Professional Documents

Culture Documents

65

Uploaded by

Tania Mery Quispe Carrizales0 ratings0% found this document useful (0 votes)

8 views3 pagesbbn

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentbbn

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views3 pages65

Uploaded by

Tania Mery Quispe Carrizalesbbn

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF or read online from Scribd

You are on page 1of 3

FILE:

ISIC 3

How To Start Manufacturing Industries

Porcelain Insulator Making Plant

‘There is a wide variety of electric

porcelain insulators which are used for

supplying electricity, and the quality

and shape differ depending on the use.

‘There are the super high-tension and

high-tension insulators used for trans.

mitting electricity along a transmission

Tine from the power station to the

substation, There are the high, middle,

and low-tension insulators used for

transmitting electricity from a sub:

station to the consumer through an

electric power company. And there

ate other types of insulators which go

with the transmitting and supplying

systems

The demand of electric insulator

is constantly increasing with regional

development, rise in cultural and living

standards of a nation, and the improve:

ment in conditions of electric supply.

The teend in various countries is toward

domestic production, depending on

internal conditions. Depending on the

variety and use, however, the method

of manufacturing requires high skill,

technology, and knowledge. ‘The

manufacture of super high-tension glass

insulator, especially, requires high

manufacturing technology

In planning to establish an insulator

plant, it would be advisable to begin

manufacturing low-tension and hi

tension insulators which are easy to

manufacture, or something similar with

a simple shape; then, by gradually

acquiring the manufacturing technology,

manufacturing should shift toward more

complicated shape or high-tension insu.

lators. This is the quickest way to suc-

ceed in the project.

A plant which is capable of producing

800 tons per year of four items (nine

types) of insulators which are relatively

easy to manufacture and which have a

huge demand has been given here as

a model. The production items are

shown in Table-1

As a characteristic of ceramic indust-

ry, research of raw materials and body

requires a considerably long time.

Accordingly, in taking up this plan

in the actual plant, sufficient research of

raw materials available in respective

countries should be effected before

setting up the plant. This plan

on the supposition that the problem of

raw materials has been solved in one

laid out

Table 1: Production Scheme

Production quanti

Item ———

palyeny Gomlyear

“Pin type insulator

Large 300,000 5 510

‘Small 230,000 ......... 161

Strain insulator

Large ......+ 30,000 36

‘Small. 30,000 21

Spool insulator

Large 100,000 50

Small 100,000 2.10

Wire holder

Large 20,000 . . 10

Middle... 30,000 . 9

Small 20,000 3

Total 860,000 pes./year 810 tons/year

Table 2: Operation Condition

1) Firing unit 3 shifts per day, 8 hours per shift

350 days/year

2) Other celevant unit: 1 shift perday, 8 hours per shift

300 days/year

way or another.

Ceramic industry also requires con-

siderable time in the aquisition of

production technics and the training

of skilled workers. For this reason, in

setting up the porcelain insulator

plant, the manufacturing should be

started from comparatively simple types

and extended gradually to more com-

plicated ones.

Producing insulators up to standard

quality requires materials of high

quality, and it will be desirable co

acquire these materials in respective

countries. But if self-support is not

possible, it will be necessary to import

them. Any obstruction in the way of

the import will cause an immediate

impediment to the production.

ies of considerable scale will be

required for the study of raw materials

and green body, and the test of pro:

duets, but in, view of the scale of the

plant proposed in this plan, it will not

be possible to install in the plant such

scale of laboratory and testing equip-

ment. Therefore, maximum assistance

should be obtained from ceramic

laboratory, electric testing institute and

others situated in respective countries.

Also, as for maintaining and repair-

ing machinery and equipment, co-

operations with maintenance workshop

would be necessary. But the minimum

facilities required to manufacture

machine tools used in the plant must be

prepared.

Table 3: Required Raw Materials

Main raw materials and subsidiary

materials are quartz, feldspar, kaolin,

ball clay or plastic clay, limestone,

gypsum plaster, alumina, ete. The

consumption will be about 1,300 tons/

year. Yearly required quantity is shown

below.

Yearly required

om _quantity (tons)

Feldspar 240

Kaolin : 200

Silien 2021) 420

Ball clay (plastic clay) 340

Limestone or Dolomite 20

Gypsum plaster... . 40

Alumina... 02

Tap bolt a 40

5

1,300.7

Tora

Fig. 1: Process Flow Sheet for Porcelain Insulator Making Plant

Glaze materials

Gay materia] [Sony mater] [Gypoum plas]

Weighing.

\

Grinding

Screening

(& Magnetic separation

Storage

——

& Magnetic separation

Glazed

Weighing,

|

Mixing

[Gypsum mould

Casting slip

Casting

|

Inspection

Ly

Fitting

Inspection

PRODUCTS

FILE: L

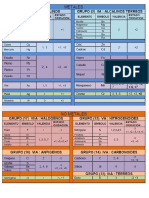

‘Table 4: Required Machinery and Equipment

Kem Quantity

5) Gypsum mould making section

Item ‘Quantity Plaster mixer... + wees se Lset

Finishing jigger machine 1 set

ishing hand jigger .- cece hl Beet

Jaw crusher... 1 set Fhe ee se

Rotating screen set a ee aaa '

Roll crusher set 6) Fittings setting section

Ball mill (4,000 kg) « + 2sets Mixers... 1 set

Ball mill ( "400 ke) - vies Resets Setting tools. lot

Filter press : Laet 7) Laboratory equipment

Diaphragm pump . 1 sat Pot mill with driving unit . . 2 set

Magnetic separator . . 2 sets Mortar with pestle. . 2set

Vibrating screen . 2 sets Standard screen . «+ Lot

Agitator . A sets Electric test kiln... fe : 1 set

De-airing auger machine Lact Testing tools sss. 1 lot

Care aoe 20 sets Extruding machine we 1 set

Weighing balance ; 2 sets Refractoriness testing apparatus pees

Bele conveyor 2 sets

t convey 8) Workshop

2) Moulding section Bench dell BosbEseneeeoReee Fs

Semi-automatic moulding press sets Grinder ‘A set

‘Semi-automatic finishing machine . +S sets rake set

Casting apparatus Lset ~

Continuous dryer 4 sets 9) Others

Hot aie geneettor » set Water supply facilites 1 oni

Ce 35 sets elcrerhead tank water pump, pipe and fittings, sets)

say sect letrie supply facilities... . wi

a eae a oa 1 (receiving facilities for primary input, transformer,

amber dryer set distributions panel, lighting equipment, wiring

Glazing conveyor and accessories . set materials and fittings ete)

4) Firing section Fuel oil supply facilities . 1 oni

Endless type tunnel kiln. set (main oil tank, ol service tank,

eae ° ‘ho sets strainer, pipe and fittings, ete.)

‘Transportation equipment 1 set

FOB price of machinery and equi

(shovel loader, forklift teuck)

ment

(approx.) SUS 1,233,001

Table 5: Required Us

1) Fuel oil (Light diesel oil)

2) Blectric power ..... 550,000 kWh

3) Industeial water... .. . 6,000 m?

4) Machine oil. « 2ke

5) Grease see ce eee e eens ORR

Table 6: Required Manpower

Item No.

7 manager Tose

Engineer... 4... aeeeeas|

Clerical worker +3

Foreman . . eeeeereeess|

Skilled worker . 25

Unskilled worker -

Total

Locational Condition

‘The main factors of selecting the

location for porcelain insulator manufac.

turing plant are as follows:

(1) Raw materials easly available

(2) Easy-torget utilities

(clean water, electricity and fuel oil)

(3) Free from iron contamination

(4) Near the atea of consumption

(5) Machine works for maintenance

ble

(6) Good workers available

Table 7: Required Area for Plant Si

oes Tome oma 000.

2) Badge:

Otel ndiabortor: * 1oma tome 200

Sundown me am

£105 informacion as been pepued

by. the Japan Consulting Institute

Gedy and’ reproduced by UNIDO

With special permission from JCI

Further reproduction of this docu-

3 ovene ithour permission of Jct is

§ probivies

Any inguiry about the information

Fans eat eet

Blorcoor, egisry “ile “No. 1D)

562/12, UNIDO, P.O. Box 300,.

8 4.1400 Vienna, Austria,

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- La Historia Detrás de SophiaDocument14 pagesLa Historia Detrás de SophiaTania Mery Quispe CarrizalesNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- 2Document17 pages2Tania Mery Quispe CarrizalesNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Modelo para TDRDocument2 pagesModelo para TDRTania Mery Quispe CarrizalesNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Estabilidad de La AtmósferaDocument3 pagesEstabilidad de La AtmósferaTania Mery Quispe CarrizalesNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Ccpna-Thomas Jefferson Institute: EssayDocument16 pagesCcpna-Thomas Jefferson Institute: EssayTania Mery Quispe CarrizalesNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- AgroDocument3 pagesAgroTania Mery Quispe CarrizalesNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- BOSQUEJODocument3 pagesBOSQUEJOTania Mery Quispe CarrizalesNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Ccpna-Thomas Jefferson Institute: EssayDocument15 pagesCcpna-Thomas Jefferson Institute: EssayTania Mery Quispe CarrizalesNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- EjerciciosQuímicaFísicaGasesLíquidosSólidosDocument3 pagesEjerciciosQuímicaFísicaGasesLíquidosSólidosTania Mery Quispe CarrizalesNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- ReportsDocument2 pagesReportsTania Mery Quispe CarrizalesNo ratings yet

- Eliminación de Sulfuros Por Oxidación en El Tratamiento Del Agua Residual de Una Curtiembre PDFDocument6 pagesEliminación de Sulfuros Por Oxidación en El Tratamiento Del Agua Residual de Una Curtiembre PDFGabriela SanchezNo ratings yet

- Valencia SDocument1 pageValencia STania Mery Quispe CarrizalesNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- IntroducciónDocument16 pagesIntroducciónTania Mery Quispe CarrizalesNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- ANEXOSDocument37 pagesANEXOSTania Mery Quispe CarrizalesNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Datos de Lab Ope3Document3 pagesDatos de Lab Ope3Tania Mery Quispe CarrizalesNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- MetaimDocument1 pageMetaimTania Mery Quispe CarrizalesNo ratings yet

- 2do Examen Agro1Document2 pages2do Examen Agro1Tania Mery Quispe CarrizalesNo ratings yet

- Art 08Document31 pagesArt 08Tania Mery Quispe CarrizalesNo ratings yet

- Cal No MetaliDocument3 pagesCal No MetaliTania Mery Quispe CarrizalesNo ratings yet

- Cal No MetaliDocument2 pagesCal No MetaliTania Mery Quispe CarrizalesNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Conminución de MineralesDocument35 pagesConminución de MineralesTania Mery Quispe CarrizalesNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Bio ProcDocument5 pagesBio ProcTania Mery Quispe CarrizalesNo ratings yet

- 1Document5 pages1Tania Mery Quispe CarrizalesNo ratings yet

- Bio ExpoDocument5 pagesBio ExpoTania Mery Quispe CarrizalesNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- DFGDFGDFGDocument1 pageDFGDFGDFGTania Mery Quispe CarrizalesNo ratings yet

- CV FBQCDocument16 pagesCV FBQCTania Mery Quispe CarrizalesNo ratings yet

- 2Document1 page2Tania Mery Quispe CarrizalesNo ratings yet

- DDDDDDocument3 pagesDDDDDTania Mery Quispe CarrizalesNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Variacion Porcentual AnualesDocument1 pageVariacion Porcentual AnualesTania Mery Quispe CarrizalesNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)