Professional Documents

Culture Documents

Flux Cored Welding Wire Supershield 711: Chemical Composition (%) According To Aws

Uploaded by

Ajesh Kumar Muraleedharan0 ratings0% found this document useful (0 votes)

18 views1 pageThis document provides information on Flux Cored Welding Wire called SuperShield 711, including its:

- Chemical composition according to AWS standards for elements like carbon, silicon, manganese, etc.

- Mechanical properties according to AWS for metrics like yield point, tensile strength, impact value.

- Applications for welding mild steel and high tensile strength structures with characteristics like stable arc and good bead appearance.

- Available diameters from 1.2mm to 1.6mm and recommended current ranges for different conditions and processes.

- Approval listings from various classification societies and standards.

Original Description:

Supershiel data

Original Title

supershield 711

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides information on Flux Cored Welding Wire called SuperShield 711, including its:

- Chemical composition according to AWS standards for elements like carbon, silicon, manganese, etc.

- Mechanical properties according to AWS for metrics like yield point, tensile strength, impact value.

- Applications for welding mild steel and high tensile strength structures with characteristics like stable arc and good bead appearance.

- Available diameters from 1.2mm to 1.6mm and recommended current ranges for different conditions and processes.

- Approval listings from various classification societies and standards.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

18 views1 pageFlux Cored Welding Wire Supershield 711: Chemical Composition (%) According To Aws

Uploaded by

Ajesh Kumar MuraleedharanThis document provides information on Flux Cored Welding Wire called SuperShield 711, including its:

- Chemical composition according to AWS standards for elements like carbon, silicon, manganese, etc.

- Mechanical properties according to AWS for metrics like yield point, tensile strength, impact value.

- Applications for welding mild steel and high tensile strength structures with characteristics like stable arc and good bead appearance.

- Available diameters from 1.2mm to 1.6mm and recommended current ranges for different conditions and processes.

- Approval listings from various classification societies and standards.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

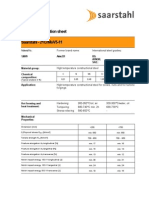

FLUX CORED WELDING WIRE

SUPERSHIELD 711

AWS : A5.20 E 71T-1

ASME : SFA 5.20 E71T-1

JIS

: Z3313 YFW-C50DR

CHEMICAL COMPOSITION ( % ) ACCORDING TO AWS:

C

Si

Mn

Cu

0.18

0.90

1.75

0.03

0.03

0.08

0.35

MECHANICAL PROPERTIES ACCORDING TO AWS:

YP

(N/mm2)

400

T.S

(N/mm2)

480

I. V (J)

- 18 oC

0 oC

27 J

EL

(%)

22

APPLICATIONS & CHARACTERISTICS

Butt, Fillet Welding of mild steel & 50 kgf/mm2 high tensile strength of structures such as buildings,

bridges, ships and industrial machinery.

Supershield 711 is titania (rutile) type flux cored wire used with CO2 or 75% Ar-25% CO2 shielding gas

and it contributes to the reduction of welding cost. It provides excellent usability with stable arc, less

spattering, good bead appearance , better slag removal.

For mechanized welding of H-Fillet this wire is an excellent choice, as it meets the requirement of

superior wire feeding properties combined with high deposition efficiency and very good resistance to

blow-hole.

The quantity of spatter is almost free compared with a solid wire, therefore cost can be saved.

DIAMETERS AVAILABLE & RECOMMENDED CURRENT (DCEP)

Wire dia. (mm)

Amp. (A)

Volt. (V)

Volt. (V)

Amp. (A)

V-down

Amp. (A)

Volt. (V)

Over Head

(Optimum

Condition)

Volt. (A)

Amp. (V)

Flat,

H-Fillet

V-up

1.2

150 ~ 320

22 ~ 34

140 ~ 250

22 ~ 30

200 ~ 300

22 ~ 34

1.6

180 ~ 450

25 ~ 38

180 ~ 280

24 ~ 32

240 ~ 320

25 ~ 36

210 ~ 230

22 ~ 26

230 ~ 250

24 ~ 30

APPROVAL

ABS : 2SAH15, 2YSAH15

GL : 2YH15S

NK : KSW2G ( C ) H, KSW52G ( C ) H

BV : SA2M, SA2YMH

KR : RSW2G(C) H, RSW52G (C) H

CWB : E4901T-9-CH (W48.5 M 1990)

DNV : II YMS (H15)

LR : 2S, 2YSH15

TUV : T 46 0 P C/M 1 EN 758

STANDARD PACKAGING : 15 KG PLASTIC SPOOL

You might also like

- Flux CoredDocument21 pagesFlux CoredmmkattaNo ratings yet

- Flux Cored Wires for Welding High Strength SteelDocument71 pagesFlux Cored Wires for Welding High Strength SteelCristian Camilo QuirogaNo ratings yet

- Mild Steel Welding Electrodes: Salient FeaturesDocument16 pagesMild Steel Welding Electrodes: Salient FeaturesHandrea Hadi SaputraNo ratings yet

- Dual Shield 7000a1Document1 pageDual Shield 7000a1Gokul RajanNo ratings yet

- Bohler Subarc t85 - Uv 421 TT en 1Document1 pageBohler Subarc t85 - Uv 421 TT en 1Dragan JerčićNo ratings yet

- 22%Cr DUPLEX STAINLESS STEEL WELDING CONSUMABLESDocument7 pages22%Cr DUPLEX STAINLESS STEEL WELDING CONSUMABLESNguyen Anh TuanNo ratings yet

- ESAB OK Autrod 12.51Document2 pagesESAB OK Autrod 12.51hooky1No ratings yet

- Metrode E2209 (B-60) ElectrodeDocument6 pagesMetrode E2209 (B-60) ElectrodeClaudia MmsNo ratings yet

- OK 48.20 ESAB 36 H (SPL) : A Basic Coated Low-Hydrogen Electrode For MMAW A Basic Coated Electrode For MMAWDocument1 pageOK 48.20 ESAB 36 H (SPL) : A Basic Coated Low-Hydrogen Electrode For MMAW A Basic Coated Electrode For MMAWGokul RajanNo ratings yet

- Mild Steel 490mpa High Tensile Strength SteelDocument38 pagesMild Steel 490mpa High Tensile Strength SteelCarlos PadillaNo ratings yet

- Welding Technology Steelconstr - EngDocument32 pagesWelding Technology Steelconstr - EngLukman Tarigan SumatraNo ratings yet

- SM-70EN MIG Welding WireDocument30 pagesSM-70EN MIG Welding WireErick Quan LunaNo ratings yet

- 1.smaw All PDFDocument76 pages1.smaw All PDFkaviatchennaiNo ratings yet

- LOW ALLOY METAL-CORED WIRE FOR HSLA STEELSDocument1 pageLOW ALLOY METAL-CORED WIRE FOR HSLA STEELSH_DEBIANENo ratings yet

- Rutile Coated Electrodes for MMAWDocument1 pageRutile Coated Electrodes for MMAWGokul RajanNo ratings yet

- Innershield NR - 305: Typical Applications Key FeaturesDocument1 pageInnershield NR - 305: Typical Applications Key FeaturesH_DEBIANENo ratings yet

- CHT81 Ni 1Document1 pageCHT81 Ni 1ImmalatulhusnaNo ratings yet

- Metalshield MC-710XL: Conformances Key FeaturesDocument1 pageMetalshield MC-710XL: Conformances Key FeaturesH_DEBIANENo ratings yet

- CHF101 CHW S16 PDFDocument1 pageCHF101 CHW S16 PDFImmalatulhusnaNo ratings yet

- OK Tubrod 15.14Document2 pagesOK Tubrod 15.14Luis DuarteNo ratings yet

- Bohler Ars 5 - e 71 T-1 C (M) H8Document1 pageBohler Ars 5 - e 71 T-1 C (M) H8Mario MolinaNo ratings yet

- Welding Consumables For Hydro Power StationsDocument16 pagesWelding Consumables For Hydro Power StationsMohamed FaragNo ratings yet

- Alumina-Silicate Type Agglomerated Submerged Arc Welding FluxDocument1 pageAlumina-Silicate Type Agglomerated Submerged Arc Welding FluxthindmanmohanNo ratings yet

- Ok10 81LDocument1 pageOk10 81LRavi GuptaNo ratings yet

- Esab c23sDocument1 pageEsab c23sGokul RajanNo ratings yet

- 2 Fcaw-AllDocument51 pages2 Fcaw-AllAhmad ShaheenNo ratings yet

- Dual Shield 8000b2Document1 pageDual Shield 8000b2Gokul RajanNo ratings yet

- Coremax 308LP DataDocument1 pageCoremax 308LP DataLIM hoon boonNo ratings yet

- Metalshield MC-6: Conformances Key FeaturesDocument1 pageMetalshield MC-6: Conformances Key FeaturesH_DEBIANENo ratings yet

- Classifications: For Atmospheric Corrosion Resisting SteelDocument1 pageClassifications: For Atmospheric Corrosion Resisting Steelhuynh thanh truongNo ratings yet

- Select Arc Catalogue Part 2Document10 pagesSelect Arc Catalogue Part 2lionheartedNo ratings yet

- 21 CR Mo V511Document1 page21 CR Mo V511uksrajNo ratings yet

- Metalshield MC - 110: Conformances Key FeaturesDocument1 pageMetalshield MC - 110: Conformances Key FeaturesH_DEBIANENo ratings yet

- S-777Q X M-12K H-14 L-8: Hyundai Welding Co., LTDDocument6 pagesS-777Q X M-12K H-14 L-8: Hyundai Welding Co., LTDSergio AlejandroNo ratings yet

- High-strength steel welding electrodeDocument6 pagesHigh-strength steel welding electrodefaridshabaniNo ratings yet

- CSF-71T en 2014Document1 pageCSF-71T en 2014Yousab CreatorNo ratings yet

- CSF-71T en 2014Document1 pageCSF-71T en 2014HoangNo ratings yet

- Macsteel VRN - Wear Abrasion Steels - Creusabro 8000Document4 pagesMacsteel VRN - Wear Abrasion Steels - Creusabro 8000jonodo89No ratings yet

- SM 80GDocument1 pageSM 80GCarlos PadillaNo ratings yet

- KISWEL Mag Welding ConsumableDocument4 pagesKISWEL Mag Welding Consumablekhwanta-btaNo ratings yet

- ACUWELD MIG &TIG Welding WiresDocument38 pagesACUWELD MIG &TIG Welding WiresALOKE GANGULYNo ratings yet

- FLUX CORED WIRES FOR SHIPBUILDING AND STRUCTURESDocument1 pageFLUX CORED WIRES FOR SHIPBUILDING AND STRUCTUREScamelod555No ratings yet

- Elgacore DWA 55EDocument2 pagesElgacore DWA 55Ecfyjdyu_684672809No ratings yet

- CHF101 Flux Wire ComboDocument1 pageCHF101 Flux Wire ComboImmalatulhusnaNo ratings yet

- CERTILAS EN Edition2023 313Document1 pageCERTILAS EN Edition2023 313Alireza KhodabandehNo ratings yet

- B-62 2507 Rev 06Document5 pagesB-62 2507 Rev 06Shaik ShahNo ratings yet

- Duplex MetrodeDocument6 pagesDuplex Metrodeandresrojas25No ratings yet

- Carbon Steel 01Document1 pageCarbon Steel 01amekkehNo ratings yet

- Arc Welding ElectrodesDocument6 pagesArc Welding ElectrodeswaleedyossefNo ratings yet

- Giới thiệu dây SAWDocument4 pagesGiới thiệu dây SAWNguyen Thanh TrungNo ratings yet

- Select 90c d2Document1 pageSelect 90c d2nateNo ratings yet

- ESAB Consumable PDFDocument165 pagesESAB Consumable PDFbond8031No ratings yet

- Boehler CN 23 12 PW-FDDocument1 pageBoehler CN 23 12 PW-FDbrayanNo ratings yet

- 107 Weldox 700 Uk Data SheetDocument2 pages107 Weldox 700 Uk Data SheetAnurag JainNo ratings yet

- Stick electrodes for welding steels and stainless steelsDocument46 pagesStick electrodes for welding steels and stainless steelsAdeKusumahNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Pipeline and Energy Plant Piping: Design and TechnologyFrom EverandPipeline and Energy Plant Piping: Design and TechnologyRating: 5 out of 5 stars5/5 (2)

- C0031 91Document5 pagesC0031 91Ajesh Kumar MuraleedharanNo ratings yet

- ASTMD4Document4 pagesASTMD4Ajesh Kumar MuraleedharanNo ratings yet

- Guidelines For Tungsten Electrodes - TheFabricatorDocument5 pagesGuidelines For Tungsten Electrodes - TheFabricatorAjesh Kumar MuraleedharanNo ratings yet

- MULTIS 2gb Data SheetDocument1 pageMULTIS 2gb Data SheetAjesh Kumar MuraleedharanNo ratings yet

- T 044-94 Solubility of Bituminous MaterialsDocument2 pagesT 044-94 Solubility of Bituminous MaterialsAjesh Kumar MuraleedharanNo ratings yet

- OK 48.20 ESAB 36 H (SPL) : A Basic Coated Low-Hydrogen Electrode For MMAW A Basic Coated Electrode For MMAWDocument1 pageOK 48.20 ESAB 36 H (SPL) : A Basic Coated Low-Hydrogen Electrode For MMAW A Basic Coated Electrode For MMAWGokul RajanNo ratings yet

- Esab Ferroweld1Document1 pageEsab Ferroweld1Gokul RajanNo ratings yet

- MSDS - Weber - Tec 301 GA-W 01Document4 pagesMSDS - Weber - Tec 301 GA-W 01Ajesh Kumar Muraleedharan100% (1)

- Esab Ferroweld2Document1 pageEsab Ferroweld2Gokul RajanNo ratings yet

- MasterSeal 475 TDSDocument3 pagesMasterSeal 475 TDSAjesh Kumar MuraleedharanNo ratings yet

- T 059-94 Testing Emulsified AsphaltsDocument3 pagesT 059-94 Testing Emulsified AsphaltsAjesh Kumar MuraleedharanNo ratings yet

- List of Banks in India - Wikipedia, The Free EncyclopediaDocument13 pagesList of Banks in India - Wikipedia, The Free EncyclopediaAjesh Kumar MuraleedharanNo ratings yet

- C0127 88aDocument5 pagesC0127 88aAjesh Kumar MuraleedharanNo ratings yet

- T 030-93 Mechanical AnalysiDocument3 pagesT 030-93 Mechanical AnalysiKammisiqNo ratings yet

- T 026-79 Quality of Water For ConcreteDocument2 pagesT 026-79 Quality of Water For ConcreteHanamant HunashikattiNo ratings yet

- E1364-90 STD Test of Road Roughness by Static Level MethodDocument6 pagesE1364-90 STD Test of Road Roughness by Static Level MethodAjesh Kumar MuraleedharanNo ratings yet

- T 299-93 Rapid Identification of Alkai Silica Reaction ProdDocument3 pagesT 299-93 Rapid Identification of Alkai Silica Reaction ProdAjesh Kumar MuraleedharanNo ratings yet

- T 022-92 Compressive Stength of Cylindrical ConcreteDocument7 pagesT 022-92 Compressive Stength of Cylindrical ConcreteKumi13No ratings yet

- E1082-90 Measurement of Vehicular Response To Traveled SurfaDocument3 pagesE1082-90 Measurement of Vehicular Response To Traveled SurfaAjesh Kumar MuraleedharanNo ratings yet

- E1442-94 STD Practice For Highway Traffic MonitoringDocument11 pagesE1442-94 STD Practice For Highway Traffic MonitoringAjesh Kumar MuraleedharanNo ratings yet

- C0413-94 Absorption of Chemical Resistant Mortars Grouts andDocument3 pagesC0413-94 Absorption of Chemical Resistant Mortars Grouts andAjesh Kumar MuraleedharanNo ratings yet

- E1166-91 Network Level Pavement ManagementDocument2 pagesE1166-91 Network Level Pavement ManagementAjesh Kumar MuraleedharanNo ratings yet

- Welding, Cutting and BrazingDocument24 pagesWelding, Cutting and BrazingAjesh Kumar MuraleedharanNo ratings yet

- E0011-95 Spec For Wire Cloth and Sieves For TestingDocument5 pagesE0011-95 Spec For Wire Cloth and Sieves For TestingAjesh Kumar MuraleedharanNo ratings yet

- Welding SolutionsDocument4 pagesWelding SolutionsDo XuanNo ratings yet

- E0011-95 Spec For Wire Cloth and Sieves For TestingDocument5 pagesE0011-95 Spec For Wire Cloth and Sieves For TestingAjesh Kumar MuraleedharanNo ratings yet

- C0067-94 Sampling and Testing Brick and Clay Tile PDFDocument10 pagesC0067-94 Sampling and Testing Brick and Clay Tile PDFAjesh kumarNo ratings yet

- A 216 2004Document4 pagesA 216 2004Ajesh Kumar MuraleedharanNo ratings yet

- ASTM C150 - Cemento PortlandDocument8 pagesASTM C150 - Cemento PortlandLuis Felipe LlerenaNo ratings yet