Professional Documents

Culture Documents

Direct Digital Synthesis Controlled Pure Sine Wave Inverter

Uploaded by

Nabil MohammadCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Direct Digital Synthesis Controlled Pure Sine Wave Inverter

Uploaded by

Nabil MohammadCopyright:

Available Formats

Direct Digital Synthesis Controlled Pure Sine Wave Inverter

Submitted by:

Nabil Mohammad, Ian Zieder, Krunal Bhargav, Damanpreet Anand

Team Project Number:

S15-033

Advisor:

Prof. Zoran Gajic

May 1, 2015

Submitted in partial fulfillment of the requirements for capstone senior design project

Electrical and Computer Engineering Department

Rutgers University, Piscataway, NJ 08854

Page |1

Project Number: S15-033

Table of Contents

1. INTRODUCTION ......................................................................................................... 2

1.1. Objective........................................................................................................... 2

2. METHODOLOGY ........................................................................................................ 3

2.1. Hardware .......................................................................................................... 3

2.2. Software ........................................................................................................... 4

2.3. Implementation ................................................................................................. 5

2.3.1. Pulse-Width-Modulation (PWM) .................................................................. 5

2.3.2. H-Bridge...................................................................................................... 5

2.3.3. Direct Digital Synthesis (DDS) .................................................................... 8

3. DESIGN AND MODELING .......................................................................................... 10

3.1. Schematic ....................................................................................................... 10

3.2. PSpice Simulation .......................................................................................... 11

4. RESULTS ............................................................................................................... 12

4.1. Oscilloscope Measurements........................................................................... 12

4.2. PCB Layout .................................................................................................... 13

5. RESEARCH CHALLENGES/FUTURE W ORK ................................................................. 14

6. COST ANALYSIS ..................................................................................................... 15

7. CONCLUSION .......................................................................................................... 15

8. REFERENCES..................................................................................................... 16

Page |2

Project Number: S15-033

1. Introduction:

1.1. Objective: Traditionally analog signal conditioning techniques are used to generate SPWM

control signals for power inverters. These generally require many passive and active

components considering we would have needed several operational amplifiers to generate the

triangle and sine wave generators. Our goal was to replace this method by implementing a

direct digital synthesis algorithm that serves the purpose of generating the SPWM control

signals. The system should be able to take in 12VDC, and convert it to a 120Vrms (170Vpp) 60

Hz signal. You can think of it as being a portable line voltage (assuming you have access to an

isolated 12VDC power supply such as a car battery). The system must also be built with as little

components as possible and still meet our desired performance requirements.

Electronics, SparkFun. Arduino Uno R3. Digital image. Wikipedia.org. 21

Jan. 2013. Web.

Project Number: S15-033

Page |3

2. Methodology:

2.1 Hardware: Four our inverter we used the novel H bridge topology, which consists of four

N-channel power MOSFETs from which two diagonal pairs will switch on and off in a manner

that ensures the output will be a SPWM AC signal with a 0VDC offset. A boost converter will be

used to generate the DC bus voltage to power the MOSFETs. The AC output will then be fed

into a transformer, which will allow us to step up the voltage to the desired 120Vrms.This signal

will then be filtered to give us a pure sine wave output. Since the voltage levels outputted from

the Arduino are too low to drive the gates of the MOSFETs, we used specialized gate drivers

with boot-strapping capability in order to step-up the gate-driving voltages. The reason we use a

boost converter is because the transformer doesnt have an ideal ratio of 1:10. Most

transformers have a frequency response where the gain varies across the frequencies. After

feeding the 31 kHz SPWM from the H Bridge to the transformers primary side, we can see

from the secondary side that there isnt 120Vrms on the output, so to compensate from the loss

in ratio, we step up the DC bus voltage from 12VDC to 21VDC to finally obtain 120Vrms.

Project Number: S15-033

Page |4

2.2 Software: We used an Arduino Uno unit to provide us with two control signals that are to

be fed into the inverter. The famous direct digital synthesis (DDS) algorithm was used to

generate these two SPWM signals, with one being 180 out of phase with the other. The

switching frequency we set the SPWM to was 31kHz with the PWM modulation frequency set to

60Hz. The FFT ideally would look like:

The switching frequency is adjustable through software, but we had to make sure that the

switching frequency was at least 30 times the SPWM frequency, but we made it much higher

from 1800 Hz to ensure that we get enough sampling to get a clean recovered signal after the

filter.

Project Number: S15-033

Page |5

2.3 Implementation:

2.3.1 PWM (Pulse-Width-Modulation)

To design the inverter we will needs several building blocks, each with their own circuitry, but

before going into that I want to discuss PWM and later go into how it will play into the design.

Depicted above we have our usual square wave, now when you drive a load with an alternating

signal that has a 50% duty cycle, the load sees the average of the peak-peak value over the

period range, which in this case is 6VDC. And as we lower or increase the duty cycle our

average will change as well.

The formula used to calculate the average is Va*(ton/period) = Vavg, in this case Va = 12VDC.

2.3.2 H-Bridge

One of the major building blocks to the inverter will be an H-bridge, it is what is typically used to

control DC/AC motors but the difference between controlling the two types comes with the

control signals. The way it works is if we apply a low voltage to the gate of Q1 and Q4 and a

high to Q2 and Q3, Va = 12V and Vb = 0V(GND), thus the voltage across the load

VL = Va - Vb = 12V. And if we apply a high voltage to the gate of Q1 and Q4 and a low to Q2

and Q3, Va = 0V and Vb = 12V(GND), thus the voltage across the load VL = Va - Vb = -12V.

Project Number: S15-033

Page |6

So we want our inverter to take in 12VDC and output a 120VAC. Our LOAD in this case will be

an ideal transformer that will step up a sinusoidal PWM signal of 12VAC to 120VAC, so VL

should equal 12VAC. So we know Va - Vb = VL. For simplicity sake I am going to simply tell you

the control signals that need to be applied on Q(1-4), and we will later go into how to generate

these signals. The frequency of the output signal will be that of the control signal.

The signal to be applied to the gates of the MOSFETs should be the sinusoidal PWM signal:

NOTE: (The blue real sinusoid just represents the way the PWM signal is behaving, we are

inputting the red PWM signal into the gate).

VC1(t) will be applied to Q1 and Q4, and VC2(t) will be applied to Q2 and Q3. The SPWM

signals must be 180 out of phase of one another.

Project Number: S15-033

Page |7

Now the voltages at point Va and Vb ideally would look like:

And across the terminals, (Va Vb), the output signal would like a SPWM AC signal with 0VDC

offset:

Now since this is the output across the primary winding of the transformer, the voltage on the

secondary winding will be the same PWM VAC signal but with an amplitude of +/-120VDC,

which acts as a 120VAC signal. Keep in mind that for our application we want a 170VAC output

because that is effectively 120Vrms (line voltage), so we will have to adjust the DC bus voltage

for the MOSFETs to compensate for the ratio in the transformer.

Project Number: S15-033

Page |8

2.3.3 Direct Digital Synthesis

SPWM signals can be generated with the use of either passive/active components or a

microcontroller. Creating a SPWM signal with passive and active components is a rather long

and tedious process because both sine and triangle waves have to be generated and then

passed through a comparator. Also, generating a sine and a triangle wave requires extra

external circuits, thus rendering this method effective but inefficient due to the large amount of

components that are necessary to bring it to fruition. Because of this, the best way to generate a

SPWM signal is through a microcontroller using Direct Digital Synthesis (DDS). The following

picture demonstrates the basic idea behind DDS:

Analog Device, Inc., A Flexible DDS System. Digital

image. Http://www.analog.com/media/en/trainingseminars/tutorials/MT-085.pdf. 2009. Web.

First, we are using an Arduino Uno as our microcontroller and this microcontroller has an

internal clock source running at 16 MHz. We are also using a phase-correct PWM mode where

the timer counts up to 255 and then back down. In total, there are 510 clock cycles in each timer

cycle and each cycle is running at 16 MHz. As a result, our reference clock source of 16MHz is

Project Number: S15-033

Page |9

divided by 510 to equal about 31000 Hz. Phase-To-Amplitude converter is basically a sine

wave lookup table and this is the heart of DDS; this determines our signals output frequency.

The phase accumulator gets updated every 31000Hz and a tuning word is added to the

previous value of the phase accumulator. Traditionally, the phase accumulator is between 24 to

48 bits, but we opted to use a 32 bit accumulator that required 2^32 data points in our sine wave

lookup table. This takes up a lot of memory, but we can truncate the bits by taking the most

significant bits (12-19 bits). Since our lookup table consisted of 2^8 data points, we truncated 24

bits and only considered the remaining 8 bits. Additionally, the tuning word is equal to (f o*2n)/fC ,

where fO is the desired output frequency, fC is the reference frequency and n is the number of

bits associated with the accumulator. The tuning word is added to the previous phase

accumulator, and we can use this to determine how fast our output frequency will change. If the

tuning word is equal to 2 as opposed to 1, we sweep through the sine look up table twice as

fast. This makes the desired output frequency twice as fast. When we coded this algorithm, we

basically assigned all the variables for registers (i.e. desired output frequency and frequency

clock) and disabled the interrupts in our void setup section. We subsequently found the tuning

word in the void loop and enabled the interrupt. After enabling the interrupt, we performed the

phase accumulator addition with the tuning word and truncated the bits. This number tells us the

amount by which our sine look up table is incremented.

Project Number: S15-033

P a g e | 10

3. Design and Modeling:

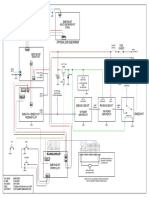

3.1 Schematic:

The Arduino will send two out-of-phase SPWM control signals into the IR2103 gate drivers.

There are several reasons why the gate drivers are used instead of feeding the control signals

into the gates of the MOSFETs. In order for the FETs to be on, it must have Vg value greater

than the DC bus value, so using the boot-strapping configuration we were able to get the gate

voltage for the high-side MOSFETs to be well above the 21V from the DC bus. The second

reason is because of shoot-through current protection. Although were sending inverted signals

to each pair of MOSFETs, there is a point in the switching process where both signals are high

and thus both FETs would conduct and cause a short from the DC bus to ground. This would

obviously destroy the MOSFETs and several other components. The gate drivers set an internal

dead-time to make sure a control signal is low before letting the other control signal go high.

The boost-converter we used is a built module with an adjustable feedback resistor to control

the output DC bus voltage. In our case, and taking into consideration the non-ideality of the

transformer, we set the DC bus voltage to 21V from the 12V input source. Now we have a

42Vpp SPWM signal across the H bridge. Now we step this voltage up to 170Vpp using the

transformer. The transformers frequency response dictates the gain at 31kHz and 60 Hz, but

instead of fiddling around with the analysis, we hooked up the transformer across the output,

filtered the signal, and adjusted the boost converter module until we got a pure sine wave at

Project Number: S15-033

P a g e | 11

170Vpp (120Vrms). One thing we had to be careful of was the polarity of the filter capacitors,

since we have an alternating signal, we cant just attach a capacitor across the transformer

terminals; we must put two of them back to back with their positive ends attached the output of

the transformer, and their negative ends tied to each other.

3.2 PSpice Simulation:

In order to reassure that the circuit behaves accordingly before being built we must first simulate

it on PSPICE. We had to first find the PSPICE model for the MOSFETs and gate drivers so that

our results are accurate as possible. Here is the PSPICE schematic for our simulation:

As you can see here we used analog signal conditioning to generate the SPWM signals; SPICE

comes with ideal sine wave and triangle wave generators, but in reality we would have to build

each of them to great precision using many op amps and other passive and active elements.

PSPICE simulation output plot:

Project Number: S15-033

P a g e | 12

4. Results:

The picture below you can see that we obtained a clean pure sine wave output. Note that the

probe used to measure the output was scaled in 10x since the oscilloscope cant observe

signals with very high amplitudes. So here you can see that we get a 12Vrms (x10 scaled down)

or 120Vrms output signal at 60 Hz. From this result, we can see that our DDS algorithm worked

effectively in generating the SPWM signals.

4.1 Oscilloscope Measurements:

Project Number: S15-033

P a g e | 13

4.2 PCB Layout:

Here is the PCB design of our project. This board contains all the components except the

Arduino and the boost converter unit. We added screw terminals to interface between the board

and other peripherals.

Project Number: S15-033

P a g e | 14

5. Research Challenges/Future work:

One of the challenges were choosing the proper microcontroller module (MSP430 or Arduino),

and weighing the tradeoffs between each of them in terms of generating the control signals

adequately. Another challenge was to find a way of compensating for shoot-through current

(which occurs when a pair of series FETs instantaneously conduct at the same time, thus

shorting the DC bus to ground). This problem was fixed through the use of gate drivers which

set the dead-time for the control signals internally. Lastly, modeling the circuit in PSPICE to

ensure proper functionality, and then prototyping it on a breadboard layout to confirm its

operation.

One thing we can do to improve the system is by including a feedback mechanism to steady

both the amplitude and frequency in order to further maintain the stability of our system. This

would be done by using the frequency to voltage converter to feed the sampled outputs

frequency back as a voltage level and then feed it to the ADC of the microcontroller, and use it

as a feedback variable in our control algorithm. This would be done for frequency stability. To

control the amplitude, we could take a reference signal from one side of the H - bridges output

through a voltage divider network and feed it into a peak detector, which will generate a voltage

in correspondence to the output amplitude; this voltage level will be sent into the ADC and will

be used in the control loop.

Project Number: S15-033

P a g e | 15

6. Cost Analysis:

2x IR2103 Gate Driver IC ---------------------------------------------------- $ 5.12

1x 6.3-0-6.3 3A Transformer (RadioShack) ------------------------------$ 10.00

2x 10uF Electrolytic Capacitor ------------------------------------------------ $ 0.20

2x 1uF Electrolytic Capacitor ------------------------------------------------- $ 0.20

1x 100uF Electrolytic Capacitor ---------------------------------------------- $ 0.10

4x IRFZ44 Power MOSFET --------------------------------------------------- $ 7.88

2x IN4007 General Purpose Diode ------------------------------------------- $ 0.20

3x Resistors ------------------------------------------------------------------------ $ 0.03

1x LED (Blue) ----------------------------------------------------------------------- $ 0.15

1x LM317 Adjustable Voltage Regulator ------------------------------------- $ 0.71

1x Output Adjustable Boost Converter Module ----------------------------- $ 6.66

1x Arduino Uno Unit --------------------------------------------------------------- $ 8.50

6x Wago Screw Terminals ------------------------------------------------------ $ 0.60

1x PCB Copper Clad -------------------------------------------------------------- $ 8.00

Total Cost: $ 48.35

We successfully designed and assembled a reliable power inverter with total parts for less

than $ 50.00.

7. Conclusion:

Our capstone design project proved to be a challenging and rewarding experience. Through

extensive research and testing, we gained a large range of knowledge of several new circuit design

techniques and theories; as well has how to properly integrate a software based system. We met several

of our original goals including designing with as few components as possible and successfully generating

a line voltage that still met our desired performance. Our design could still be improved with the use of

a feedback system, however the low cost benefits of our design seem to outweigh any possible features

that could be added. In conclusion, we have gained a vast insight and knowledge into the operations

behind an entire product development system and will use many of our newly acquired skills in our

future endeavors.

Project Number: S15-033

P a g e | 16

8. REFRENCES:

[1]

Gajic, Z., & Lelic, M. (1996). Transient and Steady State Responses. Modern Control

Systems Engineering (1st ed., pp. 261-287). Piscataway, NJ: Prentice Hall.

[2]

Wang, T. (2011). Signal Generator Based on Direct Digital Synthesis

Techniques. International Journal of Digital Content Technology and Its

Applications, Volume 5(Issue 8), 24-30.

[3]

Vinayaka, B., & Nagendra, P. (2014). Modeling and Design of Five Level Cascaded HBridge Multilevel Inverter with DC/DC Boost Converter. Int. Journal of Engineering

Research and Applications, Vol.4(Issue 6), 50-55.

[4]

Hirzel, T. (2015). Arduino - PWM. Retrieved from http://www.arduino.cc/en/Tutorial/PWM

[5]

Colak, I., & Kabalci, E. (2012). Developing a novel sinusoidal pulse width modulation

(SPWM) technique to eliminate side band harmonics. International Journal of Electrical

Power & Energy Systems, Vol.44(1), 861-871.

[6]

Jivet, I., & Dragoi, B. (2008). Performance Analysis of Direct Digital Synthesizer

Architecture with Amplitude Sequencing. WSEAS TRANSACTIONS on CIRCUITS AND

SYSTEMS, Vol.7(1), 2-5.

[7]

D.mohan, D., & B.kurub, S. (2013). A Comparative Analysis of Multi Carrier SPWM

Control Strategies using Fifteen Level Cascaded H bridge Multilevel Inverter.

International Journal of Computer Applications, Vol.2(1), 7-11.

[8]

IR2103(S)PBF Half-Bridge Driver Datasheet. (2013, April 18). Retrieved from

http://www.irf.com/product-info/datasheets/data/ir2103.pdf

[9]

Fundamentals of Direct Digital Synthesis (DDS). (2009). Retrieved from

http://www.analog.com/media/en/training-seminars/tutorials/MT-085.pdf

[10]

Sudheer, P., & Siva Prasad, K. (2014). H-Bridge Multi Level STATCOM under Different

Loads. International Journal of Scientific and Research Publications, Vol.4(5), 1-5.

[11]

Easily Applicable Graphical Layout Editor V7 Tutorial. (2014).Retrieved from

http://www.cadsoftusa.com/fileadmin/journalist/Documents/tutorial_7.1_en.pdf

You might also like

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- 3 Best Transformerless Inverters With Circuit DiagramsDocument35 pages3 Best Transformerless Inverters With Circuit Diagramswinkyi100% (1)

- Precision Time Protocol in Modern Networks PresentationDocument30 pagesPrecision Time Protocol in Modern Networks PresentationAmar HADIDINo ratings yet

- Digital Signal Processing Project Report: Ihtisham Ul HaqDocument9 pagesDigital Signal Processing Project Report: Ihtisham Ul Haqihtishamul HaqNo ratings yet

- Arduino Based Pulse Width Modulated Outp PDFDocument5 pagesArduino Based Pulse Width Modulated Outp PDFArif Johar TaufiqNo ratings yet

- PWM Signal Generators: Testing Status: Mixed. Some Untested, Some SPICE SimulatedDocument15 pagesPWM Signal Generators: Testing Status: Mixed. Some Untested, Some SPICE SimulatedSivareddy MudiyalaNo ratings yet

- Magnetically Levitated BallDocument4 pagesMagnetically Levitated BallthaisubNo ratings yet

- PWM Signal GeneratorsDocument3 pagesPWM Signal GeneratorsjalalhNo ratings yet

- Lab 2 Analog Encoder PWM R9Document5 pagesLab 2 Analog Encoder PWM R9subairiNo ratings yet

- Pure Sine Wave Inverter Circuit Using ArduinoDocument17 pagesPure Sine Wave Inverter Circuit Using ArduinoEmmanuel Gospel RajNo ratings yet

- Chapter One Controlling The Operation of Wind-Solar Hybrid Power System Using Arduino-Based Hybrid MPPT ControllerDocument48 pagesChapter One Controlling The Operation of Wind-Solar Hybrid Power System Using Arduino-Based Hybrid MPPT ControllerOdebunmi NathanielNo ratings yet

- Design Report Pss20Document46 pagesDesign Report Pss20Jaciel LMNo ratings yet

- Electronics Projects - DC Motor Speed Control Using H-Bridge - EngineersGarageDocument1 pageElectronics Projects - DC Motor Speed Control Using H-Bridge - EngineersGarageMmeli NtwanaYebhoza DubeNo ratings yet

- Arduino Wattmeter - Measure Voltage, Current and Power ConsumptionDocument9 pagesArduino Wattmeter - Measure Voltage, Current and Power ConsumptionMihai BogdanNo ratings yet

- Speed Control of A DC Motor Using Hand GestureDocument4 pagesSpeed Control of A DC Motor Using Hand GestureArka Prava LahiriNo ratings yet

- Final ProjectDocument27 pagesFinal ProjectMohit KeshriNo ratings yet

- PWM Control LED Brightness & Motor Speed Using ArduinoDocument5 pagesPWM Control LED Brightness & Motor Speed Using ArduinoNg MeriedNo ratings yet

- Digital PC OscilloscopeDocument9 pagesDigital PC OscilloscopecharlyNo ratings yet

- Session 4Document2 pagesSession 4Manoj GudiNo ratings yet

- RF Based Wireless Campus Paging SystemDocument54 pagesRF Based Wireless Campus Paging SystemjassadNo ratings yet

- Assignment 3Document18 pagesAssignment 3Bhakti KalyankastureNo ratings yet

- ADIC ExperimentsDocument41 pagesADIC ExperimentsTushar PatilNo ratings yet

- DC-DC Voltage ConverterDocument14 pagesDC-DC Voltage ConverterasifNo ratings yet

- Acs712 - 5a - enDocument11 pagesAcs712 - 5a - enJason SuthersNo ratings yet

- Diy Boost CalcDocument6 pagesDiy Boost Calckutu32No ratings yet

- Design and Implementation of Single Phase Inverter Using MicrocontrollerDocument5 pagesDesign and Implementation of Single Phase Inverter Using Microcontrollersami_yNo ratings yet

- C T I/O P: Hapter Hree RocessingDocument22 pagesC T I/O P: Hapter Hree RocessingMohamed OmarNo ratings yet

- Digital StethoscopeDocument4 pagesDigital StethoscopeDhaval ShahNo ratings yet

- PWM Using ArduinoDocument6 pagesPWM Using ArduinoJulian David RodriguezNo ratings yet

- Sequential Timer For DC Motor ControlDocument29 pagesSequential Timer For DC Motor ControlKamesh MtecNo ratings yet

- Chapter No.:-01 Introuuction: Pulse-Width Modulation (PWM), Modulation (PDM)Document63 pagesChapter No.:-01 Introuuction: Pulse-Width Modulation (PWM), Modulation (PDM)Pooja BanNo ratings yet

- Line Follwer Robot Using LM324Document11 pagesLine Follwer Robot Using LM324Ioan DorofteiNo ratings yet

- Arduino DC Motor ControlDocument4 pagesArduino DC Motor ControlKathryn WorkmanNo ratings yet

- Arduino WattmeterDocument6 pagesArduino WattmetersalmanNo ratings yet

- M4 Micro OneNoteDocument6 pagesM4 Micro OneNoteAryan RaiNo ratings yet

- The LM324 Quad Op-Amp Line Follower Robot With Pulse Width ModulationDocument15 pagesThe LM324 Quad Op-Amp Line Follower Robot With Pulse Width ModulationMeyersson BeltranNo ratings yet

- Railway Accident Monitoring System: A Project Report ONDocument13 pagesRailway Accident Monitoring System: A Project Report ONPrateek SrivastavNo ratings yet

- Analog To Digital Converter With Two-Digit Seven Segment DisplayDocument26 pagesAnalog To Digital Converter With Two-Digit Seven Segment DisplayChristian Mauricio Aldás SolísNo ratings yet

- 06 Wireless ReportDocument17 pages06 Wireless ReportshastryNo ratings yet

- Arduino PWM To DC Voltage Op Amp Converter - Henry's BenchDocument8 pagesArduino PWM To DC Voltage Op Amp Converter - Henry's BenchAlan A. TorresNo ratings yet

- PWM Outputs Enhance Sensor Signal ConditionersDocument5 pagesPWM Outputs Enhance Sensor Signal Conditionersshabir faridiNo ratings yet

- Mobile Phone Charger ReportDocument16 pagesMobile Phone Charger ReportVarun Khanna100% (3)

- PID Wall FollowerDocument12 pagesPID Wall FollowerNilanjana BhattacharyaNo ratings yet

- SAchin NegiDocument1 pageSAchin NegicallmeduguNo ratings yet

- Ec 15Document1 pageEc 15Barnik RoyNo ratings yet

- Progression Report: Temperature Controlling of The Portable Fridge Via Web ApplicationDocument5 pagesProgression Report: Temperature Controlling of The Portable Fridge Via Web ApplicationHasan ÇalışkanNo ratings yet

- Digital VoltmeterDocument20 pagesDigital VoltmeterAbhigyan PrakashNo ratings yet

- EDC ManualDocument34 pagesEDC ManualRahul Mahar100% (1)

- TMS320F2812-Analogue To Digital ConverterDocument26 pagesTMS320F2812-Analogue To Digital ConverterPantech ProLabs India Pvt LtdNo ratings yet

- Speed Control Brushless DCDocument27 pagesSpeed Control Brushless DCstanley FNo ratings yet

- High Current Pulse GeneratorDocument12 pagesHigh Current Pulse GeneratorTranminhvmi TranNo ratings yet

- Arduino Tachometer Measures RPM of DC MotorDocument7 pagesArduino Tachometer Measures RPM of DC MotorTrived DoijodNo ratings yet

- ACS712 Hall Effect Current SensorDocument7 pagesACS712 Hall Effect Current SensorWilliam BlackNo ratings yet

- FinalDocument36 pagesFinalyashNo ratings yet

- Resonant&Buck ChopperDocument18 pagesResonant&Buck ChopperKata Naresh BabuNo ratings yet

- Design and Development of 3 Phase PWM inDocument4 pagesDesign and Development of 3 Phase PWM inMarc TcheukabaNo ratings yet

- Motor Speed Control with PWM CircuitDocument9 pagesMotor Speed Control with PWM CircuitAnanta Prasetya PutraNo ratings yet

- Arduino Based DC Motor Speed Control Using PWMDocument5 pagesArduino Based DC Motor Speed Control Using PWMJinsha CNo ratings yet

- Speed Control of DC Motor Using PWMDocument6 pagesSpeed Control of DC Motor Using PWMAvinash DhanukaNo ratings yet

- La 7850Document5 pagesLa 7850Muresan SanduNo ratings yet

- Evolution and Generation of Computers: Samuel KizitoDocument69 pagesEvolution and Generation of Computers: Samuel KizitoShankar ThakareNo ratings yet

- ATA 44 - Cabin Systems (Mike Tooley)Document16 pagesATA 44 - Cabin Systems (Mike Tooley)Jagbir SinghNo ratings yet

- 0402 Small DFN Package Saves Board SpaceDocument7 pages0402 Small DFN Package Saves Board Spacecarlos rumboNo ratings yet

- MSI Slide S20 Notebook User Manaul - EnglishDocument36 pagesMSI Slide S20 Notebook User Manaul - English김종열No ratings yet

- VoLTE in IMS - Real Time CommunicationDocument16 pagesVoLTE in IMS - Real Time CommunicationSpy CameraNo ratings yet

- LeafletDocument2 pagesLeafletCarlos Jose Sanchez EsparzaNo ratings yet

- 1000 Problems Instrumentation and Measurement Topic Terms.Document7 pages1000 Problems Instrumentation and Measurement Topic Terms.Julian CeledioNo ratings yet

- High CPU 3750 StackDocument14 pagesHigh CPU 3750 StackOsvaldo SilvaNo ratings yet

- AN1128b MicrochipDocument18 pagesAN1128b MicrochipChu LamNo ratings yet

- Find node voltage equations and equivalent resistance for electrical circuitsDocument4 pagesFind node voltage equations and equivalent resistance for electrical circuitsdon karthikeyaNo ratings yet

- Installation Manual for TOA FS-7000 Voice Evacuation SystemDocument92 pagesInstallation Manual for TOA FS-7000 Voice Evacuation Systemit fukuryoNo ratings yet

- Icd2 DocDocument15 pagesIcd2 Docdag_84No ratings yet

- Audit of Telecommunications Infrastructure Assets RKRDocument8 pagesAudit of Telecommunications Infrastructure Assets RKRSabiilul Muminiin ChannelNo ratings yet

- EcsyllDocument121 pagesEcsyllDaisyQueenNo ratings yet

- Cao Question Bank Unit 1-5 BT Format 2020-2021Document4 pagesCao Question Bank Unit 1-5 BT Format 2020-2021Nikhil TiruvaipatiNo ratings yet

- Ibm Thinkpad 701 HMMDocument69 pagesIbm Thinkpad 701 HMMEduardoHenriquezNo ratings yet

- Ri Fb/I Igm V1.0 Ri Mod/I CC Ethercat Ri Mod/I CC Devicenet: / Perfect Charging / / Solar EnergyDocument44 pagesRi Fb/I Igm V1.0 Ri Mod/I CC Ethercat Ri Mod/I CC Devicenet: / Perfect Charging / / Solar Energyhardi05No ratings yet

- CM Inductor Analysis: Choosing the Proper Winding DesignDocument7 pagesCM Inductor Analysis: Choosing the Proper Winding Designdebass3No ratings yet

- 2-Wire Serial Eeprom: FeaturesDocument10 pages2-Wire Serial Eeprom: FeaturesPablo Diego Cecere CasadoNo ratings yet

- Resistance and Current CalculationsDocument11 pagesResistance and Current CalculationsMriganga SarmaNo ratings yet

- Real Time DC Motor Speed Control Using PID in LabVIEWDocument3 pagesReal Time DC Motor Speed Control Using PID in LabVIEWabsalnabiNo ratings yet

- Asus Notebook Certificate Repair Training Engineer (CHER) Level 2-1 PDFDocument44 pagesAsus Notebook Certificate Repair Training Engineer (CHER) Level 2-1 PDFGerminii100% (1)

- DC Circuit Analysis EssentialsDocument33 pagesDC Circuit Analysis EssentialsFlorin FinaruNo ratings yet

- QRO PA 144 MHz 20 kW GU36B-1 Tube AmplifierDocument51 pagesQRO PA 144 MHz 20 kW GU36B-1 Tube Amplifierverd leonardNo ratings yet

- Line Codes: Line Coding Data CodingDocument4 pagesLine Codes: Line Coding Data CodingNisha GargNo ratings yet

- Asentria 48VDC Power Supply Card Installation GuideDocument4 pagesAsentria 48VDC Power Supply Card Installation Guideaelmai70No ratings yet

- ManualDocument385 pagesManualSayak BoseNo ratings yet

- Eme158 Kit Eme158 Kit: Audio Subcarrier Kit 5.5Mhz Audio Subcarrier Kit 6.5MhzDocument1 pageEme158 Kit Eme158 Kit: Audio Subcarrier Kit 5.5Mhz Audio Subcarrier Kit 6.5MhzDUDULENo ratings yet