Professional Documents

Culture Documents

Tank Cleaning

Uploaded by

Wiwatthana KumpimCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tank Cleaning

Uploaded by

Wiwatthana KumpimCopyright:

Available Formats

Issued Date: 23/01/14

TECHNICAL

Rev.

Industrial Cleaning Services Public Company Limited

Page: 1

PROPOSAL

Technical Proposal of

10 Unit tank project

Client : Qualitech

Location: Phrapadaeng, Samutprakan

By: Wiwatthana Kumpim

Industrial Cleaning Services Co., Ltd

Office address:

88/8 Warisara 3 Moo 3 Pala Banchang - Rayong - Thailand

Work shop address:

18 Moo 2, Pala District, Ban chang, Rayong 21130 Thailand

Phone: 038 601029 Fax. 038 601030

FP-09-02 Rev.00 Eff. Date 01/08/2013

Issued Date: 23/01/14

TECHNICAL

Rev.

Page: 2

PROPOSAL

Industrial Cleaning Services Public Company Limited

1. Project Information

TANK STORAGE

Product

: Lube Oil

Type of roof

: cone roof tank

2. sequence of tank cleaning

Sequence

Target

Equipment

Complete

Heap truck

2. Tank Ventilation

LEL = 0%, O2 = 20.9 %

Air Ejector & Air Comp.

3. Cleaning Lube Oil

Tank have clear lube oil

ICS 008

4. HPWJ inside tank

Tank have clear rust

ICS 008

Rust are empty

ICS 105

pH = 6 - 8

Water, CIP Machine

Tank are clean & Dry

Rag, Air Ejector

1. Mobilization & Installation

5. Chemical cleaning (if Rust can't empty)

6. Water washing to remove acid cleaner

7. Mop Dry

FP-09-02 Rev.00 Eff. Date 01/08/2013

Issued Date: 23/01/14

TECHNICAL

Rev.

Page: 3

PROPOSAL

Industrial Cleaning Services Public Company Limited

3. Preparation

3.1.

Preparation tank cleaning machine Unit and waste tank

3.2.

Utility supply: Air compressor, Electric Generator, plant water

3.3.

Confirmation tank ready hand over to contractor from customer

3.4.

Connect drain line tank to Tank Cleaning

4. Work Procedure

Step of Tank cone roof No. 01 Tank cone roof No. 04

Step 01 Mobilization & Installation

1. Transportation all equipment and tools from ICS to Customer plant.

2. Inspection equipment and tools by owner and ICS.

3. Install air system.

4. Install equipment before start work.

Step 02 Tank Ventilation

Air Ejector

Air Ejector

Air compressor

1. Prepare two air ejector, one for blow and one for suck

2. Suck the gas inside tank out with air ejector while another air ejector blow air

to make ventilation

3. Check gas quality inside the tank regularly

4. Progress to the next step if LEL<10 %, O2 = 20.9 % to handover Confined

space work.

FP-09-02 Rev.00 Eff. Date 01/08/2013

Issued Date: 23/01/14

TECHNICAL

Rev.

Page: 4

PROPOSAL

Industrial Cleaning Services Public Company Limited

Step 03 Cleaning Lube Oil

P-8

ICS 008

Water hydrant

P-3

P-5

P-4

P-4

Pump Transfer

Pump Transfer

Waste transfer

1. Fill up Chemical cleaning ICS 008 to Skimmer Tank = 10 m3

2. Start Suction Pump for chemical cleaning inside tank

3. Continue suck liquid and chemical cleaning circulation (close loop system)

4. Step Chemical cleaning finished if sample is clear and LEL = 0

5. Transfer all waste to waste tank then flushing tank by air compressor

Step 04 Cleaning in side tank by CIP nozzle

Jet nozzle

E-1

Pump

Waste tank 20 m3

1. Start cleaning bottom tank by HP jet by use 3 % chemical 008 solution to remove the

diluted scale.

2. Transfer waste water to waste tank

FP-09-02 Rev.00 Eff. Date 01/08/2013

Issued Date: 23/01/14

TECHNICAL

Rev.

Industrial Cleaning Services Public Company Limited

Page: 5

PROPOSAL

Step 05 Chemical cleaning (Chemical cleaning if Rust can't empty)

Citric Acid

Water hydrant

P-3

P-5

P-4

P-4

Pump Transfer

Pump Transfer

Waste transfer

1. Fill up Chemical cleaning ICS 105 to Skimmer Tank = 10 m3

2. Start Suction Pump for chemical cleaning inside tank

3. Continue suck liquid and chemical cleaning circulation (close loop system)

4. Step Chemical cleaning finished if sample is clear and LEL = 0

5. Transfer all waste to waste tank then flushing tank by air compressor

Step 06. Water washing inside tank.

1. Fill up water to Skimmer Tank = 10 m3

2. Start water washing inside tank with circulation close system (pH =6 - 8).

3. Transfer sludge during water circulation to waste tank.

4. Transfer waste water after step water washing are complete to waste tank.

Step 07 Final Inspection and De-Mobilization

1. Final Inspection by Owner.

2. Housekeeping around site Area.

3. De-Mobilization.

FP-09-02 Rev.00 Eff. Date 01/08/2013

Issued Date: 23/01/14

TECHNICAL

Rev.

Page: 6

PROPOSAL

Industrial Cleaning Services Public Company Limited

Step of Cylinder No. 01 Cylinder No. 06

Step 01 Mobilization & Installation

1. Transportation all equipment and tools from ICS to Customer plant.

2. Inspection equipment and tools by owner and ICS.

3. Install air system.

4. Install equipment before start work.

Step 02 Tank Ventilation

Air Ejector

P-22

P-2

Air Ejector

Air compressor

1. Prepare two air ejector, one for blow and one for suck

2. Suck the gas inside tank out with air ejector while another air ejector blow air

to make ventilation

3. Check gas quality inside the tank regularly

4. Progress to the next step if LEL<10 %, O2 = 20.9 % to handover Confined

space work.

FP-09-02 Rev.00 Eff. Date 01/08/2013

Issued Date: 23/01/14

TECHNICAL

Rev.

Industrial Cleaning Services Public Company Limited

Page: 7

PROPOSAL

Step 03 Cleaning Lube Oil

ICS 008

Water hydrant

P-5

P-4

Pump Transfer

Pump Transfer

Waste transfer

1. Fill up Chemical cleaning ICS 008 to Skimmer Tank = 10 m3

2. Start Suction Pump for chemical cleaning inside tank

3. Continue suck liquid and chemical cleaning circulation

4. Step Chemical cleaning finished if sample is clear and LEL = 0

5. Transfer all waste to waste tank.

Step 04 Cleaning inside tank

Jet nozzle

Pump

Waste tank 20 m3

FP-09-02 Rev.00 Eff. Date 01/08/2013

Issued Date: 23/01/14

TECHNICAL

Rev.

Industrial Cleaning Services Public Company Limited

Page: 8

PROPOSAL

1. Start cleaning bottom tank by HP jet by use 3 % chemical 008 solution to remove the

diluted scale.

2. Transfer waste water to waste tank.

Step 05 Chemical cleaning (Chemical cleaning if Rust can't empty)

Citric Acid

Water hydrant

P-5

P-4

Pump Transfer

Pump Transfer

Waste transfer

1. Fill up Chemical cleaning ICS 105 to Skimmer Tank = 10 m3

2. Start Suction Pump for chemical cleaning inside tank

3. Continue suck liquid and chemical cleaning circulation (close loop system)

4. Step Chemical cleaning finished if sample is clear and LEL = 0

5. Transfer all waste to waste tank then flushing tank by air compressor

Step 06. Water washing inside tank.

1. Fill up water to Skimmer Tank = 10 m3

2. Start water washing inside tank with circulation close system (pH =6 - 8).

3. Transfer sludge during water circulation to waste tank.

4. Transfer waste water after step water washing are complete to waste tank.

Step 07 Final Inspection and De-Mobilization

1. Final Inspection by Owner.

2. Housekeeping around site Area.

3. De-Mobilization.

FP-09-02 Rev.00 Eff. Date 01/08/2013

TECHNICAL

Issued Date: 23/01/14

Rev.

Industrial Cleaning Services Public Company Limited

Page: 9

PROPOSAL

5. Equipment and Tool List

-

Air Compressor (175 CFM)

unit

Generator 60 KVA

EA

Hose ( 2 inch, 20 m )

EA

Hose ( 1-1.5 inch, 60 m )

EA

Hose ( inch, 25 m )

EA

Check valve 2 ,3

EA

High pressure water jet 250 bar

EA

Gas Detector (CO2, O2, LEL, VOC) =

unit.

Oxygen Alert

EA

Air Ejector 6"

unit

Waste tank (20 m3)

unit

CIP Pump

unit

Start stop control panel

unit

PPE (Protection suit, Mask, etc)

lot

Mechanical tools Box

Set

Electricity Control Panel 380 V

unit

Lighting 24 VDC

unit

pH meter

unit

Toilet

unit

Consumable :

Chemical ICS 008

200

liter

Chemical ICS 105

150

liter

FP-09-02 Rev.00 Eff. Date 01/08/2013

Issued Date: 23/01/14

TECHNICAL

Rev.

Industrial Cleaning Services Public Company Limited

Page: 10

PROPOSAL

6. Organization

Industrial Cleaning Services company limited

ORGANIZATION CHART

Project manager

Mr.Thananan Sonta

Tel: 090-9080675

Site engineer

Tel: 082-7169360

Foremen

Safety

Document control

Ms. Rossarin Hitaran

Tel: 089-5413432

Operation confine spec

Issued :____________

Check :_____________

On date :___________

On date :_____________

Industrial Cleaning Services

Approved :_____________

On date :_____________

MSS

FP-09-02 Rev.00 Eff. Date 01/08/2013

Issued Date: 23/01/14

TECHNICAL

Rev.

Industrial Cleaning Services Public Company Limited

Page: 11

PROPOSAL

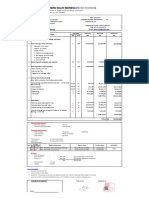

7. Manpower loading (Plan)

MANPOWER LOADING (PLAN)

2015

Item

Description

1

Day

3

Project Engineer

Safety Officer

Operation (confine space )

Foreman

SUM

8. Schedule plan

SCHEDULE PLAN (PER TANK )

CHEMICAL CLEANING INSIDE TANK

2015

No.

Description

Manpower

Duration

Days

1 2 3 4 5 6

Mobilization & Installation

Tank Ventilation

Cleaning Lube Oil

Cleaning inside tank

Chemical cleaning

Water washing

Mop Dry

FP-09-02 Rev.00 Eff. Date 01/08/2013

Issued Date: 23/01/14

TECHNICAL

Rev.

Industrial Cleaning Services Public Company Limited

Page: 12

PROPOSAL

9. MSDS chem. ICS 008

1. PRODUCT DESCRIPTION AND COMPANY IDENTIFICATION

PRODUCT NAME :

ICS 008

GERERAL DESCRIPTION :

DATE OF MSDS

PREPARATION :

Tank cleaning ( CTC Cleaner )

COMPANY IDENTIFICATION :

INDUSTRIAL CLEANING SERVICES PUBLIC CO.,LTD.

5/7/2012

99 Moo 3, Pala District,

Ban chang, Rayong 21130, Thailand.

Telp. No. : +66 038 601029

Fax. No. : +66 038 601030

NFPA HAZARD IDENTIFICATION SYSTEM

WARNING STATEMENT :

Flammability

National Fire Protection

Reactivity

Association NFPA

( Unitate State )

Health

Specific danger

2. PRODUCT COMPOSITION

Chemical name (CAS No. )

Content ( %

)

Alcoholethoxylate ( CAS # 68002-97-1 )

25%

Surfactans, complexing agent and additive

75%

3. PHYSICAL PROPERTIES

Form :

Viscose

liquid

Colour :

Yellow-brownish ( 2 phases )

Smell :

Melting point/Melting range

:

Recognizable

Boiling point/Boiling range :

100C

Flash point :

Product is non-flammable nor potential explosive

Self-inflammability :

Product is not selfigniting

Danger of explosion :

Product is not approx. potentially explosive

Vapour pressure at 20C :

Density at 20C

:

23 hPa

Solubility in / Miscibillity with water :

Product is fully miscible

Vapour Pressure at 20C :

6.5 to 7.5

Not determined

1.0 g/cm

FP-09-02 Rev.00 Eff. Date 01/08/2013

Issued Date: 23/01/14

TECHNICAL

Rev.

Industrial Cleaning Services Public Company Limited

Page: 13

PROPOSAL

4. FIRE AND EXPLOSION DATA

Extinguishing media:

Recommended:

Water, water fog or foam

Only with small fires CO2 and dry chemical can be used.

Recommendations:

Not to be used: Alcohol foam.

Exposure to decomposition products (CO) may cause a

health hazard.

Appropriate breathing apparatus may be required.

Cool closed containers exposed to fire with water.

5. HEALTH HAZARD DATA

Hazard description:

Information pertaining to particular dangers for man

and environment:

R-51/53

R-65

Xn Harmful

N environmentally hazardous

Toxic to aquatic organisms/may cause long term adverse effects in the Aquatic environment

Harmful: May cause lung damage if

swallowed.

6. FIRST AID MEASURES

General Advice:

Instantly remove any clothing soiled by the product.

After

Inhalation:

Provide fresh-air circulation. If symptms continue, consult a doctor. In case of respiratory failure or breathing

irregularities, commence

resusitation or oxygen inhalation and immediately consult a doctor. In case of unconsciousness, place and transport

the patient

in a recovery position

After Skin contact:

Instantly wash with water and soap and rinse thoroughly. If skin irritation persissts, seek medical advice.

After Eye contact:

Rinse immediately opened eye for several minute under running water. Then consult doctor.

After awallowing:

Rinse out mouth and then drink plenty of water. Do not induce vomiting: instantly call for medical.

7. REACTIVITY DATA

Thermal decomposition/ condition to be avoided : No decomposition if used according to specifications.

Dangerous reactions : No dangerous reaction known

Dangerous product of composition : No dangerous decomposition

product known

8. EXPOSER CONTROLS/PERSONAL PROTECTION

Provide adequate

Engineering measures:

ventilation.

FP-09-02 Rev.00 Eff. Date 01/08/2013

Issued Date: 23/01/14

TECHNICAL

Rev.

Industrial Cleaning Services Public Company Limited

Page: 14

PROPOSAL

Respiratory protection:

Normally not required

Hand protection

Eye protection:

Gloves

Use chemical workers

goggles.

Skin protection:

Normal working clothing.

9. TOXICOLOGICAL INFORMATION

Acute toxicity :

Primary irritant effect :

On the skin :

Non irritant effect.

On the eye :

Strong irritant with danger of severe eye injury

Sensitization :

No sensitizing effect know

additional toxicological information :

The product shows the following dangers

10. ECOLOGICAL INFORMATION

There are no data available on the preparation itself.

Material floats on water.

Biodegradability: BOD 28d (20C): 41-48%

ThOD.

LC50 (fish): 1-10 mg/1.

FP-09-02 Rev.00 Eff. Date 01/08/2013

Issued Date: 23/01/14

TECHNICAL

Rev.

Page: 15

PROPOSAL

Industrial Cleaning Services Public Company Limited

10. MSDS chem. ICS 105

1. PRODUCT DESCRIPTION AND COMPANY IDENTIFICATION

PRODUCT NAME :

ICS 105

GERERAL DESCRIPTION :

Acid solution for remove remaining scale of rust

from process equipment .

DATE OF MSDS PREPARATION :

5/7/2012

INDUSTRIAL CLEANING SERVICES PUBLIC

CO.,LTD.

COMPANY IDENTIFICATION :

99 Moo 3, Pala District,

Ban chang, Rayong 21130, Thailand.

Telp. No. : +66 038 601029

Fax. No. : +66 038 601030

NFPA HAZARD IDENTIFICATION SYSTEM

Flammability

WARNING STATEMENT :

National Fire

Protection

Association

NFPA

( Unitate

State )

Reactivity

Health

Specific danger

2. PRODUCT COMPOSITION

Chemical name (CAS No. )

Content ( % by Weight )

Acetic acid (CAS # 64-19-7)

100

3. PHYSICAL PROPERTIES

Physical state and appearance:

Liquid.

Odor:

Pungent, vinegar-like, sour (Strong.)

Molecular Weight:

60.05 g/mole

Color:

Colorless. Clear (Light.)

Boiling Point:

118.1C (244.6F)

Melting Point:

16.6C (61.9F)

Critical Temperature:

321.67C (611F)

Specific Gravity:

1.049 (Water = 1)

Vapor Pressure:

1.5 kPa (@ 20C)

Vapor Density:

2.07 (Air = 1)

Odor Threshold:

0.48 ppm

Water/Oil Dist. Coeff.:

The product is more soluble in water; log(oil/water)

FP-09-02 Rev.00 Eff. Date 01/08/2013

Issued Date: 23/01/14

TECHNICAL

Rev.

Industrial Cleaning Services Public Company Limited

Page: 16

PROPOSAL

= -0.2

Dispersion Properties:

See solubility in water, diethyl ether, acetone.

Solubility:

Easily soluble in cold water, hot water. Soluble in diethyl ether, acetone. Miscible with Glycerol, alcohol, Benzene, Carbon

Tetrachloride. Practically insoluble in Carbon Disulfide.

4. FIRE AND EXPLOSION DATA

Flammability of the Product:

Auto-Ignition Temperature:

Flash Points: CLOSED CUP:

Flammable Limits:

Products of Combustion:

Fire Hazards in Presence of Various

Substances:

Flammable.

463C (865.4F)

CLOSED CUP: 39C (102.2F). OPEN CUP: 43C

(109.4F).

LOWER: 4% UPPER: 19.9%

These products are carbon oxides (CO, CO2).

Flammable in presence of open flames and sparks, of heat. Slightly flammable to flammable in presence of oxidizing

materials, of metals.

Explosion Hazards in Presence of Various Substances:

Risks of explosion of the product in presence of mechanical impact: Not available. Risks of explosion of the product in

presence of static discharge: Not available. Slightly explosive in presence of oxidizing materials.

Fire Fighting Media and Instructions:

Flammable liquid, soluble or dispersed in water. SMALL FIRE: Use DRY chemical powder. LARGE FIRE: Use alcohol foam,

water spray or fog. Cool containing vessels with water jet in order to prevent pressure build-up, autoignition or explosion.

Special Remarks on Fire Hazards:

Reacts with metals to produces flammable hydrogen gas. It will ignite on contact with potassium-tert-butoxide. A mixture

of

ammonium nitrate and acetic acid ignites when warmed, especially if warmed.

Special Remarks on Explosion Hazards:

Acetic acid vapors may form explosive mixtures with air. Reactions between acetic acid and the following materials

are potentially explosive: 5-azidotetrazole, bromine pentafluoride, chromium trioxide, hydrogen peroxide, potassium

permanganate, sodium peroxide, and phorphorus trichloride. Dilute acetic acid and dilute hydrogen can undergo an

exothermic reaction if heated, forming peracetic acid which is explosive at 110 degrees C. Reaction between chlorine

trifluoride and acetic acid is very violent, sometimes explosive.

5. HEALTH HAZARD DATA

Potential Acute Health Effects:

Very hazardous in case of skin contact (irritant), of eye contact (irritant), of ingestion, of inhalation. Hazardous in case of

skin

contact (corrosive, permeator), of eye contact (corrosive). Liquid or spray mist may produce tissue damage particularly on

mucous membranes of eyes, mouth and respiratory tract. Skin contact may produce burns. Inhalation of the spray mist

may

produce severe irritation of respiratory tract, characterized by coughing, choking, or shortness of breath. Inflammation of

the

eye is characterized by redness, watering, and itching. Skin inflammation is characterized by itching, scaling, reddening, or,

occasionally, blistering.

Potential Chronic Health Effects:

Hazardous in case of skin contact (irritant), of ingestion, of inhalation. CARCINOGENIC EFFECTS: Not available.

FP-09-02 Rev.00 Eff. Date 01/08/2013

Issued Date: 23/01/14

TECHNICAL

Rev.

Industrial Cleaning Services Public Company Limited

Page: 17

PROPOSAL

MUTAGENIC EFFECTS: Mutagenic for mammalian somatic cells. Mutagenic for bacteria and/or yeast. TERATOGENIC

EFFECTS: Not available. DEVELOPMENTAL TOXICITY: Not available. The substance may be toxic to kidneys, mucous

membranes, skin, teeth. Repeated or prolonged exposure to the substance can produce target organs damage. Repeated

or prolonged contact with spray mist may produce chronic eye irritation and severe skin irritation. Repeated or prolonged

exposure to spray mist may produce respiratory tract irritation leading to frequent attacks of bronchial infection.

6. FIRST AID MEASURES

Eye Contact:

Check for and remove any contact lenses. In case of contact, immediately flush eyes with plenty of water for at least 15

minutes. Cold water may be used. Get medical attention immediately.

Skin Contact:

In case of contact, immediately flush skin with plenty of water for at least 15 minutes while removing contaminated

clothing

and shoes. Cover the irritated skin with an emollient. Cold water may be used.Wash clothing before reuse. Thoroughly

clean

shoes before reuse. Get medical attention immediately.

Serious Skin Contact:

Wash with a disinfectant soap and cover the contaminated skin with an anti-bacterial cream. Seek immediate medical

attention.

Inhalation:

If inhaled,remove to fresh air. If not breathing,give artificial respiration.If breathing is difficult,give oxygen.Get medical

attention immediately.

Serious Inhalation:

Evacuate the victim to a safe area as soon as possible. Loosen tight clothing such as a collar, tie, belt or waistband. If

breathing is difficult, administer oxygen. If the victim is not breathing, perform mouth-to-mouth resuscitation. WARNING:

It may

be hazardous to the person providing aid to give mouth-to-mouth resuscitation when the inhaled material is toxic,

infectious or

corrosive. Seek immediate medical attention.

Ingestion:

Do NOT induce vomiting unless directed to do so by medical personnel. Never give anything by mouth to an unconscious

person. Loosen tight clothing such as a collar, tie, belt or waistband. Get medical attention if symptoms appear.

Serious Ingestion: Not available.

7. REACTIVITY DATA

Stability:

The product is stable.

Instability Temperature:

Not available.

Conditions of Instability:

Heat, ignition sources, incompatible materials

Corrosivity:

Highly corrosive in presence of stainless steel(304). Slightly corrosive in presence of aluminum, of copper. Non-corrosive in

presence of stainless steel(316).

Special Remarks on Reactivity:

Reacts violently with strong oxidizing agents, acetaldehyde, and acetic anhydride. Material can react with metals, strong

bases, amines, carbonates, hydroxides, phosphates, many oxides,cyanides, sulfides, chromic acid, nitric acid, hydrogen

peroxide, carbonates. ammonium nitrate, ammonium thiosulfate, chlorine trifluoride, chlorosulfonic acid, perchloric acid,

permanganates, xylene, oleum, potassium hydroxide, sodium hydroxide, phosphorus isocyanate, ethylenediamine,

ethylene imine.

FP-09-02 Rev.00 Eff. Date 01/08/2013

Issued Date: 23/01/14

TECHNICAL

Rev.

Industrial Cleaning Services Public Company Limited

Page: 18

PROPOSAL

Special Remarks on Corrosivity:

Moderate corrosive effect on bronze. No corrosion

data on brass

Polymerization:

Will not occur.

8. EXPOSER CONTROLS/PERSONAL PROTECTION

Engineering Controls:

Provide exhaust ventilation or other engineering controls to keep the airborne concentrations of vapors below their

respective

threshold limit value. Ensure that eyewash stations and safety showers are proximal to the work-station location.

Personal Protection:

Splash goggles. Synthetic apron. Vapor respirator. Be sure to use an approved/certified respirator or equivalent. Gloves

(impervious).

Exposure Limits:

TWA: 10 STEL: 15 (ppm) [Australia] TWA: 25 STEL: 27 (mg/m3) [Australia] TWA: 10 STEL: 15 (ppm) from NIOSH TWA:

25

STEL: 37 (mg/m3) from NIOSH TWA: 10 STEL: 15 (ppm) [Canada] TWA: 26 STEL: 39 (mg/m3) [Canada] TWA: 25 STEL: 37

(mg/m3) TWA: 10 STEL: 15 (ppm) from ACGIH (TLV) [United States] [1999] TWA: 10 (ppm) from OSHA (PEL) [United States]

TWA: 25 (mg/m3) from OSHA (PEL) [United States]Consult local authorities for acceptable exposure limits.

9. TOXICOLOGICAL INFORMATION

Routes of Entry: Absorbed through skin. Dermal contact. Eye contact. Inhalation. Ingestion.

Toxicity to Animals:

WARNING: THE LC50 VALUES HEREUNDER ARE ESTIMATED ON THE BASIS OF A 4-HOUR EXPOSURE. Acute oral

toxicity (LD50): 3310 mg/kg [Rat]. Acute dermal toxicity (LD50): 1060 mg/kg [Rabbit]. Acute toxicity of the vapor (LC50):

5620 1 hours[Mouse].

Chronic Effects on Humans:

MUTAGENIC EFFECTS: Mutagenic for mammalian somatic cells. Mutagenic for bacteria and/or yeast. May cause damage

to

the following organs: kidneys, mucous membranes, skin, teeth.

Special Remarks on Toxicity to Animals: Not available.

Special Remarks on Chronic Effects on Humans:

May affect genetic material and may cause reproductive effects based on animal data. No human data found.

Special Remarks on other Toxic Effects on

Humans:

Acute Potential Health Effects: Skin: Extremely irritating and corrosive. Causes skin irritation (reddening and itching,

inflammation). May cause blistering , tissue damage and burns. Eyes: Extremely irritating and corrosive. Causes eye

irritation,

lacrimation, redness, and pain. May cause burns, blurred vision, conjunctivitis, conjunctival and corneal destruction and

permanent injury. Inhalation: Causes severe respiratory tract irritation. Affects the sense organs (nose, ear, eye, taste),

and blood. May cause chemical pneumonitis, bronchitis, and pulmonary edema. Severe exposure may result in lung tissue

damage and corrosion (ulceration) of the mucous membranes. Inhalation may also cause rhinitis, sneezing, coughing,

oppressive feeling in the chest or chest pain, dyspnea, wheezing, tachypnea, cyanosis, salivation, nausea, giddiness,

muscular weakness. Ingestion: Moderately toxic. Corrosive. Causes gastrointestinal tract irritation (burning and pain of the

mouth, throat, and abdomen, coughing, ulceration, bleeding, nausea, abdomial spasms, vomiting, hematemesis, diarrhea.

May Also affect the liver (impaired liver function), behavior (convulsions, giddines, muscular weakness), and the urinary

system - kidneys (Hematuria, Albuminuria, Nephrosis, acute renal failure, acute tubular necrosis). May also cause dyspnea

or asphyxia. May also lead to shock, coma and death. Chronic Potential Health Effects: Chronic exposure via ingestion may

cause blackening or erosion of the teeth and jaw necrosis, pharyngitis, and gastritis. It may also behavior (similar to acute

FP-09-02 Rev.00 Eff. Date 01/08/2013

Issued Date: 23/01/14

TECHNICAL

Rev.

Industrial Cleaning Services Public Company Limited

Page: 19

PROPOSAL

ingestion), and metabolism (weight loss). Chronic exposure via inhalation may cause asthma and/or bronchitis with cough,

phlegm, and/or shortness of breath . It may also affect the blood (decreased leukocyte count), and urinary system

(kidneys).

Repeated or prolonged skin contact may cause thickening, blackening, and cracking of the skin.

10. ECOLOGICAL INFORMATION

Ecotoxicity:

Ecotoxicity in water (LC50): 423 mg/l 24 hours [Fish (Goldfish)]. 88 ppm 96 hours [Fish (fathead minnow)]. 75

ppm 96 hours

[Fish (bluegill sunfish)]. >100 ppm 96 hours [Daphnia].

BOD5 and COD: BOD-5: 0.34-0.88 g oxygen/g

Products of Biodegradation:

Possibly hazardous short term degradation products are not likely. However, long term degradation products may arise.

Toxicity of the Products of Biodegradation: The products of degradation are less toxic than the product

itself.

Special Remarks on the Products of Biodegradation: Not available.

FP-09-02 Rev.00 Eff. Date 01/08/2013

You might also like

- Operating & Instructions: ManualDocument20 pagesOperating & Instructions: ManualjujuroyaleNo ratings yet

- 6.16.2.3 ENI Tank Cleaning ProcedureDocument28 pages6.16.2.3 ENI Tank Cleaning ProcedurePopa Vasile71% (7)

- Steam Turbine and Governor (SimPowerSystems)Document5 pagesSteam Turbine and Governor (SimPowerSystems)hitmancuteadNo ratings yet

- RA Templates - Tank CleaningDocument26 pagesRA Templates - Tank Cleaningkoib78981% (16)

- JO Tankers Tank Cleaning GuideDocument48 pagesJO Tankers Tank Cleaning Guidekhebiloğlu100% (1)

- Tank Cleaning: Hydrojetting MethodDocument18 pagesTank Cleaning: Hydrojetting MethodSu Ka100% (2)

- Procedure of High Pressure Water Jet CleaningDocument15 pagesProcedure of High Pressure Water Jet CleaningIqbal Safirul Barqi100% (7)

- BP Tank Cleaning GuideDocument21 pagesBP Tank Cleaning GuideIlyas Rangga Ramadhan100% (1)

- Cleaning Petroleum Storage TanksDocument34 pagesCleaning Petroleum Storage Tankschapulincolorado100% (2)

- Nevada Reply BriefDocument36 pagesNevada Reply BriefBasseemNo ratings yet

- Water Tank Cleaning ProceduresDocument3 pagesWater Tank Cleaning ProceduresOlumide Aina83% (12)

- Standard procedures for tank cleaning, purging and gas free operationDocument7 pagesStandard procedures for tank cleaning, purging and gas free operationDhitya Agil Harnowo100% (1)

- Tank Cleaning Guide For Oil and Chemical TankerDocument28 pagesTank Cleaning Guide For Oil and Chemical TankerRuyinggly100% (12)

- TankCleaningManual TM TC 1 PDFDocument110 pagesTankCleaningManual TM TC 1 PDFDaniel Vaideanu100% (1)

- PT BERLIAN LAJU TANKER Tbk Tank Cleaning GuideDocument66 pagesPT BERLIAN LAJU TANKER Tbk Tank Cleaning Guideandri wirawan100% (1)

- Drew Marine Tank Cleaning ManualDocument102 pagesDrew Marine Tank Cleaning ManualStasio8090% (10)

- MS - Tank Cleaning and DesludgingDocument7 pagesMS - Tank Cleaning and DesludgingkoyahassanNo ratings yet

- Automated Tank Cleaning GuideDocument53 pagesAutomated Tank Cleaning Guideschjhdfi38100% (1)

- Safety Training Hydrojetting of Exchangers GeneralDocument15 pagesSafety Training Hydrojetting of Exchangers GeneralandinumailNo ratings yet

- Crude Oil Tank CleaningDocument7 pagesCrude Oil Tank CleaningSandip Mahata100% (1)

- Procedure For Tank Washing and CleaningDocument3 pagesProcedure For Tank Washing and CleaningSachin Yadav54% (13)

- Idrabel Tank CleaningDocument8 pagesIdrabel Tank CleaningMuTe JameeLa BimbimShopNo ratings yet

- Tank Cleaning Chemical ManualDocument37 pagesTank Cleaning Chemical Manualukal100% (1)

- 036-Nitrogen Purging Procedure PDFDocument13 pages036-Nitrogen Purging Procedure PDFKöksal Patan78% (9)

- Standard Procedures For Tank Cleaning, Purging and Gas Free Operation For Oil TankersDocument8 pagesStandard Procedures For Tank Cleaning, Purging and Gas Free Operation For Oil TankersGopu Thalikunnath100% (3)

- Chemical CleaningDocument22 pagesChemical Cleaningamareshscribd100% (1)

- Stage 1 Chemical Cleaning ProcedureDocument19 pagesStage 1 Chemical Cleaning ProcedureMarcos2089100% (3)

- CEMEX Global Strategy CaseDocument4 pagesCEMEX Global Strategy CaseSaif Ul Islam100% (1)

- Tank Cleaning MethodDocument6 pagesTank Cleaning MethodSnehilNo ratings yet

- Jsa-Hot Oil FlushingDocument2 pagesJsa-Hot Oil Flushingyelsa otrebla100% (5)

- Cleaning of Storage TanksDocument2 pagesCleaning of Storage Tanksgshdavid100% (1)

- Tank Cleaning GuidanceDocument8 pagesTank Cleaning Guidancedumitro67% (3)

- Tank Cleaning MethodsDocument9 pagesTank Cleaning MethodsAmr A. Nader100% (1)

- Tank Commissioning ProcedureDocument7 pagesTank Commissioning ProcedureYo Wee Liam100% (5)

- TankCleaning WallWashing November2014Document18 pagesTankCleaning WallWashing November2014Goldy100% (3)

- Standard Operating Procedure of Tank Cleaning - Fixed / Floating RoofDocument3 pagesStandard Operating Procedure of Tank Cleaning - Fixed / Floating RoofZulhilmi Zalizan50% (2)

- Commissioning of Transformers and Reactors - ArunDocument70 pagesCommissioning of Transformers and Reactors - Arunvikrampunia3No ratings yet

- Tank Cleaning Guide (BP 2004)Document1 pageTank Cleaning Guide (BP 2004)g66666100% (3)

- Chemical CleaningDocument32 pagesChemical Cleaningkae kae100% (2)

- Sand Blasting Procedure-SNIPLDocument4 pagesSand Blasting Procedure-SNIPLSurendra Kumar Chordia100% (2)

- Scope of Work - Naptha Tank Internal Cleaning 3000009815Document2 pagesScope of Work - Naptha Tank Internal Cleaning 3000009815nhariwijayaNo ratings yet

- Habawel V Court of Tax AppealsDocument1 pageHabawel V Court of Tax AppealsPerry RubioNo ratings yet

- Variant Configuration Step by Step ConfigDocument18 pagesVariant Configuration Step by Step Configraghava_83100% (1)

- Method Statement DPE GL1 Cooling Water Line CleaningDocument15 pagesMethod Statement DPE GL1 Cooling Water Line CleaningDheeraj Chowdary DhanekulaNo ratings yet

- Sludge Removal PDFDocument35 pagesSludge Removal PDFNeeta AgrawalNo ratings yet

- Chemical Tanker Design and Cargo SystemsDocument15 pagesChemical Tanker Design and Cargo SystemsJayakumar Sankaran100% (6)

- A400 PDFDocument4 pagesA400 PDFsnarmeNo ratings yet

- Purging Gas Freeing Inerting ProcedureDocument3 pagesPurging Gas Freeing Inerting ProcedureRahulChoudhary100% (1)

- 132KV Siemens Breaker DrawingDocument13 pages132KV Siemens Breaker DrawingAnil100% (1)

- Manual Tank Cleaning & Decontamination Support ServicesDocument22 pagesManual Tank Cleaning & Decontamination Support ServicesLee Hunter Jr100% (1)

- OES Crude Tank Cleaning ProceduresDocument3 pagesOES Crude Tank Cleaning ProceduresBach DoanNo ratings yet

- How To Measure False AirDocument3 pagesHow To Measure False AirTamer Fathy100% (3)

- Fuel Oil Tank Cleaning ProcedureDocument3 pagesFuel Oil Tank Cleaning ProcedureIqbal Safirul Barqi80% (5)

- Tank Cleaning Guide by DR VerweyDocument0 pagesTank Cleaning Guide by DR Verweykostov_vladi63% (8)

- Tank Cleaning ProcedureDocument35 pagesTank Cleaning ProcedureAch Dja'far S93% (15)

- Tank CleaningDocument6 pagesTank Cleaningmember1000No ratings yet

- Clean crude oil storage tanksDocument2 pagesClean crude oil storage tanksOgochukwu100% (1)

- 10 Unit Tank Project: Technical ProposalDocument19 pages10 Unit Tank Project: Technical ProposalkothandapaniNo ratings yet

- Boiler Chemical Cleaning ProcedureDocument20 pagesBoiler Chemical Cleaning ProcedureHandoko AurelNo ratings yet

- Tank Cleaning & De-SludgingDocument1 pageTank Cleaning & De-SludgingShaiful AnnuarNo ratings yet

- Typical Acid Cleaning Procedure For Compressor LinesDocument1 pageTypical Acid Cleaning Procedure For Compressor Linesrenjithv_4No ratings yet

- Tank Cleaning ProcessDocument7 pagesTank Cleaning ProcessgbogboiweNo ratings yet

- RFQ - Tank DemuckingDocument12 pagesRFQ - Tank Demuckingmuhamadrafie1975100% (1)

- QO-2020-011 Tank Cleaning, Inspection, Repair LindeDocument6 pagesQO-2020-011 Tank Cleaning, Inspection, Repair LindeReza KurniaNo ratings yet

- Tank Cleaning Method For TankersDocument4 pagesTank Cleaning Method For TankersErsin SaltNo ratings yet

- Tank Cleaning Guide - BP New 2006Document1 pageTank Cleaning Guide - BP New 2006reda hmr100% (1)

- Manual of Triple Effect Vacuum Evaporator-GoldcheerDocument24 pagesManual of Triple Effect Vacuum Evaporator-GoldcheerValeria MellaNo ratings yet

- Supply AnalysisDocument5 pagesSupply AnalysisCherie DiazNo ratings yet

- SMG Wireless Gateway ManualV2.2.0Document95 pagesSMG Wireless Gateway ManualV2.2.0shahedctgNo ratings yet

- KCC Strategic Plan 2020-2023Document103 pagesKCC Strategic Plan 2020-2023Kellogg Community CollegeNo ratings yet

- Sahrudaya Health Care Private Limited: Pay Slip For The Month of May-2022Document1 pageSahrudaya Health Care Private Limited: Pay Slip For The Month of May-2022Rohit raagNo ratings yet

- TVS Sport User Manual BS6Document69 pagesTVS Sport User Manual BS6tonemetoneNo ratings yet

- RAMA - 54201 - 05011381320003 - 0025065101 - 0040225403 - 01 - Front - RefDocument26 pagesRAMA - 54201 - 05011381320003 - 0025065101 - 0040225403 - 01 - Front - RefMardiana MardianaNo ratings yet

- Bataan Peninsula State University - Balanga Campus: Certificate of RegistrationDocument1 pageBataan Peninsula State University - Balanga Campus: Certificate of RegistrationMichael PeraltaNo ratings yet

- IT ManagementDocument7 pagesIT ManagementRebaz Raouf Salih MohammedNo ratings yet

- AGE-WELL Annual Report 2021-2022Document31 pagesAGE-WELL Annual Report 2021-2022Alexandra DanielleNo ratings yet

- CIGB B164 Erosion InterneDocument163 pagesCIGB B164 Erosion InterneJonathan ColeNo ratings yet

- Eileen MarcelDocument3 pagesEileen Marcelapi-3825833No ratings yet

- Yamaha Stagepas 300Document54 pagesYamaha Stagepas 300Ammar MataradzijaNo ratings yet

- Motor Controllers AC Semiconductor Motor Controller Types RSE 22 .. - B, RSE 4. .. - B, RSE 60 .. - BDocument4 pagesMotor Controllers AC Semiconductor Motor Controller Types RSE 22 .. - B, RSE 4. .. - B, RSE 60 .. - BAbdul Aziz KhanNo ratings yet

- PH Measurement TechniqueDocument5 pagesPH Measurement TechniquevahidNo ratings yet

- تقرير سبيس فريم PDFDocument11 pagesتقرير سبيس فريم PDFAli AkeelNo ratings yet

- SAPGLDocument130 pagesSAPGL2414566No ratings yet

- CS221 - Artificial Intelligence - Machine Learning - 3 Linear ClassificationDocument28 pagesCS221 - Artificial Intelligence - Machine Learning - 3 Linear ClassificationArdiansyah Mochamad NugrahaNo ratings yet

- 60 Years of Cannes Lions Infographics: The 50sDocument9 pages60 Years of Cannes Lions Infographics: The 50sSapientNitroNo ratings yet

- Balanced Modulator and Demodulator ExperimentDocument6 pagesBalanced Modulator and Demodulator ExperimentShubham SharmaNo ratings yet

- Rubrics For Lab Report For PC1 Lab, PC2 Lab, CIC LabDocument4 pagesRubrics For Lab Report For PC1 Lab, PC2 Lab, CIC LabHunie PopNo ratings yet

- Counsel For Plaintiff, Mark Shin: United States District Court Northern District of CaliforniaDocument21 pagesCounsel For Plaintiff, Mark Shin: United States District Court Northern District of CaliforniafleckaleckaNo ratings yet

- Kj1010-6804-Man604-Man205 - Chapter 7Document16 pagesKj1010-6804-Man604-Man205 - Chapter 7ghalibNo ratings yet

- MACROECONOMICSDocument95 pagesMACROECONOMICSClaudine Jeanne NillamaNo ratings yet