Professional Documents

Culture Documents

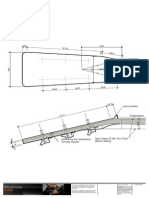

Crack alignment jig dimensions and instructions

Uploaded by

Giorgio NapoleoneOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Crack alignment jig dimensions and instructions

Uploaded by

Giorgio NapoleoneCopyright:

Available Formats

9.

9

8.7

6.4

27.9

1 3/32"

0 1/4"

Drill Holes For Tuning Machine Peg. Screw

Machine Head To Side of Jig.

Width of Bandsaw

Cut

39.7

1 9/16"

Lay Opposite End Of Tuner Peg In 1/2

Hole. Tip: Make Both Legs Of Jig Same

Height, Drill Both Holes - Straight Through

and Cut Down The Second Leg As Shown

10.2

13/32"

1/16" Dia. Hole For E String

Threading

Round Nose Of Blade And

Sharpen On A Belt Sander

6.4

27.9

1 3/32"

0 1/4"

9.8

3/8"

6.3

1/4"

6.8

9/32"

24.4

31/32"

11.7

15/32"

6.4

1/4"

Basswood or Mahogany

24.4

31/32"

Use a Single Tuning Machine For This Jig. I like

the Old Vintage Open Gear Style Because It Has

Less It Smaller and Lighter.

The Interior Block Can Be Any Size You Like. I

Made Mine About 5/8" x 5/8" x 1/2" Thick.

Crack Alignment Jig

Note That Dimensions Should Be Adjusted

Per The Tuning Machine That You Actually

Use. This Diagram Is A Guide Only.

80.3

3 5/32"

6.4

8.4

0 11/32"

37.5

15/32"

213.8Brass1Rivits

(2)

8 13/32"

10.0

Use Exotic Wood For Handle

Material

9.8

3/8"

27.9

8.4

37.5

1 3/32"

0 11/32"

Shaded

Area Indicates

Cut OfChamfer

A1 15/32"

10"All Table

Saw

Edges Slightly

Blade. To Cut Wedge A Piece Of Wood In The Cut

Jaw Opening To Prevent Cutting The Upper Jaw.

24.4

31/32"

32.4

1 9/32"

Brace Probe

33.8

6.3

1 11/32" 1/4"

5.7

7/32"

3/32" Stop

Hole

76.2

3"

2.5

3/32"

Pivot Point: Use A 3/16" Spring

Steel Split Pin

Adjusted

Actually

.

sition

3/16" Spring Steel Split Pins. Place

Directly Tangent To Steel Bar

Laminate Wood And Metal Blade

With Epoxy and Brass Rivits

The Interior Block Can Be Any Size You Like. I

Made Mine About 5/8" x 5/8" x 1/2" Thick.

Cam

Note: Do Not Cut Jaws Apart Until

You Have Drilled The Channel For

The Steel Bar Through Both Jaws

At One Time

8.0

6.8

9/32"

6.4

0 1/4"

7.9

5

5/16" 7

0 5/16"

Round Nose Of Blade And

Sharpen On A Belt Sander

17.5

11/16"

Jig

19.1

3/4"

0 13/32"

62.3

2 7/16"

10.2

13/32"

Lay Opposite End Of Tuner Peg In 1/2

Hole. Tip: Make Both Legs Of Jig Same

Height, Drill Both Holes - Straight Through

and Cut Down The Second Leg As Shown

27.9

1 3/32"

0 1/4"

6.3

Drill Holes For Tuning Machine Peg. Screw

Machine1/4"

Head To Side of Jig.

252.9

9 31/32"

Cut This Slot With a Band Saw Or

A Japanese Pull Saw

Place Sheet Cork On The Top and

Bottom Jaws.

Put A 1mm Chamfer Around All Exposed

Edges Of Clamps

32"

Table Saw

19.1

3/4"

24.3

Note:

31/32"

Do Not Cut Jaws Apart Until

You Have Drilled The Channel For

The Steel Bar Through Both Jaws

At One Time

3/16" S

Throug

Ancho

7.9

5.7

5/16" 7/32"

This Drawing or Drawings Are To Used For One

Use Only And Not Reproduced For Any Other

Purpose Than Construction Of This Particular

Instrument.

185.3

7 9/32"

Reproduction, Distribution or Sales For Any Other

Use Is Strictly Prohibitied And Falls Under U.S

Copyright Laws For Ultimate Guitar OnLine 2010

Date: Feb 15, 2010

Revisions:

Note: These Plans Are

Drawn Full Scale Are Are

Labeled in mm & Fractional

Inches

10" Wood Cam Clamp Side

Sheet Number

42.2

1 21/32"

You might also like

- Projeto para Encaixe Rabo de AndorinhaDocument8 pagesProjeto para Encaixe Rabo de AndorinhaVInixsoad100% (2)

- Neck & Fretboard Templates & Routing Templates: Les Paul StandardDocument1 pageNeck & Fretboard Templates & Routing Templates: Les Paul StandardAlexMarinhoNo ratings yet

- Thinline Plan PDFDocument1 pageThinline Plan PDFAnonymous y83ITj4nw6No ratings yet

- April 2015 Professional Guitar Price ListDocument1 pageApril 2015 Professional Guitar Price ListAndrey BalalinNo ratings yet

- Instructions Neck AngleDocument21 pagesInstructions Neck Angleandua40100% (2)

- Construcción Paso A Paso UkeleleDocument20 pagesConstrucción Paso A Paso UkeleleNosoytansolo Unabarbabonita100% (1)

- The History and Manufacture of the GuitarDocument9 pagesThe History and Manufacture of the GuitarMeiliana NaNo ratings yet

- HHHDocument3 pagesHHHAsemNo ratings yet

- BluestemLowMandoPlanFree PDFDocument1 pageBluestemLowMandoPlanFree PDFRoberthe NichanNo ratings yet

- O'Brien Neck Joint Routing Jig Assembly GuideDocument16 pagesO'Brien Neck Joint Routing Jig Assembly GuideRamon CoelhoNo ratings yet

- Archtop Build Journal - Fifth Edition - (Low Res) PDFDocument122 pagesArchtop Build Journal - Fifth Edition - (Low Res) PDFVladimir Mandarić100% (2)

- Make A Steel GuitarDocument6 pagesMake A Steel GuitarPimpinela GrooveNo ratings yet

- Curso Luthier by Johnny GuitarDocument95 pagesCurso Luthier by Johnny GuitaradmlewisNo ratings yet

- Martin V Joint NeckDocument1 pageMartin V Joint Neckandua40100% (2)

- Mortise & Tenon Template InstDocument2 pagesMortise & Tenon Template InstRamon CoelhoNo ratings yet

- Acoustic Guitar Building InstructionsDocument40 pagesAcoustic Guitar Building InstructionsLeeUnder100% (2)

- Original Floyd Rose tremolo routing guideDocument2 pagesOriginal Floyd Rose tremolo routing guideErnesto Jeminguey100% (2)

- BanjoPlanWineboxPanel1 PDFDocument1 pageBanjoPlanWineboxPanel1 PDFAdrianoEngelNo ratings yet

- Voicing Steel String Guitar TopsDocument12 pagesVoicing Steel String Guitar Topsandrea_albrile100% (1)

- Electric Ukulele Plan NotesDocument9 pagesElectric Ukulele Plan Notesmking_6100% (1)

- Guitar Making - Building NotesDocument12 pagesGuitar Making - Building NotesMarkNo ratings yet

- Vintage guitar blueprintDocument1 pageVintage guitar blueprintMarcelo M. MachadoNo ratings yet

- 9 String Acoustic Guitar PDFDocument39 pages9 String Acoustic Guitar PDFSemih Oksay100% (1)

- Tools For Guitar KitsDocument4 pagesTools For Guitar KitsAnthonyMcLean100% (1)

- Acoustic Guitar PlansDocument7 pagesAcoustic Guitar PlansFrançesko Astroza80% (5)

- Electric Guitar Order Form: Custom Fitted Instrument CasesDocument1 pageElectric Guitar Order Form: Custom Fitted Instrument CasesArnab BhattacharyaNo ratings yet

- Tonewood Technical DataDocument24 pagesTonewood Technical DataCaps Lock100% (4)

- Resonator Guitar Kit: Assembly InstructionsDocument32 pagesResonator Guitar Kit: Assembly InstructionstazzorroNo ratings yet

- Compensated String Spacing Layout ToolDocument1 pageCompensated String Spacing Layout ToolAdam AcostaNo ratings yet

- U.S. Patent 5,932,827, Entitled "Sustainer For Musical Instrument", To Osborne, Aug. 3, 1999.Document58 pagesU.S. Patent 5,932,827, Entitled "Sustainer For Musical Instrument", To Osborne, Aug. 3, 1999.Anonymous a7S1qyXNo ratings yet

- A Benchtop BenchDocument2 pagesA Benchtop Benchcorneliu.modilca67% (3)

- Building A Basic Lap Steel GuitarDocument27 pagesBuilding A Basic Lap Steel GuitarCarlos SpeedhertzNo ratings yet

- Guitar Assembly Work Board - Top View 1937 Hauser Classical Guitar ShapeDocument1 pageGuitar Assembly Work Board - Top View 1937 Hauser Classical Guitar ShapeDaniel Garfo100% (1)

- Delano Installation GuideDocument19 pagesDelano Installation GuideDébora MaravilhaNo ratings yet

- The Kasha GuitarDocument15 pagesThe Kasha GuitarhaziboNo ratings yet

- Bolt On Acoustic Guitar NeckDocument1 pageBolt On Acoustic Guitar NeckJayMorgan50% (2)

- Top Plate Brace Layouts: Classical Guitar Plan #3Document1 pageTop Plate Brace Layouts: Classical Guitar Plan #3Michele PacilliNo ratings yet

- Easy-to-Build Kitchen StoolDocument3 pagesEasy-to-Build Kitchen StoolJvlValenzuela100% (1)

- Acoustic Guitar Buying GuideDocument11 pagesAcoustic Guitar Buying GuideAnkitYadavNo ratings yet

- Wooden JointsDocument14 pagesWooden JointsAparna KulshresthaNo ratings yet

- Voicing The GuitarDocument24 pagesVoicing The GuitarHoàng Ngọc-TuấnNo ratings yet

- French Polishing Orville and Robert MilburnDocument34 pagesFrench Polishing Orville and Robert MilburnΓιάννης ΜαρουλάκηςNo ratings yet

- Guitar Guru: What'S The Difference Between Handmade and Handcrafted?Document2 pagesGuitar Guru: What'S The Difference Between Handmade and Handcrafted?Jared WilliamsNo ratings yet

- How Tonewood Selection Defines Guitar SoundDocument6 pagesHow Tonewood Selection Defines Guitar SoundEgner Quero100% (1)

- Ulmia Workbench (55p)Document55 pagesUlmia Workbench (55p)pippitiamo100% (1)

- Hollows and rounds molding planes guideDocument3 pagesHollows and rounds molding planes guideKaren RathbunNo ratings yet

- Mold Resurfacing Guide with Duratec & Aqua-BuffDocument34 pagesMold Resurfacing Guide with Duratec & Aqua-BuffhollabackcockNo ratings yet

- Como Trabalhar Com Goca-LacaDocument26 pagesComo Trabalhar Com Goca-LacaThiago MadureiraNo ratings yet

- Rosettes PDFDocument7 pagesRosettes PDFjuvemoraisNo ratings yet

- Tele Wiring Diagram Pete Biltoft Vintage Vibe Guitars (925) 337-0991Document1 pageTele Wiring Diagram Pete Biltoft Vintage Vibe Guitars (925) 337-0991Marcos CardosoNo ratings yet

- Making A Guitar Neck PDFDocument8 pagesMaking A Guitar Neck PDFhoskencues100% (1)

- Guitar Shapes Navigator: Measuring the shapes of the guitar and the positions of its elementsFrom EverandGuitar Shapes Navigator: Measuring the shapes of the guitar and the positions of its elementsNo ratings yet