Professional Documents

Culture Documents

QSP 8.7 Control of Nonconforming Outputs (Preview)

Uploaded by

Centauri Business Group Inc.Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QSP 8.7 Control of Nonconforming Outputs (Preview)

Uploaded by

Centauri Business Group Inc.Copyright:

Available Formats

Quality System Procedure

info@c-bg.com

www.c-bg.com

QSP

Subject:

8.7

Control of nonconforming outputs

Content

1 Purpose

2 Scope

3 Responsibility and Authority

4 Procedure

4.1.

Nonconforming outputs detected at Sample Company

4.2.

Nonconforming outputs detected after delivery or use.

4 Control of nonconforming outputs process criteria and risks

5.1. The criteria

5.2. Addressing the risks and opportunities

5 Documented information of process Control of nonconforming

outputs

6 Revision History

Revision A

Date

This document is UNCONTROLLED if printed

Check master computer files for latest revision

Page 1 of 3

Quality System Procedure

info@c-bg.com

www.c-bg.com

QSP

Subject:

8.7

Control of nonconforming outputs

4. Procedure

The diagram of Control of nonconforming outputs process is shown on Fig.1.

. 1 Control of nonconforming outputs Process Diagram

4.1

Nonconforming outputs detected at Sample Company

4.1.1.

Nonconforming outputs can be detected in many ways, by any

person, at any time.

4.1.2.

When nonconforming outputs is detected, it is immediately

removed from the normal process flow and one of the following people

is notified: The President, Quality Manager, or Sales Manager. The

product or material is removed from the normal process flow by being

placed on the designated hold shelf. (Note- you may wish to lock up

your nonconforming material to prevent unintended use.)

Revision A

Date

This document is UNCONTROLLED if printed

Check master computer files for latest revision

Page 2 of 3

Quality System Procedure

info@c-bg.com

www.c-bg.com

QSP

Subject:

8.7

Control of nonconforming outputs

4.1.3.

Nonconforming material is identified with a HOLD tag, which is

filled out and attached to the affected item(s). The HOLD tag contains

part number, quantity, description, reason for being on hold, name of

the person who detected the problem, and the date.

4.1.4.

Disposition of nonconforming products can be determined by

any of the above 3 listed people. The Quality Manager will periodically

go thru all the items on the hold shelf to dispose of the products. Noncompliance protocol is created that describes the nonconformity,

describes the actions taken, describes the concessions obtained (if

obtained), and identifies the authority deciding the action in respect of

the nonconformity. No nonconforming material shall be removed from

the hold shelf except by the Quality Manager, the President, and the

Sales Manager.

Purchase the full version of the

Control of Nonconforming Outputs

Procedure

$19.00

More info

Related products:

ISO 9001:2015 Quality System

Manual

Actions to Address Risks and

Opportunities Procedure

ISO 9001:2015 Overview.

Comparative Analysis of ISO

9001:2015 vs. ISO 9001:2 008

QMS Transition Program

(to the New Version of ISO

9001:2015)

Control of Documented

Information in ISO 9001:2015 Clauses

Presentation for Training

Other ISO 9001:2015 Documents and Template

Revision A

Date

This document is UNCONTROLLED if printed

Check master computer files for latest revision

Page 3 of 3

You might also like

- ISO 9001:2015 QMS Implementation Program (Presentation)Document16 pagesISO 9001:2015 QMS Implementation Program (Presentation)Centauri Business Group Inc.96% (46)

- IMS 9001/14001/45001 Requirements ComparisonDocument1 pageIMS 9001/14001/45001 Requirements ComparisonCentauri Business Group Inc.95% (20)

- Corrective and Preventive ActionsDocument33 pagesCorrective and Preventive ActionsSonam Dhonde100% (2)

- Complete Set of ISO 9001 ProceduresDocument13 pagesComplete Set of ISO 9001 ProceduresCentauri Business Group Inc.77% (13)

- QSP 8.4 Control of Externally Provided Processes (Preview)Document4 pagesQSP 8.4 Control of Externally Provided Processes (Preview)Centauri Business Group Inc.67% (3)

- QSP 8.3.1 Nonconforming Product - SampleDocument3 pagesQSP 8.3.1 Nonconforming Product - SampleGladys Calvo100% (2)

- Management Review Meeting FormatDocument2 pagesManagement Review Meeting FormatThusitha LakpriyaNo ratings yet

- ISO 9001 Quality Manual 2015 TemplateDocument13 pagesISO 9001 Quality Manual 2015 Templatebimmodwi100% (3)

- ISO 9001:2015 Quality Manual 2nd Edition PreviewDocument12 pagesISO 9001:2015 Quality Manual 2nd Edition PreviewCentauri Business Group Inc.100% (12)

- Need Expectation of Interested Parties According To I So 220002018Document2 pagesNeed Expectation of Interested Parties According To I So 220002018Shivyog SanatanNo ratings yet

- Iso 9001-14001 Ims ManualDocument38 pagesIso 9001-14001 Ims ManualFarhan100% (2)

- Control of Non-Conforming Products ProcedureDocument4 pagesControl of Non-Conforming Products ProcedureAlmario Sagun100% (1)

- ISO 9001:2015 QMS Implementation ProgramDocument6 pagesISO 9001:2015 QMS Implementation ProgramCentauri Business Group Inc.100% (7)

- Risk & Opportunities Analysis PDFDocument2 pagesRisk & Opportunities Analysis PDFpremnath RNo ratings yet

- Corrective and Preventive ActionDocument3 pagesCorrective and Preventive ActionIgnacioNo ratings yet

- ISO 9001:2015 Audit Checklist in MS Excel (Preview)Document7 pagesISO 9001:2015 Audit Checklist in MS Excel (Preview)Centauri Business Group Inc.56% (18)

- ISO 9001:2015 Methodical Manual. Actions To Address Risks and Opportunities in QMS ProcessesDocument2 pagesISO 9001:2015 Methodical Manual. Actions To Address Risks and Opportunities in QMS ProcessesCentauri Business Group Inc.No ratings yet

- ISO 9001:2015 Methodical Manual. Actions To Address Risks and Opportunities in QMS ProcessesDocument2 pagesISO 9001:2015 Methodical Manual. Actions To Address Risks and Opportunities in QMS ProcessesCentauri Business Group Inc.No ratings yet

- Service ContractsDocument92 pagesService Contractssantosh7ck0% (2)

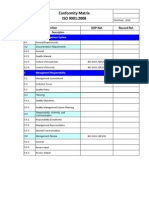

- ISO 9001 Conformity MatrixDocument3 pagesISO 9001 Conformity Matrixkashifbutty2kNo ratings yet

- Star Ecn Form 2012Document4 pagesStar Ecn Form 2012BERK YENİLMEZNo ratings yet

- ISO 9001:2015 Questions Answered: Suppliers CertificationDocument3 pagesISO 9001:2015 Questions Answered: Suppliers CertificationCentauri Business Group Inc.100% (1)

- ISO 9001:2015 Questions Answered: Suppliers CertificationDocument3 pagesISO 9001:2015 Questions Answered: Suppliers CertificationCentauri Business Group Inc.100% (1)

- 01 Documented Information 1Document11 pages01 Documented Information 1Noor Muddassir KhanNo ratings yet

- SWOT ANALYSIS For ISO Context of The OrganizationDocument1 pageSWOT ANALYSIS For ISO Context of The OrganizationZach JavelonaNo ratings yet

- Clause 8 ReqmntsDocument48 pagesClause 8 ReqmntsAkhil GuptaNo ratings yet

- Form - Management Review Meeting MinutesDocument6 pagesForm - Management Review Meeting Minutesmgamal1080100% (1)

- ISO 14001:2015 Environmental Management System Manual Template PreviewDocument10 pagesISO 14001:2015 Environmental Management System Manual Template PreviewCentauri Business Group Inc.78% (18)

- Form - Management Review Meeting MinutesDocument6 pagesForm - Management Review Meeting Minutesshahrilzainul77No ratings yet

- Important Steps To Implement Risk Management in QMS ProcessesDocument2 pagesImportant Steps To Implement Risk Management in QMS ProcessesCentauri Business Group Inc.No ratings yet

- ISO 13485:2016 Quality Systems Manual: Document No. QMD-001Document11 pagesISO 13485:2016 Quality Systems Manual: Document No. QMD-001Roslan.Affandi2351100% (1)

- Supplier Audit FormatDocument4 pagesSupplier Audit FormatPratik KarekarNo ratings yet

- Effective Implementation of an ISO 50001 Energy Management System (EnMS)From EverandEffective Implementation of an ISO 50001 Energy Management System (EnMS)Rating: 4 out of 5 stars4/5 (1)

- ISO 9001 Evidence ChecklistDocument40 pagesISO 9001 Evidence ChecklistsanrexiNo ratings yet

- Control of RecordsDocument3 pagesControl of Recordschahi100% (1)

- Iso 9001:2000 Sample Audit Plan Schedule (Registrar)Document0 pagesIso 9001:2000 Sample Audit Plan Schedule (Registrar)Muhammad ShafiNo ratings yet

- OH&S Requirements in ISO 45001 Clauses - Presentation (Preview)Document9 pagesOH&S Requirements in ISO 45001 Clauses - Presentation (Preview)Centauri Business Group Inc.100% (8)

- Iso 9001 Toolkit File ListDocument3 pagesIso 9001 Toolkit File ListEl KhanNo ratings yet

- ISO 9001 Internal Audit ChecklistDocument14 pagesISO 9001 Internal Audit ChecklistEsterNTNo ratings yet

- Quality Manual 9001-2008 Elsmar 1Document13 pagesQuality Manual 9001-2008 Elsmar 1luis miguel perez cruzNo ratings yet

- ISO 9001 DocumentsDocument5 pagesISO 9001 DocumentsManish PandeyNo ratings yet

- Issue No.01 PAD/NCR/20 Forms/Records Rev. No. 01 Form 20: Non Conformance ReportDocument1 pageIssue No.01 PAD/NCR/20 Forms/Records Rev. No. 01 Form 20: Non Conformance ReportVIKASH PEERTHYNo ratings yet

- Managemnet Review SOP & RecordsDocument3 pagesManagemnet Review SOP & RecordsPritam MitraNo ratings yet

- ISO 45001 Occupational Health and Safety Management Systems: Information GuideDocument14 pagesISO 45001 Occupational Health and Safety Management Systems: Information GuideHélio René Lopes da RochaNo ratings yet

- Life Cycle Thinking As Per Iso 14001-2015 (By SRS)Document5 pagesLife Cycle Thinking As Per Iso 14001-2015 (By SRS)Ranganayaki Tirumale Srinivasa RangacharNo ratings yet

- Control Nonconformities in Provision of Services (Preview)Document3 pagesControl Nonconformities in Provision of Services (Preview)Centauri Business Group Inc.100% (5)

- Control Nonconformities in Provision of Services (Preview)Document3 pagesControl Nonconformities in Provision of Services (Preview)Centauri Business Group Inc.100% (5)

- Operational Control SampleDocument19 pagesOperational Control Sampleeduardog1972No ratings yet

- X, Ems For Die Cast IndustryDocument216 pagesX, Ems For Die Cast IndustryAMIN100% (1)

- QSP.7.5 Control of Documented Information (Preview)Document3 pagesQSP.7.5 Control of Documented Information (Preview)Centauri Business Group Inc.100% (2)

- AMM Procedures ManualDocument62 pagesAMM Procedures ManualSyrem RegunaNo ratings yet

- QSP 7.1-03 Control of Organizational Knowledge (Preview)Document4 pagesQSP 7.1-03 Control of Organizational Knowledge (Preview)Centauri Business Group Inc.100% (1)

- Iso 9001 Requirements MatrixDocument24 pagesIso 9001 Requirements MatrixVictor SuNo ratings yet

- (Risks Element) : by Kamarrudin AliDocument35 pages(Risks Element) : by Kamarrudin AliChandrashekhar Thiramdasu100% (1)

- Preview of ISO 9001:2015 QSP 7.1-02 Control of Infrastructure Quality ProcedureDocument4 pagesPreview of ISO 9001:2015 QSP 7.1-02 Control of Infrastructure Quality ProcedureCentauri Business Group Inc.50% (2)

- LINCS 1.2 Presentation r3 HiQ - Operator HandoutsDocument110 pagesLINCS 1.2 Presentation r3 HiQ - Operator HandoutsLuis Torres100% (1)

- 45001:2018 Audit Checklist (Preview)Document7 pages45001:2018 Audit Checklist (Preview)Centauri Business Group Inc.94% (17)

- QSP 7.1-02. Control of Monitoring and Measuring Resources (Preview)Document4 pagesQSP 7.1-02. Control of Monitoring and Measuring Resources (Preview)Centauri Business Group Inc.100% (1)

- QSP 7.1-02. Control of Monitoring and Measuring Resources (Preview)Document4 pagesQSP 7.1-02. Control of Monitoring and Measuring Resources (Preview)Centauri Business Group Inc.100% (1)

- QSP 8.3 Design and Development (Preview)Document3 pagesQSP 8.3 Design and Development (Preview)Centauri Business Group Inc.50% (2)

- QSP 8.3 Design and Development (Preview)Document3 pagesQSP 8.3 Design and Development (Preview)Centauri Business Group Inc.50% (2)

- Iso 9001 10 Clauses InterpretationDocument34 pagesIso 9001 10 Clauses InterpretationJojo DollolasaNo ratings yet

- Ethics in Ict An Australian Perspective PDFDocument2 pagesEthics in Ict An Australian Perspective PDFAndrew0% (1)

- ISO 45001:2018 Gap AnalysisDocument1 pageISO 45001:2018 Gap AnalysisCentauri Business Group Inc.100% (1)

- Annex 2 to ММ 6.1-01-01: Examples of Risk wording and Risk reduction activities .PreviewDocument2 pagesAnnex 2 to ММ 6.1-01-01: Examples of Risk wording and Risk reduction activities .PreviewCentauri Business Group Inc.0% (1)

- Annex 2 to ММ 6.1-01-01: Examples of Risk wording and Risk reduction activities .PreviewDocument2 pagesAnnex 2 to ММ 6.1-01-01: Examples of Risk wording and Risk reduction activities .PreviewCentauri Business Group Inc.0% (1)

- Corrective and Preventive ActionDocument3 pagesCorrective and Preventive ActionmurugesanNo ratings yet

- QSP 8.2 Contract Analysis (Preview)Document3 pagesQSP 8.2 Contract Analysis (Preview)Centauri Business Group Inc.No ratings yet

- QSP 8.2 Contract Analysis (Preview)Document3 pagesQSP 8.2 Contract Analysis (Preview)Centauri Business Group Inc.No ratings yet

- PR - 30 - Procedure For R& O Management - R1Document21 pagesPR - 30 - Procedure For R& O Management - R1Purna Chandra BaruaNo ratings yet

- DSE8610 MKII Installation Instructions PDFDocument2 pagesDSE8610 MKII Installation Instructions PDFManuel Ortiz Galán100% (1)

- QSP.8.5 Service Provision (Preview)Document3 pagesQSP.8.5 Service Provision (Preview)Centauri Business Group Inc.No ratings yet

- QSP.8.5 Service Provision (Preview)Document3 pagesQSP.8.5 Service Provision (Preview)Centauri Business Group Inc.No ratings yet

- Quality Plan Example - Iso 10005Document14 pagesQuality Plan Example - Iso 10005neurolepsia379033% (3)

- QSP 9.3 Management Review (Preview)Document3 pagesQSP 9.3 Management Review (Preview)Centauri Business Group Inc.100% (2)

- OH&S Requirements in ISO 45001 Clauses - References (Preview)Document6 pagesOH&S Requirements in ISO 45001 Clauses - References (Preview)Centauri Business Group Inc.No ratings yet

- ISO 50001:2011 Energy Management System Manual PreviewDocument8 pagesISO 50001:2011 Energy Management System Manual PreviewCentauri Business Group Inc.No ratings yet

- Supply Chain - ABCDocument15 pagesSupply Chain - ABCYulia Tri AngganiNo ratings yet

- QSP 10.2 Corrective Action (Preview)Document3 pagesQSP 10.2 Corrective Action (Preview)Centauri Business Group Inc.50% (2)

- QSP.9.2 Internal Audit (Preview)Document3 pagesQSP.9.2 Internal Audit (Preview)Centauri Business Group Inc.No ratings yet

- QSP6 1 Risks Preview PDFDocument3 pagesQSP6 1 Risks Preview PDFCentauri Business Group Inc.100% (4)

- QSP 7.1. Control of Personnel (Preview)Document3 pagesQSP 7.1. Control of Personnel (Preview)Centauri Business Group Inc.No ratings yet

- Requirements For Bodies Providing Audit and Certification of Healthcare Management Systems To The Core Standards For SafetyDocument9 pagesRequirements For Bodies Providing Audit and Certification of Healthcare Management Systems To The Core Standards For SafetyTahir Masood100% (1)

- MRM AgendaDocument2 pagesMRM AgendaBAlaNo ratings yet

- Control of Nonconforming ProductDocument2 pagesControl of Nonconforming ProductAliyantahir100% (2)

- KEY-QMS-05 - F-01 Document Change Request FormDocument1 pageKEY-QMS-05 - F-01 Document Change Request FormMenuka SiwaNo ratings yet

- Ims Iso 9001 Iso 14001 Ohsas 18001 All in One PackageDocument43 pagesIms Iso 9001 Iso 14001 Ohsas 18001 All in One PackagemitchNo ratings yet

- Training ProgramsDocument1 pageTraining Programshunain zafarNo ratings yet

- ISO/DIS 45001:2017 OH&S Manual (Preview)Document16 pagesISO/DIS 45001:2017 OH&S Manual (Preview)info-390712No ratings yet

- The Methodical Manual Actions To Address Risks and Opportunities in QMS Processes - PreviewDocument4 pagesThe Methodical Manual Actions To Address Risks and Opportunities in QMS Processes - PreviewCentauri Business Group Inc.No ratings yet

- QSP 7.1. Control of Personnel (Preview)Document3 pagesQSP 7.1. Control of Personnel (Preview)Centauri Business Group Inc.No ratings yet

- QSP 8.1 Marketing (Preview)Document4 pagesQSP 8.1 Marketing (Preview)Centauri Business Group Inc.No ratings yet

- ISO 9001:2015 QMS Transition QnADocument2 pagesISO 9001:2015 QMS Transition QnACentauri Business Group Inc.No ratings yet

- Rohit Bhai RateDocument3 pagesRohit Bhai RateYogesh AryaNo ratings yet

- Analysis of Vibration Detection Using Active Controller in The Smart Cantilever Composite Beam With LQR and Fuzzy TechniquesDocument10 pagesAnalysis of Vibration Detection Using Active Controller in The Smart Cantilever Composite Beam With LQR and Fuzzy TechniquesTJPRC PublicationsNo ratings yet

- What Is The Difference Between 0.2 and 0.2S Class CTDocument5 pagesWhat Is The Difference Between 0.2 and 0.2S Class CTshaik abdulaleemNo ratings yet

- Miss Komal Ranvir: ObjectiveDocument1 pageMiss Komal Ranvir: ObjectiveKomal RanvirNo ratings yet

- Network Forensic Log AnalysisDocument5 pagesNetwork Forensic Log AnalysisEditor IJRITCCNo ratings yet

- IgniteDocument2 pagesIgniteMartinito MacraméNo ratings yet

- TR 101290v010201pDocument175 pagesTR 101290v010201pAndreas_HBNo ratings yet

- Thelook E-Commerce Analysis: Assignment Fahmi DayantoDocument31 pagesThelook E-Commerce Analysis: Assignment Fahmi DayantoAdamMaulaNo ratings yet

- MongoDB TCO Comparison MongoDB OracleDocument12 pagesMongoDB TCO Comparison MongoDB Oracleowen liuNo ratings yet

- Manual de Servicio Ventilador Bear Cub 750psvDocument64 pagesManual de Servicio Ventilador Bear Cub 750psvVladimir BorjaNo ratings yet

- Electronic Bill PaymentDocument2 pagesElectronic Bill PaymentHeikkiNo ratings yet

- The Market For Airborne ASW Sensors: Product Code #F672Document18 pagesThe Market For Airborne ASW Sensors: Product Code #F672Gautam NatrajanNo ratings yet

- Bluetooth Low Energy Device: Using The MT8852B To Test A Controlled Through A Proprietary InterfaceDocument7 pagesBluetooth Low Energy Device: Using The MT8852B To Test A Controlled Through A Proprietary InterfaceAlberto SaldivarNo ratings yet

- REVA University Bangalore, India: Arjun Haragaller, Rajeev RanjanDocument1 pageREVA University Bangalore, India: Arjun Haragaller, Rajeev RanjanmeghaNo ratings yet

- 4804 4Document11 pages4804 4abhaybhosaleNo ratings yet

- Read This FirstDocument21 pagesRead This FirstNíkolas BorgesNo ratings yet

- 16N50Document7 pages16N50Astro Sam HanNo ratings yet

- Module-4 Cloud Computing Architecture PDFDocument19 pagesModule-4 Cloud Computing Architecture PDFVTU ML WorkshopNo ratings yet

- Asphalt and Asphalt Mixtures PPT2023Document53 pagesAsphalt and Asphalt Mixtures PPT2023Brian ReyesNo ratings yet

- Mid Term Paper Maintenance EngineeringDocument1 pageMid Term Paper Maintenance EngineeringKhadeejaNo ratings yet

- Airbus Supplier Approval List September 2014Document57 pagesAirbus Supplier Approval List September 2014adip1971890No ratings yet

- UWG IT Security PlanDocument111 pagesUWG IT Security PlanManuel SantanaNo ratings yet

- Maxi Flow TechDocument12 pagesMaxi Flow TechazkNo ratings yet

- Dna Computing: Assignment 1Document4 pagesDna Computing: Assignment 1ShaheerNo ratings yet

- Taniya Rawat: ObjectiveDocument1 pageTaniya Rawat: Objectiveanuj sharmaNo ratings yet