PASS - Longitudinal capacity of web weld is adequate (0.055)

Transverse capacity of web weld

Tension force in web;

Ftw = abs(Fc)(A-2Bt)/(2A) = ;27.8; kN

Transverse weld force per mm;

fwwt = Ftw/(D-2t) = ;0.208; kN/mm

Transverse capacity of 8 mm fillet weld;

pwwt = 1.540 kN/mm; (Cl. 6.8.7.3)

PASS - Transverse capacity of web weld is adequate (0.135)

Web weld combined effect

ratioww = (fwwl/pwwl)2 + (fwwt/pwwt)2 = 0.021

Resultant effect (cl. 6.8.7.3);

PASS - Web weld is adequate (0.021)

Holding down bolts

Force per bolt;

Fbolt = (2Tf)/ Nbolt = 75.1 kN

Tensile area per bolt;

At_b = 245.0 mm2

Tensile strength;

pt_b = 560 N/mm2

Tension capacity (cl. 6.6);

Pt_b = 0.8 pt_b At_b = ;109.8; kN;

PASS - Bolt capacity is adequate (0.684)

Anchor plates

Force per anchor plate;

Fap = Fbolt = 75.1 kN

Bolt hole diameter in anchor plate;

dh = 22 mm

Anchor plate bearing area;

Aap = bap2 - dh2/4 = 17845 mm2

Bearing capacity;

Pap = 0.6 fcu Aap = 535.3 kN

PASS - Anchor plate bearing capacity is adequate (0.140)

Bearing pressure on anchor plate;

fap = Fap / Aap = 4.2 N/mm2

Width of bolt head (across flats);

dbh = 30.0 mm

Maximum cantilever length;

lap = bap/2 (2) - dbh/2 = 80.5 mm

Bending moment in plate;

map = fap lap2/2 = 13.6 Nm/mm

Bending capacity;

mcap = pyap tap2/4 = 26.5 Nm/mm

PASS - Anchor plate bending capacity is adequate (0.514)

Holding down bolt anchorage

Note - the following calculation to check the holding down bolt anchorage into the foundation assumes that the

distance from the edge of an anchor plate to the nearest edge of the foundation is at least equal to the depth of

embedment of the anchor plate.

Tension force to be resisted;

Ft = Tf = 150.2 kN

The clear distance between anchor plates is less than the embedment (E).

Aplan_eff = [sbolt(Nbolt/2-1)+bap](bap+2E)+E2+2bapE-

Effective concrete plan area;

(Nbolt/2)bap2

Aplan_eff = 573518 mm2

For tension failure pull-out, effective tensile area;

At_eff = Aplan_eff = 573518 mm2

Tensile strength of concrete;

pt = 1.62 N/mm2

Pull-out capacity of tension bolts;

Pt = pt At_eff = 929.1 kN

PASS - Holding down bolt anchorage is adequate (0.162)

Shear transfer to concrete

Assumed coefficient of friction;

Available shear resistance;

= 0.30

Pv = Cf = ;9; kN

WARNING - Friction alone is not adequate to resist applied shear force

Additional design measures required which are not covered by this calculation

You might also like

- Column Base Plate DesignDocument1 pageColumn Base Plate DesignBunkun15No ratings yet

- COMPARISON OF COMPOSITE BEAM DESIGNDocument8 pagesCOMPARISON OF COMPOSITE BEAM DESIGNMohamed Abo-ZaidNo ratings yet

- COLUMN BASE PLATE DESIGN CALCULATIONS (BS5950-1:2000Document7 pagesCOLUMN BASE PLATE DESIGN CALCULATIONS (BS5950-1:2000Shakil Akhter100% (1)

- ABP12 - Q - AASHTO Vessel Collision Design of Highway Bridges (2009)Document60 pagesABP12 - Q - AASHTO Vessel Collision Design of Highway Bridges (2009)_jesseca0% (1)

- Bolted Cover Plate Splice Connection B1Document4 pagesBolted Cover Plate Splice Connection B1ikanyu79No ratings yet

- Design Slip-Critical Steel ConnectionDocument9 pagesDesign Slip-Critical Steel ConnectionKURONo ratings yet

- 9.3.2 Bolt Strength Limit StatesDocument4 pages9.3.2 Bolt Strength Limit StatesDanielNo ratings yet

- RC Beam Torsion DesignDocument33 pagesRC Beam Torsion Design2011kumarNo ratings yet

- Splice Connection Design by AijDocument2 pagesSplice Connection Design by AijdantevariasNo ratings yet

- Evo Design - Structural Design: Calculation SheetDocument7 pagesEvo Design - Structural Design: Calculation SheetAnand.5No ratings yet

- Torsion Validation ShayanDocument10 pagesTorsion Validation ShayanGicuNo ratings yet

- Stiffner Design For Beam Column ConnectionsDocument84 pagesStiffner Design For Beam Column ConnectionsfabnameNo ratings yet

- Design of base plate for ISMB 200 columnDocument1 pageDesign of base plate for ISMB 200 columnAnonymous HkX2aE9Fx0% (1)

- Bolted Cover SpliceDocument4 pagesBolted Cover SpliceChee Fong MakeNo ratings yet

- Corbel BS8110Document3 pagesCorbel BS8110Nugraha BintangNo ratings yet

- Circular WeldDocument12 pagesCircular WeldJohn Paul UmaliNo ratings yet

- Beam pin connection design calculationsDocument22 pagesBeam pin connection design calculationsballisnothingNo ratings yet

- Design of Crane Runway GirdersDocument22 pagesDesign of Crane Runway GirdersScooby DooNo ratings yet

- Structural Design 50M SST - Medium Duty - Zone Ii, Exposure C Rev. No. 00 F0736Document39 pagesStructural Design 50M SST - Medium Duty - Zone Ii, Exposure C Rev. No. 00 F0736Henj MirasolNo ratings yet

- Monorail CalculationDocument10 pagesMonorail CalculationMiftakhu ZaimNo ratings yet

- Column Base Plate Design PDFDocument2 pagesColumn Base Plate Design PDFDrewNo ratings yet

- Scaffold Brackets BoltDocument2 pagesScaffold Brackets BoltHafiz KamarudinNo ratings yet

- Astm Steel Grade: RN FNV Ab RN 2.4 D T Fu (Critical RN Will Be The Least of The Two RN'S)Document5 pagesAstm Steel Grade: RN FNV Ab RN 2.4 D T Fu (Critical RN Will Be The Least of The Two RN'S)Kim TrixieNo ratings yet

- Drop Panel CalculationDocument2 pagesDrop Panel Calculationsandiok86No ratings yet

- Design Base Plate for Platform 1 ColumnDocument93 pagesDesign Base Plate for Platform 1 ColumnAnand.5No ratings yet

- Crane 5TANDocument11 pagesCrane 5TANAnh Do VoNo ratings yet

- Base Plate & Anchor BoltDocument40 pagesBase Plate & Anchor BoltSiva baalanNo ratings yet

- Computer Aided Engineering Space Gass Tutorial Questions (Beam Frames Trusses)Document9 pagesComputer Aided Engineering Space Gass Tutorial Questions (Beam Frames Trusses)April IngramNo ratings yet

- AISC LRFD Column DesignDocument4 pagesAISC LRFD Column Designwinlugue3059No ratings yet

- Calculation Sheet Connection DesignDocument1 pageCalculation Sheet Connection DesignJay SenjaliaNo ratings yet

- Baseplate MonorailDocument31 pagesBaseplate Monorailmohamad chandraNo ratings yet

- Strength and Behavior of Reinforced Concrete Obtuse Corners Under Opening Bending MomentsDocument6 pagesStrength and Behavior of Reinforced Concrete Obtuse Corners Under Opening Bending MomentsValdemir ColaresNo ratings yet

- Design of Column BaseDocument2 pagesDesign of Column BasepragneshozaNo ratings yet

- Apex HaunchDocument34 pagesApex HaunchDanny ArimaNo ratings yet

- End Plate Beam To Column Moment ConnectionDocument84 pagesEnd Plate Beam To Column Moment Connectionakshay chauhanNo ratings yet

- Base Plate For Thickness CalculationsDocument7 pagesBase Plate For Thickness CalculationsyunuswsaNo ratings yet

- Lecture 11-1 Bases by H.J. MtyanaDocument29 pagesLecture 11-1 Bases by H.J. MtyanaHarold Jackson Mtyana100% (1)

- PRYING9.xls AISC Prying Action AnalysisDocument5 pagesPRYING9.xls AISC Prying Action AnalysisCarlos Valverde PortillaNo ratings yet

- Diagram Drawing Design Forces and DetailsDocument6 pagesDiagram Drawing Design Forces and Detailswaweng22No ratings yet

- Base Plate Cal PDFDocument5 pagesBase Plate Cal PDFMyunSu GooNo ratings yet

- Transverse Shear-Build Up SectionsDocument8 pagesTransverse Shear-Build Up SectionsKavish DayaNo ratings yet

- Giao An Thep 1Document33 pagesGiao An Thep 1Trinh Duy KhanhNo ratings yet

- Beam DesignDocument7 pagesBeam DesignKasi ViswanathanNo ratings yet

- R.R. Rojo and Associates: Anchor Bolt Design The Anchor Rod Design Is AdequateDocument10 pagesR.R. Rojo and Associates: Anchor Bolt Design The Anchor Rod Design Is AdequateMarkNo ratings yet

- Stair Hand Rail Connection Design Calculation-WPCDocument12 pagesStair Hand Rail Connection Design Calculation-WPCUmesh ChamaraNo ratings yet

- Splice Connection 200Document19 pagesSplice Connection 200Gheorghe IonicaNo ratings yet

- Members With Combined Bending and Axial ForceDocument32 pagesMembers With Combined Bending and Axial ForceJohn RomanusNo ratings yet

- Mechanical Columns Buckling FailureDocument19 pagesMechanical Columns Buckling FailurePraful Patil100% (1)

- Detail Estimate of RailingDocument5 pagesDetail Estimate of Railingdebasispal78No ratings yet

- Design of Fillet and Butt WeldsDocument29 pagesDesign of Fillet and Butt WeldsDarsHan MoHanNo ratings yet

- Directly Welded Flange FR Moment ConnectionsDocument1 pageDirectly Welded Flange FR Moment ConnectionssuperpiojooNo ratings yet

- Staircase Design: 8.28kN/m 15.57kN/mDocument3 pagesStaircase Design: 8.28kN/m 15.57kN/mBikki CyamaNo ratings yet

- Axially Loaded Columns - Base Plate DesignDocument2 pagesAxially Loaded Columns - Base Plate DesignaomareltayebNo ratings yet

- Flat Slab Equivalent Frame MethodDocument3 pagesFlat Slab Equivalent Frame MethodNp Pw100% (1)

- ENDPLMC9.xlsDocument4 pagesENDPLMC9.xlssiva0% (1)

- Column Base Plate Design (Bs5950-1:2000) : Project Job RefDocument4 pagesColumn Base Plate Design (Bs5950-1:2000) : Project Job RefronyNo ratings yet

- Column Base Plate DesignDocument5 pagesColumn Base Plate Design_jessecaNo ratings yet

- Column Base Plate Design CalculationDocument3 pagesColumn Base Plate Design CalculationPilippenge Asanka Iraj LaknathaNo ratings yet

- COLUMN BASE PLATE DESIGN FORCE CALCULATIONSDocument3 pagesCOLUMN BASE PLATE DESIGN FORCE CALCULATIONStoliveira80No ratings yet

- Bernard M. BaruchDocument1 pageBernard M. Baruch_jessecaNo ratings yet

- Live As If You Were To Die Tomorrow Learn As If You Were To Live ForeverDocument1 pageLive As If You Were To Die Tomorrow Learn As If You Were To Live Forever_jessecaNo ratings yet

- Broshure Fom Fon BMDocument2 pagesBroshure Fom Fon BM_jessecaNo ratings yet

- You Must Be The Change You Wish To See in The WorldDocument1 pageYou Must Be The Change You Wish To See in The World_jessecaNo ratings yet

- Albert EinsteinDocument1 pageAlbert Einstein_jessecaNo ratings yet

- "So Many Books, So Little Time." : Frank ZappaDocument1 page"So Many Books, So Little Time." : Frank Zappa_jessecaNo ratings yet

- First They Ignore You, Then They Laugh at You, Then They Fight You, Then You WinDocument1 pageFirst They Ignore You, Then They Laugh at You, Then They Fight You, Then You Win_jessecaNo ratings yet

- "A Room Without Books Is Like A Body Without A Soul." : Marcus Tullius CiceroDocument1 page"A Room Without Books Is Like A Body Without A Soul." : Marcus Tullius Cicero_jessecaNo ratings yet

- Children's Victory Over EvilDocument1 pageChildren's Victory Over Evil_jessecaNo ratings yet

- Method Statement: 1) Cut Close Along Edge of Joint For Installation of Bridge JointDocument1 pageMethod Statement: 1) Cut Close Along Edge of Joint For Installation of Bridge Joint_jessecaNo ratings yet

- Ms-Bridge 419 Klang Banting - 1Document1 pageMs-Bridge 419 Klang Banting - 1_jessecaNo ratings yet

- Ms Column StiffenerDocument1 pageMs Column Stiffener_jessecaNo ratings yet

- Ms-Crack Sealing Using Epoxy CompoundDocument1 pageMs-Crack Sealing Using Epoxy Compound_jessecaNo ratings yet

- 2 Way SlabDocument22 pages2 Way SlabAhmed Al-AmriNo ratings yet

- Ms-Bridge 419 Klang Banting - 1Document1 pageMs-Bridge 419 Klang Banting - 1_jessecaNo ratings yet

- Jesus Christ Knocks and Invites You InDocument1 pageJesus Christ Knocks and Invites You In_jessecaNo ratings yet

- "Two Things Are Infinite: The Universe and Human Stupidity and I'm Not Sure About The Universe."Document1 page"Two Things Are Infinite: The Universe and Human Stupidity and I'm Not Sure About The Universe."_jessecaNo ratings yet

- For Everyone Who Exalts Himself Will Be Humbled, and Everyone Who Humbles Himself Will Be Exalted. Jesus ChristDocument1 pageFor Everyone Who Exalts Himself Will Be Humbled, and Everyone Who Humbles Himself Will Be Exalted. Jesus Christ_jessecaNo ratings yet

- So I Say To You, Ask and It Will Be Given To You Search, and You Will Find Knock, and The Door Will Be Opened For You. Jesus ChristDocument1 pageSo I Say To You, Ask and It Will Be Given To You Search, and You Will Find Knock, and The Door Will Be Opened For You. Jesus Christ_jessecaNo ratings yet

- 10Document1 page10_jessecaNo ratings yet

- Give To Everyone Who Begs From You and of Him Who Takes Away Your Goods Do Not Ask Them Again. and As You Wish That Men Would Do To You, Do So To Them. Jesus ChristDocument1 pageGive To Everyone Who Begs From You and of Him Who Takes Away Your Goods Do Not Ask Them Again. and As You Wish That Men Would Do To You, Do So To Them. Jesus Christ_jessecaNo ratings yet

- Let The One Among You Who Is Without Sin Be The First To Cast A Stone. Jesus ChristDocument1 pageLet The One Among You Who Is Without Sin Be The First To Cast A Stone. Jesus Christ_jessecaNo ratings yet

- Do Not Let Your Hearts Be Troubled. Trust in God Trust Also in Me. Jesus ChristDocument1 pageDo Not Let Your Hearts Be Troubled. Trust in God Trust Also in Me. Jesus Christ_jessecaNo ratings yet

- Jesus' New Command: Love One AnotherDocument1 pageJesus' New Command: Love One Another_jessecaNo ratings yet

- Ifihadanhourtosolvea Problem I'D Spend 55 Minutes Thinking About The Problem and 5 Minutes Thinking About Solutions."Document1 pageIfihadanhourtosolvea Problem I'D Spend 55 Minutes Thinking About The Problem and 5 Minutes Thinking About Solutions."_jessecaNo ratings yet

- Jesus Christ's Quote 2Document1 pageJesus Christ's Quote 2_jessecaNo ratings yet

- Einstein QuoteDocument1 pageEinstein QuoteGabriel JimenezNo ratings yet

- Coral Redang Island ResortDocument2 pagesCoral Redang Island Resort_jessecaNo ratings yet

- General Notes For Post-Installed Reinforcing Bars SpecificationDocument1 pageGeneral Notes For Post-Installed Reinforcing Bars Specification_jessecaNo ratings yet

- IT SyllabusDocument3 pagesIT SyllabusNeilKumarNo ratings yet

- Conserve O Gram: Understanding Histograms For Digital PhotographyDocument4 pagesConserve O Gram: Understanding Histograms For Digital PhotographyErden SizgekNo ratings yet

- 277Document18 pages277Rosy Andrea NicolasNo ratings yet

- Youth, Time and Social Movements ExploredDocument10 pagesYouth, Time and Social Movements Exploredviva_bourdieu100% (1)

- 3.2 Probability DistributionDocument38 pages3.2 Probability Distributionyouservezeropurpose113No ratings yet

- Mba Project GuidelinesDocument8 pagesMba Project GuidelinesKrishnamohan VaddadiNo ratings yet

- WA Beretta M92FS Parts ListDocument2 pagesWA Beretta M92FS Parts ListDenis Deki NehezNo ratings yet

- Rakpoxy 150 HB PrimerDocument1 pageRakpoxy 150 HB Primernate anantathatNo ratings yet

- Marijuana Grow Basics - Jorge CervantesDocument389 pagesMarijuana Grow Basics - Jorge CervantesHugo Herrera100% (1)

- E-banking and transaction conceptsDocument17 pagesE-banking and transaction conceptssumedh narwadeNo ratings yet

- Febrile SeizureDocument3 pagesFebrile SeizureClyxille GiradoNo ratings yet

- EE-434 Power Electronics: Engr. Dr. Hadeed Ahmed SherDocument23 pagesEE-434 Power Electronics: Engr. Dr. Hadeed Ahmed SherMirza Azhar HaseebNo ratings yet

- January 2013 Igcse Timetable 22-06-2012Document2 pagesJanuary 2013 Igcse Timetable 22-06-2012Rizwanur RahmanNo ratings yet

- Chapter 1 - IntroductionDocument42 pagesChapter 1 - IntroductionShola ayipNo ratings yet

- Neonatal SepsisDocument87 pagesNeonatal Sepsisyhanne100% (129)

- Chapter 9-10 (PPE) Reinzo GallegoDocument48 pagesChapter 9-10 (PPE) Reinzo GallegoReinzo GallegoNo ratings yet

- The Wafer-God and the Bloody History of the VaticanDocument58 pagesThe Wafer-God and the Bloody History of the VaticanMin Hotep Tzaddik BeyNo ratings yet

- Rubric - Argumentative EssayDocument2 pagesRubric - Argumentative EssayBobNo ratings yet

- English Skills BookDocument49 pagesEnglish Skills BookAngela SpadeNo ratings yet

- Policies and Regulations On EV Charging in India PPT KrishnaDocument9 pagesPolicies and Regulations On EV Charging in India PPT KrishnaSonal ChoudharyNo ratings yet

- Trimble Oem Gnss Bro Usl 0422Document3 pagesTrimble Oem Gnss Bro Usl 0422rafaelNo ratings yet

- Universal Robina Co. & Bdo Unibank Inc.: Research PaperDocument25 pagesUniversal Robina Co. & Bdo Unibank Inc.: Research PaperSariephine Grace ArasNo ratings yet

- What Is Rack Chock SystemDocument7 pagesWhat Is Rack Chock SystemSarah Perez100% (1)

- 4 - Complex IntegralsDocument89 pages4 - Complex IntegralsryuzackyNo ratings yet

- Hastrof Si Cantril. 1954. The Saw A Game. A Case StudyDocument6 pagesHastrof Si Cantril. 1954. The Saw A Game. A Case Studylandreea21No ratings yet

- Nature and Scope of Marketing Marketing ManagementDocument51 pagesNature and Scope of Marketing Marketing ManagementFeker H. MariamNo ratings yet

- Intec Waste PresiDocument8 pagesIntec Waste Presiapi-369931794No ratings yet

- The Emperor Jones: What's Inside in ContextDocument27 pagesThe Emperor Jones: What's Inside in ContextHarshvardhan RaiNo ratings yet

- IE399 Summer Training ReportDocument17 pagesIE399 Summer Training ReportgokanayazNo ratings yet