Professional Documents

Culture Documents

Loop Checking and Field Instrument Testing Procedure

Uploaded by

charzreeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Loop Checking and Field Instrument Testing Procedure

Uploaded by

charzreeCopyright:

Available Formats

Loop Checking and Field Instrument Testing Procedure

1 of 7

http://www.controlglobal.com/blogs/controlling-interests/loop-checkin...

LOGIN | REGISTER

MENU

Control's editors weigh in with timely insights and tidbits on goings-on in the process automation world,

mostly news and technology but also interesting perspectives gleaned from our daily conversations with

end users and the challenges of the craft.

Category: Implementation Loop Analysis Loop Performance Usability

Submitted by Katherine Bonfante on Thu, 10/04/2012 - 10:00

Everybody knows that loop checking and field instrument testing is the last piece of the puzzle in each project

before commencing the commissioning of any system. It is time-consuming and depends upon the

completion of other systems like piping, electrical equipment, control valves etc.

Each contractor or company has its own procedure and common practices for instrument loop checking and

functional testing. I found this forum is good place to discuss this topic in more detail, for example:

1. Can we have a common or guide line procedure for loop checking?

2. Can we illustrate all the required drawings, specification and forms required for loop checking?

3. Can we build a flow chart for loop checking which illustrates the rule of operation, maintenance,

engineering and inspection for example?

Login or register to post comments

52895 reads

Permalink

7 Comments

We welcome your thoughtful comments. Please comply with our Community rules.

All comments will display your user name.

Want to participate in the discussion?

29-10-2015 11:42

Loop Checking and Field Instrument Testing Procedure

2 of 7

http://www.controlglobal.com/blogs/controlling-interests/loop-checkin...

REGISTER FOR FREE

Log in for complete access.

Submitted by santhiraj sathanna on Fri, 09/06/2013 - 08:58

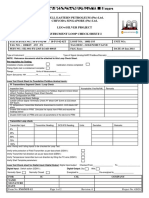

<p>This is a very good topic for discussion.</p> <p>We do the following in our organisation</p> <p>1.A

detailed loop check format is prepared for each project 2.Above is based on latest I/O list , P&ID and

process narrative. 3.For each I/O point, all connected details/elements like PLC/DCS I/O module,Panel

Terminal Block, Marshalling panel Terminal Block, Junction Box Terminal Block,Instrument/Final Control

element tag, Service description,calibration range,cable tag.... 4.We do this testing by involving owner's as

well as prime EPC bidder's Engineer as witnesses. After successful completion, the document gets signed by

them.</p> <p>We follow the same procedure for commissioning the logic as well as to demonstrate the same

to end user!</p> <p>This is time consuming and we do it religiously to eliminate last minute surprises.</p>

Reply

Submitted by on Tue, 10/29/2013 - 12:24

<p>I fully agree with all 3 points. A guide is really needed. I takes much time to get agreed such procedure in

every new project and a unified approach would be very effective here. To the second point I may add that a

list of such documents would be very useful as well to avoid creating of a huge dossier and got all needed

papers in place. Templates for certificates would be fine. As to the third point I'd a recommended list of

personal of performing and witnessing parties. Mikhail Aravin, Senoir Instrument Commissioning Engineer.

</p>

Reply

Submitted by Edward Smigo on Fri, 12/27/2013 - 10:45

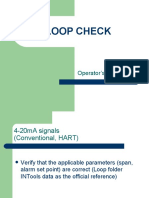

<p>The loop testing procedure can vary depending on the instrumentation and I/O infrastructure. A

foundation fieldbus or Profibus PA based system would be different from a system using conventional or

HART instrumentation on a system with HART I/O cards.</p> <p>While one can perform a loop test with a

handheld communicator when HART I/O is not present on the automation system that process would require

multiple people similar to performing loop tests with conventional instruments. One benefit HART

instrumentation has over conventional is the non intrusive nature of the testing. One does not need to break

the loop to insert a mA simulator. HART instruments have a Loop Test method that allows the tester to drive

the mA output of the instrument from a hand held communicator or an Asset Management Software

application, When using Asset Management software, testing can be done more efficiently because a single

person can be commanding devices from one window and observing results on another. An additional benefit

when using Asset Management software is that multiple instruments can be put into loop test simutaneously

which allows one to incorporate interlock logic checks along with the loop tests which further streamlines the

comissioning process.</p> <p>Since loop tests are often the final step before start-up, and projects

schedules often slip, there is always pressure on the loop testing team to gain efficiencies to pull in the plant

startup milestone.</p>

Reply

Submitted by Tom Dotts on Tue, 12/30/2014 - 08:30

<p>Unfortunately, even today's large manufacturers have lost qualified process control specialists and

engineers, leaving sometimes, unqualified personnel to decide how a "system" should be validated. A

systematic approach is necessary and a legitimate step towards ensuring the "completeness" of even the

smallest of project, upgrade or change to or within a BPCS or SIS on the plant floor. Of course regulations

apply to safeties, but many times the even the fundamentals of instrumentation go unchecked and now

become a liability. Standardization is needed - especially within chemical and petro-chemical applications.

29-10-2015 11:42

Loop Checking and Field Instrument Testing Procedure

3 of 7

http://www.controlglobal.com/blogs/controlling-interests/loop-checkin...

T.Dotts, Contract EI&C Technician / Project manager.</p>

Reply

Submitted by Charles Palmer on Wed, 01/14/2015 - 03:23

<p>I would like to share some perspectives : Loop testing and plant commissioning done in-house is one

aspect. Naturally the requirement for policies and procedures is mandatory ( as in both cases) Things change

slightly when this work is been done under contract by a 3rd party. Once again the policies and procedures

are required. FAT and SAT procedures should be issued to the supplier/contractor within 30 days of contract

signature. As a Consultant, I have witnessed so many poor FAT and SAT company procedures in many

different countries ( Cultures if you like). This has compounded poor FAT testing into total SAT failures as the

fault could not be isolated to Panel or Field . Many hours could have been saved if the bookwork had been

done up front.</p>

Reply

Submitted by Sankar Kumar R on Tue, 02/24/2015 - 03:43

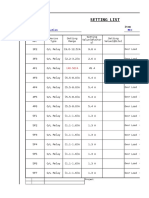

<p>I would like to summarize the requirement prior to start the loop check activity as follows:</p> <p>1. SAT

of DCS/ESD/F&G and IAMS system shall be completed and ready with all pre-requisites completed. 2.

Total IO's shall be divided into loops & Loop Folder shall be prepared and approved from PMC/Client. 3.

Loop folder shall contain the following documents as a minimum : a) Loop test record format (To enter the

details of the Instrument subjected to loop check and the master instrument used). b) Instrument Data

sheet(s) related with the loop. c) P&ID sheet related to the Instrument(s) d) Instrument(s) loop drawing

(derived from Intools which shall contain termination details from Field through JB's to Rack Room) e)

C&E sheet (For logic checks) f) IO Point Database (To refer : Ranges, Alarm Points, Controller action

etc) g) Calibration sheet of Instruments in loop. h) Observation sheet (To note down any observations during

loop check/logic check activity for necessary corrective action). 4. Prerequisites like HVAC, Utilities shall be

ensured 5. Loop check shall be carried with Handheld communicator / Calibrators or from IAMS system (For

both FF & HART devices). 6. The checks shall be witnessed & loop folder documents shall be

signed by DCS contractor, EPC contractor, PMC & Client.</p> <p>The preparation of above said

document is time consuming but these will ease the loop / logic checks as all data's will be available in a

single folder.</p> <p>This is the procedure we are following in our Greenfield Petrochemical Project.</p>

Reply

Submitted by jberge on Tue, 09/08/2015 - 11:44

<p>The details of 4-20 mA loop checking is slightly different for each device but the general principle is the

same. The basics of the loop testing procedure is explained in the loop checking tutorial found here: <a

href="http://www.eddl.org/DeviceManagement/">http://www.eddl.org/DeviceManagement/</a></p>

Reply

RSS feed for comments on this page | RSS feed for all comments

29-10-2015 11:42

Loop Checking and Field Instrument Testing Procedure

4 of 7

E-Newsletters

http://www.controlglobal.com/blogs/controlling-interests/loop-checkin...

Digital Editions

Biweekly updates delivering feature articles, headlines with direct links to the top news stories that are critical

to staying up to date on the industry company news, product announcements, technical issues and more.

Subscribe Today.

Past 7 Days

Past 30 Days

Past 6 Months

All Time

29-10-2015 11:42

Loop Checking and Field Instrument Testing Procedure

5 of 7

http://www.controlglobal.com/blogs/controlling-interests/loop-checkin...

Contact Us

Advertise

Media Kit

Rates & Spec

29-10-2015 11:42

Loop Checking and Field Instrument Testing Procedure

6 of 7

http://www.controlglobal.com/blogs/controlling-interests/loop-checkin...

Privacy Policy

Legal / T&C

Voices

Blogs

Out of Control Cartoons

White Papers

Multimedia

Events

Products

Technology Roundups

E-lits

Subscribe

Digital Edition

Issue Archive

Reprints

Jobs

Knowledge Center

Microsites

Company Profiles

Site Map

My Account

Newsletters

Social Media

RSS

Contact Us | Advertise | Privacy Policy | Legal Disclaimers, Terms & Conditions

Copyright 2004 - 2015 Control Global. All rights reserved.

P: 630-467-1300 | 1501 E. Woodfield Road, Suite 400N, Schaumburg, IL 60173

Chemical Processing | Control | Control Design | Food Processing | Industrial Networking | Pharmaceutical Manufacturing |

29-10-2015 11:42

Loop Checking and Field Instrument Testing Procedure

7 of 7

http://www.controlglobal.com/blogs/controlling-interests/loop-checkin...

Pharma QBD | Plant Services | Wellness Foods

29-10-2015 11:42

You might also like

- Instrument Loop Testing ProcedureDocument9 pagesInstrument Loop Testing ProcedureSusanto Pausinugroho100% (1)

- Instrument Commissioning ChecklistDocument13 pagesInstrument Commissioning Checklistrajeshkumarab100% (10)

- MQDP4 instrument loop checkDocument2 pagesMQDP4 instrument loop checkshanks263100% (1)

- Loop check procedure E1Document3 pagesLoop check procedure E1mc_prayer50% (2)

- Loop Checking Procedure IdeasDocument2 pagesLoop Checking Procedure IdeasJonatas13No ratings yet

- Loop Check PresentationDocument39 pagesLoop Check Presentationsaqib javaid100% (5)

- Instrument Loop Check ProcedureDocument3 pagesInstrument Loop Check ProcedureMiko Quijano100% (1)

- Loop Check Sheet TransmitterDocument2 pagesLoop Check Sheet Transmittershanks263100% (1)

- IEC-62382 Electrical and Instrumentation Loop CheckDocument24 pagesIEC-62382 Electrical and Instrumentation Loop CheckFreddy100% (7)

- Instrument ITPDocument4 pagesInstrument ITPVictor Biacolo100% (2)

- Saudi Aramco Test Report: 30.apr.13 Inst SATR-J-6501 Instrument Loop - Inputs - Transmitter Circuit TestDocument4 pagesSaudi Aramco Test Report: 30.apr.13 Inst SATR-J-6501 Instrument Loop - Inputs - Transmitter Circuit TestRashid Arshad100% (1)

- (EMERSON) Loop CheckingDocument29 pages(EMERSON) Loop CheckingDavid Chagas80% (5)

- ICSS Loop Test Presentation UpdatedDocument31 pagesICSS Loop Test Presentation UpdatedHashemAliHashem50% (2)

- Loop Check Procedure PDFDocument8 pagesLoop Check Procedure PDFImran Nawaz Mehthal75% (4)

- How To Do Loop Checks During Plant Pre-CommissioningDocument18 pagesHow To Do Loop Checks During Plant Pre-Commissioningtom2626No ratings yet

- Loop Test ReportDocument7 pagesLoop Test ReportAldeline Sungahid100% (1)

- Loop Checking Technicians GuideDocument151 pagesLoop Checking Technicians GuideVipin Nair89% (19)

- Detail Engineering SummaryDocument15 pagesDetail Engineering SummaryDattatray Nikam100% (6)

- Loop Checking GuideDocument66 pagesLoop Checking Guidefazilpaf100% (5)

- General Specification of InstrumentationDocument41 pagesGeneral Specification of InstrumentationMaulani CandraNo ratings yet

- P-5000T - Loop Folder PDFDocument15 pagesP-5000T - Loop Folder PDFSrikant SuruNo ratings yet

- BN-SP-K10 Instrument CalibrationDocument24 pagesBN-SP-K10 Instrument Calibrationaugur886No ratings yet

- Check List For Instrumentation DesignDocument22 pagesCheck List For Instrumentation Designmanjunath8685100% (4)

- Chapter 38 Instrument Installation and Commissioning 2010 Instrumentation Reference Book Fourth EditionDocument6 pagesChapter 38 Instrument Installation and Commissioning 2010 Instrumentation Reference Book Fourth EditionMotasim_mNo ratings yet

- FAT Procedure Rev.1Document9 pagesFAT Procedure Rev.1Rahul Deva100% (1)

- PC-J-95 Instrument Loop Check (Analogue Inputs)Document1 pagePC-J-95 Instrument Loop Check (Analogue Inputs)Memyhu MahmudahNo ratings yet

- ITP For Bench Calibration of Instruments Rev.ADocument9 pagesITP For Bench Calibration of Instruments Rev.AGanga DaranNo ratings yet

- Loop Check: Operator's GuideDocument21 pagesLoop Check: Operator's Guidemc_prayerNo ratings yet

- FAT Procedure-FGI Kakinada Rev-1Document13 pagesFAT Procedure-FGI Kakinada Rev-1vsrikala68No ratings yet

- FAT Procedure of PLC PanelDocument25 pagesFAT Procedure of PLC PanelDipti Bhanja83% (6)

- ITP (Instrumentation)Document9 pagesITP (Instrumentation)Yaser A. Al-Bustanji100% (1)

- Loop Test Procedure 71259C-0100-PP-941 - OpenDocument40 pagesLoop Test Procedure 71259C-0100-PP-941 - Opensaid250009250No ratings yet

- Instr 12306 Perform Pressure & Leak Test, Tubing & PipingDocument19 pagesInstr 12306 Perform Pressure & Leak Test, Tubing & PipingMeliana Butar-ButarNo ratings yet

- Method Statement Loop CheckDocument4 pagesMethod Statement Loop CheckMohamed Rafih100% (1)

- F-NC-174 (Elephant) Field Development Project - GOSP: Inspection and Test Plan (Itp)Document5 pagesF-NC-174 (Elephant) Field Development Project - GOSP: Inspection and Test Plan (Itp)bhct1987100% (1)

- Instrumentation General Procedure-InstallationDocument23 pagesInstrumentation General Procedure-InstallationDewAngga Yudistira100% (7)

- Instrumentation QC JobDocument7 pagesInstrumentation QC JobShabeer CVNo ratings yet

- 006 Field Instrument InstallationDocument8 pages006 Field Instrument InstallationMohamed KasemNo ratings yet

- Hookup LibraryDocument221 pagesHookup Librarykapilarora123100% (6)

- Icl 009 PLC PanelDocument2 pagesIcl 009 PLC Panelsamwel kariukiNo ratings yet

- Instrument Process Hook-Up DetailsDocument301 pagesInstrument Process Hook-Up DetailsNikki Roberts100% (6)

- Instrumentation Tubing and Their Connections-Nirbhay GuptaDocument127 pagesInstrumentation Tubing and Their Connections-Nirbhay Guptanirbhay111100% (13)

- Instrument Design CriteriaDocument41 pagesInstrument Design CriteriasanthaNo ratings yet

- Instrumentation Job Interview Preparation GuideDocument11 pagesInstrumentation Job Interview Preparation GuideJignesh Banava100% (1)

- Instrument Loop DiagramDocument121 pagesInstrument Loop Diagramchamp2006No ratings yet

- DCS Commisioning StepsDocument7 pagesDCS Commisioning StepsJoven BabieraNo ratings yet

- SL # 1-13 ACTIVITY AND CHARACTERISTICSDocument2 pagesSL # 1-13 ACTIVITY AND CHARACTERISTICSprasanta2011100% (4)

- Instrumentation Work ProcedureDocument10 pagesInstrumentation Work ProcedureAbdelRhman Elfky100% (1)

- Loop CheckDocument9 pagesLoop CheckyangherNo ratings yet

- STFFD-P1-004003-P05-0001 Rev C FAT Procedure For Complete SkidDocument50 pagesSTFFD-P1-004003-P05-0001 Rev C FAT Procedure For Complete SkidTuyen Pham100% (2)

- Conduit and Instrumentation Fittings LayoutDocument221 pagesConduit and Instrumentation Fittings LayoutMr.thawatchai100% (1)

- Certified Automation Professional A Complete Guide - 2020 EditionFrom EverandCertified Automation Professional A Complete Guide - 2020 EditionNo ratings yet

- Loop Checking and Field Instrument Testing ProcedureDocument3 pagesLoop Checking and Field Instrument Testing Procedureamirubote4No ratings yet

- Technical White Paper: Fieldbus Testing With Online Physical Layer DiagnosticsDocument11 pagesTechnical White Paper: Fieldbus Testing With Online Physical Layer DiagnosticsgminayasNo ratings yet

- Acceptance Testing & Documentation To Support Validation-PresentationDocument34 pagesAcceptance Testing & Documentation To Support Validation-PresentationpoketupiNo ratings yet

- WP Online Safety Valve Testing 04.2008 PDFDocument10 pagesWP Online Safety Valve Testing 04.2008 PDFAntonio PerezNo ratings yet

- Guidelines on Testing DP SystemsDocument28 pagesGuidelines on Testing DP SystemsFrancis ButlerNo ratings yet

- Qurayyah Combined Cycle Power Plant - SATDocument10 pagesQurayyah Combined Cycle Power Plant - SATrenjithv_4100% (1)

- Advanced Automation and Project Management ArticleDocument5 pagesAdvanced Automation and Project Management Articlesarfaraz055No ratings yet

- Generator Reactive PowerDocument1 pageGenerator Reactive PowercharzreeNo ratings yet

- Directional OvercurrentDocument1 pageDirectional OvercurrentcharzreeNo ratings yet

- VDR - Farabi Paraffin Derivative ComplexDocument7 pagesVDR - Farabi Paraffin Derivative ComplexcharzreeNo ratings yet

- Mal-Function of Electrical Equipment at SuvliDocument1 pageMal-Function of Electrical Equipment at SuvlicharzreeNo ratings yet

- Question: What Are The Effects of Switching Transients and Are Suppressors Necessary?Document4 pagesQuestion: What Are The Effects of Switching Transients and Are Suppressors Necessary?charzreeNo ratings yet

- Cable Sizing NotepadDocument1 pageCable Sizing NotepadcharzreeNo ratings yet

- 1.15.3.-LTR 393-Wrmsp-Suv-15Document1 page1.15.3.-LTR 393-Wrmsp-Suv-15charzreeNo ratings yet

- LTR Draft To Ortex - Ground Fault of Incoming Cable in Kizil RavatDocument2 pagesLTR Draft To Ortex - Ground Fault of Incoming Cable in Kizil RavatcharzreeNo ratings yet

- Capacitive BreakingDocument1 pageCapacitive BreakingcharzreeNo ratings yet

- HarmonicsDocument2 pagesHarmonicscharzreeNo ratings yet

- K-E-161226-01 Necessity of DG Fuel at All PSDocument2 pagesK-E-161226-01 Necessity of DG Fuel at All PScharzreeNo ratings yet

- Mal-Function of Electrical Equipment at SuvliDocument1 pageMal-Function of Electrical Equipment at SuvlicharzreeNo ratings yet

- Harmonic FilterDocument2 pagesHarmonic FiltercharzreeNo ratings yet

- Mal-Function of Electrical Equipment at SuvliDocument1 pageMal-Function of Electrical Equipment at SuvlicharzreeNo ratings yet

- Detuned Reactor StudyDocument3 pagesDetuned Reactor StudycharzreeNo ratings yet

- The Residual Voltage That Is Developed Is Equal To Three Times The Zero Sequence VoltageDocument2 pagesThe Residual Voltage That Is Developed Is Equal To Three Times The Zero Sequence VoltagecharzreeNo ratings yet

- Furkat PT FuseDocument1 pageFurkat PT FusecharzreeNo ratings yet

- Star Delta Capacitor LocationDocument2 pagesStar Delta Capacitor LocationcharzreeNo ratings yet

- How To Resize Pictures To Fit Cells in ExcelDocument7 pagesHow To Resize Pictures To Fit Cells in ExcelcharzreeNo ratings yet

- Setting List (LV 7A-7037)Document34 pagesSetting List (LV 7A-7037)charzreeNo ratings yet

- QuestionsDocument1 pageQuestionscharzreeNo ratings yet

- BP-0000 Operation Flow (Master) - 20140217aDocument32 pagesBP-0000 Operation Flow (Master) - 20140217acharzreeNo ratings yet

- How To Select A Pump-By Majid HamedyniaDocument72 pagesHow To Select A Pump-By Majid Hamedyniamajid100% (2)

- Neutral Voltage ShiftDocument3 pagesNeutral Voltage ShiftcharzreeNo ratings yet

- Symmetrical Components ZmudaDocument2 pagesSymmetrical Components ZmudacharzreeNo ratings yet

- The Temperature High Fault Has Occurred in 2 NoDocument2 pagesThe Temperature High Fault Has Occurred in 2 NocharzreeNo ratings yet

- MS-Excel, Understanding Variables, Conditions & Loops in Excel VBA - A Demo Application UsDocument22 pagesMS-Excel, Understanding Variables, Conditions & Loops in Excel VBA - A Demo Application UscharzreeNo ratings yet

- Intake Pump LOP Terminal DetailsDocument1 pageIntake Pump LOP Terminal DetailscharzreeNo ratings yet

- Assembly InstructionsDocument11 pagesAssembly InstructionscharzreeNo ratings yet

- Booster Pump LOPDocument1 pageBooster Pump LOPcharzreeNo ratings yet

- Conestoga College English International Brochure Aug 2012Document4 pagesConestoga College English International Brochure Aug 2012api-236990434No ratings yet

- SIA Format For The FE100 Digital Receiver: Rev Date CommentsDocument15 pagesSIA Format For The FE100 Digital Receiver: Rev Date CommentsGabi DimaNo ratings yet

- Self-Organizing Networks - FAJ 801 0435 R3 - PresentationDocument30 pagesSelf-Organizing Networks - FAJ 801 0435 R3 - PresentationvaleNo ratings yet

- Control of Boiler Operation Using PLC - SCADADocument9 pagesControl of Boiler Operation Using PLC - SCADARoshan RaiNo ratings yet

- Enrollment SystemDocument9 pagesEnrollment SystemNeil Joseph Alcala100% (1)

- BMC Company Profile R05 (2020)Document15 pagesBMC Company Profile R05 (2020)Mohamed SamehNo ratings yet

- Week 9 Logistics Management - Ch-8 Materials HandlingDocument41 pagesWeek 9 Logistics Management - Ch-8 Materials HandlingImmortal 909No ratings yet

- Smart HAZOPDocument15 pagesSmart HAZOPjesus_manrique2753No ratings yet

- CNC 8037T New FeaturesDocument40 pagesCNC 8037T New FeaturessongcjswoNo ratings yet

- T.E. 2019 Pattern Endsem Timetable For Nov-Dec-2022 ExamDocument24 pagesT.E. 2019 Pattern Endsem Timetable For Nov-Dec-2022 Examsudhir divekarNo ratings yet

- Forum NXT Application Battle CardDocument6 pagesForum NXT Application Battle CardJOOOOONo ratings yet

- Masterdrives Motion ControlDocument16 pagesMasterdrives Motion ControlRaj ChavanNo ratings yet

- Hotel-Project-Report 12Document95 pagesHotel-Project-Report 12Neha Sable DeshmukhNo ratings yet

- Motercontrol CardinDocument28 pagesMotercontrol CardinaNo ratings yet

- Ventilation in HAP: QB Tip 001Document6 pagesVentilation in HAP: QB Tip 001Abdul RaheemNo ratings yet

- 'O' Level - Computer Studies Notes PDFDocument97 pages'O' Level - Computer Studies Notes PDFProgress jeffrey Sithole100% (1)

- Sensor Technology - IITB - June2021Document24 pagesSensor Technology - IITB - June2021DeepakSwarnaNo ratings yet

- Avidyne Retail Price List: Effective March, 2011Document2 pagesAvidyne Retail Price List: Effective March, 2011appanna_No ratings yet

- Micro Channel 1355150788Document2 pagesMicro Channel 1355150788Slim KanounNo ratings yet

- Today Testing Jobs PDFDocument34 pagesToday Testing Jobs PDFSudheer GangisettyNo ratings yet

- SSL 101Document105 pagesSSL 101Anh TranNo ratings yet

- Industrial Cooling Systems (ICS) TAE EVO 081 Refrigerated Water ChillerDocument2 pagesIndustrial Cooling Systems (ICS) TAE EVO 081 Refrigerated Water ChillerDanlap 11No ratings yet

- Aom Chapter IDocument18 pagesAom Chapter IMay Claire M. GalangcoNo ratings yet

- FinalDocument16 pagesFinalCarl OrejudosNo ratings yet

- Fanuc IC697VRD008 User ManualDocument59 pagesFanuc IC697VRD008 User ManualsunhuynhNo ratings yet

- ETL500 Presentacion TransparenciasDocument47 pagesETL500 Presentacion Transparenciasfrbueno100% (1)

- 3BSE069079 A en System 800xa System Guide SummaryDocument76 pages3BSE069079 A en System 800xa System Guide Summarylgrome73No ratings yet

- India Skills Report 2022 explores re-engineering educationDocument87 pagesIndia Skills Report 2022 explores re-engineering educationRohit KaulNo ratings yet

- SAS Forecast StudioDocument29 pagesSAS Forecast StudioBhavishya GuptaNo ratings yet

- IT Solutions for Disaster Management in Indian RailwaysDocument12 pagesIT Solutions for Disaster Management in Indian RailwaysAjit MishraNo ratings yet