Professional Documents

Culture Documents

Appendix

Uploaded by

pescanova3Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Appendix

Uploaded by

pescanova3Copyright:

Available Formats

APPENDIX

A

GENERAL PILE-DATA AND PILE

HAMMER TABLES

Representative steel and prestressed pile data are provided for the book user. The HP pile

data are similar to those in the AISC Steel Construction Manual except for the addition of

Algoma sections. The sheetpiling data are generally representative of those available both in

the United States and elsewhere. The pipe piling data are only a partial list of available diameters and wall thicknesses. The prestressed pile data are a partial list of available sections.

The SI conversions have been made by the author based on the best currently available

data on nominal section sizes and rounding. The European sections dimensions are as given

by them except where values have been provided in centimetersa non-SI term. Generally

the use of section values in meters (m) with a 10"" where n = 3 or 6 is the best format since

the exponential term can usually be canceled without even having to write it down. Using

millimeters gives numbers too large to write, and decimal shifting is difficult.

Because of the great difficulty in finding sources (some trade organizations charge for a

list of manufacturers), I have elected to provide addresses for pile hammer manufacturers

and the address of at least one producer of HP piles, sheet piles, pipe piles, and concrete

piles. Although these addresses are correct at the time of publication (I did not include any

representatives' addresses), no warranty can be made that they will remain correct for the

life of this publication.

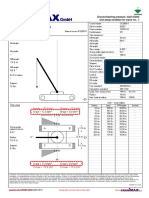

TABLE A-I

HP pile dimensions and section properties

Metric units in dark type, Fps units in light type.

Designation

nominal size/wt,

in. x lb/ft

mm x kg/m

HP 14 X 117

HP360 x 174

HP 14 X 102

HP360 x 152

HP 14 X 89

HP360 x 132

HP 14 x 73

HP360 x 108

HP 13 x 100

HP330 x 149

HP 13 X 87

HP330 x 129

HP 13 x 73

HP330 X 109

HP 13 x 60

HP330X 89

*HP 12 x 117

HP310 x 174

*HP 12 X 102

HP310 x 152

*HP 12 x 89

HP310 x 132

HP 12 x 84

HP310 x 125

HP 12 x 74

HP310 x 110

HP 12 x 63

HP310X 93

HP 12 X 53

HP310 X 79

HP 10 X 57

HP250X 85

HP 10X 42

HP250X 62

HP 8 x 36

HP200X 53

Section properties

Flange

Area,

in.2

2

m x 10

34.4

22.2

30.0

19.4

26.1

16.9

21.4

13.9

29.4

19.0

25.5

16.5

21.6

13.9

17.5

11.3

34.3

22.2

30.0

19.4

26.2

16.7

24.6

15.9

21.8

14.1

18.4

11.9

15.5

10.0

16.8

10.8

12.4

8.0

10.6

6.84

Depth,

in.

mm

Width,

in.

mm

Thick,

in.

mm

Web,

in.

mm

14.21

361

14.01

356

13.83

351

13.61

346

13.15

334

12.95

329

12.75

324

12.54

319

12.77

324

12.55

319

12.35

314

12.28

312

12.13

308

11.94

303

11.78

299

9.99

254

9.70

246

8.02

204

14.89

378

14.78

376

14.70

373

14.59

371

13.20

335

13.10

333

13.01

330

12.90

328

12.87

327

12.62

321

12.33

313

12.30

312

12.22

310

12.13

308

12.05

306

10.22

260

10.08

256

8.16

207

0.805

20.4

0.705

17.9

0.615

15.6

0.505

12.8

0.765

19.4

0.665

16.9

0.565

14.4

0.460

11.7

0.930

23.6

0.820

20.8

0.720

18.3

0.685

17.4

0.610

15.5

0.515

13.1

0.435

11.0

0.565

14.4

0.420

10.7

0.445

11.3

0.805

20.4

0.705

17.9

0.615

15.6

0.505

12.8

0.765

19.4

0.665

16.9

0.565

14.4

0.460

11.7

0.930

23.6

0.820

20.8

0.720

18.3

0.685

17.4

0.605

15.4

0.515

13.1

0.435

11.0

0.565

14.4

0.415

10.5

0.445

11.3

in.4

4

m x 10

1220

508

1050

437

904

373

729

303

886

369

755

314

630

262

503

209

946

394

812

338

693

287

650

271

569

236

472

196

393

163

294

122

210

87.4

119

49.5

*From Algoma Steel Co. (Canadian); all others available in both United States and Canada.

All shapes not designated with an * are available from:

Bethlehem Steel Corp.

501 East 3rd Street

Bethlehem, PA 18016-7699

Sx,

in.3

m 3 x 10

172

2.817

150

2.458

131

2.147

107

1.753

135

2.212

117

1.917

98.8

1.619

80.3

1.315

148

2.43

129

2.120

112

1.830

106

1.737

93.8

1.537

79.1

1.296

66.8

1.095

58.8

0.964

43.4

0.711

29.8

0.488

Sy,

Iy>

in.4

m4 x 10

443

184

380

158

326

136

261

109

294

122

250

104

207

86.2

165

68.7

331

138

275

115

226

93.7

213

88.7

186

77.4

153

63.7

127

52.9

101

42.0

71.7

29.8

40.3

16.8

in.3

6

m3 x 10

59.5

0.975

51.4

0.842

44.3

0.726

35.8

0.587

44.5

0.729

38.1

0.624

31.9

0.522

25.5

0.417

51.4

0.843

43.6

0.716

36.7

0.599

34.6

0.566

30.4

0.498

25.3

0.415

21.1

0.346

19.7

0.323

14.2

0.233

9.88

0.162

TABLE A-2

Typical pile-driving hammers from various sources

Consult manufacturers' catalogs for additional hammers, later models, other details.

Max. rated energy, Working weight, Ram weighty

Model no.

type*

kips ft

Drop hammers

Vulcan Iron Works

West Palm Beach, FL 33407

SA

400C

DA

200C

DA

140C

DA

80C

DA

65C

SA

1-106

DA

7

D

4N100

D

IN100

SA

0

kN*m

Variable

kips

kN

kips

kN

0.50-10 2.2-45

Stroke

m

Blow

rate/min

Variable*

Very few

ft

Approx.

length, m

153.86

68.05

48.80

33.14

26.03

20.33

5.63

58.8

33.4

33.04

83

39

28

18

15

9.7

5.1

12.8

7.6

16.0

369

174

125

80

67

43

22.7

56.9

33.8

71.2

40

20

14

8

6.5

5.0

0.8

5.3

3.0

7.5

177.9

89.0

62.3

35.58

28.91

22.24

3.56

23.5

13.3

33.4

1.37

1.29

1.29

1.37

1.29

3.0

0.78

8.13

8.13

3.25

0.42

0.39

0.39

0.42

0.39

0.91

0.24

2.48

2.48

0.99

100

98

103

111

117

60

225

50-60

50-60

50

5.1

4.0

3.7

3.7

3.7

4.0

1.8

McKiernan-Terry, Koehring-MKT Division

Dover, NJ 07801

489.57

SA

361.15

MBRS-7000

SA

122.0

90.0

OS-30

SA

60.0

81.34

S-20

SA

26.0

35.25

S-8

SA

16.25

22.03

S-5

D

79.4

107.63

IHI-J44

D

38.0

51.51

DA55B

D

32.0

43.38

DE40

D

22.4

30.37

DE30

161

50.5

39.0

18.3

12.5

21.5

19.6

11.2

9.1

712

225

173

81.4

55.4

95.6

87.3

49.9

40.4

88.0

30.0

20.0

8.0

5.0

9.7

5.0

4.0

2.8

391.4

133.4

88.9

35.6

22.2

43.2

22.2

17.8

12.4

4.10

3.0

3.0

3.25

3.25

8.17

8.0

10.7

10.7

1.25

0.91

0.91

0.99

0.99

2.49

2.44

3.26

3.26

40

60

60

53

60

42-70

48

48

48

8.5

6.4

4.6

4.3

4.0

4.6

5.1

4.6

4.6

52.0

26.5

32.5

18.8

17.9

14.7

11.0

231.2

117.6

144.5

83.4

79.5

65.3

48.9

30.0

17.5

15.0

10.0

8.0

6.5

5.0

133.4

77.8

66.7

44.5

35.6

28.9

22.2

2.5

3.25

1.50

3.25

1.38

1.33

3.0

0.76

0.99

0.46

0.99

0.42

0.41

0.91

70

44

95-105

50

95-105

110

60

5.8

5.1

4.8

4.6

3.7

3.7

4.0

The Foundation Equipment Corp. (distributor of Delmag Hammers)

New Commerstown, OH 43832

D

26.3

116.9

D55

117.175t 158.84

D

117.94

22.4

99.6

D44

87.0

D

100.02

17.8

79.1

D36

73.78

D

12.4

55.1

D30

73.47

54.2

D

11.1

49.4

D22

53.93

39.78

D

2.7

12.0

D5

9.05

12.27

11.9

9.5

7.9

6.6

4.8

1.1

52.8

42.1

35.3

29.4

21.5

4.9

36-47

37-55

37-53

40-60

40-60

40-60

5.5

4.8

4.8

4.3

4.3

4.0

113.5

50.2

36.0

24.45

19.2

15.0

4.15

43.4

24.6

24.38

Raymond International, Inc.

2801 South Post Road, Houston, TX 77027

30X

DA

75.0

5/0

SA

56.9

150C

DA

48.8

2/0

SA

32.5

80C

DA

24.5

65C

DA

19.5

1

SA

15.0

107.67

77.10

66.09

44.06

33.14

26.43

20.33

4.6

TABLE A-2

Typical pile-driving hammers from various sources (continued)

Consult manufacturers' catalogs for additional hammers, later models, other details.

Max. rated energy,

Model no. Type*

kips ft

kN*m

Working weight,

kips

kN

Ram weighty

Stroke

kips

ft

Link Belt

Link Belt Speeder Division, FMC Corp., Cedar Rapids, IA 52406

5.07

12.6

26.3

D

56.0

35.65

520

4.0

10.3

18.2

D

45.8

24.67

440

3.86

10.4

15.0

D

46.2

20.33

312

4.6

8.1

D

1.72

20.5

10.98

180

L. B. Foster Co. (distributor for Kobe Diesel Hammers)

7 Parkway Center, Pittsburgh, PA 15220

D

80.5 358.0

381.33

281.3

K150

D

25.6 113.8

123.51

91.1

K45

D

24.0 106.7

107.09

79.0

K42

D

17.8

81.47

60.1

K32

79.2

D

13.1

68.73

50.7

K25

58.2

D

8.0

33.08

24.4

K13

35.6

Berminghammer Corp., Ltd.

Hamilton, Ontario (Canada)

D

75.0

B500

D

B225

25.0

kN

22.55

17.79

17.15

7.67

33.1

9.9

9.26

7.1

5.5

2.9

147.2

44.0

41.2

31.4

24.5

12.7

Blow

rate/min

5.18

4.35

3.89

4.70

1.58

1.39

1.18

1.43

80-84

86-90

100-105

90-95

8.5

9.17

8.5

8.5

9.17

8.5

2.59

2.80

2.59

2.59

2.80

2.59

45-60

39-60

45-60

45-60

39-60

45-60

16.5

6.8

73.4

30.2

6.9

2.9

30.7

12.7

12.0

9.7

3.66

2.96

40-60

40-60

Mitsubishi International Corp.

875 North Michigan Avenue, Chicago, IL 60611

D

MB70

137.0

185.72

46.0

D

M43

84.0

113.87

22.6

D

M33

64.0

86.76

16.9

D

M23

45.0

61.00

11.2

D

M14

26.0

35.25

7.3

204.6

100.5

75.2

49.8

32.5

15.84

9.46

7.26

5.06

2.97

70.5

42.1

32.3

22.5

1.32

8.5

8.5

8.5

8.5

8.5

2.59

2.59

2.59

2.59

2.59

38-60

40-60

40-60

42-60

42-60

101.67

33.89

*SA = single-acting; DA = double-acting or differential-acting; D = diesel.

tEnergy varies from maximum shown to about 60 percent of maximum depending on stroke and soil.

$ Variable stroke; stroke = energy out/weight of ram.

H Ram weight or weight of striking part.

Approx.

length, m

8.5

5.8

5.8

5.5

5.5

5.1

6.1

4.8

4.8

4.3

4.3

TABLE A-3a

Steel sheetpiling sections produced in the United States*

Section

modulus*

per pile,

in.3

m3 x 10 3

Moment of

inertia

per pile,

40.0

195.3

35.0

170.9

99.6

1.632

91.4

1.498

805.4

335.23

681.5

283.7

40.5

60.3

40.3

60.0

27.0

131.8

22.0

107.4

45.3

0.742

33.1

0.542

276.3

115.0

154.7

64.39

19.69

500

50.9

75.7

31.0

151.4

3.3

0.054

5.3

2.206

PS27.5

19.69

500

45.1

67.1

27.5

134.3

3.3

0.054

5.3

2.206

PSA23

16.00

405

30.7

45.7

23.0

112.3

3.2

0.052

5.5

2.290

45.28

1150

261.2

388.7

Depth

d,

in.

mm

Driving

distance,

in.

mm

16.1

410

14.9

380

19.69

500

22.64

575

65.6

97.6

66.0

98.2

12

305

9

230

18

460

22

560

PS31

Section

index

PZ40

PZ35

PZ27

PZ22

Box pile

31.0

787

Driving distance

Load side

*These sections are now available only from Bethlehem Steel Corporation.

Steel grades: A328 with Fy = 270 MPa (39 ksi)

A572 with Fy = 345 and 415 MPa (50 and 60 ksi)

A690 with Fy = 345 MPa (50 ksi) for marine environments

Weight

lb/ft

lb/ft2

kg/m kg/m2

480.7

7.877

in.4

m4 x 10

7618

3170.9

TABLE A-3b

Steel sheetpiling sections produced in Europe

Section

index

Section

modulus

Depth Driving

Weight

per pile,

distance,

d,

mm

mm

kg/m kg/m2 m3 x 10 3

Moment of

inertia

per pile,

m4 X 10 6

AZ 13

303

670

72.0

107

0.870

132.0

AZ 18

380

630

74.4

118

1.135

215.40

AZ 26

427

630

97.8

155

1.640

349.70

AZ 36

460

630

122.2

194

2.270

521.60

500

72.3

145

0.047

1.80

AS500-12.0

TABLE \-3b (continued)

AS500-12.7

500

HZ775A/ZH9.5

775

1585

75.2

150 0.047

1.80

Driving

distance

Combination 10/13

184

222

4.80

1859.9

Driving

distance

Sheetpiling produced by International Sheet Piling Group

ARBED Group

3-7, rue Schiller

L-2930 Luxemburg, TeL: (352)-5550-2060

TABLE A-4

Typical available steel pipe sections used for piles and caisson shells

In spiral welded pipe almost any wall thickness and diameter can be produced.

[Courtesy Skyline Steel Corporation, Pipe Division, Peachtree Industrial Boulevard, Duluth,

GA, TeL: 404-623-6200]

^nal

mm (in.)

WaUthickness

w

Area m2 x 103

'

mm

in.

kg/m

Concrete

Steel

254

(10)

4.78

5.56

6.35

0.188

0.219

0.250

29.2

34.0

38.7

46.9

46.3

45.9

3.75

4.35

4.94

273

(1Of)

4.78

6.35

7.79

9.27

0.188

0.250

0.307

0.365

31.5

41.7

51.0

60.3

54.5

53.2

52.1

50.9

4.03

5.32

6.50

7.68

305

(12)

4.78

5.56

6.35

0.188

0.219

0.250

35.2

41.0

46.7

68.5

67.7

67.0

4.49

5.23

5.97

325

(12|)

4.78

6.35

7.92

9.53

12.70

0.188

0.250

0.312

0.375

0.500

37.4

49.7

61.8

73.8

97.3

77.6

76.0

74.5

73.0

69.9

4.79

6.34

7.86

9.41

12.41

TABLE A-4 (continued)

In spiral welded pipe almost any wall thickness and diameter can be produced.

[Courtesy Skyline Steel Corporation, Pipe Division, Peachtree Industrial Boulevard, Duluth,

GA, TeL: 404-623-6200]

Nominal

OD,

mm (in.)

n thickness

mi

'

Concrete

Area

x 10

mm

in.

Weight,

kg/m

356

(14)

5.56

6.35

7.92

9.53

12.70

0.219

0.250

0.312

0.375

0.500

47.9

54.6

68.0

81.3

107.3

93.2

92.3

90.6

89.0

85.6

6.12

6.97

8.66

10.35

13.68

410

(16)

4.78

6.35

7.92

9.53

12.70

0.188

0.250

0.312

0.375

0.500

41.2

62.7

78.0

93.2

123.2

123.7

121.7

119.8

117.8

114.0

6.03

7.98

9.92

11.88

15.71

460

(18)

5.56

6.35

7.92

9.53

0.219

0.250

0.312

0.375

61.8

70.5

87.8

105.1

156.3

155.2

153.0

150.8

7.89

8.99

11.19

13.39

510

(20)

6.35

7.92

9.53

12.70

0.250

0.312

0.375

0.500

78.4

97.8

117.0

154.9

192.6

190.3

187.7

182.9

10.01

12.45

14.92

19.76

610

(24)

6.35

7.92

9.53

12.70

0.250

0.312

0.375

0.500

94.3

117.7

140.8

186.8

279.8

276.9

273.9

268.1

12.06

14.97

17.94

23.81

760

(30)

9.53

12.70

0.375

0.500

176.6

234.4

433.5

426.1

22.52

29.87

915

(36)

9.53

12.70

0.375

0.500

212.4

282.2

629.5

620.7

27.10

36.00

1070

(42)

9.53

12.70

0.375

0.500

248.1

329.8

862.2

851.7

31.61

42.06

1220

(48)

9.53

12.70

0.375

0.500

283.8

377.5

1131.2

1119.4

36.19

48.13

1370

(54)

9.53

12.70

0.375

0.500

320.0

424.1

1436.8

1423.4

40.76

54.19

Steel

TABLE A-5

Typical prestressed-concrete pile sectionsboth solid and hollow-core (HC)*

Nominal

pile size

mm

Size

Wire spiral

Size

Core

diameter

Solid

Hollow

Prestressing

strand

Size

Core

diameter

Solid or hollow

(in.)

Area

concrete,

m2 x 10 3

Approx. Minimum

weight,

pre-stress

kN/m

force, $ kN

No. of strands

in pile,H

Mom. of inertia /,

11.1/12.7 mm

m4 X 10 6

Perimeter,

m

250

300

360

410

(10)

(12)

(14)

(16)

64.5

92.9

126.5

171.0

1.52

2.19

2.99

4.04

311

449

610

830

4/4

6/5

8/6

11/8

346.7

719.2

1332.4

2273.0

1.02

1.22

1.42

1.63

460

510

560

610

(18)

(20)

(22)

(24)

209.0

258.1

312.3

371.6

4.93

6.09

7.37

8.77

1010

1250

1500

1790

13/10

16/12

20/15

23/18

3641.2

5549.6

8125.3

11508.0

1.83

2.03

2.24

2.44

510

560

610

(2O)HCt

(22)HC

(24)HC

196.7

226.5

257.4

4.64

5.35

6.07

950

1095

1245

13/10

14/11

16/12

5250.8

7504.8

10473.6

2.03

2.24

2.44

250

300

360

410

(10)

(12)

(14)

(16)

53.5

76.8

104.5

136.8

1.26

1.81

2.47

3.23

260

370

500

660

4/4

5/4

7/5

9/7

231.0

472.0

876.2

1495.1

0.84

1.02

1.17

1.35

460

510

560

610

(18)

(20)

(22)

(24)

172.9

213.5

258.7

307.7

4.08

5.04

6.11

7.26

835

1030

1250

1485

11/8

14/10

16/12

19/15

2374.6

3650.3

5343.2

7567.1

1.52

1.68

1.85

2.03

510

560

610

(2O)HC

(22)HC

(24)HC

132.3

172.9

193.5

3.12

4.08

4.57

735

835

835

10/8

11/8

12/9

3350.7

4761.7

6533.2

1.68

1.85

2.03

*Additional data available from Prestressed Concrete Institute, 20 North Wacker Drive, Chicago, IL 60606.

f Voids in 510-, 560-, and 610-mm diameter HC piles are 279-, 330-, and 381-mm diameter, respectively, to provide a

minimum 115-mm wall thickness.

^Minimum prestress force based on fp =4.8 MPa after losses.

UUses 11.1 (-J^ -in.) and 12.7 (^-in.) stress-relieved strands with />uU = 138 and 184 kN, respectively.

You might also like

- AugerDocument104 pagesAugerOmar TaréNo ratings yet

- Liebherr Casing Oscillator Deep Foundation enDocument4 pagesLiebherr Casing Oscillator Deep Foundation enNararya Muh Pratito Anditya100% (1)

- Drilling ToolsDocument88 pagesDrilling ToolsSanja RadovicNo ratings yet

- Spun Pile WIKA-TP 800&1000 PDFDocument3 pagesSpun Pile WIKA-TP 800&1000 PDFiwanguna71No ratings yet

- Drilling Bucket, Model Tqdc-14001200Document4 pagesDrilling Bucket, Model Tqdc-14001200Val DimlaNo ratings yet

- Hydraulic Vibratory Hammer Brochure-Vibro Hammer-Bruce Vibro HammerDocument28 pagesHydraulic Vibratory Hammer Brochure-Vibro Hammer-Bruce Vibro Hammerarjuna1210No ratings yet

- DRWDocument42 pagesDRWMahmoud Abuibaid100% (1)

- Karakteristik KendaraanDocument23 pagesKarakteristik KendaraanMiftachul DimasNo ratings yet

- Rumus Hiley Untuk Hammer D100Document5 pagesRumus Hiley Untuk Hammer D100Prapto bwiNo ratings yet

- PC Spun PilesDocument2 pagesPC Spun PilesFaridah Zahra100% (1)

- 2.PC PilesDocument6 pages2.PC PilesRajinda BintangNo ratings yet

- Joint Welding Method PHC D600A-100Document2 pagesJoint Welding Method PHC D600A-100sochealaoNo ratings yet

- 2-3 SchöepfDocument45 pages2-3 SchöepflingamkumarNo ratings yet

- Fill in The Cells in Light GreenDocument9 pagesFill in The Cells in Light Greenperunding thdNo ratings yet

- Upn (Unp) European Standard U Channels, Upn Steel Profile Specifications, Dimensions, PropertiesDocument3 pagesUpn (Unp) European Standard U Channels, Upn Steel Profile Specifications, Dimensions, PropertiesshankerNo ratings yet

- PC Spun PilesDocument2 pagesPC Spun PilesJoglo Solo100% (1)

- Spec Diesel HammerDocument30 pagesSpec Diesel Hammerallbert aliminNo ratings yet

- 8706 Phase2Document2 pages8706 Phase2reluNo ratings yet

- Shibata Catalogue 2012Document99 pagesShibata Catalogue 2012Amara Krishna KishorNo ratings yet

- Kumpulan Mesin PancangDocument48 pagesKumpulan Mesin PancangFajrin M. NatsirNo ratings yet

- Iph750 Hydraulic Piling Hammer and Rig: Impact-Power Hydraulics Sdn. BHDDocument4 pagesIph750 Hydraulic Piling Hammer and Rig: Impact-Power Hydraulics Sdn. BHDAdam LimNo ratings yet

- GeoDocument5 pagesGeoRizal AdyNo ratings yet

- Thumb Rule For Selection of Vibro HammerDocument4 pagesThumb Rule For Selection of Vibro Hammerlspartha100% (1)

- MTDF-CV-300-SPE-1011-R3A - Specification For PilingDocument22 pagesMTDF-CV-300-SPE-1011-R3A - Specification For PilingDidi Hadi RiantoNo ratings yet

- Spec NH 70 2Document10 pagesSpec NH 70 2yosep26100% (2)

- Crawler CraneDocument11 pagesCrawler CraneidonotspammeNo ratings yet

- DSI Underground Systems Mechanical Rock Bolts Extension Bolts Stelpipe Bolts US 01Document16 pagesDSI Underground Systems Mechanical Rock Bolts Extension Bolts Stelpipe Bolts US 01Tato Del AguilaNo ratings yet

- Facade & Fenestration Glass Embedding General GuidelinesDocument20 pagesFacade & Fenestration Glass Embedding General GuidelinesFrancisco BastidasNo ratings yet

- Brosur Fender & Bollard MKA PDFDocument26 pagesBrosur Fender & Bollard MKA PDFSari Dian AnggraeniNo ratings yet

- Traveled Way Width: 6.6 MetersDocument10 pagesTraveled Way Width: 6.6 MetersRichard Dean SantosNo ratings yet

- 52 - Interface With SAP2000 - DocDocument12 pages52 - Interface With SAP2000 - DocFauzankalibataNo ratings yet

- Bearing Capacity of Driven Pile 20201110Document5 pagesBearing Capacity of Driven Pile 20201110Tuan LeNo ratings yet

- 2.0 Method StatementDocument2 pages2.0 Method StatementArden NeriNo ratings yet

- Microsoft Word - Annex L Tower Crane Footing Structural Design For TC 1, 3, 4 & 5Document14 pagesMicrosoft Word - Annex L Tower Crane Footing Structural Design For TC 1, 3, 4 & 5Revathy RanjithNo ratings yet

- Steel Cage Lifting PDFDocument5 pagesSteel Cage Lifting PDFAnonymous S7Cq7ZDgPNo ratings yet

- Analysis of Steel Sheet PilingDocument5 pagesAnalysis of Steel Sheet PilingTawachal IqbalNo ratings yet

- Project Name: Set Wind PressureDocument10 pagesProject Name: Set Wind PressureshoebNo ratings yet

- Lifting Hook DesignDocument7 pagesLifting Hook DesignAji V0% (1)

- Design of Reinforcement For RC Capping Beam: ProjectDocument1 pageDesign of Reinforcement For RC Capping Beam: ProjectNikit MaskeNo ratings yet

- Detai Rip Plate: Penerangan Jalan UmumDocument1 pageDetai Rip Plate: Penerangan Jalan UmumGo PeaksNo ratings yet

- Pile Hammer PDFDocument2 pagesPile Hammer PDFMohd Azual JaafarNo ratings yet

- L9 - Construction Methodology - 1Document20 pagesL9 - Construction Methodology - 1J. Kumar Infraprojects LtdNo ratings yet

- BW 250Document1 pageBW 250Adhitya Hidayat0% (1)

- Armador Bored Piling Tools 2010 PDFDocument30 pagesArmador Bored Piling Tools 2010 PDFjovanangelssNo ratings yet

- Keman Rubber FenderDocument34 pagesKeman Rubber FendersigNo ratings yet

- PMCM Form-050 Concrete Pouring MonitoringDocument1 pagePMCM Form-050 Concrete Pouring MonitoringAbnar KumplishaNo ratings yet

- Tech ManualDocument137 pagesTech Manualsilvereyes18No ratings yet

- Bulb Plate Section ModulusDocument1 pageBulb Plate Section ModulusRupesh KarmakerNo ratings yet

- FRP Tank Price PackageDocument8 pagesFRP Tank Price PackageWira Brata SamodraNo ratings yet

- Universal Columns in Accordance With BS4Document1 pageUniversal Columns in Accordance With BS4RajNo ratings yet

- Ibeam DatDocument1 pageIbeam Datdinhtan85No ratings yet

- Hss - Cuadrado (Per) : Hollow Structural Section-Square 대형 철강 파이프Document3 pagesHss - Cuadrado (Per) : Hollow Structural Section-Square 대형 철강 파이프Isaias BarbaNo ratings yet

- Shrink Disc DimensionsDocument1 pageShrink Disc Dimensionsbugoff700No ratings yet

- Fractional Size Stainless Steel TubingDocument2 pagesFractional Size Stainless Steel TubingmarkcoatesNo ratings yet

- Cálculo de Rigideces en Los MurosDocument11 pagesCálculo de Rigideces en Los MurosAndy Muñoz DuranNo ratings yet

- Footing ReportDocument2 pagesFooting ReportSyed Fahad AliNo ratings yet

- Jotun Loading TableDocument26 pagesJotun Loading TableOsama KheadryNo ratings yet

- Steel Beam Sizes From The AISC Manual of Steel ConstructionDocument3 pagesSteel Beam Sizes From The AISC Manual of Steel ConstructionWashington RodriguesNo ratings yet

- Hercules Laminated Elastomeric BearingsDocument7 pagesHercules Laminated Elastomeric BearingsjohnsonNo ratings yet

- Speaking C1Document16 pagesSpeaking C1Luca NituNo ratings yet

- Indonesian High School Student Motivational Orientations For Learning English As A Foreign LanguageDocument18 pagesIndonesian High School Student Motivational Orientations For Learning English As A Foreign LanguageAlberth DalopeNo ratings yet

- t10 2010 Jun QDocument10 pagest10 2010 Jun QAjay TakiarNo ratings yet

- Sepulveda v. de Las CasasDocument2 pagesSepulveda v. de Las CasasNova GaveNo ratings yet

- Ethics - FinalsDocument18 pagesEthics - Finalsannie lalangNo ratings yet

- Business Information Systems 2021: Cardiff Metropolitan UniversityDocument30 pagesBusiness Information Systems 2021: Cardiff Metropolitan UniversityMichelle FernandoNo ratings yet

- Asterisk 10.0.0 Beta1 SummaryDocument113 pagesAsterisk 10.0.0 Beta1 SummaryFaynman EinsteinNo ratings yet

- A Terence McKenna Audio Archive - Part 1Document203 pagesA Terence McKenna Audio Archive - Part 1BabaYagaNo ratings yet

- Test - To Kill A Mockingbird - Chapter 17 - Quizlet PDFDocument2 pagesTest - To Kill A Mockingbird - Chapter 17 - Quizlet PDFchadlia hadNo ratings yet

- Minimum Structural Properties and Test Procedure For TG20 Compliant Prefabricated Structural Transom UnitsDocument16 pagesMinimum Structural Properties and Test Procedure For TG20 Compliant Prefabricated Structural Transom UnitsPrimelift Safety Resources LimitedNo ratings yet

- Privileged Communications Between Husband and Wife - Extension of PDFDocument7 pagesPrivileged Communications Between Husband and Wife - Extension of PDFKitingPadayhagNo ratings yet

- ERP Test BankDocument29 pagesERP Test BankAsma 12No ratings yet

- Keir 1-2Document3 pagesKeir 1-2Keir Joey Taleon CravajalNo ratings yet

- Dexter Quilisadio-Tanzo BSA-2 Unit-1 Quiz-1: OPMATQM-490Document1 pageDexter Quilisadio-Tanzo BSA-2 Unit-1 Quiz-1: OPMATQM-490Red AriesNo ratings yet

- Songs of KabirDocument342 pagesSongs of KabirSant MatNo ratings yet

- Concept of Leadership (Session-1) MARSDocument14 pagesConcept of Leadership (Session-1) MARShudaNo ratings yet

- PRS Product DescriptionDocument42 pagesPRS Product DescriptioneliaezekielNo ratings yet

- Building Social CapitalDocument17 pagesBuilding Social CapitalMuhammad RonyNo ratings yet

- Parathyroid Agents PDFDocument32 pagesParathyroid Agents PDFRhodee Kristine DoñaNo ratings yet

- Apcr MCR 3Document13 pagesApcr MCR 3metteoroNo ratings yet

- Modern State and Contemporaray Global GovernanceDocument34 pagesModern State and Contemporaray Global GovernancePhoebe BuffayNo ratings yet

- Experiment No 5 ZenerDocument3 pagesExperiment No 5 ZenerEugene Christina EuniceNo ratings yet

- Laser 1Document22 pagesLaser 1Mantu KumarNo ratings yet

- Hyrons College Philippines Inc. Sto. Niño, Tukuran, Zamboanga Del Sur SEC. No.: CN200931518 Tel. No.: 945 - 0158Document5 pagesHyrons College Philippines Inc. Sto. Niño, Tukuran, Zamboanga Del Sur SEC. No.: CN200931518 Tel. No.: 945 - 0158Mashelet Villezas ValleNo ratings yet

- Bnblist3559 PDFDocument430 pagesBnblist3559 PDFJagroopSinghBalhraNo ratings yet

- Novel Synthesis of BarbituratesDocument3 pagesNovel Synthesis of BarbituratesRafaella Ferreira100% (2)

- Knapp TestDocument2 pagesKnapp TestGeorge Litu67% (3)

- Case Study Beta Management Company: Raman Dhiman Indian Institute of Management (Iim), ShillongDocument8 pagesCase Study Beta Management Company: Raman Dhiman Indian Institute of Management (Iim), ShillongFabián Fuentes100% (1)

- 1Document13 pages1Victor AntoNo ratings yet

- Birnbaum - 2006 Registration SummaryDocument14 pagesBirnbaum - 2006 Registration SummaryEnvironmental Evaluators Network100% (1)